Rapid Deployment with Lida Group’s Prefab Mobile Container House

2025-Oct-29 16:10:27

By Admin

1. Introduction

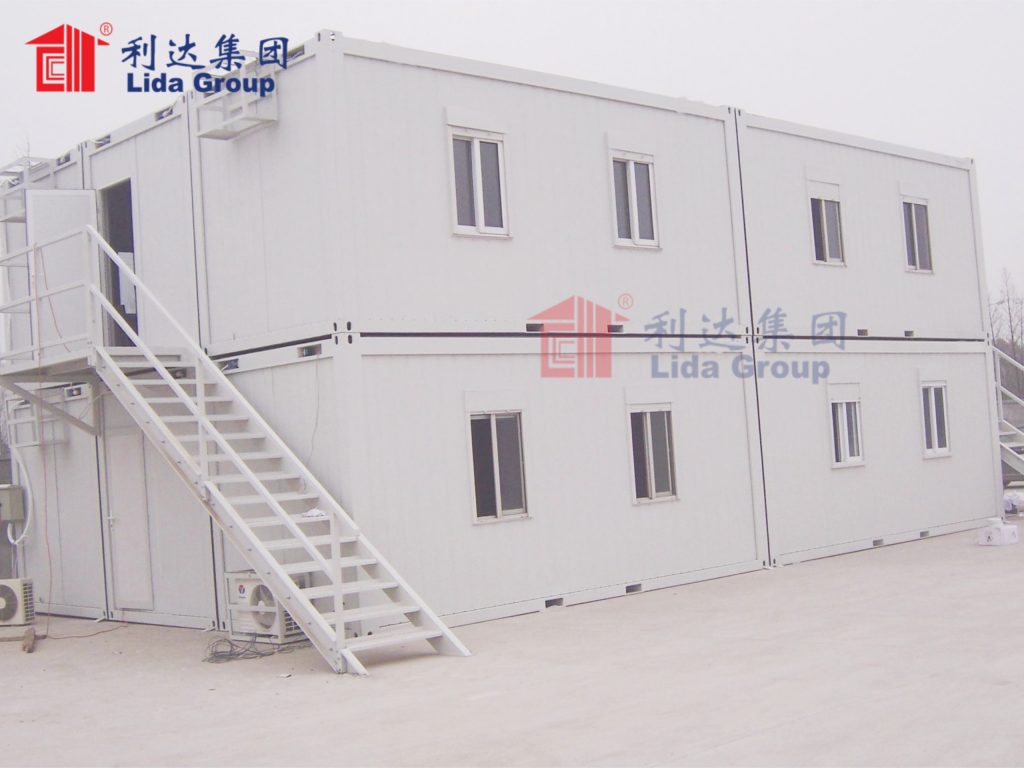

In today’s fast-paced world, the demand for rapid, flexible, and cost-effective building solutions has never been higher. From emergency disaster relief to temporary construction site offices, from pop-up commercial spaces to affordable housing projects, traditional construction methods often fall short due to their long construction cycles, high costs, and inflexibility. This is where prefabricated mobile container houses come into play, and among the leading providers in this field is Lida Group. Lida Group has established itself as a pioneer in the design, manufacturing, and supply of high-quality prefab mobile container houses, with a strong focus on rapid deployment. This article will delve into the various aspects of Lida Group‘s prefab mobile container houses, exploring how they achieve rapid deployment, their key features and advantages, real-world applications, technological innovations, quality control measures, environmental benefits, and the future outlook of this innovative building solution. By the end of this article, readers will have a comprehensive understanding of why Lida Group’s prefab mobile container houses are becoming the go-to choice for projects that require speed, efficiency, and reliability.

2. The Need for Rapid Deployment in Modern Building Scenarios

2.1 Emergency Response and Disaster Relief

Natural disasters such as earthquakes, floods, hurricanes, and wildfires often leave thousands of people homeless and disrupt essential services. In these critical situations, the ability to quickly provide shelter, medical facilities, and administrative offices is crucial for saving lives and facilitating relief efforts. Traditional construction methods, which can take months or even years to complete, are simply not feasible in emergency scenarios. Prefab mobile container houses, however, can be deployed in a matter of days or even hours. Lida Group’s products are designed to be transported easily and assembled quickly, making them ideal for emergency response teams. For example, after an earthquake hits a region, Lida Group can dispatch its prefab mobile container houses via trucks, ships, or even airplanes to the affected area. Once on-site, a small team can assemble the houses within a short period, providing immediate shelter for victims and workspaces for relief workers. These houses are also durable enough to withstand the harsh conditions often present in disaster-stricken areas, such as strong winds, heavy rains, and unstable terrain.

2.2 Temporary Construction Sites

The construction industry relies heavily on temporary facilities to support ongoing projects. These facilities include offices for project managers and engineers, dormitories for construction workers, storage rooms for materials and equipment, and canteens. Setting up these facilities using traditional methods can be time-consuming and expensive, delaying the start of the actual construction work. Lida Group’s prefab mobile container houses offer a perfect solution for construction site temporary facilities. They can be customized to meet the specific needs of the construction project, whether it’s a small office with a few workstations or a large dormitory complex that can accommodate hundreds of workers. The rapid deployment of these houses means that construction companies can start their projects sooner, reducing overall project timelines and costs. Additionally, once the construction project is completed, the prefab mobile container houses can be easily disassembled, transported to the next site, and reused, making them a cost-effective and sustainable option.

2.3 Pop-Up Commercial and Event Spaces

In the commercial world, the ability to quickly set up temporary spaces for events, promotions, or retail activities is a valuable asset. Pop-up shops, exhibition booths, food stalls at festivals, and temporary ticket offices all require fast and flexible building solutions. Lida Group’s prefab mobile container houses can be transformed into attractive and functional commercial spaces in a short time. They can be customized with branding, windows, doors, and interior fixtures to create a unique and inviting environment for customers. For example, a retail brand looking to launch a new product can use Lida Group’s prefab mobile container house as a pop-up shop in a high-traffic area. The house can be delivered and set up within a few days, allowing the brand to start promoting and selling its product quickly. After the promotion period is over, the house can be moved to another location or stored for future use. This flexibility allows businesses to adapt to changing market conditions and take advantage of short-term opportunities without making a long-term commitment to a permanent space.

2.4 Affordable Housing Solutions

The global housing crisis is a pressing issue, with millions of people unable to afford adequate housing. Traditional housing construction is often expensive, especially in urban areas where land and labor costs are high. Prefab mobile container houses offer an affordable alternative, as they are cheaper to manufacture and construct compared to traditional houses. Lida Group’s prefab mobile container houses are designed to be comfortable, safe, and functional, providing a viable housing option for low-income families, students, and migrant workers. The rapid deployment of these houses means that housing projects can be completed quickly, helping to address the housing shortage in a timely manner. For instance, in areas with a high demand for affordable housing, Lida Group can work with local governments or housing organizations to build large-scale housing complexes using its prefab mobile container houses. These complexes can be completed in a fraction of the time it would take to build traditional houses, providing much-needed housing to those in need.

3. Key Features of Lida Group’s Prefab Mobile Container House Enabling Rapid Deployment

3.1 Modular Design

One of the main reasons why Lida Group’s prefab mobile container houses can be deployed quickly is their modular design. Each container house is composed of standardized modules that are manufactured in a factory under controlled conditions. These modules are designed to fit together seamlessly, eliminating the need for on-site cutting, drilling, and other time-consuming construction processes. The modular design also allows for easy customization, as different modules can be combined to create houses of various sizes and configurations. For example, a single module can be used as a small office or dormitory room, while multiple modules can be connected to form a larger building with multiple rooms, such as a hotel, a school, or a hospital ward. The standardized nature of the modules also ensures that they are compatible with each other, making the assembly process simple and efficient. Workers on-site only need to align the modules, connect them using pre-installed fasteners, and complete a few finishing touches, such as installing electrical and plumbing systems, to have a fully functional house.

3.2 Factory Prefabrication

Lida Group’s prefab mobile container houses are fully prefabricated in its state-of-the-art factories. This means that all the components of the house, including the walls, floors, ceilings, windows, doors, electrical wiring, plumbing pipes, and interior fixtures, are manufactured and assembled in the factory before being transported to the construction site. Factory prefabrication offers several advantages that contribute to rapid deployment. First, it allows for mass production, which increases efficiency and reduces manufacturing time. Lida Group’s factories are equipped with advanced machinery and production lines that can produce a large number of container house modules in a short period. Second, factory production ensures consistent quality. Each component is manufactured to strict standards, and the assembly process is closely monitored to ensure that the final product meets the highest quality requirements. This eliminates the need for on-site quality checks and rework, which can delay the construction process. Third, prefabrication in the factory reduces the amount of on-site work required. Once the modules arrive at the site, they only need to be installed and connected, rather than being built from scratch. This significantly shortens the construction timeline.

3.3 Lightweight and Easy to Transport

Lida Group’s prefab mobile container houses are designed to be lightweight, making them easy to transport. The use of lightweight materials, such as high-quality steel frames and lightweight composite panels, reduces the overall weight of the container house without compromising its strength and durability. This lightweight design allows the houses to be transported using a variety of means, including trucks, ships, trains, and even airplanes. For example, a standard 20-foot container house module can be loaded onto a truck and transported to the construction site, even in areas with narrow roads or limited access. For long-distance transportation, such as overseas projects, the modules can be shipped in containers, which are widely available and cost-effective. The ease of transportation means that Lida Group can deliver its prefab mobile container houses to any location in the world quickly, regardless of the distance or the complexity of the transportation route. This is a crucial factor in ensuring rapid deployment, especially for projects in remote or hard-to-reach areas.

3.4 Simple Assembly Process

The assembly process of Lida Group’s prefab mobile container houses is designed to be simple and straightforward, requiring minimal skill and equipment. The modules are equipped with pre-installed connection points and fasteners, which allow them to be easily joined together. Even workers with limited construction experience can assemble the houses with the help of detailed installation manuals and on-site guidance from Lida Group’s technical team. The assembly process typically involves the following steps: first, the site is prepared by leveling the ground and installing a simple foundation, such as concrete blocks or a steel frame. Second, the container house modules are delivered to the site and placed in the correct position using a crane or a forklift. Third, the modules are connected to each other using the pre-installed fasteners, ensuring a secure and stable structure. Fourth, the electrical and plumbing systems are connected between the modules, and any necessary finishing work, such as installing flooring, painting, and adding interior fixtures, is completed. Finally, the house is inspected to ensure that it meets all safety and quality standards. This entire process can be completed in a matter of days, depending on the size and complexity of the project. For example, a single 20-foot container house can be fully assembled and ready for use within 24 to 48 hours, while a larger building composed of multiple modules can be completed in a week or two.

4. Technological Innovations Supporting Rapid Deployment

4.1 Advanced Design Software

Lida Group leverages advanced design software to streamline the design process of its prefab mobile container houses and ensure that they are optimized for rapid deployment. The company uses 3D modeling software, such as AutoCAD, Revit, and SolidWorks, to create detailed digital models of the container houses. These models allow designers to visualize the entire structure, including all the components and systems, and make any necessary adjustments before the manufacturing process begins. The 3D models also enable Lida Group to conduct virtual tests and simulations to ensure that the container houses meet the required structural, thermal, and acoustic performance standards. For example, the software can simulate the effects of strong winds, earthquakes, and other environmental factors on the structure, allowing designers to make modifications to enhance its durability and safety. Additionally, the design software facilitates communication between different departments within Lida Group, such as the design team, the manufacturing team, and the sales team. The digital models can be easily shared, ensuring that everyone has access to the latest design information and that there are no misunderstandings or delays in the production process. This efficient design process reduces the time it takes to develop new container house models and customize existing ones to meet the specific needs of customers, contributing to rapid deployment.

4.2 Automated Manufacturing Equipment

To further increase the efficiency of the manufacturing process and ensure consistent quality, Lida Group has invested in advanced automated manufacturing equipment. The company’s factories are equipped with automated production lines for cutting, welding, bending, and assembling the steel frames of the container houses. These automated machines can perform tasks with high precision and speed, reducing the time required to manufacture each module. For example, an automated welding machine can weld the steel components of a container house frame in a fraction of the time it would take a manual welder, while also ensuring a stronger and more consistent weld. In addition to the steel frame production, Lida Group also uses automated equipment for the installation of interior fixtures, such as electrical outlets, lighting fixtures, and plumbing fixtures. This automation reduces the amount of manual labor required, minimizes the risk of human error, and speeds up the manufacturing process. The use of automated manufacturing equipment also allows Lida Group to scale up its production capacity quickly to meet the increasing demand for its prefab mobile container houses. This means that the company can deliver large orders in a short time, ensuring rapid deployment for its customers.

4.3 Smart Construction Management Systems

Lida Group has implemented smart construction management systems to monitor and manage the entire construction process, from the manufacturing of the modules to the on-site assembly. These systems use advanced technologies such as the Internet of Things (IoT), cloud computing, and big data analytics to collect and analyze real-time data about the construction project. For example, sensors installed on the container house modules can track their location, status, and condition during transportation and storage. This information is transmitted to a cloud-based platform, where project managers can monitor the progress of the project and ensure that the modules are delivered to the site on time and in good condition. On the construction site, IoT devices can be used to track the work progress of the assembly team, monitor the use of materials and equipment, and ensure that safety protocols are being followed. The data collected by these devices is analyzed using big data analytics to identify any potential issues or delays and take proactive measures to address them. For instance, if the data shows that the assembly process is taking longer than expected, project managers can adjust the work schedule or send additional personnel to the site to speed up the process. The smart construction management systems also enable real-time communication between all stakeholders involved in the project, including the customer, the design team, the manufacturing team, and the on-site assembly team. This ensures that everyone is kept informed about the project’s progress and that any changes or issues are addressed promptly. By optimizing the construction process and improving communication and collaboration, these smart systems contribute to the rapid deployment of Lida Group’s prefab mobile container houses.

5. Real-World Applications and Case Studies

5.1 Disaster Relief in Southeast Asia

In 2023, a severe flood hit several countries in Southeast Asia, causing widespread destruction and displacing millions of people. The local governments and international relief organizations were in urgent need of temporary shelter and medical facilities to support the affected population. Lida Group received an emergency order from a leading international relief organization to supply 500 prefab mobile container houses, including 300 shelter units and 200 medical units. Lida Group’s team immediately sprang into action, prioritizing the manufacturing of the container house modules in its factories. Thanks to the modular design and automated manufacturing equipment, the company was able to produce the 500 modules within two weeks. The modules were then loaded onto ships and transported to the flood-stricken areas. Upon arrival, Lida Group’s technical team worked closely with the local relief workers to assemble the container houses. The simple assembly process allowed the team to set up 100 shelter units and 50 medical units within the first three days. Within a week, all 500 container houses were fully assembled and ready for use. The shelter units provided a safe and dry place for the displaced families to live, while the medical units were equipped with beds, medical equipment, and supplies to treat the injured and sick. The rapid deployment of these container houses played a crucial role in providing immediate relief to the affected population and helping to restore order in the disaster-stricken areas. The relief organization praised Lida Group for its quick response, high-quality products, and professional service, stating that the prefab mobile container houses were a game-changer in the disaster relief efforts.

5.2 Construction Site Facilities for a Large Infrastructure Project

A major construction company in the Middle East was awarded a contract to build a new highway connecting two major cities. The project required the construction of temporary facilities to accommodate 1,000 construction workers, including dormitories, a canteen, offices, and storage rooms. The construction company approached Lida Group to provide a solution that could be deployed quickly to avoid delaying the start of the highway construction. Lida Group worked closely with the construction company to design a customized solution based on its specific needs. The solution included 200 dormitory modules (each accommodating 5 workers), 20 office modules, 10 canteen modules, and 30 storage modules. The modular design allowed Lida Group to customize each module to meet the unique requirements of the construction company, such as installing air conditioning in the dormitories and offices to cope with the hot climate in the Middle East. The manufacturing process began immediately after the design was finalized, and the modules were produced in Lida Group’s factory in China within three weeks. The modules were then transported to the construction site via ships and trucks. The on-site assembly team, with the support of Lida Group’s technical experts, began assembling the modules as soon as they arrived. The simple assembly process and the use of pre-installed connection points allowed the team to assemble all the modules within two weeks. The construction company was able to move its workers into the dormitories and start using the offices and canteen within a month of placing the order, which was much faster than the estimated three months required for traditional construction. The prefab mobile container houses proved to be durable and comfortable, withstanding the harsh desert conditions and providing a safe and functional living and working environment for the construction workers. The construction company was so satisfied with the solution that it has since ordered additional prefab mobile container houses for other projects.

5.3 Pop-Up Retail Space for a Global Brand

A well-known global fashion brand wanted to launch a limited-edition collection in a major European city and needed a pop-up retail space in a prime location to attract customers. The brand wanted the pop-up shop to be set up quickly to coincide with the launch date and to be visually appealing to reflect its brand image. Lida Group was commissioned to design and build the pop-up retail space. The design team at Lida Group worked closely with the brand’s marketing team to create a unique and eye-catching design that incorporated the brand’s colors, logo, and aesthetic. The pop-up shop was designed as a single 40-foot container house module, which was customized with large glass windows to showcase the products, a branded facade, and a modern interior with wooden flooring, lighting fixtures, and display racks. The manufacturing of the module was completed in Lida Group’s factory within two weeks, including the installation of all the interior fixtures and the branding elements. The module was then transported to the European city via truck, which took three days. Upon arrival, the assembly team used a small crane to place the module in the designated location and completed the final connections, such as electrical and lighting, within a day. The pop-up shop was ready to open its doors to customers on the scheduled launch date, much to the delight of the brand. The pop-up shop attracted a large number of customers, thanks to its prime location and attractive design, and the limited-edition collection sold out within a month. After the pop-up period ended, the module was disassembled and transported to another city for a similar event, demonstrating the flexibility and

versatility of Lida Group’s prefab mobile container houses. The brand expressed high satisfaction with the speed, quality, and design of the pop-up space, noting that it had exceeded their expectations and contributed significantly to the success of the limited-edition launch.

6. Quality Control Measures Ensuring Reliability in Rapid Deployment

While rapid deployment is a core advantage of Lida Group’s prefab mobile container houses, the company never compromises on quality. A series of strict quality control measures are implemented throughout the entire production and assembly process to ensure that each container house meets international standards for safety, durability, and performance. These measures not only guarantee the reliability of the product but also support rapid deployment by minimizing the risk of on-site errors or rework.

6.1 Raw Material Inspection

The quality of Lida Group’s prefab mobile container houses starts with the selection and inspection of raw materials. The company sources high-quality materials from trusted suppliers, including high-strength steel for the frame, fire-resistant and waterproof composite panels for the walls and roofs, and eco-friendly interior materials. Before any material is used in production, it undergoes a rigorous inspection process. For example, steel frames are tested for tensile strength, corrosion resistance, and dimensional accuracy using advanced testing equipment. Composite panels are checked for fire resistance, thermal insulation, and water tightness to ensure they can withstand various environmental conditions. Any material that fails to meet the required standards is rejected immediately, preventing substandard components from entering the manufacturing process. This strict raw material inspection lays a solid foundation for the overall quality of the container houses and ensures that they can perform reliably even in harsh environments.

6.2 In-Process Quality Monitoring

During the manufacturing process in Lida Group’s factories, each step is closely monitored to maintain consistent quality. The company has established a dedicated quality control team that oversees every stage of production, from the cutting and welding of steel frames to the installation of electrical and plumbing systems. Advanced monitoring technologies, such as real-time video surveillance and sensor-based data collection, are used to track the production process and identify any deviations from the standard procedures. For instance, in the welding process, sensors are used to monitor the temperature, voltage, and welding speed to ensure that each weld meets the required strength and quality standards. If a problem is detected, the production line is paused immediately, and the issue is resolved before continuing. This in-process quality monitoring ensures that each module is manufactured to the same high standard, reducing the need for on-site adjustments and enabling faster assembly.

6.3 Pre-Delivery Testing

Before the container house modules are shipped to the customer, they undergo a comprehensive pre-delivery testing process. This testing covers all aspects of the module, including structural integrity, electrical functionality, plumbing performance, and interior finishing. Structural tests involve subjecting the module to simulated loads and environmental conditions to ensure it can withstand strong winds, earthquakes, and heavy rains. Electrical tests include checking the wiring connections, lighting fixtures, and power outlets to ensure they are safe and functional. Plumbing tests involve running water through the pipes and checking for leaks or blockages. Interior finishing tests focus on the quality of the flooring, painting, and installation of fixtures to ensure they meet the customer’s requirements. Only after the module passes all these tests is it approved for delivery. This pre-delivery testing ensures that the modules are ready for immediate assembly on-site, eliminating the need for time-consuming repairs or modifications and supporting rapid deployment.

6.4 On-Site Quality Assurance

Lida Group also provides on-site quality assurance services to ensure that the assembly process is carried out correctly and that the final product meets the required standards. A team of experienced technical experts is sent to the construction site to supervise the assembly work, provide guidance to the local workers, and conduct regular quality checks. The experts review the site preparation, module placement, connection of modules, and installation of electrical and plumbing systems to ensure that everything is done in accordance with the design plans and standard procedures. They also conduct a final inspection of the completed building to verify its structural integrity, functionality, and safety. Any issues identified during the on-site quality assurance process are addressed immediately, ensuring that the container house is ready for use as soon as possible. This on-site support not only guarantees the quality of the final product but also helps to speed up the assembly process by resolving problems quickly.

7. Environmental Benefits of Lida Group’s Prefab Mobile Container House

In addition to their rapid deployment and high quality, Lida Group’s prefab mobile container houses offer significant environmental benefits, making them a sustainable building solution. As the world becomes increasingly concerned about climate change and environmental protection, the demand for eco-friendly building materials and methods is growing. Lida Group’s container houses address this demand by minimizing waste, reducing energy consumption, and promoting the reuse of materials.

7.1 Reduced Construction Waste

Traditional construction methods generate a large amount of waste, including leftover materials, cut-off pieces, and debris. This waste not only takes up landfill space but also contributes to environmental pollution. Lida Group’s prefab mobile container houses, however, are manufactured in a factory using precise measurements and standardized processes, which significantly reduces construction waste. The modules are designed to use materials efficiently, with minimal cutting or trimming required during production. Any leftover materials from the manufacturing process are collected and recycled, rather than being discarded. For example, excess steel from the frame production is melted down and reused to make new components, while leftover composite panels are cut into smaller pieces for use in other parts of the module. This reduced construction waste not only benefits the environment but also lowers the cost of production, making the container houses more affordable for customers.

7.2 Energy Efficiency

Lida Group’s prefab mobile container houses are designed to be energy-efficient, helping to reduce energy consumption and lower carbon emissions. The walls, floors, and roofs of the container houses are made of high-quality insulation materials, such as polyurethane foam or rock wool, which provide excellent thermal insulation. This insulation helps to keep the interior of the house cool in summer and warm in winter, reducing the need for heating and cooling systems. Additionally, the container houses can be equipped with energy-efficient windows and doors that are designed to minimize heat transfer. Lida Group also offers optional renewable energy solutions, such as solar panels and wind turbines, which can be installed on the container houses to generate clean energy. These energy-efficient features not only reduce the environmental impact of the container houses but also help customers save on energy costs over the long term.

7.3 Reusability and Recyclability

One of the key environmental benefits of Lida Group’s prefab mobile container houses is their reusability. Unlike traditional houses, which are often demolished once they are no longer needed, container houses can be easily disassembled, transported to a new location, and reassembled for reuse. This reusability reduces the need for new construction and the associated consumption of materials and energy. For example, a container house used as a construction site office can be moved to another construction site once the first project is completed, rather than being torn down. Even when a container house reaches the end of its useful life, its components can be recycled. The steel frame can be melted down and reused to make new steel products, while the composite panels can be recycled into other building materials. This high level of recyclability ensures that the container houses have a minimal impact on the environment throughout their lifecycle.

7.4 Low Carbon Footprint

The entire lifecycle of Lida Group’s prefab mobile container houses, from manufacturing to transportation to use, has a low carbon footprint. The factory prefabrication process is more energy-efficient than on-site construction, as factories can optimize energy use and reduce emissions through the use of advanced equipment and technologies. The lightweight design of the container houses reduces the fuel consumption required for transportation, as fewer trips are needed to transport the modules to the construction site. Additionally, the energy-efficient features of the container houses reduce the carbon emissions associated with heating, cooling, and electricity use during their operation. By choosing Lida Group’s prefab mobile container houses, customers can significantly reduce their carbon footprint and contribute to global efforts to combat climate change.

8. Future Outlook of Lida Group’s Prefab Mobile Container House

The future of Lida Group’s prefab mobile container house looks promising, as the demand for rapid, flexible, and sustainable building solutions continues to grow. The company is committed to continuous innovation and improvement, investing in research and development to enhance the performance, functionality, and sustainability of its products. Here are some key trends and developments that are expected to shape the future of Lida Group’s prefab mobile container houses.

8.1 Integration of Smart Home Technologies

As smart home technologies become increasingly popular, Lida Group is exploring ways to integrate these technologies into its prefab mobile container houses. This includes the installation of smart thermostats, lighting systems, security cameras, and home automation systems that can be controlled remotely via a smartphone or tablet. Smart thermostats can automatically adjust the temperature based on the user’s preferences and occupancy, improving energy efficiency. Smart lighting systems can be programmed to turn on and off at specific times or in response to motion, reducing energy waste. Smart security cameras provide real-time monitoring of the property, enhancing safety. The integration of these smart home technologies will make Lida Group’s container houses more comfortable, convenient, and energy-efficient, appealing to a wider range of customers, including residential users and commercial clients.

8.2 Expansion into New Markets

Lida Group currently serves customers in various regions around the world, including Asia, Africa, Europe, and North America. In the future, the company plans to expand its presence into new markets, such as South America, Australia, and the Middle East. This expansion will be supported by the company’s global supply chain network, which allows it to deliver container houses to any location in the world quickly and efficiently. Lida Group will also adapt its products to meet the specific needs and requirements of different markets. For example, in regions with extreme weather conditions, such as hot deserts or cold polar areas, the company will develop container houses with enhanced thermal insulation and weather resistance. In urban areas with limited space, the company will focus on compact and modular designs that can be stacked or combined to maximize space utilization. By expanding into new markets and adapting to local needs, Lida Group will be able to reach more customers and increase its global market share.

8.3 Development of Sustainable Materials

Lida Group is committed to using sustainable materials in its prefab mobile container houses and is investing in research and development to find new and more eco-friendly materials. The company is exploring the use of recycled materials, such as recycled steel, recycled plastic, and recycled wood, in the manufacturing process. Recycled steel has the same strength and durability as virgin steel but requires less energy to produce, reducing carbon emissions. Recycled plastic can be used to make interior fixtures and components, reducing the amount of plastic waste in landfills. Recycled wood can be used for flooring and wall panels, providing a natural and eco-friendly look. Lida Group is also researching the use of bio-based materials, such as bamboo and hemp, which are renewable and have a low environmental impact. The development and use of these sustainable materials will further enhance the environmental benefits of Lida Group’s container houses and align with the global trend towards sustainability.

8.4 Collaboration with Industry Partners

To drive innovation and expand its product offerings, Lida Group plans to collaborate with other industry partners, including technology companies, construction firms, and research institutions. These collaborations will allow the company to leverage the expertise and resources of its partners to develop new technologies, improve manufacturing processes, and create innovative building solutions. For example, collaborating with a technology company could help Lida Group integrate advanced smart home technologies into its container houses. Collaborating with a construction firm could provide insights into the specific needs of construction site facilities and help the company develop more tailored solutions. Collaborating with a research institution could support the development of new sustainable materials and construction methods. By working with industry partners, Lida Group will be able to stay at the forefront of innovation and continue to provide high-quality, rapid-deployment building solutions to its customers.

9. Conclusion

In conclusion, Lida Group’s prefab mobile container houses represent a revolutionary building solution that addresses the growing demand for rapid, flexible, cost-effective, and sustainable construction. Through their modular design, factory prefabrication, lightweight structure, and simple assembly process, these container houses can be deployed in a matter of days or weeks, far outpacing the timeline of traditional construction methods. This rapid deployment makes them ideal for a wide range of applications, including emergency disaster relief, temporary construction site facilities, pop-up commercial spaces, and affordable housing projects, as demonstrated by the real-world case studies discussed in this article.

The success of Lida Group’s prefab mobile container houses is not only due to their rapid deployment capabilities but also their high quality, which is ensured through strict raw material inspection, in-process quality monitoring, pre-delivery testing, and on-site quality assurance. Additionally, these container houses offer significant environmental benefits, including reduced construction waste, energy efficiency, reusability, recyclability, and a low carbon footprint, making them a sustainable choice for environmentally conscious customers.

Looking to the future, Lida Group is well-positioned to capitalize on the growing demand for innovative building solutions by integrating smart home technologies, expanding into new markets, developing sustainable materials, and collaborating with industry partners. As the world continues to face challenges such as natural disasters, housing shortages, and climate change, Lida Group’s prefab mobile container houses will play an increasingly important role in providing quick, reliable, and eco-friendly building solutions.

For customers seeking to complete projects quickly without compromising on quality or sustainability, Lida Group’s prefab mobile container houses are the ideal choice. Whether it’s providing emergency shelter to disaster victims, supporting the efficient operation of construction projects, creating temporary commercial spaces for businesses, or addressing the global housing crisis, Lida Group’s container houses deliver on their promise of rapid deployment, high performance, and environmental responsibility. As the industry continues to evolve, Lida Group will remain a leader in the prefab mobile container house market, driving innovation and setting new standards for excellence in the construction industry.

Related news

-

Versatile Temporary Container Building for Multiple Applications

2025-10-29 15:58:54

-

Lida Group Champions Cost-Effective Prefab Construction Methods

2025-10-29 16:03:46

-

Discover Cost-Effective Prefab Construction with Lida Group

2025-10-29 15:48:16

contact us

- Tel: +86-532-88966982

- Whatsapp: +86-13793209022

- E-mail: sales@lidajituan.com