Post-Pandemic Compliance: High-Quality Container Houses by Lida Group Integrate Health-Focused Prefab Building Ventilation Systems

2025-Aug-21 14:48:16

By Admin

1. Introduction

The global pandemic has reshaped our understanding of health and safety in built environments, emphasizing the critical role of ventilation in preventing the spread of airborne pathogens. As industries and communities adapt to post-pandemic norms, there is a heightened demand for accommodation and workspace solutions that prioritize health compliance without compromising on efficiency, durability, or comfort.

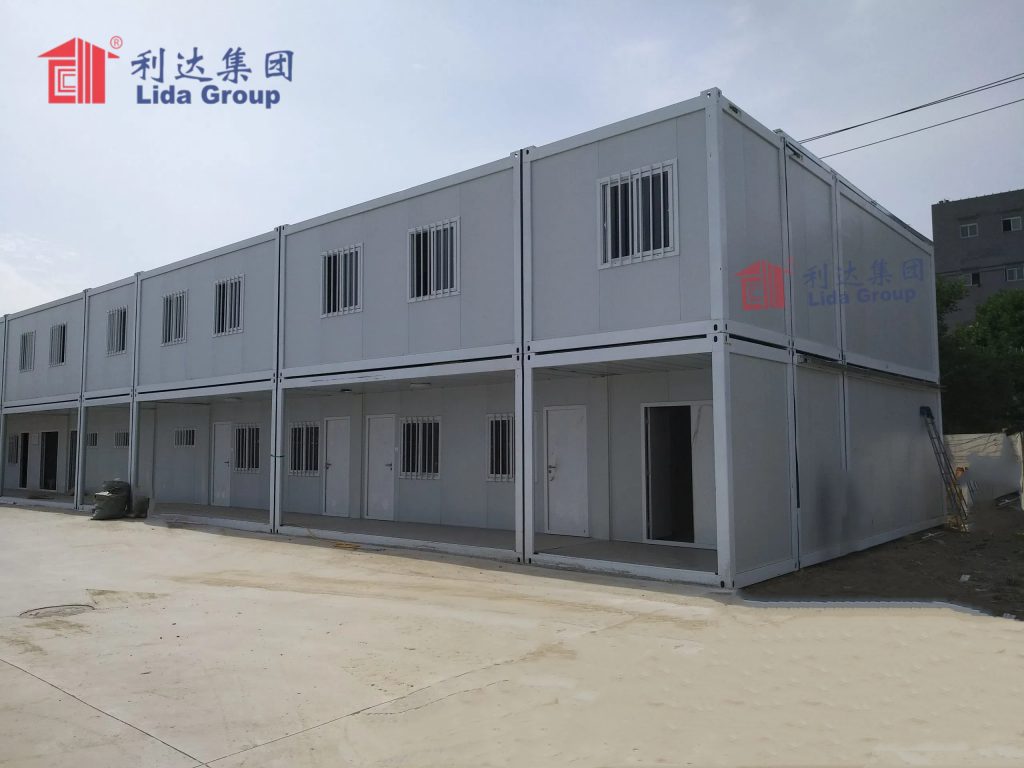

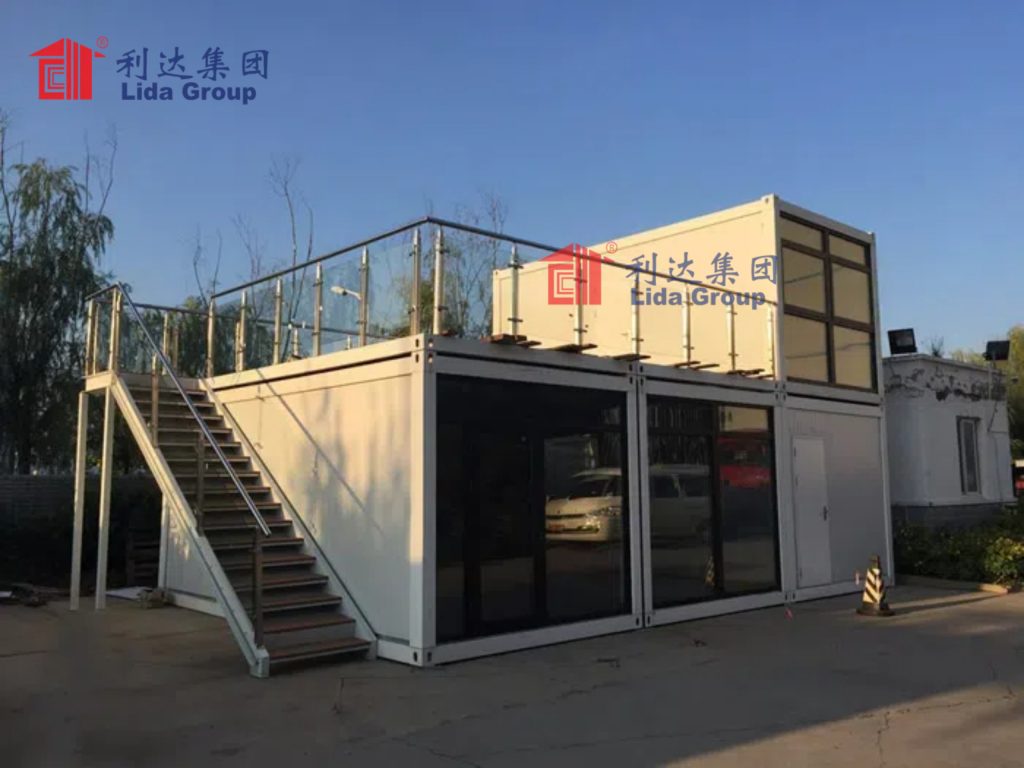

Lida Group, a leader in prefabricated building solutions, has responded to this demand with high-quality container houses integrated with advanced, health-focused ventilation systems. These innovative structures combine the versatility and rapid deployment of container-based construction with cutting-edge air management technologies, setting new standards for post-pandemic compliance. This article explores how Lida Group’s container houses address the evolving health requirements of the post-pandemic world, from their ventilation system design to real-world applications and future potential.

2. The Post-Pandemic Shift in Health Compliance for Built Environments

2.1. The Role of Ventilation in Airborne Pathogen Control

The pandemic underscored the risks of poor indoor air quality, with studies showing that airborne transmission of viruses (including COVID-19) is a significant mode of spread in enclosed spaces. Adequate ventilation—by bringing in fresh outdoor air, filtering recirculated air, and removing stale air—reduces the concentration of pathogens, lowering infection risks.

Post-pandemic regulations, such as those from the World Health Organization (WHO) and national health agencies, now mandate specific ventilation rates (often 6-12 air changes per hour) and air filtration standards (e.g., MERV 13 or higher) for indoor spaces. These requirements apply not only to permanent buildings but also to temporary and modular structures, including container houses used for housing, healthcare, or workspace.

2.2. Challenges in Traditional Container and Prefab Structures

Traditional container houses and prefab buildings often have inadequate ventilation systems, designed primarily for basic comfort rather than health compliance. Common issues include:

- Insufficient Air Exchange: Many rely on natural ventilation (windows and vents) or basic fans, failing to meet the higher air change rates required post-pandemic.

- Poor Filtration: Recirculated air is rarely filtered to remove small airborne particles, including pathogens.

- Moisture Buildup: Inadequate ventilation can lead to high humidity, promoting mold growth—a health hazard in itself and a contributor to poor indoor air quality.

- Cross-Contamination Risks: Shared ventilation systems in multi-unit container complexes may allow pathogens to spread between units if not properly designed.

These shortcomings make traditional container structures non-compliant with post-pandemic health standards, limiting their use in critical applications such as worker housing, quarantine facilities, or temporary clinics.

2.3. Demand for Health-Focused Modular Solutions

The post-pandemic era has seen a surge in demand for modular and container-based structures, driven by their rapid deployment, cost-effectiveness, and flexibility. Industries such as construction, healthcare, and disaster response require temporary or semi-permanent accommodation that can be quickly set up while adhering to strict health guidelines.

Workers in remote sites, patients in quarantine, and displaced communities all need spaces that prioritize air quality to prevent disease spread. This has created a need for container houses that integrate ventilation systems specifically engineered to meet post-pandemic compliance, balancing health, comfort, and practicality.

3. Lida Group’s High-Quality Container Houses: A Foundation for Health Compliance

3.1. Container House Design and Construction

Lida Group’s container houses are built on a foundation of high-quality materials and precision engineering. Using modified shipping containers (20-foot, 40-foot, or custom sizes), the company transforms these durable steel structures into habitable spaces suitable for a range of applications, from worker dormitories and emergency shelters to temporary offices and healthcare clinics.

Key features of their container houses include:

- Structural Integrity: Galvanized steel frames resist corrosion and withstand harsh weather, ensuring longevity and safety.

- Insulation: High-performance insulation (polyurethane foam, rock wool) maintains thermal comfort while reducing energy use for heating and cooling.

- Modularity: Units can be stacked or connected to form larger complexes, with flexible layouts to suit different needs (e.g., single rooms, shared spaces, or specialized areas like medical examination rooms).

- Sustainability: Use of recycled materials (e.g., 98% recycled steel in some components) and energy-efficient designs minimizes environmental impact.

These features provide a robust base for integrating health-focused ventilation systems, ensuring that the structures can support the mechanical and filtration requirements of post-pandemic compliance.

3.2. Compliance with Global Health Standards

Lida Group’s container houses are designed to meet or exceed international health and safety standards, including those set by the WHO, CDC (Centers for Disease Control and Prevention), and local regulatory bodies. This includes compliance with ventilation requirements, fire safety, and structural stability, making them suitable for use in healthcare and high-risk environments.

The company’s commitment to quality is backed by certifications such as ISO 9001 (quality management) and ISO 14001 (environmental management), ensuring that every container house undergoes rigorous testing and inspection before deployment.

4. Health-Focused Prefab Building Ventilation Systems in Lida Group’s Container Houses

4.1. System Design and Components

Lida Group’s ventilation systems are engineered specifically for container houses, addressing the unique challenges of enclosed, modular spaces. The systems combine mechanical ventilation, advanced filtration, and air distribution to achieve post-pandemic compliance. Key components include:

- Mechanical Ventilation Units (MVUs): These units draw in fresh outdoor air, filter it, and distribute it throughout the container. They also extract stale air, ensuring consistent air exchange. MVUs are sized to achieve 6-12 air changes per hour, depending on the application (e.g., higher rates for healthcare settings).

- High-Efficiency Air Filters: Both supply and return air streams pass through filters rated MERV 13 or higher, capable of capturing 90% or more of particles as small as 0.3-1.0 microns—including most viruses, bacteria, and allergens. Some systems use HEPA filters (99.97% efficiency) for critical environments like quarantine units.

- Heat Recovery Ventilators (HRVs): In climates requiring heating or cooling, HRVs recover heat from exhaust air to precondition incoming fresh air, reducing energy waste while maintaining ventilation rates.

- Zone Control: In multi-unit complexes, ventilation systems are zoned to prevent cross-contamination. Each unit has its own air supply and exhaust, with pressure differentials (e.g., negative pressure in quarantine rooms) to contain pathogens.

- Humidity Regulation: Dehumidifiers or humidifiers integrate with the ventilation system to maintain indoor humidity between 40-60%—a range that inhibits mold growth and optimizes filter performance.

4.2. How the System Enhances Indoor Air Quality

The ventilation system works in a continuous cycle to ensure high indoor air quality:

- Fresh Air Intake: Outdoor air is drawn into the MVU, where it passes through a pre-filter to remove large particles (dust, pollen) and then a MERV 13/HEPA filter to capture fine particles, including pathogens.

- Air Distribution: Filtered fresh air is distributed via ducts to diffusers throughout the container, ensuring even coverage.

- Stale Air Removal: Contaminated air is extracted from the container, either through return ducts (passing through another filter) or direct exhaust (for high-risk areas like isolation rooms).

- Heat Recovery (if applicable): In HRV-equipped systems, heat from exhaust air is transferred to incoming fresh air, reducing the load on heating or cooling systems.

- Humidity Control: Sensors monitor indoor humidity, activating dehumidifiers or humidifiers to maintain optimal levels.

This process ensures that pathogen concentrations are kept low, while temperature and humidity remain comfortable—critical for both health and occupant well-being.

4.3. Smart Monitoring and Control

To ensure ongoing compliance, Lida Group’s ventilation systems include smart monitoring and control features:

- Sensors: Real-time sensors track air change rates, filter pressure (indicating when filters need replacement), temperature, humidity, and CO₂ levels (a proxy for indoor air quality).

- Digital Interfaces: Controllers allow users to adjust ventilation settings, view system performance data, and receive alerts for maintenance (e.g., filter replacement) or anomalies (e.g., low air flow).

- Remote Monitoring: In large complexes, a central dashboard enables facility managers to monitor all units from a distance, ensuring consistent performance and quickly addressing issues.

This smart technology not only simplifies compliance but also reduces operational costs by optimizing energy use and enabling proactive maintenance.

5. Benefits of Lida Group’s Health-Focused Container Houses Post-Pandemic

5.1. Reduced Infection Risk

The primary benefit of the integrated ventilation systems is a significant reduction in the risk of airborne disease transmission. By maintaining high air change rates and using advanced filtration, Lida Group’s container houses create environments where pathogens are diluted and removed, lowering the likelihood of outbreaks.

This is particularly valuable in settings such as worker dormitories (where many people live in close proximity), quarantine facilities (housing individuals with contagious diseases), and temporary clinics (treating patients with respiratory illnesses). In these contexts, the ventilation systems act as a critical line of defense against infection.

5.2. Compliance with Post-Pandemic Regulations

By meeting or exceeding ventilation standards set by global health authorities, Lida Group’s container houses help organizations avoid regulatory penalties and reputational damage. They provide a turnkey solution for industries needing to quickly deploy compliant accommodation or workspace, ensuring that health requirements are met without sacrificing speed or cost-effectiveness.

For example, construction companies operating in regions with strict post-pandemic labor housing regulations can use these container houses to ensure worker safety and avoid project delays due to non-compliance.

5.3. Enhanced Occupant Comfort and Productivity

Good indoor air quality is linked to improved health, cognitive function, and mood. Lida Group’s ventilation systems ensure that occupants breathe clean air, reducing symptoms like headaches, fatigue, and respiratory irritation. This translates to higher productivity in workspaces and better recovery rates in healthcare settings.

The systems also maintain consistent temperatures and humidity, avoiding the discomfort of stuffy or overly dry air—common issues in poorly ventilated container houses. This comfort is especially important for long-term occupancy, such as worker dormitories or extended quarantine stays.

5.4. Energy Efficiency and Cost Savings

While health-focused ventilation could potentially increase energy use, Lida Group’s integration of HRVs and smart controls minimizes this impact. HRVs reduce the energy required to heat or cool incoming air, while sensors and variable-speed fans adjust operation based on occupancy and outdoor conditions.

Over time, these efficiencies lead to lower utility costs compared to traditional ventilation systems. Additionally, the modular design of the container houses and ventilation components reduces installation and maintenance costs, making compliance affordable even for large-scale deployments.

5.5. Versatility Across Applications

Lida Group’s container houses with health-focused ventilation systems are versatile enough to serve multiple post-pandemic needs:

- Worker Housing: Dormitories for construction, mining, or energy workers, ensuring safe communal living.

- Quarantine Facilities: Isolation units for individuals exposed to or infected with contagious diseases.

- Temporary Healthcare Clinics: Examination rooms and staff quarters in areas with overwhelmed healthcare systems.

- Disaster Response Shelters: Safe accommodation for communities displaced by natural disasters, where disease spread is a high risk.

- Remote Research Stations: Living spaces for scientists in isolated locations, where medical support is limited.

This versatility makes them a valuable asset for organizations adapting to the evolving demands of the post-pandemic world.

6. Real-World Applications: Post-Pandemic Use Cases

6.1. Construction Worker Dormitories in the Middle East

A large construction company in the Middle East needed to house 300 workers on a remote project site, with strict compliance to local post-pandemic regulations requiring enhanced ventilation in shared accommodation. Lida Group supplied 75 container houses, each equipped with MERV 13-filtered ventilation systems and zone control to prevent cross-contamination between rooms.

The system maintained 8 air changes per hour, with CO₂ sensors ensuring indoor air quality remained optimal. Workers reported fewer respiratory issues compared to previous accommodation, and the company avoided regulatory fines by meeting ventilation standards. The modular design allowed the dormitory to expand as the workforce grew, with ventilation systems easily scaled to match.

6.2. Quarantine Facility in Southeast Asia

A government in Southeast Asia required a temporary quarantine facility to handle surges in COVID-19 cases. Lida Group’s container houses were chosen for their rapid deployment and ability to integrate negative-pressure ventilation systems—critical for containing the virus.

Each container was converted into a single quarantine room with its own supply and exhaust fans, creating negative pressure to prevent air from escaping into shared areas. HEPA filters ensured that exhaust air was fully decontaminated before release. The facility, which housed 50 patients, was set up in just two weeks and operated with zero cases of cross-contamination between rooms, according to health officials.

6.3. Temporary Healthcare Clinic in Sub-Saharan Africa

A non-governmental organization (NGO) established a temporary healthcare clinic in a rural area of Sub-Saharan Africa, providing primary care and disease screening. The clinic required consultation rooms and staff accommodation that met international health standards for ventilation, to protect both patients and workers from airborne illnesses.

Lida Group’s container houses featured HRV-equipped ventilation systems with MERV 13 filters, ensuring clean air while reducing energy use in the hot climate. The consultation rooms maintained 10 air changes per hour, while staff quarters provided comfortable living conditions with controlled humidity to prevent mold. The clinic reported improved staff retention and patient satisfaction, with health workers noting the difference in air quality compared to traditional temporary structures.

7. Challenges and Solutions in Implementing Health-Focused Ventilation

7.1. Balancing Ventilation Rates and Energy Use

Higher ventilation rates increase energy consumption, a concern in off-grid or remote locations where power is limited. Lida Group addresses this by:

- Integrating HRVs: Recovering heat from exhaust air reduces the need for heating/cooling, offsetting energy use from fans.

- Using Variable-Speed Fans: Fans adjust speed based on occupancy (detected via motion sensors), reducing energy use when rooms are unoccupied.

- Solar Power Integration: Ventilation systems can be paired with solar panels and battery storage in off-grid sites, ensuring compliance without relying on diesel generators.

7.2. Maintenance of Filtration Systems

Clogged or expired filters reduce system efficiency and pose health risks, but maintenance can be challenging in remote locations. Solutions include:

- Smart Filter Monitoring: Sensors track filter pressure and send alerts when replacements are needed, preventing unplanned downtime.

- Easy Access Design: Filters are positioned for quick replacement, requiring minimal tools or training.

- Pre-Packaged Filter Kits: Lida Group provides bulk filter kits for large deployments, ensuring supplies are available on-site.

7.3. Adapting to Climate Variability

Ventilation needs vary by climate—e.g., high humidity in tropical regions requires dehumidification, while cold climates need heat recovery. Lida Group’s systems are customizable:

- Climate-Specific Packages: Systems are pre-configured for tropical, arid, or temperate climates, with appropriate dehumidifiers, heaters, or HRVs.

- Weatherproof Components: Ventilation units are designed to withstand dust, rain, and extreme temperatures, ensuring reliability in diverse environments.

7.4. Cost Considerations for Small-Scale Deployments

For smaller projects, the upfront cost of health-focused ventilation systems may be prohibitive. Lida Group offers:

- Scalable Solutions: Basic systems (e.g., MERV 13 filters with standard fans) for low-budget projects, with the option to upgrade components later.

- Leasing Options: Rental packages that include maintenance, reducing initial investment for short-term needs.

8. Future Outlook for Health-Focused Container Houses

8.1. Advances in Filtration and Air Purification

Future ventilation systems will integrate even more advanced filtration technologies, such as:

- UV-C Disinfection: Ultraviolet light integrated into ducts to kill pathogens, complementing filters for enhanced safety.

- Photocatalytic Oxidation: Air purification technology that breaks down volatile organic compounds (VOCs) and pathogens, improving air quality beyond particle filtration.

- Nanofiber Filters: Lighter, more efficient filters with longer lifespans, reducing maintenance needs.

These innovations will further reduce infection risks while improving energy efficiency.

8.2. AI-Driven Ventilation Optimization

Artificial intelligence (AI) will play a larger role in ventilation control, with systems that:

- Predict Occupancy: Use historical data and external factors (e.g., work schedules) to adjust ventilation rates proactively.

- Learn from Air Quality Trends: Identify patterns in pathogen risk (e.g., higher rates during flu season) and adjust filtration or air changes accordingly.

- Integrate with Health Data: In healthcare settings, link ventilation adjustments to real-time disease transmission data, creating dynamic, responsive systems.

8.3. Standardization of Post-Pandemic Compliance

As post-pandemic regulations become more standardized globally, Lida Group’s container houses will evolve to meet universal benchmarks, simplifying compliance for multinational organizations. This may include pre-certified ventilation packages that align with regional standards (e.g., EU, North America, Asia), reducing the need for custom engineering.

8.4. Expansion into New Markets

The success of health-focused container houses will drive expansion into new sectors, such as:

- Education: Temporary classrooms with enhanced ventilation for schools.

- Aging Care: Modular housing for elderly populations, where air quality is critical for respiratory health.

- Events: Temporary accommodation for festivals or conferences, ensuring safe communal living.

9. Conclusion

Lida Group’s high-quality container houses, integrated with health-focused prefab building ventilation systems, represent a vital innovation in post-p

and emic compliance, addressing the critical need for safe, adaptable, and health-conscious built environments. By integrating advanced ventilation systems into their high-quality container houses, Lida Group has successfully merged the practical advantages of modular construction—rapid deployment, scalability, and cost-effectiveness—with the stringent health requirements of the post-pandemic era.

These structures stand out for their ability to maintain optimal indoor air quality through high-efficiency filtration, controlled air exchange, and smart monitoring, directly reducing the risk of airborne pathogen transmission. Real-world applications across construction, healthcare, and disaster response demonstrate their versatility, proving that compliance with global health standards can be achieved even in remote or challenging settings.

The challenges of balancing ventilation efficiency with energy use, maintaining filtration systems in remote locations, and adapting to diverse climates are met with innovative solutions—from solar integration and HRVs to smart sensor technology and climate-specific designs. These solutions ensure that health-focused ventilation is not only effective but also sustainable and accessible across different project scales.

Looking ahead, the integration of advanced filtration technologies, AI-driven optimization, and standardized compliance packages will further enhance the performance and accessibility of these container houses. As industries and communities continue to prioritize health in built environments, Lida Group’s innovation sets a blueprint for responsible, adaptable, and health-focused modular construction.

In essence, Lida Group’s container houses with health-focused ventilation systems are more than just temporary structures—they are a testament to how prefabricated solutions can evolve to meet emerging global challenges. By placing indoor air quality at the forefront of design, they contribute to safer, healthier, and more resilient communities in the post-pandemic world.

Related news

-

Arctic-Grade Accommodation: Lida Group's Insulated Container Worker Dormitories Feature High-Quality Prefab Building Envelope

2025-08-21 14:21:54

-

Mega-Project Efficiency: Prefab Building Solutions Deliver Rapid Container Worker Dormitory Deployment for Remote Construction Sites

2025-08-21 13:21:44

-

Lida Group Raises Worker Welfare Standards with High-Quality Container House Dormitories Using Advanced Prefab Building Technology

2025-08-20 17:56:38

contact us

- Tel: +86-532-88966982

- Whatsapp: +86-13793209022

- E-mail: sales@lidajituan.com