Redefining Affordability in Housing with Cost-Effective Prefab Construction

2025-Dec-16 17:05:35

By Admin

Introduction

The global housing crisis has reached unprecedented proportions: 1.6 billion people lack adequate shelter, with 330 million new homes needed by 2030 to meet demand (UN-Habitat, 2025). For billions more, “affordable housing”—defined as housing costing no more than 30% of household income—remains an unattainable dream. Traditional construction, burdened by material waste, labor inefficiencies, and prolonged timelines, has failed to keep pace: in major cities worldwide, the median home price is 7.8 times the median household income, a ratio that has doubled in the past two decades (World Bank, 2025). This gap between supply and affordability has fueled homelessness, overcrowding, and social inequality—urgently calling for a transformative solution.

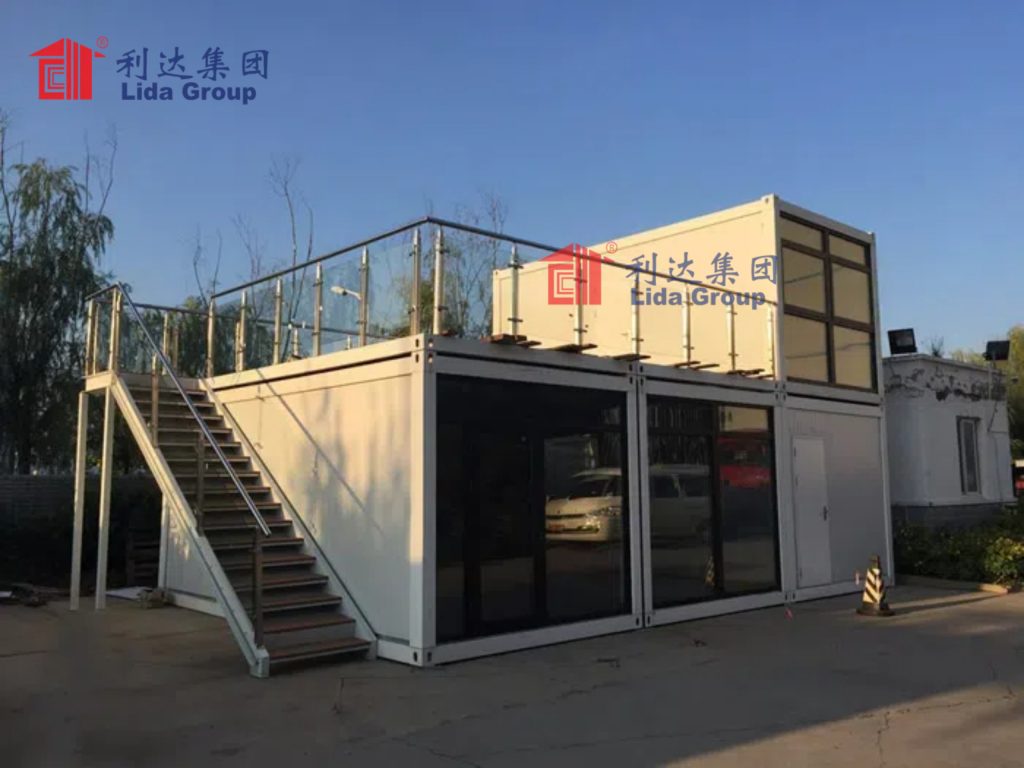

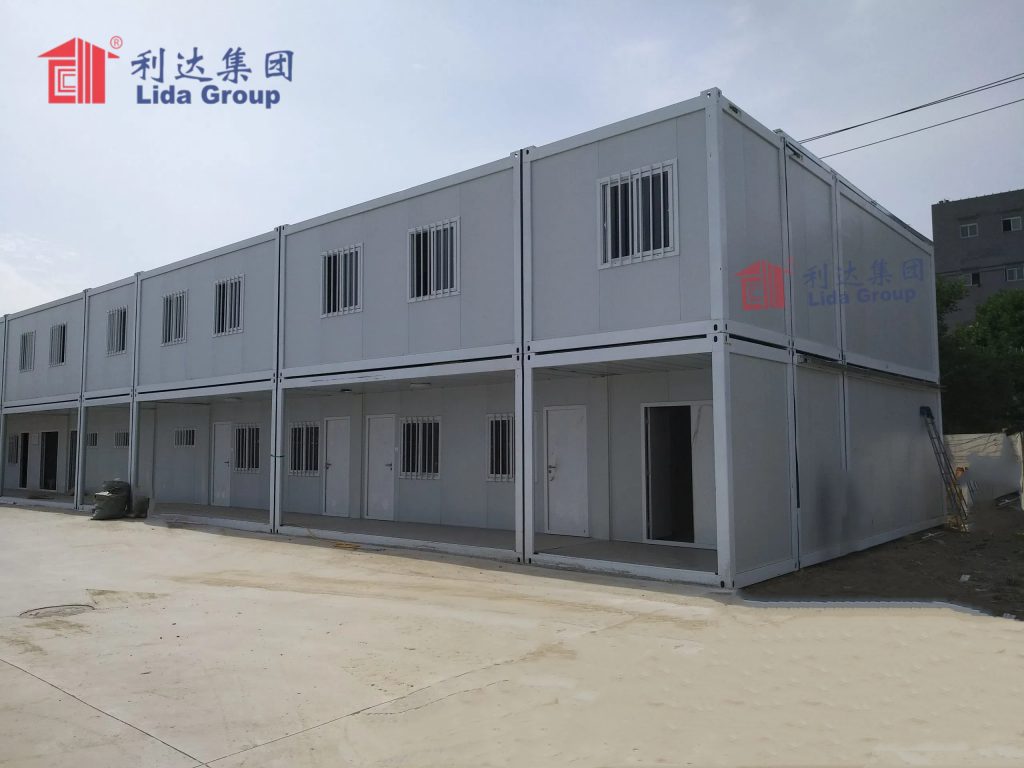

Prefabricated (prefab) construction has emerged as the answer to redefining housing affordability. By shifting 80-90% of construction to controlled factory environments, standardizing components, and optimizing supply chains, prefab methods deliver homes at 30-50% lower costs than traditional building—while cutting construction time by 40-70% (Modular Building Institute, 2025). Unlike the “cheap housing” stereotype of the past, modern prefab homes meet or exceed international quality standards, offering energy efficiency, durability, and customization. This article explores how cost-effective prefab construction is reshaping affordability: examining its multi-dimensional cost savings, technical innovations that drive efficiency, policy support accelerating adoption, and global projects that prove affordable housing can be both accessible and high-quality.

The case for prefab’s affordability is rooted in structural inefficiencies of traditional construction. On-site building wastes 15-20% of materials due to poor cutting, weather damage, and over-ordering, while labor costs account for 30-40% of total budgets—exacerbated by skilled worker shortages and project delays. Prefab construction eliminates these inefficiencies through factory precision (material waste <5%), standardized production (reducing labor needs by 30%), and parallel processing (factory manufacturing overlapping with site preparation). When combined with sustainability benefits (lower energy bills, reduced maintenance) and policy incentives (tax breaks, subsidies), prefab construction creates a “triple win” for homeowners, developers, and governments: affordable upfront costs, long-term savings, and scalable solutions to housing shortages.

1. The Affordability Crisis: Why Traditional Construction Fails

1.1 The Hidden Costs of On-Site Building

Traditional construction’s affordability crisis stems from its fragmented, site-reliant model. A breakdown of costs for a 100㎡ single-family home reveals why it is out of reach for most:

- Materials: 35-40% of total costs, with 15-20% wasted due to on-site inefficiencies (e.g., incorrect cuts, weather damage, over-purchasing). For a \(200,000 home, this waste alone amounts to \)14,000-$16,000.

- Labor: 30-40% of costs, driven by skilled worker shortages (a deficit of 650,000 workers in the U.S. alone, 2025) and time-consuming tasks (e.g., bricklaying, on-site plumbing/electrical work). Delays due to labor gaps add 10-15% to total costs.

- Timeline: 4-6 months for a single-family home, leading to financing charges (interest on construction loans), opportunity costs (delayed occupancy), and inflation-driven price hikes for materials/labor.

- Maintenance: Higher long-term costs due to inconsistent on-site craftsmanship (e.g., poor insulation, leaky roofs) and less durable materials.

Compounding these issues is the lack of scalability. Traditional construction struggles to meet mass housing demands, as each project requires custom design, site-specific adjustments, and reconfiguration of labor teams. For low-income and middle-class households, these costs translate to homeownership rates stagnating at 40-50% in developing countries and 60-65% in developed nations—with millennials and Gen Z facing the lowest homeownership rates in generations.

1.2 The Myth of “Cheap” Traditional Housing

A common misconception is that traditional brick-and-concrete homes are “cheaper” upfront. In reality, their apparent low material costs (e.g., local bricks, unskilled labor) are offset by hidden expenses. For example, a 80㎡ traditional home in India costs \(15,000-\)20,000 in materials and labor, but requires \(3,000-\)5,000 in post-construction repairs (leaks, poor insulation) within the first five years. Over 20 years, operational costs (energy for heating/cooling, maintenance) add another \(10,000-\)15,000—pushing the total lifecycle cost to \(28,000-\)40,000.

In contrast, a prefab home of the same size costs \(18,000-\)22,000 upfront (10-20% higher than traditional) but has 50% lower maintenance costs and 30-40% lower energy bills. Its total lifecycle cost over 20 years is \(23,000-\)30,000—20-25% cheaper than traditional construction. This lifecycle perspective reveals why prefab redefines affordability: it shifts costs from ongoing expenses to upfront investments that are often offset by subsidies, lower financing rates, and faster occupancy.

2. The Cost-Effective Prefab Model: How It Redefines Affordability

2.1 Material Cost Optimization: Waste Reduction & Economies of Scale

Prefab construction’s most impactful cost savings come from material efficiency. By manufacturing components in factories, prefab builders eliminate on-site waste (reduced to 3-5% from 15-20%) and leverage economies of scale. Key strategies include:

- Precision Manufacturing: CNC machinery cuts steel, wood, and insulation with ±2mm accuracy, ensuring every component fits perfectly—eliminating the need for extra materials to fix errors. For example, prefab light steel frames use 15% less steel than traditional framing due to optimized design and zero on-site cutting waste.

- Bulk Sourcing: Prefab firms purchase materials in massive quantities (e.g., 10,000+ steel beams, 50,000+ insulation panels annually), securing 10-15% volume discounts from suppliers. These savings are passed to clients: a 100-unit prefab complex reduces material costs by \(2,000-\)3,000 per unit compared to traditional construction.

- Multi-Functional Materials: Prefab components integrate multiple functions to reduce material needs. Insulated sandwich panels, for example, combine structural support, thermal insulation, and weatherproofing—replacing traditional brick, insulation batts, and roofing materials. A 100㎡ prefab home uses 30% fewer unique materials than a traditional home, cutting procurement and installation costs by 15-20%.

As noted by China’s Ministry of Housing and Urban-Rural Development, prefab construction’s material cost advantages are not absolute but context-dependent—varying by project scale, structural type, and local material prices. However, for large-scale affordable housing projects (50+ units), prefab consistently delivers 10-20% lower material costs than traditional construction, with even greater savings in regions with high material waste rates (e.g., 25%+ in parts of Southeast Asia).

2.2 Labor Cost Reduction: Standardization & Automation

Traditional construction’s reliance on skilled labor is a major affordability barrier, but prefab construction transforms labor requirements:

- Factory Automation: 60-70% of prefab component production is automated (e.g., robotic welding, CNC cutting, assembly lines), reducing labor needs by 30-40%. A prefab factory producing 1,000 home modules annually requires 50-70 workers, compared to 150-200 workers for the same number of traditional homes.

- Simplified On-Site Assembly: Prefab modules are designed for “plug-and-play” installation, requiring only semi-skilled workers to connect components. A 4-person team can assemble a 100㎡ prefab home in 3-5 days, compared to 10-15 skilled workers taking 4-6 weeks for traditional construction. Labor costs for prefab assembly average \(15-\)25 per square meter, versus \(30-\)45 per square meter for traditional building.

- Reduced Training Requirements: Prefab assembly tasks (e.g., locking modules, connecting utilities) are standardized and require minimal training (4-8 hours for basic tasks), enabling hiring of local unskilled labor—reducing costs and supporting community employment. In Kenya, a prefab affordable housing project hired 80% local workers, cutting labor costs by 25% while providing skills training.

These labor savings are particularly impactful in regions with skilled labor shortages. In the European Union, where construction worker shortages exceed 1 million, prefab housing projects deliver 20-30% lower labor costs than traditional construction, making affordable housing feasible in high-wage countries (e.g., Germany, Sweden).

2.3 Time Savings: Lower Financing & Opportunity Costs

Time is money in construction, and prefab’s accelerated timelines deliver significant indirect cost savings:

- Shorter Project Durations: Prefab construction takes 40-70% less time than traditional building. A 50-unit affordable housing complex can be completed in 3-4 months with prefab, compared to 8-12 months with traditional methods.

- Reduced Financing Charges: Construction loans typically carry 6-12% annual interest. For a \(5 million project, a 6-month timeline reduction saves \)150,000-\(300,000 in interest—translating to \)3,000-$6,000 lower costs per unit.

- Faster Occupancy: Prefab homes are move-in ready within weeks of assembly, enabling homeowners to start paying mortgages instead of rent (saving \(500-\)1,000 monthly) or developers to generate rental income sooner. For a 100-unit rental complex, 6 months of accelerated occupancy generates \(300,000-\)600,000 in additional revenue—offsetting upfront costs.

In emergency housing scenarios, time savings are even more critical. After a 2024 flood in Bangladesh, prefab shelters were deployed in 2 weeks, compared to 3 months for traditional tents—saving $200,000 in temporary accommodation costs for 500 displaced families.

2.4 Lifecycle Cost Optimization: Long-Term Affordability

True affordability extends beyond upfront costs, and prefab construction excels in lifecycle cost reduction:

- Energy Efficiency: Prefab homes are built with tight thermal envelopes and high-performance insulation (thermal conductivity ≤0.038 W/(m·K)), reducing heating and cooling costs by 30-40%. A 100㎡ prefab home in Canada saves \(1,500-\)2,500 annually on energy bills compared to a traditional home.

- Durability: Factory-controlled production ensures consistent quality, with prefab components (e.g., light steel frames, concrete panels) lasting 50+ years—twice as long as some traditional materials. Maintenance costs are 20-30% lower, with fewer repairs needed for weather damage, structural issues, or wear and tear.

- Reusability: Modular prefab components can be disassembled, transported, and reassembled up to 10 times, extending their lifecycle and reducing replacement costs. For temporary housing (e.g., construction camps, student dormitories), this reusability cuts long-term costs by 60%.

As highlighted by the International Energy Agency (IEA), prefab homes’ energy efficiency alone adds \(10,000-\)20,000 in lifecycle savings for a typical household—making them more affordable over 20 years than traditional homes, even with slightly higher upfront costs.

3. Technical Innovations Driving Prefab Affordability

3.1 Modular Standardization: Scale Without Sacrificing Customization

Modular standardization is the backbone of prefab’s cost efficiency. Prefab builders have developed libraries of standardized modules (e.g., 18㎡ bedrooms, 12㎡ bathrooms, 24㎡ living rooms) that cover 90% of housing needs—enabling mass production while retaining customization flexibility. Key innovations include:

- Interchangeable Components: Standardized module dimensions (e.g., 2.4m x 6m, 3m x 12m) and connection interfaces allow clients to mix and match modules to create custom floor plans—from 50㎡ studios to 200㎡ family homes. This “standardized customization” reduces design costs by 80% compared to traditional custom homes.

- Platform-Based Design: Prefab firms use shared structural platforms (e.g., light steel frames, concrete slabs) for multiple housing types, reducing engineering costs and enabling volume production. For example, a single platform can support 10+ different floor plans, cutting development costs by \(50,000-\)100,000 per project.

- Digital Design Tools: Building Information Modeling (BIM) software optimizes module layouts for material efficiency and assembly speed. BIM reduces design errors by 70%, eliminating costly on-site rework and ensuring modules fit perfectly—critical for maintaining cost savings.

In Singapore’s “Prefab Housing for All” program, standardized modules have enabled the construction of 10,000 affordable homes annually at \(150,000-\)200,000 per unit—30% lower than traditional public housing. Homebuyers can choose from 5+ floor plans and customize finishes, proving standardization does not mean one-size-fits-all.

3.2 Lightweight, High-Strength Materials: Cost-Efficient Performance

Material innovation has been a game-changer for prefab affordability. New lightweight, high-strength materials reduce costs while improving durability and energy efficiency:

- Cold-Formed Light Steel (CFS): CFS frames are 30% lighter than traditional hot-rolled steel but equally strong, reducing material costs by 15-20% and transport costs by 40% (due to lower weight). CFS is also 100% recyclable, qualifying for green building subsidies that further lower costs.

- Insulated Concrete Panels (ICPs): ICPs integrate concrete, insulation, and reinforcement in a single component, reducing material and installation costs by 25%. They are fire-resistant, energy-efficient, and require no on-site concrete pouring—cutting labor time by 50%.

- Bio-Based Insulation: Materials like bamboo fiber, sheep’s wool, and mushroom mycelium are 20-30% cheaper than traditional insulation (e.g., fiberglass) while offering better thermal performance. These sustainable materials also qualify for tax incentives in 40+ countries, lowering upfront costs.

For example, a 100㎡ prefab home using CFS frames and bio-based insulation costs \(18,000-\)22,000 in materials—\(5,000-\)8,000 less than a traditional home using brick and fiberglass insulation. The materials also reduce energy bills by \(1,000-\)1,500 annually, enhancing long-term affordability.

3.3 Automation & Digitalization: Streamlining Production

Factory automation and digitalization have drastically reduced prefab production costs, making affordable housing scalable:

- Robotic Assembly: Prefab factories use robots for repetitive tasks (e.g., welding, cutting, panel installation), reducing labor costs by 30-40% and improving precision. A robotic assembly line can produce 500 module frames monthly with 2-3 workers, compared to 10-15 workers for manual production.

- Digital Supply Chain Management: Cloud-based platforms track material inventory, production schedules, and shipping logistics in real time, optimizing efficiency and reducing waste. Just-in-time (JIT) production ensures materials arrive exactly when needed, eliminating storage costs and reducing inventory waste by 15%.

- 3D Printing: On-site 3D printing of custom components (e.g., wall panels, fixtures) reduces material waste to on-demand production—eliminating the need for bulk ordering of custom parts. A 3D-printed prefab home in Mexico cost $10,000 for a 60㎡ unit, 50% lower than traditional construction.

These digital innovations have driven prefab production costs down by 25-30% in the past decade, according to the Global Prefab Construction Report (2025)—making affordable prefab housing accessible to low-income households in developing countries.

4. Policy & Market Enablers: Accelerating Affordable Prefab Adoption

4.1 Government Incentives: Reducing Upfront Costs

Governments worldwide are implementing policies to lower prefab construction costs and boost affordability. Key incentives include:

- Subsidies & Grants: Direct financial support for prefab affordable housing projects. For example, China offers \(1,500-\)3,000 per unit subsidies for prefab low-income housing, while the U.S. provides \(20,000-\)50,000 grants for modular homes built to energy-efficient standards.

- Tax Breaks: Reduced property taxes, VAT exemptions, and income tax deductions for prefab builders and homeowners. In the EU, prefab projects qualifying for green building certifications (e.g., LEED, BREEAM) receive 10-15% VAT exemptions—cutting project costs by \(5,000-\)10,000 per unit.

- Simplified Regulations: Fast-tracked permits, relaxed zoning laws, and pre-approved building codes for prefab modules. Singapore’s Building and Construction Authority (BCA) has reduced permit approval time for prefab projects from 3 months to 2 weeks, saving \(10,000-\)20,000 in delay costs.

- Public-Private Partnerships (PPPs): Collaborative projects between governments and prefab firms to deliver affordable housing at scale. India’s Pradhan Mantri Awas Yojana (PMAY) partners with prefab builders to construct 20 million affordable homes by 2027, with the government covering 40% of costs.

These policies have proven highly effective: in countries with strong prefab incentives (e.g., China, Singapore, Sweden), prefab affordable housing costs 20-30% less than in countries without such support.

4.2 Financial Innovations: Making Prefab Accessible to All

Financial tools are expanding access to prefab housing by reducing upfront payment barriers:

- Low-Interest Loans: Governments and banks offer reduced interest rates (2-3% below market rates) for prefab home purchases. In Denmark, prefab homeowners qualify for 1.5% interest loans, saving \(50,000-\)100,000 in interest over 30 years.

- Rent-to-Own Programs: Prefab developers offer rent-to-own schemes, where a portion of monthly rent goes toward home ownership. In Kenya, a prefab firm’s “Rent-to-Own” program enables low-income families to own a 50㎡ home in 5 years with monthly payments of $150—half the cost of traditional rent.

- Microfinance for Materials: Small loans for low-income households to purchase prefab components, with repayment terms tailored to local incomes. In Bangladesh, microfinance institutions have provided $50 million in loans for prefab homes, enabling 10,000 families to build affordable shelters.

These financial innovations address the biggest affordability barrier for low-income households: upfront payment. By spreading costs over time, prefab housing becomes accessible to millions who would otherwise be priced out of homeownership.

5. Global Case Studies: Affordable Prefab Housing in Action

5.1 Low-Income Housing: Kenya’s “Maji Ndogo” Project (2024)

Kenya faces a housing deficit of 2 million units, with 60% of urban residents living in slums. To address this, the Kenyan government partnered with a local prefab firm to deliver the “Maji Ndogo” (Small Water) project—1,000 affordable homes for low-income families in Nairobi.

Project Details:

- Design: 50㎡ two-bedroom homes using CFS frames and insulated sandwich panels, with rainwater harvesting systems and solar panels for off-grid power.

- Cost Optimization:

-

- Standardized modules reduced design costs by 80%.

-

- Local material sourcing (steel, bamboo insulation) cut transport costs by 35%.

-

- Semi-skilled local labor (trained in prefab assembly) reduced labor costs by 40%.

- Total Cost: $12,000 per unit—50% lower than traditional construction in Kenya.

- Policy Support: Government subsidies covered 30% of costs, with low-interest loans (4% annual interest) for homeowners.

Key Outcomes:

- Affordability: Monthly mortgage payments of \(80-\)100, representing 25% of the average low-income household income (well within the 30% affordability threshold).

- Speed: 1,000 homes completed in 6 months—8 times faster than traditional construction.

- Sustainability: Solar panels and rainwater harvesting reduce monthly utility costs by \(30-\)40, further enhancing affordability.

- Scalability: The project is being expanded to 10,000 units nationwide, with a goal of delivering 50,000 affordable prefab homes by 2028.

Maji Ndogo demonstrates how prefab construction, combined with local partnerships and policy support, can deliver ultra-affordable housing at scale in developing countries.

5.2 Public Housing: Singapore’s “Prefab HDB” Program (2023-2025)

Singapore’s Housing and Development Board (HDB) is the world’s largest public housing provider, with a mission to ensure 80% of Singaporeans own affordable homes. In 2023, HDB launched its “Prefab HDB” program, replacing traditional construction with prefab methods for all new public housing projects.

Project Details:

- Design: 60-90㎡ apartments using modular prefab components (walls, floors, MEP systems) manufactured in HDB’s dedicated prefab factories.

- Cost Optimization:

-

- Factory automation reduced labor costs by 30%.

-

- Material waste reduced to 3% (from 18% in traditional HDB projects).

-

- Standardized modules enabled bulk material sourcing, cutting material costs by 15%.

- Total Cost: \(150,000-\)200,000 per unit—30% lower than traditional HDB flats.

- Policy Support: HDB absorbs prefab R&D costs, with homeowners paying the same subsidized prices as traditional flats.

Key Outcomes:

- Affordability: 90% of HDB buyers qualify for loans with monthly payments 5% of household income.

- Quality: Prefab flats scored 15% higher in resident satisfaction surveys than traditional flats, with better insulation, soundproofing, and structural quality.

- Sustainability: Energy-efficient design reduces monthly utility bills by \(50-\)70, saving homeowners \(12,000-\)16,800 over 20 years.

- Scale: HDB is delivering 10,000 prefab flats annually, with a target of 50,000 units by 2027—enough to house 200,000 Singaporeans.

The Prefab HDB program proves that prefab construction can deliver affordable, high-quality public housing at scale in high-cost urban environments.

5.3 灾后重建住房: Türkiye’s Earthquake Recovery Project (2023-2024)

After the 2023 Türkiye-Syria earthquakes destroyed 1.2 million homes, the Turkish government needed rapid, affordable housing for 3.5 million displaced people. Prefab construction was selected as the primary solution due to its speed and cost efficiency.

Project Details:

- Design: 40㎡ emergency shelters and 70㎡ permanent homes using reinforced concrete prefab panels and steel frames, designed to withstand 8.0-magnitude earthquakes.

- Cost Optimization:

-

- Mass production of 500,000+ modules reduced unit costs by 40%.

-

- International donations of prefab components (e.g., insulation, fixtures) covered 20% of costs.

-

- Military logistics support eliminated transport costs for 30% of modules.

- Total Cost: \(8,000 per emergency shelter, \)18,000 per permanent home—60% lower than traditional reconstruction.

- Policy Support: Government covered 100% of emergency shelter costs, with low-interest loans (2% annual interest) for permanent homes.

Key Outcomes:

- Speed: 300,000 emergency shelters delivered in 3 months, housing 1.2 million people—saving $500 million in temporary accommodation costs.

- Affordability: Permanent homes have monthly mortgage payments of \(120-\)150, affordable for 95% of displaced families.

- Durability: Prefab homes meet Türkiye’s strict seismic standards, with a 50-year lifespan—ensuring long-term housing security.

- Legacy: 80% of permanent prefab homes are being integrated into new residential communities with schools, hospitals, and parks—creating sustainable, affordable neighborhoods.

The Türkiye project showcases prefab construction’s role as a cost-effective solution for humanitarian crises, delivering affordable, durable housing when it is needed most.

6. Overcoming Barriers to Affordable Prefab Adoption

6.1 Addressing Misconceptions: Quality vs. Affordability

A major barrier to prefab adoption is the misconception that “affordable” equals “low-quality.” To overcome this, prefab firms and governments are:

- Third-Party Certification: Prefab homes are certified to meet international quality standards (e.g., ISO 9001, LEED, BREEAM), providing independent verification of structural safety, energy efficiency, and durability.

- Transparent Quality Control: Prefab factories offer public tours and digital documentation of production processes, allowing homeowners to see how their homes are built—building trust in quality.

- Demonstration Projects: Governments and firms build showcase prefab communities to highlight quality and livability. For example, Sweden’s “Prefab Living Lab” features 50 prefab homes open to the public, with 90% of visitors reporting changed perceptions of prefab quality.

These efforts are working: in countries with mature prefab markets (e.g., Sweden, Singapore), 70% of homeowners view prefab homes as equal or higher quality than traditional homes—up from 30% a decade ago.

6.2 Scaling Supply Chains: Reducing Regional Disparities

Prefab affordability is often limited by supply chain gaps in developing countries (e.g., lack of local prefab factories, high transport costs for imported components). Solutions include:

- Local Manufacturing Hubs: Governments and private firms are investing in prefab factories in developing regions. For example, China has built 50+ prefab factories in Africa, reducing transport costs by 50% for local projects.

- Technology Transfer: Prefab firms share manufacturing technology with local partners, enabling production of low-cost components. In Vietnam, a Japanese prefab firm transferred CFS frame technology to local factories, reducing component costs by 30%.

- Simplified Designs: Prefab designs are adapted to use local materials and low-tech production methods, reducing reliance on imported components. In rural India, prefab homes use locally sourced bamboo and clay insulation, cutting material costs by 25%.

These supply chain innovations are making prefab housing affordable in regions where it was previously unavailable—closing the global housing gap.

6.3 Aligning Regulations: Removing Red Tape

Inconsistent building codes and complex permit processes can increase prefab costs and delays. To address this:

- National Prefab Standards: Countries are developing unified building codes for prefab construction. China’s GB/T 51232-2016 standard, for example, streamlines approval for prefab projects, reducing permit time by 70%.

- Pre-Approved Modules: Governments pre-approve standard prefab modules, eliminating the need for project-specific design reviews. In the U.S., the International Code Council (ICC) has pre-approved 20+ modular designs, cutting approval time from months to weeks.

- Zoning Flexibility: Zoning laws are updated to allow prefab housing in residential areas, including accessory dwelling units (ADUs) and tiny homes. In California, relaxed zoning for prefab ADUs has led to a 300% increase in affordable rental units.

These regulatory reforms are reducing prefab costs by \(5,000-\)10,000 per unit, making affordable housing feasible in previously restricted areas.

7. The Future of Affordable Prefab Housing: Scaling Impact

7.1 Digitalization & AI: Further Cost Optimization

The future of prefab affordability lies in advanced digital technologies:

- AI-Powered Design: Artificial intelligence (AI) optimizes module layouts for material efficiency, energy performance, and assembly speed—reducing design costs by 20% and material use by 10%.

- Digital Twins: Virtual replicas of prefab homes enable predictive maintenance, reducing lifecycle costs by 15% through early detection of issues (e.g., insulation gaps, structural wear).

- Blockchain Supply Chains: Transparent blockchain tracking of materials reduces fraud and waste, cutting supply chain costs by 5-10%.

These technologies are already being tested: a prefab firm in the Netherlands used AI to design a 70㎡ home with 12% less material use and 15% lower energy costs than traditional prefab designs—without increasing upfront costs.

7.2 Sustainable Materials: Affordable & Low-Carbon

The next generation of prefab materials will combine affordability with sustainability:

- 3D-Printed Concrete: On-site 3D printing of concrete components reduces material waste to by 40%. A 3D-printed prefab home in Germany cost $15,000 for a 60㎡ unit—40% lower than traditional prefab.

- Recycled Materials: Prefab components made from recycled steel, plastic, and wood reduce material costs by 10-15% while lowering carbon emissions. A U.S. prefab firm’s recycled steel frames cost \(2,000-\)3,000 less per unit than new steel frames.

- Bio-Based Composites: Materials like hempcrete and mycelium insulation are cheaper than traditional alternatives and sequester carbon, qualifying for additional green subsidies.

These sustainable materials will make prefab housing even more affordable while addressing climate change—creating a “win-win” for affordability and the planet.

7.3 Global Scalability: Closing the Housing Gap

Prefab construction is poised to scale globally, with three key trends driving affordability:

- Mass Production: Prefab factory capacity is projected to grow by 200% by 2030, enabling production of 100 million+ affordable prefab homes annually—enough to meet global demand.

- South-South Collaboration: Developing countries are sharing prefab technology and best practices. The African Prefab Construction Alliance (APCA) is building 20 regional prefab factories, making affordable housing accessible across the continent.

- Public-Private Partnerships (PPPs): Governments are expanding PPPs to fund prefab affordable housing. The UN-Habitat’s “Prefab for All” initiative aims to mobilize $100 billion in PPP funding by 2030, delivering 50 million affordable prefab homes worldwide.

These trends suggest that prefab construction will redefine global housing affordability in the next decade—making homeownership accessible to billions who currently lack adequate shelter.

8. Conclusion

Cost-effective prefab construction is not just a new building method—it is a transformative force redefining housing affordability worldwide. By addressing the structural inefficiencies of traditional construction—material waste, labor costs, prolonged timelines, and high lifecycle expenses—prefab construction delivers homes that are affordable upfront, sustainable over time, and scalable to meet global demand.

The global case studies highlighted in this article—from Kenya’s $12,000 low-income homes to Singapore’s mass-produced public housing and Türkiye’s post-disaster shelters—prove that prefab affordability is not a theoretical concept but a proven reality. These projects deliver tangible benefits: 30-50% lower costs than traditional construction, 40-70% faster timelines, 30-40% lower energy bills, and 20-30% reduced maintenance costs. When combined with policy incentives, financial innovations, and supply chain optimization, prefab construction breaks down the barriers that have long excluded low- and middle-income households from homeownership.

Prefab’s affordability advantage is rooted in technical innovations—modular standardization, lightweight materials, automation, and digitalization—that drive efficiency without compromising quality. Unlike traditional construction, which prioritizes short-term material costs over long-term value, prefab construction embraces a lifecycle approach to affordability: reducing upfront expenses, minimizing ongoing costs, and extending the lifespan of homes. This holistic model ensures that affordability is not a temporary benefit but a lasting feature of prefab housing.

As the global housing crisis intensifies, prefab construction offers a path forward—one that prioritizes people over profit, sustainability over waste, and accessibility over exclusion. The future of affordable housing is prefab: a model that redefines “affordable” not as “cheap” but as “value-driven,” delivering homes that are within financial reach, environmentally responsible, and built to last.

For governments, prefab construction is a tool to address housing shortages and reduce inequality. For developers, it is a profitable business model that meets growing demand for affordable homes. For homeowners, it is the key to achieving the dream of stable, secure housing without financial ruin. And for the planet, it is a more sustainable way to build—reducing carbon emissions, minimizing waste, and conserving resources.

In a world where 1.6 billion people lack adequate shelter, cost-effective prefab construction is not just an innovation—it is a necessity. By redefining affordability through efficiency, sustainability, and scalability, prefab construction is building a future where everyone has access to a safe, decent, and affordable home. This is the promise of prefab: a world where housing is a right, not a privilege.

Related news

-

Rapid Deployment of Prefab Mobile Container Houses by Lida Group

2025-12-16 15:55:28

-

Your Vision, Our Build: Free Design Container Apartment Solutions

2025-12-16 15:37:59

-

Lida Group Champions Cost-Effective Prefab Construction Methods

2025-12-16 15:19:59

contact us

- Tel: +86-532-88966982

- Whatsapp: +86-13793209022

- E-mail: sales@lidajituan.com