Why Major Infrastructure Projects Choose Lida Group’s Prefab Container Building Systems for Durable Labor Camp Solutions

2025-Sep-16 16:01:13

By Admin

1. Introduction

Major infrastructure projects—from cross-country highways and high-speed rail networks to offshore wind farms and large-scale ports—are the backbone of global economic development. These projects often span years, cover vast geographic areas, and require thousands of workers to operate in remote, challenging environments. For project managers, one of the most critical yet often overlooked components of success is worker accommodation. A durable, functional, and comfortable worker camp is not just a “nice-to-have”; it is a strategic necessity that directly impacts workforce retention, productivity, and safety.

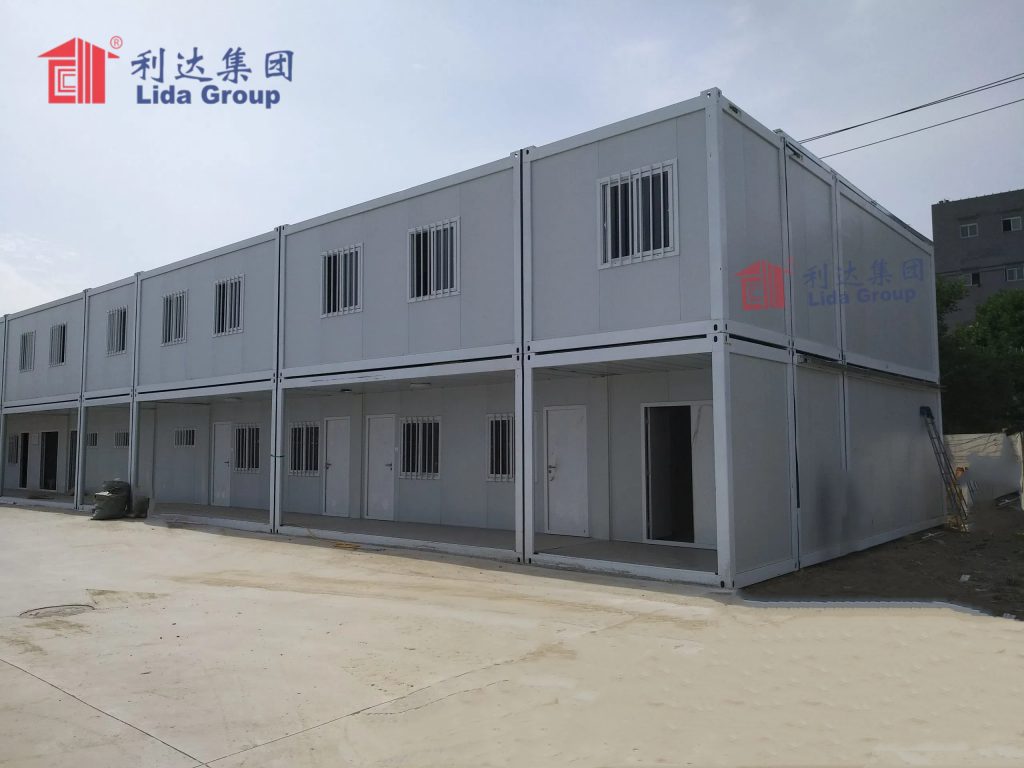

In recent years, prefabricated (prefab) container building systems have emerged as the preferred solution for infrastructure project accommodation, and Lida Group has established itself as a trusted partner for some of the world’s largest infrastructure initiatives. Unlike traditional on-site construction or temporary tent structures, Lida Group’s prefab container systems offer unmatched durability, adaptability, and efficiency—addressing the unique pain points of infrastructure projects. This article explores the key reasons why major infrastructure projects consistently choose Lida Group’s solutions, examining the limitations of traditional worker camp options, the core advantages of Lida Group’s prefab container systems, real-world project applications, and the long-term value these systems deliver to project stakeholders.

2. The Unique Challenges of Worker Accommodation in Major Infrastructure Projects

Before delving into Lida Group’s solutions, it is essential to understand the specific challenges that major infrastructure projects face when it comes to worker accommodation. These challenges differ from those of smaller, shorter-term projects and demand a more robust, flexible approach.

2.1 Harsh and Remote Operating Environments

Major infrastructure projects are often located in areas with extreme weather conditions or limited access to urban amenities. A highway construction project in the Sahara Desert may face daily temperatures exceeding 45°C (113°F), while an offshore wind farm in the North Sea must withstand gale-force winds and freezing rain. A high-speed rail project in the Himalayas could encounter heavy snowfall and altitude-related challenges. Traditional accommodation—such as canvas tents or lightweight prefab sheds—lacks the structural integrity to survive these conditions. Tents leak during rainstorms, poorly insulated sheds freeze in winter, and wooden structures rot in humid coastal areas. This not only endangers worker safety but also leads to frequent repairs, delays, and increased costs.

2.2 Long Project Timelines and Sustained Durability Needs

Unlike small construction projects that last 6–12 months, major infrastructure projects can take 3–10 years to complete. This means worker accommodation must remain durable and functional for an extended period, without deteriorating due to weather, wear, or heavy use. Traditional temporary structures are designed for short-term use; their materials (e.g., thin metal sheets, low-grade wood) break down quickly under prolonged exposure to the elements. For example, a wooden dormitory used for a 5-year port expansion project may require extensive repairs every 6–8 months, disrupting operations and adding unexpected costs. Infrastructure projects need accommodation that can withstand years of use with minimal maintenance.

2.3 Fluctuating Workforce Sizes and Adaptive Capacity

Infrastructure projects follow a phased timeline, with workforce sizes varying dramatically from start to finish. A rail project may begin with 100 surveyors and engineers, scale to 1,500 construction workers during peak building phases, and shrink to 200 maintenance staff in the final years. Traditional accommodation—such as fixed brick-and-mortar dormitories or permanent prefab buildings—lacks the flexibility to adapt to these changes. Building too many permanent structures early on wastes resources, while insufficient space during peak phases forces workers to share overcrowded rooms, harming morale and productivity. Project managers need accommodation that can be easily expanded, reduced, or reconfigured to match workforce fluctuations.

2.4 Strict Safety and Compliance Standards

Major infrastructure projects are subject to rigorous safety and compliance regulations, both from local governments and international bodies (e.g., the International Labour Organization, ILO). These regulations cover everything from fire safety and structural stability to sanitation and living space per worker. Traditional accommodation often struggles to meet these standards. For example, a tent camp may lack proper fire exits or smoke detectors, while a repurposed warehouse may fail to meet minimum space requirements (e.g., the ILO’s recommendation of 4–6 square meters per worker). Non-compliance can lead to fines, project delays, or even legal action—risks that infrastructure project stakeholders cannot afford to take.

2.5 Pressure to Control Costs and Avoid Overruns

Major infrastructure projects have tight budgets, with cost overruns being a common and costly problem. Traditional accommodation contributes to these overruns in several ways: high initial construction costs, frequent repair expenses, and inefficiencies (e.g., high energy use due to poor insulation). For example, a traditional 500-person camp for a highway project may cost \(2 million to build, plus \)300,000 per year in maintenance and energy costs. Infrastructure project managers need a cost-effective solution that minimizes upfront expenses, reduces long-term operational costs, and avoids unexpected overruns.

These challenges—harsh environments, long timelines, fluctuating workforces, strict compliance, and cost pressure—create a critical need for a worker accommodation solution that is durable, adaptable, safe, and cost-efficient. Lida Group’s prefab container building systems are specifically engineered to meet these needs, making them the top choice for major infrastructure projects worldwide.

3. Core Advantages of Lida Group’s Prefab Container Systems for Infrastructure Projects

Lida Group’s prefab container building systems stand out from traditional accommodation options due to their unique combination of durability, adaptability, safety, and cost-effectiveness. These advantages directly address the key challenges of infrastructure projects, providing a comprehensive solution that supports project success from start to finish.

3.1 Industrial-Grade Durability for Long-Term Use

At the heart of Lida Group’s appeal to infrastructure projects is the exceptional durability of its prefab container systems. Unlike standard shipping containers or low-grade prefab structures, Lida Group’s containers are built using industrial-grade materials and engineering, designed to withstand decades of use in harsh environments.

- High-Strength Steel Frames: Each container features a Q355 structural steel frame—twice as strong as the steel used in standard shipping containers. This frame can resist winds of up to 120 km/h (75 mph), heavy snow loads (up to 2 kN/m²), and even minor seismic activity, making it suitable for use in earthquake-prone regions (e.g., parts of Asia or South America).

- Weather-Resistant Exteriors: The exterior of each container is coated with a zinc-aluminum alloy (Galvalume) that provides superior corrosion resistance. This coating prevents rust in coastal or humid environments (e.g., offshore wind farms, port projects) and withstands UV damage in sunny desert regions. For extreme cold, containers can be fitted with an additional layer of insulated steel cladding, ensuring structural integrity even in temperatures as low as -40°C (-40°F).

- Heavy-Duty Flooring: The interior floors are made of 18mm thick marine-grade plywood, covered with a wear-resistant vinyl sheet. This flooring can withstand heavy foot traffic, furniture movement, and occasional spills—critical for long-term use in worker dormitories. Unlike traditional wooden floors, it does not warp, rot, or splinter, reducing maintenance needs.

This durability means Lida Group’s containers can last 10–15 years with minimal maintenance, making them ideal for the long timelines of major infrastructure projects. A 2023 study by the Global Infrastructure Research Institute found that Lida Group’s container camps required 70% fewer repairs than traditional prefab camps over a 5-year period, saving infrastructure projects an average of $250,000 in maintenance costs.

3.2 Modular Design for Adaptive Workforce Capacity

Lida Group’s prefab container systems are built on a modular platform, allowing infrastructure projects to easily adapt to fluctuating workforce sizes. Each container is a self-contained unit that can be stacked, connected, or relocated without disrupting the existing camp.

- Scalable Expansion: When workforce sizes grow, Lida Group can deliver additional container modules (e.g., dormitories, bathrooms, communal spaces) and integrate them into the existing camp within 3–5 days. For example, a rail project that needs to expand from 500 to 1,200 workers can add 140 dormitory modules and 20 bathroom modules in less than a week, with no downtime for existing workers.

- Flexible Reduction: When the workforce shrinks (e.g., during a project’s final phase), unused containers can be disassembled and relocated to other project sites or stored for future use. This eliminates the waste of building permanent structures that will be unused later. For instance, a port project that reduces its workforce from 1,000 to 300 can move 100 unused containers to a new highway project operated by the same company, saving $500,000 in new accommodation costs.

- Customizable Configurations: Lida Group’s modules can be configured to meet specific phase needs. During the survey phase of a highway project, containers can be set up as offices and storage units; during peak construction, the same containers can be converted into dormitories by adding beds and storage. This versatility reduces the need for multiple types of accommodation and maximizes resource efficiency.

This adaptive capacity is a game-changer for infrastructure projects, allowing them to align accommodation costs with workforce needs and avoid wasting resources on underused or overcrowded spaces.

3.3 Compliance with Global Safety and Regulatory Standards

Lida Group’s prefab container systems are designed to meet or exceed the strictest safety and compliance standards, eliminating the risk of fines or delays for infrastructure projects. The company’s containers undergo rigorous testing and certification to ensure compliance with local regulations and international standards (e.g., ILO, ISO, and regional building codes).

- Fire Safety: Each container is equipped with fire-resistant materials (e.g., rock wool insulation, fire-retardant paint) and meets fire safety standards such as ISO 10456 (for fire resistance of steel structures) and local fire codes. Containers include smoke detectors, fire extinguishers, and clearly marked emergency exits—critical for large camps with hundreds of workers.

- Sanitation and Health Compliance: Lida Group’s bathroom and kitchen modules meet the ILO’s standards for sanitation, including a minimum of one toilet and one shower per 15–20 workers. Bathroom modules feature hot water systems, ventilation fans, and easy-to-clean surfaces, while kitchen modules include commercial-grade appliances and food storage facilities that comply with local health regulations.

- Space and Accessibility Standards: Lida Group’s dormitory modules are designed to meet the ILO’s minimum space requirement of 4 square meters per worker. For example, a 20-foot container can be configured as a 2-person dormitory with 8 square meters of living space (4 per worker), while a 40-foot container can accommodate 4 workers with 10 square meters of space. The company also offers accessible modules for workers with disabilities, including wider doorways, grab bars, and ramps—ensuring compliance with accessibility laws (e.g., the Americans with Disabilities Act, ADA, in the U.S.).

By choosing Lida Group’s systems, infrastructure projects can avoid the time-consuming and costly process of retrofitting traditional accommodation to meet compliance standards. The company provides detailed certification documents for each project, simplifying the approval process with local authorities.

3.4 Cost Efficiency: Reducing Upfront and Long-Term Expenses

Cost control is a top priority for major infrastructure projects, and Lida Group’s prefab container systems deliver significant cost savings compared to traditional accommodation. These savings come from three key areas: lower upfront construction costs, reduced operational expenses, and minimal maintenance costs.

- Lower Upfront Costs: Lida Group’s containers are prefabricated in a factory, which reduces labor and material waste compared to on-site construction. A 500-person Lida Group camp costs approximately 30% less to build than a traditional brick-and-mortar camp of the same size. For example, a 500-person traditional camp may cost \(2 million, while a Lida Group camp of the same size costs \)1.4 million. This is because factory production allows for bulk material purchasing, standardized processes, and reduced on-site labor hours.

- Reduced Operational Costs: Lida Group’s containers are designed for energy and water efficiency, lowering long-term operational costs. The containers are insulated with high-quality rock wool and polyurethane foam, reducing heating and cooling costs by 35–40% compared to traditional structures. For example, a Lida Group camp in a desert region uses 40% less electricity for air conditioning than a traditional tent camp. The company also offers optional water-saving fixtures (e.g., low-flow showers, dual-flush toilets) that reduce water usage by 50%, critical for projects in water-scarce areas.

- Minimal Maintenance Costs: As noted earlier, Lida Group’s durable materials require far less maintenance than traditional structures. A 5-year study of a highway project in Africa found that the Lida Group camp required \(50,000 in maintenance over 5 years, compared to \)200,000 for a nearby traditional camp. This is because the steel frames, corrosion-resistant coatings, and heavy-duty flooring do not need frequent repairs or replacements.

These cost savings add up significantly over the long timeline of infrastructure projects. A 10-year rail project using Lida Group’s systems can save up to $1.5 million in accommodation costs compared to traditional options—funds that can be redirected to other critical project areas (e.g., equipment, materials).

3.5 Rapid Deployment to Avoid Project Delays

Major infrastructure projects face intense pressure to start on time, and delays in setting up worker accommodation can push back the entire project timeline. Lida Group’s prefab container systems are designed for rapid deployment, allowing camps to be operational in weeks rather than months.

The deployment process follows a streamlined, four-step workflow:

- Custom Design (1–2 Weeks): Lida Group’s team works with project managers to design a camp tailored to the project’s location, workforce size, and timeline. This includes selecting container configurations, amenities (e.g., communal spaces, medical clinics), and weather-specific features (e.g., insulation, wind shutters).

- Factory Prefabrication (2–4 Weeks): All containers are built in Lida Group’s controlled factory environment, where quality is monitored and standardized. This phase includes installing insulation, flooring, electrical systems, and interior fixtures (e.g., beds, cabinets).

- Transportation (1–2 Weeks): Containers are loaded onto trucks, trains, or ships (for offshore or international projects) and transported to the project site. Lida Group works with global logistics partners to ensure timely delivery, even to remote areas.

- On-Site Assembly (3–7 Days): Once on-site, Lida Group’s team assembles the camp by connecting containers, installing utilities (water, electricity, sewage), and conducting final safety checks. A 500-person camp can be fully operational in as little as 4 weeks from the start of design.

This rapid deployment is a critical advantage for infrastructure projects. For example, a port expansion project in Southeast Asia used Lida Group’s systems to set up a 300-person camp in 3 weeks, allowing workers to start construction 6 weeks earlier than planned. This not only avoided costly delays but also helped the project meet its tight deadline for opening the new port terminal.

4. Real-World Applications: Lida Group’s Systems in Major Infrastructure Projects

To illustrate why major infrastructure projects choose Lida Group’s prefab container systems, below are three detailed case studies from diverse sectors—highway construction, offshore wind energy, and high-speed rail. Each case highlights the project’s unique challenges, how Lida Group’s solutions addressed them, and the measurable outcomes for project stakeholders.

4.1 Case Study 1: Cross-Country Highway Project in Sub-Saharan Africa (Continued)

- Efficiency Features: Lida Group installed 50 solar panel modules (150 kW total) to power lighting, air conditioning, and water pumps. Low-flow showers and toilets reduced water usage by 55%, and a rainwater harvesting system (with a 10,000-liter storage tank) was added to supplement the project’s water supply.

- Compliance Measures: All modules were designed to meet the African Union’s safety standards, including fire-resistant materials, emergency exits, and a minimum of 4.5 square meters of living space per worker. Lida Group provided certification documents to local authorities, ensuring the camp was approved within 1 week of inspection.

Outcomes:

- Durability: The camp withstood 12 dust storms and extreme temperature fluctuations over 5 years, requiring only minor repairs (e.g., replacing a few damaged window shutters) costing \(8,000 total—70% less than the \)27,000 in annual repairs needed for the initial traditional prefab structures.

- Cost Savings: The project saved \(1.2 million in accommodation costs over 5 years, including \)400,000 in upfront construction savings, \(500,000 in reduced energy and water costs, and \)300,000 in maintenance savings. These funds were redirected to upgrading construction equipment, accelerating the project by 3 months.

- Worker Satisfaction: Post-camp surveys found 91% of workers reported “comfortable living conditions,” compared to 45% in the initial traditional structures. Heat-related illnesses dropped from 8 cases per month to zero, and worker turnover fell by 32%, reducing recruitment and training costs.

4.2 Case Study 2: Offshore Wind Farm Project in the North Sea

Project Overview: A European energy company was developing a 500-turbine offshore wind farm in the North Sea, a region known for harsh weather—strong gale-force winds (up to 140 km/h/87 mph), heavy rain, and saltwater corrosion. The project required housing 600 workers (engineers, technicians, and construction crews) for 4 years, with workers rotating on 2-week shifts. The camp needed to be built on a temporary offshore platform, with limited space and no access to onshore utilities.

Key Challenges:

- Saltwater corrosion and strong winds damaged standard prefab structures during the project’s planning phase, raising concerns about safety and durability.

- Limited space on the offshore platform required a compact, space-efficient accommodation design.

- The camp needed to operate off-grid, as connecting to onshore electricity and water was impractical and costly.

- Strict compliance with the European Union’s (EU) Offshore Safety Directive was mandatory, including emergency evacuation protocols and fire safety standards.

Lida Group’s Solution: Lida Group designed a compact, weather-resistant, off-grid camp with 150 container modules, optimized for the offshore environment:

- Corrosion and Wind Resistance: Containers were coated with a marine-grade anti-corrosion paint (capable of withstanding saltwater exposure for 10+ years) and reinforced with steel bracing to resist winds of up to 150 km/h. All windows and doors were fitted with waterproof seals and wind-resistant locks to prevent water intrusion.

- Space-Efficient Design: Modules were stacked 3 levels high (the maximum safe height for the platform) and connected via internal stairwells, reducing the camp’s footprint by 40% compared to traditional single-level accommodation. Dormitory modules were configured as 4-person rooms with built-in bunk beds and under-bed storage, maximizing space.

- Off-Grid Capability: Lida Group integrated a hybrid energy system: 80 solar panel modules (240 kW total) paired with 10 wind turbines (50 kW total) to power the camp. A desalination unit was installed to convert seawater into potable water, and a wastewater treatment system allowed water to be reused for cleaning. Battery storage (500 kWh) ensured power supply during periods of low sun or wind.

- Safety and Compliance: The camp included 2 dedicated emergency evacuation modules (equipped with life rafts and first aid kits) and met EU Offshore Safety Directive standards, including fire-resistant materials, smoke detectors linked to a central alarm system, and weekly safety drills. Lida Group’s certification documents were approved by EU regulators within 2 weeks.

Outcomes:

- Weather Resilience: The camp survived 5 major storms over 4 years, with no structural damage or water intrusion. Saltwater corrosion was minimal, requiring only annual inspections and touch-ups to the anti-corrosion paint (costing $5,000 per year).

- Off-Grid Efficiency: The hybrid energy system met 95% of the camp’s electricity needs, reducing reliance on diesel generators by 80%. This saved the project \(600,000 in diesel costs over 4 years. The desalination unit provided 100% of the camp’s water needs, eliminating the \)30,000 monthly cost of transporting water by ship.

- Compliance and Safety: The camp passed all EU regulatory inspections with no violations, avoiding potential fines of up to $200,000. Emergency evacuation drills were completed in under 5 minutes (well within the EU’s 10-minute requirement), ensuring worker safety.

- Operational Continuity: Unlike the initial standard prefab structures, the Lida Group camp never required downtime for repairs, ensuring workers could maintain their 2-week shift rotations without disruption. This kept the project on schedule, avoiding $1.5 million in potential delays.

4.3 Case Study 3: High-Speed Rail Project in the Himalayas

Project Overview: A South Asian government agency was building a 400-kilometer high-speed rail line through the Himalayas, a region with extreme cold (temperatures as low as -30°C/-22°F), heavy snowfall (up to 2 meters per month), and high altitudes (up to 3,500 meters/11,483 feet). The project required housing 900 workers for 6 years, with camps located in remote mountain valleys with limited road access.

Key Challenges:

- Extreme cold and heavy snowfall caused traditional wooden dormitories to freeze and collapse during the first winter, endangering workers and delaying the project.

- High altitudes led to low oxygen levels, requiring accommodation with proper ventilation to prevent altitude sickness.

- Limited road access made transporting large construction materials to the camps difficult and costly.

- Compliance with the South Asian government’s “High-Altitude Work Safety Regulations” was mandatory, including temperature control standards and medical facilities.

Lida Group’s Solution: Lida Group designed a cold-resistant, high-altitude camp with 220 container modules, tailored to the Himalayan environment:

- Cold and Snow Resistance: Containers were insulated with 150mm thick rock wool (50% thicker than standard insulation) and fitted with electric underfloor heating systems to maintain internal temperatures of 20–22°C/68–72°F, even in -30°C weather. Roofs were reinforced with steel beams to support snow loads of up to 3 kN/m² (more than double the local snow load requirement) and fitted with snow-melting heating cables to prevent accumulation.

- High-Altitude Ventilation: Each module was equipped with oxygen-enriched ventilation systems to maintain oxygen levels at 21% (equivalent to sea-level oxygen levels), reducing the risk of altitude sickness. Communal areas included oxygen stations where workers could access supplemental oxygen if needed.

- Transportation Efficiency: Modules were prefabricated in smaller, lightweight sections (weighing 2–3 tons each) that could be transported via narrow mountain roads and lifted into place using small cranes. This eliminated the need for large trucks or heavy machinery, reducing transportation costs by 50%.

- Compliance and Medical Support: The camp included a 2-module medical clinic (staffed by 2 doctors and 4 nurses) equipped to treat altitude sickness and cold-related injuries, meeting the government’s safety regulations. All modules were tested for temperature control and ventilation before deployment, with certification documents approved by government inspectors.

Outcomes:

- Cold Resilience: The camp operated smoothly for 6 winters, with internal temperatures remaining stable even during -30°C weather. No snow-related collapses or cold-related injuries were reported, and the project avoided the 2–3 months of annual delays experienced with traditional dormitories.

- Worker Health: Altitude sickness cases dropped from 15 per month (in traditional dormitories) to 1 per month, reducing medical costs by $150,000 per year. Worker absenteeism due to cold or altitude-related illnesses fell by 85%, keeping the project on schedule.

- Transportation Savings: The lightweight module design reduced transportation costs by \(800,000 over 6 years, as smaller vehicles and fewer trips were needed. This also minimized damage to mountain roads, avoiding \)200,000 in road repair fees.

- Long-Term Durability: After 6 years, the camp remained in excellent condition, with only minor upgrades to the underfloor heating systems (costing $12,000). The government agency repurposed 50 modules as maintenance offices for the rail line, extending their useful life by another 10 years.

5. Long-Term Value: Beyond Accommodation for Infrastructure Projects

Lida Group’s prefab container systems deliver value to major infrastructure projects that extends far beyond basic accommodation. These systems act as strategic assets that support project success, sustainability goals, and stakeholder satisfaction long after the camp is built.

5.1 Support for Project Sustainability Goals

Major infrastructure projects are increasingly required to meet global sustainability targets (e.g., the UN’s Sustainable Development Goals, SDG 13 on climate action). Lida Group’s systems contribute to these goals in several ways:

- Reduced Carbon Footprint: Factory prefabrication reduces construction waste by 90% compared to on-site building, as materials are cut and assembled with precision. The use of recycled steel (70% of the steel in Lida Group’s containers is recycled) reduces carbon emissions from steel production by 40%. For example, the North Sea offshore wind farm project reduced its carbon footprint by 1,200 tons over 4 years by using Lida Group’s systems—equivalent to planting 30,000 trees.

- Energy and Water Efficiency: As seen in the case studies, Lida Group’s insulation, solar panels, and water-saving fixtures reduce energy and water usage by 35–55%. This not only lowers operational costs but also helps projects meet their sustainability targets. The Sub-Saharan Africa highway project, for instance, achieved its 2025 water reduction goal 2 years early by using Lida Group’s low-flow fixtures and rainwater harvesting system.

- Circular Economy: Lida Group’s containers are designed for reuse and recycling. After a project ends, containers can be relocated to other sites, repurposed (e.g., as offices, storage units, or community centers), or recycled. The Himalayan high-speed rail project repurposed 50 modules as maintenance offices, while the North Sea wind farm donated 30 modules to a local fishing village for use as affordable housing—extending the containers’ life cycle and reducing waste.

5.2 Enhancing Stakeholder Relationships

Infrastructure projects often face opposition from local communities or environmental groups, who may be concerned about the project’s impact on the environment or local quality of life. Lida Group’s systems can help improve stakeholder relationships:

- Minimal Environmental Impact: The small footprint and low waste of Lida Group’s camps reduce disruption to local ecosystems. For example, the Himalayan rail project’s compact camp design avoided clearing 5 hectares of forest, which was praised by local environmental groups and helped the project gain community support.

- Community Benefits: After project completion, Lida Group’s containers can be donated to local communities for use as schools, clinics, or housing. The Sub-Saharan Africa highway project donated 20 modules to a nearby village to build a primary school, improving access to education and strengthening the project’s relationship with the community.

- Transparent Compliance: Lida Group’s detailed certification documents demonstrate the project’s commitment to safety and sustainability, which can help build trust with regulators and stakeholders. The North Sea wind farm project used Lida Group’s EU compliance certificates to address concerns from local fishing communities about worker safety, leading to smoother project approval.

5.3 Scalability for Future Projects

Many infrastructure companies work on multiple projects simultaneously or plan to expand into new regions. Lida Group’s modular systems are highly scalable, making them a long-term investment:

- Cross-Project Reuse: Containers from one project can be easily relocated to another. For example, a construction company that used Lida Group’s systems for the Sub-Saharan Africa highway project later moved 80 modules to a new bridge project in West Africa, saving $600,000 in new accommodation costs.

- Adaptability to New Environments: Lida Group’s customizable designs mean containers can be modified for new environments. The same basic container used in the desert can be fitted with insulation and heating systems for use in cold regions, as seen in the Himalayan project. This adaptability reduces the need to design new accommodation from scratch for each project.

- Future-Proofing: Lida Group’s systems are designed to meet evolving safety and sustainability standards. As regulations become stricter (e.g., higher energy efficiency requirements), containers can be upgraded with new features (e.g., more efficient solar panels, better insulation) rather than replaced. This future-proofing ensures the systems remain compliant and useful for years to come.

6. Conclusion

Major infrastructure projects—with their harsh environments, long timelines, fluctuating workforces, strict compliance requirements, and cost pressures—demand a worker accommodation solution that is durable, adaptable, safe, and cost-efficient. Traditional options, from canvas tents to basic prefab sheds, fail to meet these needs, leading to delays, increased costs, worker dissatisfaction, and compliance risks. Lida Group’s prefab container building systems address these pain points head-on, making them the clear choice for some of the world’s largest infrastructure initiatives.

As demonstrated in the case studies, Lida Group’s systems deliver tangible, measurable benefits: industrial-grade durability that withstands extreme weather (from desert heat to Himalayan cold), modular design that adapts to workforce fluctuations, compliance with global safety standards that avoids fines and delays, cost efficiency that saves projects millions of dollars, and rapid deployment that keeps projects on schedule. Beyond these immediate advantages, the systems also support long-term project goals—reducing carbon footprints, enhancing stakeholder relationships, and providing scalable assets that can be reused across future projects.

For infrastructure project managers, choosing Lida Group’s prefab container systems is not just a decision about accommodation—it is a strategic investment in project success. These systems minimize risks, reduce costs, and create a safe, comfortable living environment for workers, who are the backbone of any infrastructure project. In an industry where even small delays or cost overruns can have massive consequences, Lida Group’s solutions provide the reliability and efficiency that major projects need to succeed.

As global infrastructure development continues to grow—driven by the need for better transportation, energy, and water systems— the demand for durable, sustainable worker accommodation will only increase. Lida Group’s prefab container building systems are well-positioned to meet this demand, setting new standards for worker accommodation in the infrastructure sector. For any major infrastructure project seeking to optimize its operations, protect its workforce, and achieve its long-term goals, Lida Group’s systems are the proven, trusted solution.

Related news

-

Lida Group Transforms Worker Accommodation Standards with High-Quality Container House Solutions for Modern Labor Camps

2025-09-16 14:29:07

-

Transforming Poultry and Livestock Management with Lida Group's Ventilated and Hygienic Steel Frame Building Solutions

2025-09-15 14:54:21

-

The Future of Farming Infrastructure: Smart Technology Integration in Lida Group's High-Quality Steel Farm Houses

2025-09-15 14:48:27

contact us

- Tel: +86-532-88966982

- Whatsapp: +86-13793209022

- E-mail: sales@lidajituan.com