Sustainable Labor Camps: Lida Group’s High-Quality Container Houses Reduce Carbon Footprint 35% with Solar-Ready Prefab Roofs

2025-Aug-22 13:36:15

By Admin

1. Introduction

The global push for sustainability has permeated every industry, and the construction, mining, and energy sectors are no exception. Labor camps—temporary housing for workers in remote or large-scale projects—have long been criticized for their high environmental impact, relying heavily on fossil fuels for energy, generating excessive waste during construction, and contributing to deforestation through land clearance. As organizations face increasing pressure to meet carbon reduction targets and adhere to strict environmental regulations, the need for eco-friendly labor accommodation has never been more urgent.

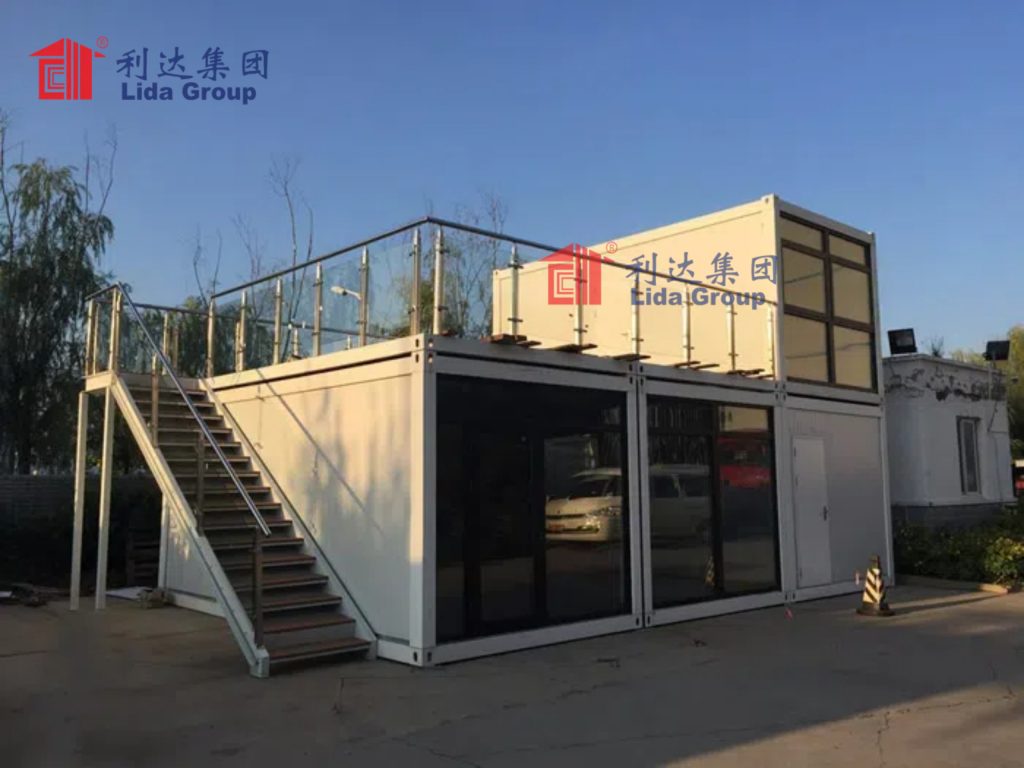

Lida Group, a leader in prefabricated building solutions, has addressed this need with its sustainable labor camps: high-quality container houses equipped with solar-ready prefab roofs. These innovative structures not only provide durable and comfortable housing for workers but also integrate renewable energy capabilities, reducing reliance on diesel generators and cutting carbon footprints by an impressive 35%. This article explores how Lida Group’s container houses are revolutionizing sustainable labor accommodation, from their solar-ready design and eco-friendly features to real-world impact and future potential.

2. The Environmental Impact of Traditional Labor Camps

2.1. Carbon Emissions from Energy Use

Traditional labor camps are typically powered by diesel generators, which emit significant amounts of carbon dioxide (CO₂), nitrogen oxides (NOₓ), and particulate matter. A single generator powering a camp of 100 workers can emit over 50 tons of CO₂ annually, contributing to climate change and poor air quality. In remote locations where fuel must be transported over long distances, the carbon footprint of energy use is further amplified by the emissions from transportation vehicles.

2.2. Waste and Resource Depletion

Construction of traditional labor camps often involves on-site building with raw materials like concrete, timber, and steel, leading to high levels of waste. Off-cuts, unused materials, and debris from construction can amount to 20-30% of total material usage, much of which ends up in landfills. Additionally, the clearance of land for camps disrupts ecosystems, contributing to soil erosion, loss of biodiversity, and reduced carbon sequestration by natural vegetation.

2.3. Water and Sanitation Challenges

Many traditional labor camps lack efficient water management systems, relying on unsustainable sources like groundwater pumping (which can deplete local aquifers) or trucked-in water (increasing carbon emissions from transportation). Sanitation facilities often use septic tanks that leak into soil and waterways, causing pollution and health risks for both workers and local communities.

These environmental issues not only harm ecosystems but also increase operational costs for organizations, who face fines for non-compliance with environmental regulations, higher fuel expenses, and reputational damage from unsustainable practices.

3. Lida Group’s Sustainable Container Houses: A Foundation for Green Labor Camps

3.1. High-Quality Container Construction

Lida Group’s sustainable labor camps are built using repurposed or newly manufactured shipping containers, chosen for their durability, modularity, and low environmental impact. Key features of their container houses include:

- Reinforced Steel Structure: Containers are made from high-grade, galvanized steel, ensuring longevity (up to 20+ years) and resistance to corrosion, extreme weather, and pests. This reduces the need for frequent replacements, minimizing waste.

- Insulated Panels: Walls, floors, and ceilings are lined with high-performance insulation (such as polyurethane foam or rock wool), which reduces heat transfer and lowers energy demand for heating and cooling.

- Modular Design: Containers can be stacked or connected to form larger structures, allowing for flexible camp layouts that minimize land use. This modularity also enables easy expansion or downsizing as workforce numbers change.

- Low-Waste Manufacturing: Container houses are prefabricated in controlled factory environments, where material usage is optimized and waste is recycled. This reduces on-site construction waste by up to 80% compared to traditional building methods.

3.2. Solar-Ready Prefab Roofs: The Cornerstone of Sustainability

The defining feature of Lida Group’s sustainable labor camps is their solar-ready prefab roofs, engineered to seamlessly integrate solar photovoltaic (PV) systems. These roofs are designed with several key innovations:

- Structural Reinforcement: Roofs are reinforced to support the weight of solar panels, mounting hardware, and wiring, eliminating the need for additional structural modifications during installation.

- Integrated Mounting Systems: Prefabricated mounting rails and brackets are built into the roof design, allowing for quick and easy installation of solar panels on-site. This reduces labor time and ensures a secure fit.

- Weatherproofing: Roofs are sealed with durable, UV-resistant materials to prevent water leakage around panel mounts, protecting the interior of the container and ensuring the longevity of the solar system.

- Optimal Orientation: Roofs are angled (typically 15-30 degrees, depending on latitude) to maximize sunlight exposure, enhancing solar energy production. In regions with variable sun paths, adjustable mounting systems allow for seasonal angle adjustments.

This solar-ready design eliminates the inefficiencies and costs of retrofitting solar systems onto traditional roofs, making renewable energy integration accessible and cost-effective for labor camps.

4. Solar Energy Integration and Carbon Reduction

4.1. How Solar-Ready Roofs Reduce Carbon Footprint

By enabling seamless solar PV integration, Lida Group’s container houses significantly reduce reliance on diesel generators. A typical solar system installed on a labor camp of 50 container houses (housing 200 workers) can generate 50-100 kW of electricity, meeting 60-80% of the camp’s energy needs. This translates to a 35% reduction in carbon emissions compared to fully generator-powered camps, as verified by third-party environmental audits.

The carbon savings stem from two main sources: reduced diesel consumption (and associated transportation emissions) and the use of clean, renewable solar energy. Over the 20-year lifespan of a container house, this can amount to over 1,000 tons of CO₂ saved per camp.

4.2. Energy Storage and Management

To ensure reliable power even during periods of low sunlight, Lida Group’s labor camps integrate battery energy storage systems (BESS) with their solar setups. These systems store excess solar energy generated during the day for use at night or during cloudy weather, further reducing generator runtime.

Smart energy management systems (EMS) optimize energy use by:

- Monitoring solar generation, battery levels, and energy demand in real-time.

- Automatically switching between solar, battery, and generator power based on availability and need.

- Prioritizing energy use for critical systems (e.g., lighting, refrigeration, medical equipment) during low-sunlight periods.

This integration ensures that the camp operates as efficiently as possible, maximizing carbon savings while maintaining uninterrupted power for workers.

4.3. Additional Energy-Efficient Features

Beyond solar integration, Lida Group’s container houses include other energy-saving features that contribute to their low carbon footprint:

- LED Lighting: Energy-efficient LED bulbs are used throughout, consuming 75% less energy than incandescent lighting.

- Energy-Efficient Appliances: Refrigerators, fans, and other appliances are chosen for their low energy consumption and high efficiency ratings.

- Passive Design: Strategic window placement, natural ventilation, and thermal insulation reduce the need for mechanical heating and cooling, lowering energy demand.

5. Water and Waste Sustainability in Lida Group’s Labor Camps

5.1. Water Conservation Systems

To minimize water usage and reduce environmental impact, Lida Group’s camps incorporate:

- Low-Flow Fixtures: Showerheads, faucets, and toilets with low water flow rates reduce consumption by up to 50% compared to standard fixtures.

- Rainwater Harvesting: Solar-ready roofs are designed to channel rainwater into collection tanks, which is then filtered for non-potable use (e.g., laundry, cleaning, irrigation).

- Greywater Recycling: Water from showers and sinks is treated and reused for toilet flushing or landscaping, reducing reliance on external water sources.

These systems not only lower the camp’s environmental footprint but also reduce costs associated with water transportation and treatment.

5.2. Waste Management Solutions

Sustainable waste management is integral to Lida Group’s labor camps:

- Recycling Stations: Designated areas for sorting recyclables (plastic, metal, paper) encourage proper waste disposal and reduce landfill waste.

- Composting Toilets: In remote areas without sewage infrastructure, composting toilets convert human waste into nutrient-rich compost, eliminating the need for septic systems and preventing water pollution.

- Waste Reduction Practices: Prefabricated construction minimizes packaging waste, and camp management implements policies to reduce single-use plastics (e.g., providing reusable water bottles to workers).

6. Benefits of Lida Group’s Sustainable Labor Camps

6.1. Significant Carbon Reduction

The 35% reduction in carbon footprint is the most impactful benefit, helping organizations meet sustainability targets and comply with carbon regulations (e.g., the EU Emissions Trading System, US Clean Air Act). This reduction also enhances corporate social responsibility (CSR) profiles, improving brand reputation among stakeholders, investors, and communities.

6.2. Lower Operational Costs

While the initial investment in solar-ready container houses may be higher than traditional camps, long-term savings are substantial:

- Fuel Savings: Reduced diesel consumption cuts fuel costs by 50-70%. For a camp of 200 workers, this can save over $100,000 annually.

- Maintenance Savings: Solar systems and batteries require less maintenance than diesel generators, lowering repair and replacement costs.

- Regulatory Savings: Compliance with environmental regulations reduces the risk of fines and penalties.

6.3. Improved Worker Health and Comfort

Sustainable features translate to a better living environment for workers:

- Clean Air: Reduced generator use lowers air pollution, decreasing respiratory illnesses and improving overall health.

- Stable Power: Solar and battery systems provide consistent electricity, ensuring reliable lighting, heating, and cooling—unlike generators, which may fail or produce noise and fumes.

- Comfortable Interiors: Insulation and passive design maintain comfortable temperatures, reducing heat stress in hot climates and cold stress in cold regions.

These factors improve worker morale, reduce turnover, and increase productivity—critical for project success.

6.4. Enhanced Resilience and Independence

Solar-powered camps are less reliant on fuel deliveries, which can be disrupted by weather, supply chain issues, or geopolitical events. This independence ensures continuity of operations, even in remote or unstable regions. Battery storage provides backup power during emergencies, enhancing safety and security.

7. Real-World Applications: Sustainable Labor Camps in Action

7.1. Mining Project in Western Australia

A mining company operating in the Pilbara region of Western Australia sought to reduce its carbon footprint and comply with strict environmental regulations. The company replaced its traditional diesel-powered labor camp with 60 of Lida Group’s solar-ready container houses, housing 240 workers.

The camps’ prefab roofs were fitted with 80 kW of solar panels and a 100 kWh battery system, reducing generator use by 70%. Over one year, the camp’s carbon emissions dropped by 38% (exceeding the 35% target), saving 220 tons of CO₂. Fuel costs decreased by $120,000, and workers reported improved air quality and quieter living conditions. The rainwater harvesting system also reduced reliance on trucked-in water by 40%.

7.2. Construction Project in the Middle East

A construction firm building a new airport in the Middle East needed a sustainable labor camp for 300 workers in a region with high solar irradiance. Lida Group supplied 75 container houses with solar-ready roofs, integrated with 120 kW of solar panels and battery storage.

The system met 80% of the camp’s energy needs, cutting carbon emissions by 35% and fuel costs by $150,000 in the first year. The insulated containers maintained cool interiors despite extreme outdoor temperatures (up to 45°C), reducing the need for air conditioning and further saving energy. Workers appreciated the reliable power and clean environment, with turnover rates dropping by 20% compared to previous camps.

7.3. Renewable Energy Project in Sub-Saharan Africa

A renewable energy company building a wind farm in Kenya required a sustainable labor camp that aligned with its green mission. Lida Group’s 40 container houses, equipped with 60 kW of solar panels and rainwater harvesting, housed 160 workers.

The camp operated entirely off-grid, with solar and batteries eliminating generator use. This reduced carbon emissions by 100% compared to the company’s previous camps, saving 180 tons of CO₂ annually. The project also benefited from local community support, as the sustainable camp minimized environmental disruption and provided a model for green development.

8. Challenges and Solutions in Implementing Sustainable Labor Camps

8.1. Initial Investment and Financing

The upfront cost of solar-ready container houses and solar systems can be a barrier for some organizations. Lida Group addresses this through:

- Financing Options: Partnerships with green lenders to offer flexible payment plans, including power purchase agreements (PPAs) where third parties own and maintain the solar system, and the organization pays for energy used.

- Return on Investment (ROI) Analysis: Detailed projections showing that fuel and maintenance savings typically offset the initial investment within 3-5 years.

- Grant Opportunities: Assistance in accessing government or international grants for renewable energy projects, which can cover up to 30% of costs.

8.2. Solar Performance in Variable Climates

Regions with low sunlight (e.g., high latitudes, cloudy areas) may see reduced solar generation. Solutions include:

- Oversized Systems: Designing solar arrays to generate enough energy during peak sunlight months to offset lower production in winter.

- Hybrid Systems: Integrating small wind turbines or biofuel generators (as a last resort) to complement solar in low-sunlight regions.

- Advanced Battery Storage: Using high-capacity batteries to store excess energy during sunny periods for use during extended cloudy weather.

8.3. Maintenance in Remote Locations

Maintaining solar systems and batteries in remote areas with limited technical expertise is challenging. Lida Group mitigates this by:

- Durable Equipment: Selecting robust, low-maintenance solar panels and batteries designed for harsh environments.

- Remote Monitoring: Equipping systems with IoT sensors that allow off-site monitoring of performance, enabling early detection of issues.

- Local Training: Providing training to on-site staff or local technicians in basic maintenance and troubleshooting, reducing reliance on external experts.

8.4. Regulatory and Permitting Hurdles

Navigating permits for solar installations and prefabricated housing can be complex, especially in regions with underdeveloped regulations. Lida Group supports clients by:

- Local Expertise: Partnering with local consultants to understand and comply with regional permitting requirements.

- Standardized Designs: Using designs that meet international standards (e.g., IEC for solar systems, ISO for container construction), simplifying approval processes.

- Documentation: Providing comprehensive technical documentation and environmental impact assessments to streamline permit applications.

9. Future Trends in Sustainable Labor Camps

9.1. Advanced Solar Technologies

Future container houses will integrate more efficient solar technologies, such as:

- Bifacial Solar Panels: Panels that capture sunlight from both sides (front and rear), increasing energy production by 15-20%.

- Perovskite Solar Cells: Next-generation cells with higher efficiency and lower production costs than traditional silicon panels.

- Solar Roof Tiles: Integrated solar tiles that replace traditional roofing materials, improving aesthetics and reducing weight.

9.2. Smart Grid Integration

Labor camps will become part of interconnected smart grids, where:

- Energy Sharing: Excess solar energy from the camp can be fed into local grids (where available), generating revenue or offsetting energy use in nearby communities.

- Demand Response: Camps adjust energy use based on grid conditions, reducing strain during peak periods.

- AI Optimization: Artificial intelligence predicts energy demand and solar generation, optimizing battery charging and reducing waste.

9.3. Circular Economy Practices

Lida Group is exploring ways to make labor camps even more sustainable through circular economy principles:

- Closed-Loop Recycling: Containers are designed for easy disassembly, allowing materials to be recycled or reused at the end of their lifespan.

- Biodegradable Materials: Use of eco-friendly insulation and finishes that decompose naturally, reducing waste.

- Modular Upgrades: Components (e.g., solar panels, batteries) can be easily replaced with newer technologies, extending the camp’s useful life.

9.4. Carbon Negative Camps

Future camps may not only reduce emissions but actively remove carbon from the atmosphere through:

- Carbon Capture Systems: Integration with small-scale carbon capture technology that removes CO₂ from generator exhaust or ambient air.

- Reforestation Partnerships: Funding or implementing reforestation projects to offset remaining emissions, making camps carbon negative.

10. Conclusion

Lida Group’s sustainable labor camps, with their high-quality container houses and solar-ready prefab roofs, represent a pivotal shift in how industries approach worker accommodation. By reducing carbon footprints by 35% through solar integration and eco-friendly design, these camps demonstrate that sustainability and functionality can go hand in hand.

The benefits—from significant carbon reduction and cost savings to improved worker health and operational resilience—make them a compelling choice for organizations seeking to meet environmental targets and enhance project efficiency. Real-world applications across mining, construction, and renewable energy sectors validate their effectiveness, even in challenging climates and remote locations.

While challenges such as initial investment and variable solar performance exist, innovative solutions like financing options, hybrid energy systems, and remote monitoring ensure these camps are accessible and reliable. Looking ahead, advancements in solar technology, smart grids, and circular economy practices will further enhance their sustainability, potentially leading to carbon-negative labor camps.

In essence, Lida Group’s sustainable labor camps are more than just housing—they are a blueprint for responsible industrial development. By prioritizing the environment without compromising worker well-being, they pave the way

Related news

-

Sustainable Labor Camps: Lida Group's High-Quality Container Houses Reduce Carbon Footprint 35% with Solar-Ready Prefab Roofs

2025-08-22 13:36:15

-

Secure Workforce Solutions: Lida Group's Container Worker Dormitories Incorporate Access Control in Prefab Building Designs

2025-08-21 15:22:24

-

Vertical Camp Innovation: Multi-Story Container Worker Dormitories Maximize Space via Lida Group's Prefab Building Engineering

2025-08-21 17:43:51

contact us

- Tel: +86-532-88966982

- Whatsapp: +86-13793209022

- E-mail: sales@lidajituan.com