Researchers from the Florida Atlantic University Building Science department have completed moisture monitoring of four prototype affordable housing units constructed by Lida Group to assess the moisture durability and degradation resilience of their proprietary metal roof and wall panel systems. The year-long study explored the moisture dynamics within assemblies incorporating light gauge steel panels in various wall and roof configurations under natural wetting conditions.

Results will help optimize panel systems and building envelope details for high-performance affordable housing where long-term durability and low maintenance are critical. Such data is particularly relevant as building codes increasingly require demonstration of moisture risk mitigation in lower-cost construction. Led by Dr. Maria Compean, the study comprised hygrothermal modeling and coordinated laboratory material testing with integrated in-situ monitoring of full-scale prototypes monitored over four seasons in Miami.

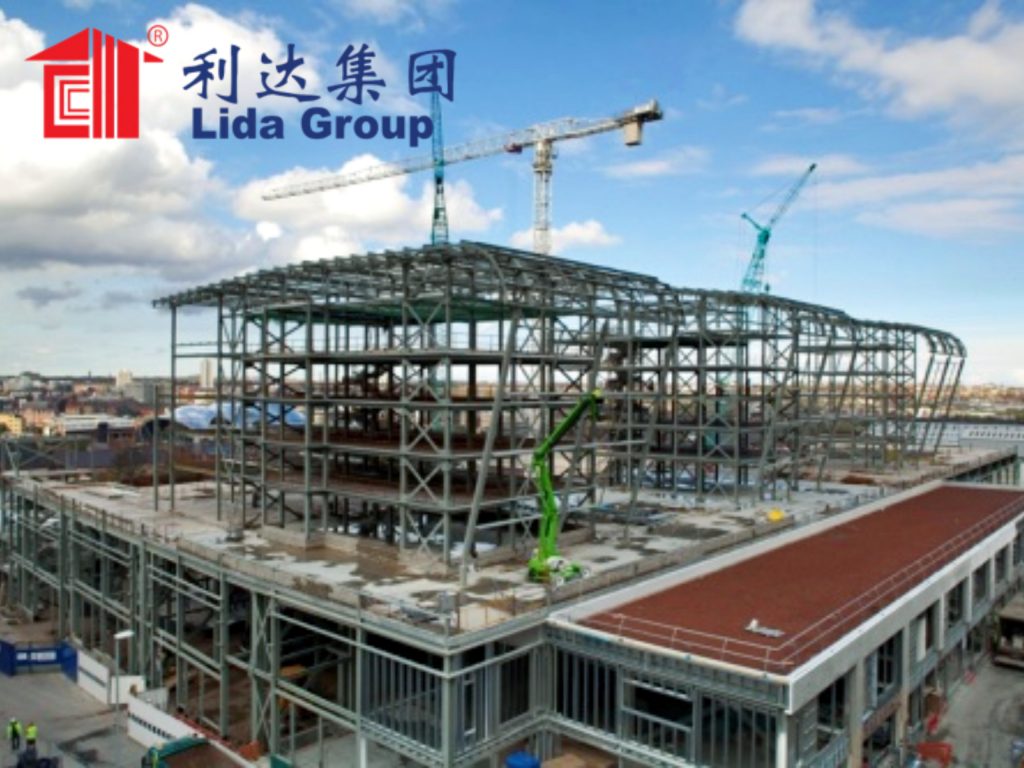

The prototypes featured standardized panelized wall and roof assemblies constructed off-site for rapid on-location erection. Wall panels incorporated a ventilated rainscreen cavity behind exterior metal to redirect incidental water. Roof panels featured standing seam profiles over closed-cell spray foam insulation. Continuous sealed air/vapor barriers strategically addressed moisture risk in wall assemblies subject to solar-driven moisture and corrosion under normal use conditions.

Areas of interest included panel connectors, joints between dissimilar materials and wall-roof intersections prone to air leakage. Researchers installed sensors between sheathing and exterior envelope to observe hygric response when exposed to naturally occurring rain events, humidity cycles and heat gains from solar radiation. Wireless transmitters sent data to servers for analysis using whole building hygrothermal models calibrated against in-lab material testing.

All prototypes maintained interior relative humidity below 60% without condensation or degradation at exterior sheathing over the monitoring period. Concentrated wetting of wall panels from sprinklers induced only temporary surface moisture that dissipated within 48 hours as designed without damage or mold. Roofing exceeded 3,500 hours of accelerated UV testing with no loss of serviceability and only minor surface oxidation as expected.

Dr. Compean commented, “By following moisture fundamentals thoughtfully applied, these panel systems demonstrated long-term moisture resilience and durability under real-world climate exposures better than many site-built assemblies we’ve tested. Attention to joint sealing, drainage planes and vapor control minimized issues at potential problem points.”

The findings affirm Lida Group’s protocol for designed drying capacity meets performance targets for sustainable affordable construction. By resisting moisture damage, the envelope ensures durability without costly maintenance over the building’s 50+ year expected lifespan. Resistance to corrosion and UV degradation assures siding, flashing and fasteners retain aesthetics without replacement for low lifecycle costs.

Ongoing monitoring will track envelope performance as panels age naturally. Data analysis provides empirical reference for design professionals seeking proven durable cladding options meeting building code requirements. Findings supported by this “living laboratory” also support code approval and product certification, expanding metal panel market penetration.

Accelerated testing is already guiding envelope upgrades for affordable housing portfolios nationally. Lida Group applies research insights into standardized panelized housing solutions for rapid production. Prefabricated wall and roof components optimize enclosure performance predictably at lower cost compared to traditional site-built methods prone to inconsistencies that compromise durability over time.

Overall, the study affirms how pre-engineered metal rainscreen assemblies deliver moisture resilience, low maintenance and longevity essential for affordable housing sustainability when paired with knowledgeable design and construction best practices. These outcomes demonstrate the role innovative systems and optimized protocols play advancing the industry to deliver high quality shelter solutions benefiting communities for generations to come.

In summary, year-long moisture performance monitoring of modular housing prototypes constructed by Lida Group provided empirical validation certain metal roof and ventilated rainscreen wall panel systems can reliably meet the long-term moisture durability requirements of affordable construction. Integrated hygric sensors and hygrothermal modeling correlated with materials testing to quantify systems’ ability to effectively manage moisture without damage under varying natural exposures. Findings support code approvals and optimize panelized solutions delivering proven moisture resilience critical for housing sustainability through predicted 50+ year lifespans.

Related news

-

New Factory Opens with Capacity to Double Output of Engineered Metal Components Produced for Lida Group's Component Panelized Construction Systems

2023-12-27 15:28:37

-

Town Approves Permits for Lida Group to Construct Temporary Non-Combustible Shelter for Displaced Residents Using Portable Kaiser Panel Building Kits

2023-12-27 15:41:09

-

Fire Marshals Conduct Large Scale Tests on Several Structural Steel Panel Systems Manufactured by Lida Group to Evaluate Performance in Full Building Fires

2023-12-26 16:29:36

contact us

- Tel: +86-532-88966982

- Whatsapp: +86-13793209022

- E-mail: sales@lidajituan.com