Arctic Research Breakthrough: Lida Group’s Insulated High Quality Container Houses Utilize Specialized Prefab Construction Techniques

2025-Jul-30 11:59:24

By Admin

1. Introduction

The Arctic region has long been a focal point of scientific research due to its unique ecological systems, rich natural resources, and its crucial role in global climate regulation. However, conducting research in the Arctic presents numerous challenges, not least of which is the extreme climate. Temperatures in the Arctic can plummet to well below – 30°C in winter, and the region is also prone to strong winds, blizzards, and permafrost conditions. These harsh environmental factors make it difficult to establish and maintain suitable research facilities.

Lida Group, a renowned name in the construction industry since its establishment in 1993, has stepped forward to address these challenges. Specializing in the design, production, installation, and marketing of engineering construction, Lida Group offers a diverse range of products, including large – scale labor camps, steel structure buildings, container houses, prefab houses, and other integrated buildings. With multiple international certifications such as ISO 9001, ISO 14001, ISO 45001, and EU CE certification (EN 1090), along with professional construction qualifications, Lida Group is well – equipped to provide innovative solutions. The company’s global presence, with seven subsidiaries and numerous overseas branch offices, further enhances its ability to serve clients worldwide, especially in the demanding Arctic research environment.

2. The Significance of Arctic Research

2.1 Understanding Climate Change

The Arctic is a key area for understanding the impacts of climate change. It is experiencing some of the most rapid warming on the planet. The retreat of Arctic sea ice, for example, is not only a visible sign of climate change but also has far – reaching consequences. As the ice melts, it reduces the Earth’s albedo (the ability to reflect sunlight), leading to further warming. Research in the Arctic helps scientists to model future climate scenarios more accurately. By studying the Arctic’s changing sea ice extent, ocean currents, and atmospheric patterns, researchers can better predict how global sea levels will rise, how weather patterns will shift in other parts of the world, and how ecosystems will be affected.

2.2 Biodiversity and Ecosystem Studies

The Arctic is home to a unique and fragile ecosystem. Polar bears, Arctic foxes, walruses, and a variety of seabirds and fish species inhabit this region. The complex food web in the Arctic, which is based on the productivity of the cold waters and the seasonal availability of sea ice, is still not fully understood. Studying the biodiversity in the Arctic can provide insights into how species adapt to extreme cold and changing environmental conditions. Additionally, understanding the Arctic ecosystem is crucial for its conservation, as it is under threat from climate change, pollution, and increased human activities such as shipping and resource extraction.

2.3 Resource Exploration

The Arctic is believed to hold significant reserves of oil, gas, and minerals. The development of these resources requires careful planning and environmental assessment. Research in the Arctic helps to determine the extent of these resources, the best methods for their extraction, and how to minimize the environmental impact. For example, understanding the behavior of permafrost is essential for building stable infrastructure for resource extraction. If permafrost thaws, it can cause land subsidence, which can damage pipelines, roads, and other structures.

3. Challenges in Constructing Research Facilities in the Arctic

3.1 Extreme Climate Conditions

3.1.1 Cold Temperatures

The extremely low temperatures in the Arctic pose a major challenge for construction. Traditional building materials and construction methods are often not suitable. For example, concrete curing processes can be severely disrupted in cold weather. Water in concrete can freeze, expanding and causing cracks in the structure. The low temperatures also make it difficult for workers to perform tasks, as their dexterity is reduced, and they are at risk of cold – related injuries such as frostbite.

3.1.2 Strong Winds and Blizzards

The Arctic is known for its strong winds, which can reach hurricane – force speeds in some areas. These winds can make it dangerous to work at heights and can also damage partially constructed buildings. Blizzards, which are common in the winter months, can reduce visibility to near – zero, halting construction work for extended periods. The constant exposure to wind and snow also accelerates the wear and tear of building materials.

3.1.3 Permafrost

Permafrost, which is ground that remains frozen for at least two consecutive years, is a unique feature of the Arctic. Building on permafrost requires special techniques. If the permafrost thaws under a building, it can cause the structure to sink or tilt. Traditional foundation – laying methods need to be modified to account for the presence of permafrost. For example, piles may need to be driven deep into the ground to reach stable layers below the permafrost or thermosyphons may be used to keep the permafrost frozen.

3.2 Logistics and Accessibility

The Arctic is a vast and remote region, with limited infrastructure. Access to many research sites is difficult, especially during the winter months when sea ice can impede shipping and snow – covered terrain can make over – land travel challenging. Transporting building materials and equipment to these sites is costly and time – consuming. There are often few local suppliers, so most materials need to be shipped from distant locations. In addition, the short construction season in the Arctic, typically limited to the summer months when the weather is relatively more favorable, puts pressure on construction schedules.

3.3 Environmental Sensitivity

The Arctic environment is extremely sensitive. Construction activities in the region need to be carefully planned to minimize the impact on the ecosystem. Even small disturbances can have long – lasting effects. For example, clearing vegetation for construction can disrupt the habitat of local wildlife. The discharge of waste materials, such as construction debris or chemicals, can contaminate the soil and water. Construction companies need to comply with strict environmental regulations, which adds to the complexity and cost of building research facilities in the Arctic.

4. Lida Group’s Specialized Prefab Construction Techniques

4.1 Modular Design Concept

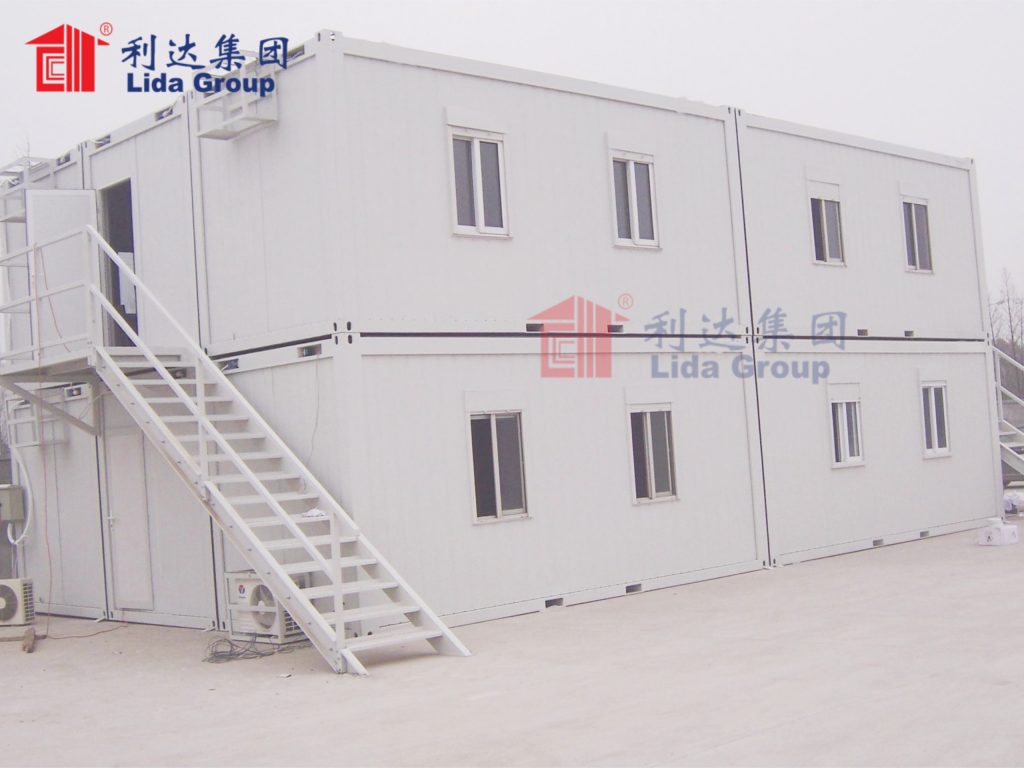

Lida Group’s container houses for Arctic research are based on a modular design concept. The basic units, which are modified shipping containers, can be easily transported to the Arctic region. These containers are highly durable, made of steel, which can withstand the harsh environmental conditions. Multiple containers can be combined in various configurations. For example, they can be stacked vertically or placed side – by – side to create different types of research facilities, such as laboratories, living quarters, and storage areas. The modular design allows for easy expansion or modification of the facilities as the research needs change over time.

4.2 Advanced Insulation Technologies

4.2.1 High – Performance Insulation Materials

To combat the extreme cold in the Arctic, Lida Group uses advanced insulation materials in its container houses. For instance, polyurethane foam insulation is commonly used. This material has a very low thermal conductivity, which means it effectively reduces heat transfer. By insulating the walls, floors, and ceilings of the container houses with polyurethane foam, the indoor temperature can be maintained at a comfortable level with minimal energy consumption. In addition, the use of insulated panels with reflective coatings can further enhance the insulation performance. These panels reflect heat back into the building, reducing heat loss through radiation.

4.2.2 Air – Tight Sealing

In addition to using high – quality insulation materials, Lida Group pays great attention to air – tight sealing in its container houses. Specialized gaskets and seals are used around doors, windows, and joints to prevent air leakage. Air leakage can significantly increase heat loss in cold environments. By ensuring air – tightness, the container houses can maintain a stable indoor temperature, reducing the need for continuous heating and thus saving energy.

4.3 Cold – Resistant Material Selection

4.3.1 Steel Grades for Extreme Conditions

The steel used in Lida Group’s container houses is carefully selected to withstand the cold and harsh Arctic conditions. Special cold – resistant steel grades are chosen, which have high impact toughness even at low temperatures. These steel grades can resist cracking and embrittlement that can occur in extremely cold environments. For example, some of the steel used has been tested to maintain its structural integrity at temperatures as low as – 50°C.

4.3.2 Other Cold – Resistant Components

In addition to the steel structure, other components of the container houses are also selected for their cold – resistant properties. The plumbing systems, for example, use pipes made of materials such as cross – linked polyethylene (PEX), which is known for its flexibility and ability to withstand freezing temperatures without bursting. The electrical wiring is also designed to operate safely in cold conditions, with insulation materials that do not become brittle at low temperatures.

5. Design and Structure of Lida Group’s Insulated Container Houses for Arctic Research

5.1 Structural Reinforcement for Wind and Snow Loads

The container houses are designed to withstand the strong winds and heavy snow loads common in the Arctic. The steel frames of the containers are reinforced with additional bracing and thicker steel members. The roofs are designed with a steep pitch to prevent snow accumulation. In areas with particularly high wind speeds, the containers may be anchored to the ground using special foundation systems. These foundation systems are designed to resist the uplift forces caused by strong winds while also taking into account the presence of permafrost.

5.2 Interior Layout Optimization for Research Needs

The interior layout of the container houses is optimized for the specific needs of Arctic research. Laboratories are designed with easy – to – clean surfaces and proper ventilation systems to handle chemical fumes and biological agents. Living quarters are arranged to provide maximum comfort for researchers during their long stays in the Arctic. There are often common areas for social interaction, which are important for the well – being of the research teams in the isolated Arctic environment. The layout also takes into account the efficient use of space, as transporting large amounts of building materials to the Arctic is costly.

5.3 Integration of Energy – Efficient Systems

Lida Group’s container houses are equipped with energy – efficient systems. Solar panels can be installed on the roofs of the containers to capture sunlight and generate electricity, especially during the long summer days in the Arctic when sunlight is abundant. Energy – efficient heating systems, such as heat pumps, are used to provide warmth. These heat pumps can extract heat from the cold outside air, even at very low temperatures, and transfer it indoors. In addition, energy – efficient lighting fixtures are installed throughout the container houses to reduce overall energy consumption.

6. Construction Process and Efficiency

6.1 Off – Site Prefabrication

A significant advantage of Lida Group’s approach is off – site prefabrication. The container houses are mostly prefabricated in a factory environment. This allows for better quality control, as the construction process can be carried out under more controlled conditions. The prefabrication also saves time on – site. In the factory, the containers can be outfitted with plumbing, electrical systems, insulation, and interior finishes. Once completed, the prefabricated containers are transported to the Arctic research site, where they can be quickly assembled.

6.2 On – Site Assembly

The on – site assembly of the container houses is relatively quick. A small team of workers can use cranes and other equipment to lift and position the containers. The containers are designed to be easily connected to each other using pre – engineered connectors. The connection process is straightforward, and once the containers are in place, the final connections for plumbing, electrical, and other systems can be completed. This on – site assembly process can be completed in a matter of days or weeks, depending on the size and complexity of the research facility, much faster than traditional on – site construction methods in the Arctic.

6.3 Minimizing Environmental Impact during Construction

During the construction process, Lida Group takes steps to minimize the environmental impact. The off – site prefabrication reduces the amount of construction waste generated on – site. Any waste materials that are produced during the on – site assembly are carefully collected and removed from the area. The company also follows strict environmental regulations regarding the use of chemicals and the disposal of waste water. For example, any cleaning agents used during the construction process are environmentally friendly, and waste water is treated before being discharged.

7. Benefits of Lida Group’s Container Houses for Arctic Research

7.1 Providing a Stable and Comfortable Research Environment

The insulated high – quality container houses provide a stable and comfortable research environment in the harsh Arctic climate. The advanced insulation and energy – efficient systems ensure that the indoor temperature is suitable for researchers and the sensitive equipment used in research. The structural integrity of the container houses protects against strong winds and snow, allowing research to continue even during severe weather conditions. The comfortable living quarters also contribute to the well – being of the research teams, which is important for the success of long – term research projects.

7.2 Cost – Efficiency in the Long Run

Although the initial investment in Lida Group’s container houses may seem significant, they offer cost – efficiency in the long run. The off – site prefabrication and quick on – site assembly reduce labor costs and the time required for construction. The energy – efficient design of the container houses reduces energy consumption, which is costly in the Arctic where energy sources are often limited and expensive. In addition, the durability of the container houses means that they require less maintenance over time, further reducing long – term costs.

7.3 Facilitating Mobility and Adaptability

The modular and mobile nature of Lida Group’s container houses is a major advantage for Arctic research. Research needs may change over time, and the container houses can be easily moved or reconfigured. For example, if a research project expands, additional containers can be added to the existing facility. If a research site needs to be relocated, the container houses can be disassembled and transported to a new location. This mobility and adaptability make the container houses a flexible solution for the dynamic nature of Arctic research.

8. Case Studies of Lida Group’s Container House Projects in the Arctic

8.1 A Remote Arctic Climate Research Station

Lida Group was contracted to build a remote Arctic climate research station. The station consisted of multiple container houses, including laboratories for analyzing climate data, living quarters for the research team, and storage facilities for equipment and samples. The container houses were equipped with state – of – the – art insulation and energy – efficient systems. The construction process was completed within a short time frame, allowing the research team to start their work sooner. The station has been operating successfully for several years, providing valuable data on Arctic climate change.

8.2 A Temporary Research Camp for a Mineral Exploration Project

For a mineral exploration project in the Arctic, Lida Group provided a temporary research camp. The camp included container houses for sleeping, dining, and administrative purposes. The modular design of the container houses allowed for easy setup and takedown. When the mineral exploration project was completed, the container houses were disassembled and transported to another location for reuse. This project demonstrated the mobility and reusability of Lida Group’s container houses in the context of Arctic research.

9. Comparison with Traditional Construction Methods in the Arctic

9.1 Construction Time

Traditional construction methods in the Arctic are extremely time – consuming. The need to deal with permafrost, extreme weather conditions, and limited access often leads to long delays. In contrast, Lida Group’s prefab container house construction method is much faster. The off – site prefabrication and quick on – site assembly can reduce the construction time by months or even years compared to traditional methods.

9.2 Cost

The cost of traditional construction in the Arctic is high due to factors such as the need for specialized equipment, the high cost of transporting materials over long distances, and the extended construction time. Lida Group’s container houses offer cost – savings. The off – site prefabrication reduces labor costs on – site, and the energy – efficient design reduces long – term energy costs. The modular nature of the container houses also allows for more efficient use of materials, reducing waste and further lowering costs.

9.3 Environmental Impact

Traditional construction methods in the Arctic can have a significant environmental impact. The large – scale clearing of land for construction, the use of heavy equipment, and the disposal of construction waste can all damage the fragile Arctic ecosystem. Lida Group’s approach, with its off – site prefabrication and careful waste management during on – site assembly, minimizes the environmental impact. The energy – efficient design of the container houses also reduces the overall energy consumption, which is beneficial for the environment.

10. Future Perspectives and Potential Developments

10.1 Technological Advancements in Arctic – Suitable Construction

In the future, technological advancements are likely to further improve the performance of Lida Group’s container houses in the Arctic. New insulation materials with even lower thermal conductivity may be developed, allowing for even more energy – efficient buildings. Smart building technologies can be integrated into the container houses. For example, sensors can be installed to monitor energy usage, temperature, and humidity, and the building systems can be adjusted automatically to optimize performance. Advanced construction materials that are even more resistant to the harsh Arctic environment may also be developed.

10.2 Expansion of Applications in the Arctic

Lida Group may expand the applications of its container houses in the Arctic. In addition to research facilities, the container houses could be used for tourism infrastructure, such as eco – lodges in remote Arctic areas. They could also be used for emergency shelters in case of natural disasters or accidents in the Arctic. The company could also explore partnerships with other industries operating in the Arctic, such as the shipping and fishing industries, to provide suitable accommodation and working spaces.

11. Conclusion

The Arctic region is of great importance for scientific research, climate change studies, and resource exploration. However, constructing research facilities in the Arctic is fraught with challenges due to the extreme climate, difficult logistics, and environmental sensitivity. Lida Group’s specialized prefab construction techniques, as demonstrated in its insulated high – quality container houses, offer a viable solution to these challenges.

The modular design, advanced insulation technologies, and cold – resistant material selection of Lida Group’s container houses make them suitable for the harsh Arctic environment. The construction process, with its off – site prefabrication and quick on – site assembly, is efficient and minimizes environmental impact. The case studies of Lida Group’s projects in the Arctic highlight the practicality and effectiveness of its container houses.

When compared with traditional construction methods, Lida Group’s approach shows clear advantages in terms of construction time, cost, and environmental impact. Looking to the future, technological advancements and the expansion of applications in the Arctic hold great promise for Lida Group’s container houses. As the demand for Arctic research continues to grow, driven by the need to understand climate change, protect biodiversity, and responsibly explore resources, Lida Group’s innovative solutions will play an increasingly vital role.

These container houses not only provide a reliable and comfortable base for researchers but also set a new standard for sustainable construction in extreme environments. By combining functionality, durability, and environmental consciousness, Lida Group is contributing significantly to breaking down the barriers that have long hindered effective Arctic research. As more projects adopt these specialized prefab construction techniques, we can expect to see accelerated progress in our understanding of the Arctic and its global significance, ultimately leading to better – informed decisions for the preservation and sustainable development of this critical region.

Related news

-

Sustainable Urban Expansion: Lida Group Delivers High Quality Container Apartments Using Recycled Prefab Construction Materials

2025-07-30 11:15:35

-

Flood-Resistant Innovation: Lida Group's Temporary Container Buildings Feature Elevated Prefab Construction for Coastal Emergency Housing

2025-07-30 09:38:44

-

Why Mining Camps Choose Lida Group's High Quality Container Houses with Durable Prefab Construction for Extreme Environments

2025-07-29 17:44:00

contact us

- Tel: +86-532-88966982

- Whatsapp: +86-13793209022

- E-mail: sales@lidajituan.com