**Introduction: The Tyranny of Time in Traditional Construction**

In the world of construction, time is not just money; it is risk, opportunity, and viability. Traditional building methods, with their sequential, weather-dependent, and labor-intensive processes, are notoriously slow and prone to delays. A project timeline stretching over months or even years is the accepted norm, often accompanied by budget overruns, logistical nightmares, and immense opportunity costs. For businesses needing rapid expansion, communities requiring urgent housing after a disaster, or entrepreneurs seizing a fleeting market opportunity, this protracted timeline is a significant barrier.

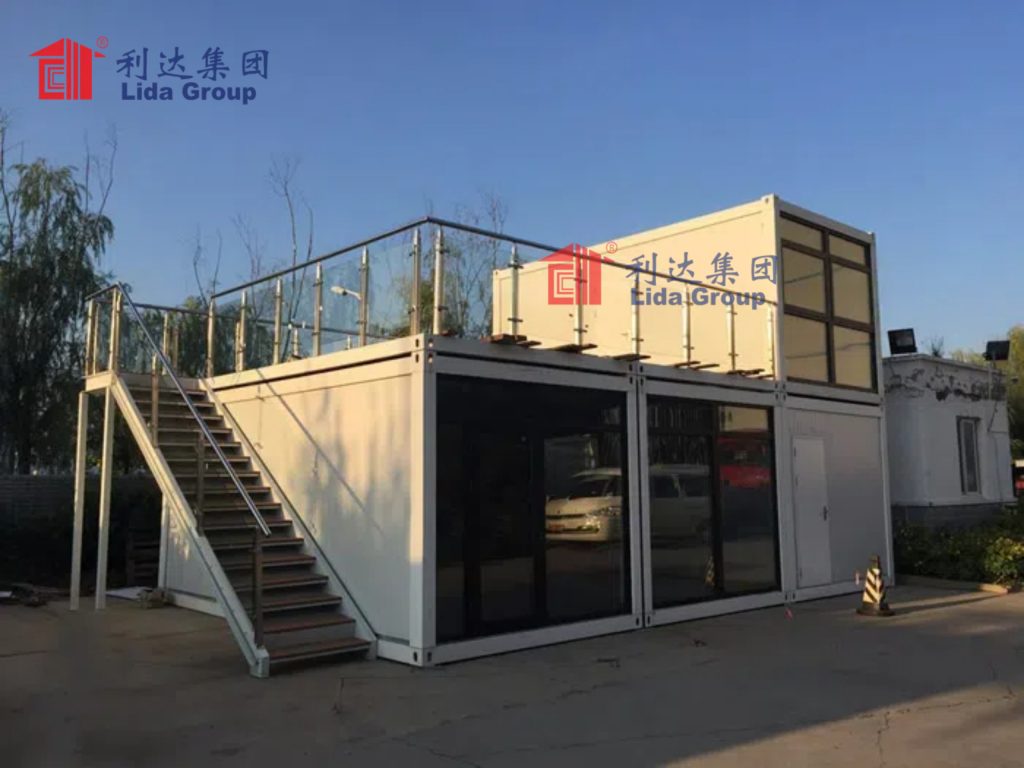

It is against this backdrop of chronic delay that Lida Group’s Prefab Mobile Container House emerges not merely as an alternative building solution, but as a paradigm-shifting response to the industry’s most persistent challenge. This innovative approach to construction fundamentally reengineers the entire building process, moving the bulk of the work from the unpredictable construction site to the controlled precision of a factory floor. The result is a staggering reduction in build times—often by 50% to 70%—without compromising on quality, durability, or design. This article provides a deep and comprehensive exploration of the mechanisms, processes, and inherent advantages that allow Lida Group to achieve these unprecedented speed-to-completion milestones, transforming the way we think about creating space.

**Chapter 1: Deconstructing Delay – The Inefficiencies of Conventional Building**

To fully appreciate the speed of Lida Group’s solution, one must first understand the inherent bottlenecks of traditional construction.

1. **The Sequential Dependency Trap:** Conventional building is a linear process. The foundation must be perfectly set and cured before the framing can begin. The framing must be fully inspected and signed off before roofing and wiring can start. Each trade—concreters, framers, roofers, electricians, plumbers, drywallers, painters—waits for the previous one to finish. A delay at any stage creates a cascading ripple effect, pushing the entire project timeline back.

2. **Weather and Seasonality:** Construction sites are at the mercy of the elements. Rain halts concrete pouring and exterior work. Extreme heat or cold can affect material properties and worker productivity. High winds can stop crane operations. These weather-related delays can accumulate into weeks or months of lost time over the course of a project.

3. **Logistical Coordination on Site:** A traditional site becomes a chaotic hub of simultaneous deliveries and trades. Delays in material delivery, miscommunication between subcontractors, and the constant movement of equipment and personnel create a environment rife with inefficiency and waiting time.

4. **Skilled Labor Shortages and Scheduling Conflicts:** The construction industry globally faces a shortage of skilled labor. Securing a skilled crew and coordinating their schedules with the project timeline is a constant challenge. If the electrician is booked for another job, the entire project stalls.

5. **Regulatory and Inspection Delays:** Each phase of traditional construction requires inspection and approval from local authorities before proceeding to the next stage. Scheduling these inspections and navigating bureaucratic hurdles can introduce significant, and often unpredictable, pauses.

This combination of factors makes the traditional construction timeline a fragile and often unreliable estimate. Lida Group’s model systematically dismantles each of these bottlenecks.

**Chapter 2: The Paradigm Shift: From On-Site Construction to Factory-Based Manufacturing**

The core principle behind the dramatic time savings of Lida Group’s Prefab Mobile Container House is the radical shift from *on-site construction* to *off-site manufacturing*. This is not a minor tweak but a complete re-imagination of the building process.

**2.1 Parallel Processing vs. Sequential Dependency**

While a traditional project is sequentially preparing its site, the Lida Group factory is already in full production. This is the single most critical factor in reducing time.

* **Site Work:** On the project site, work begins on preparing the foundation. For a container house, this is often a simple, low-impact foundation such as concrete piers, gravel pads, or screw piles. This process is exponentially faster than pouring a full basement or extensive concrete slab. It requires less curing time and is less susceptible to minor grading imperfections.

* **Factory Work:** Simultaneously, in Lida Group’s state-of-the-art manufacturing facility, the container modules are being built. The steel frame is fabricated, wall and roof panels are insulated and sealed, windows and doors are installed, and interior finishes are applied. Electrical wiring, plumbing lines, and data cabling are routed within the walls with precision.

This parallel processing—site preparation and unit fabrication happening at the same time—eliminates the vast majority of the sequential delays inherent in traditional building. The “construction” of the building and the preparation of its site are no longer a linear sequence but concurrent operations.

**2.2 The Controlled Factory Environment: Banishing Weather Delays**

A factory is a climate-controlled, disciplined environment. There are no rainouts, no scorching heat waves, and no frozen ground to halt production. Work continues unimpeded 24/7 if necessary, under optimal lighting and temperature conditions. This consistent environment not only accelerates the pace of work but also significantly enhances quality control. Materials are stored properly, preventing moisture damage or warping, and precision machinery can operate at peak efficiency.

**Chapter 3: The Anatomy of Speed: Key Features of the Prefab Container House that Accelerate Timelines**

The design of the Lida Group container house itself is engineered for rapid deployment. Every component is optimized for speed.

**3.1 Standardization and Modular Design**

The units are based on standardized, modular dimensions that are compatible with the global container logistics network. This standardization allows for:

* **Mass Production of Components:** Wall panels, floor cassettes, and roofing elements can be prefabricated in batches, reducing the time required for custom fabrication for each project.

* **Simplified Assembly:** Workers on the assembly line become highly specialized and efficient in repeating specific tasks, much like in an automotive plant. This repetition breeds speed and eliminates the learning curve associated with unique, on-site builds.

* **Predictable Logistics:** The standardized size means the modules are designed for easy transport via standard trucks, ships, and railcars, simplifying the often-complex logistics of delivering building components.

**3.2 Plug-and-Play Integrated Systems**

In a traditional build, the coordination between electricians, plumbers, and HVAC technicians is a major source of delay. Lida Group solves this by designing the units with integrated, pre-tested utility systems.

* **Pre-Installed Utilities:** During factory assembly, all electrical conduits, plumbing pipes, and ventilation ducts are installed within the walls and floors. Light fixtures, sockets, switches, and even bathroom fixtures are often mounted in place.

* **Consolidated Connection Points:** Instead of a complex web of connections throughout a building, the unit arrives on site with a few, robust, and clearly labeled connection points. Typically, this includes one main electrical hookup, one main water inlet, one sewer outlet, and one data connection. This reduces on-site hookup time from days or weeks to a matter of hours.

**3.3 Rapid On-Site Assembly and Installation**

The culmination of the off-site process is the breathtaking speed of on-site assembly.

* **Delivery and Placement:** Once the foundation is ready and the modules arrive on site, they are lifted by a crane and positioned onto their foundations. This process for a single unit can take just a few hours.

* **Joining Modules:** For multi-module projects, the connection systems are engineered for swift and secure coupling. Inter-module connectors for structure, utilities, and data are designed to be bolted or locked together quickly by a small crew.

* **Final Hookup and Commissioning:** The final step involves connecting the pre-identified utility points to the main site services. Because the internal systems are already complete and tested, the unit can often be occupied and operational within 24 to 48 hours of being placed on its foundation.

**Chapter 4: A Comparative Timeline Analysis: Traditional Build vs. Lida Group Prefab**

To illustrate the dramatic difference, let us compare the timelines for a small, single-story commercial building (e.g., a site office or a retail kiosk) of approximately 40 square meters.

**Traditional Construction Timeline (Estimated: 10-14 Weeks):**

* **Weeks 1-2:** Site preparation, excavation, and foundation forming.

* **Weeks 3-4:** Pouring concrete foundation and waiting for full cure.

* **Weeks 5-6:** Delivery of materials and erection of structural frame and roof.

* **Weeks 7-8:** Installation of exterior sheathing, windows, doors, and roofing. Rough-in for electrical and plumbing.

* **Weeks 9-10:** Installation of insulation and interior drywall. Multiple days for drying joint compound.

* **Weeks 11-12:** Interior painting, flooring, and installation of fixtures.

* **Weeks 13-14:** Final touches, cleaning, inspections, and punch-list resolution.

*Note: This timeline assumes no significant weather delays, no material shortages, and perfect subcontractor scheduling—a highly optimistic scenario.*

**Lida Group Prefab Container House Timeline (Estimated: 3-4 Weeks Total):**

* **Week 1 (Factory):** Order placed. Manufacturing of the container house unit begins in parallel with site work.

* **Week 1-2 (Site):** Site is graded and simple foundation (concrete piers) is installed.

* **Week 2-3 (Factory):** Unit fabrication continues: structure, insulation, utilities, interiors.

* **Week 4 (Site & Final):** Completed unit is transported to the site. It is lifted onto the foundation, utilities are connected, and the unit is operational within 1-2 days.

This side-by-side comparison reveals a time saving of approximately 70%. For larger, multi-module projects, the time savings are even more profound, as multiple units are manufactured simultaneously in the factory while the site is being prepared.

**Chapter 5: Case Study – Speed in Action: A Humanitarian Response Project**

Consider a real-world scenario where time is of the essence: providing immediate shelter after a natural disaster.

* **The Challenge:** A humanitarian agency needs to establish a field clinic and temporary housing for 50 aid workers within two weeks in a remote, affected area with damaged infrastructure.

* **The Traditional Impossibility:** A traditional build is unthinkable. Sourcing local materials would be difficult, skilled labor may be unavailable, and the sequential process is far too slow to meet the urgent need.

* **The Lida Group Solution:**

1. **Day 1-2:** The order is placed. Units are selected from stock or rapidly configured from standard designs.

2. **Day 3-10:** Units are manufactured and prepped for shipping. Simultaneously, an advance team levels the deployment site and prepares simple gravel pads or pier foundations.

3. **Day 11:** Shipping containers carrying the fully-equipped clinic and housing units arrive.

4. **Day 12:** Using a mobile crane, the units are offloaded, positioned, and interconnected. The utility modules are connected to a temporary generator and water tanker.

5. **Day 13:** The fully-functional clinic is open, and aid workers move into their secure, weatherproof, and comfortable accommodations.

This accelerated timeline can mean the difference between life and death, demonstrating that the value of reduced build time extends far beyond mere financial profit.

**Chapter 6: The Ripple Effects of Speed: Broader Economic and Operational Benefits**

The benefit of drastically reduced build times is not an isolated metric; it creates a cascade of positive outcomes.

* **Earlier Return on Investment (ROI):** For a commercial business like a pop-up store, a cafe, or a worksite office, a building that is operational in weeks instead of months begins generating revenue or enabling cost savings much earlier. This dramatically improves the project’s financial viability and ROI.

* **Reduced Financing Costs:** Construction loans are expensive. Shortening the project duration directly reduces the interest payments and carrying costs associated with the loan.

* **Mitigation of Inflation and Material Price Volatility:** By compressing the procurement and construction timeline into a much shorter window, the project is less exposed to the risk of sudden price increases for materials and labor.

* **Enhanced Agility and Competitive Advantage:** A company that can physically deploy new facilities—be it a sales office in a new market or a production facility near a new client—in a matter of weeks possesses a tremendous strategic agility that competitors using traditional methods cannot match.

* **Minimized Community and Environmental Disruption:** A fast build means less noise, dust, and traffic disruption for the surrounding community. The reduced on-site activity also minimizes the risk of soil erosion and local environmental damage.

**Conclusion: Building a Faster, Smarter Future**

Lida Group’s Prefab Mobile Container House is far more than a product; it is a sophisticated methodology that systematically attacks and eliminates the chronic inefficiencies of traditional construction. By shifting the primary locus of work to a controlled factory environment, implementing parallel processing, and engineering the final product for rapid deployment, it achieves a revolutionary compression of the project timeline.

The ability to reduce build times by 50% to 70% is not a marginal improvement; it is a transformative leap. It empowers businesses to act faster on opportunities, allows governments and aid agencies to respond more effectively to crises, and provides individuals with high-quality housing solutions in a fraction of the time. In a world that moves at an ever-accelerating pace, the speed and efficiency offered by Lida Group’s prefabricated solution are no longer just a convenient alternative—they are an undeniable strategic imperative. This innovation redefines what is possible in construction, proving that with intelligent design and modern manufacturing, we can build not just better, but exponentially faster.

Related news

-

Lida Group Launches New Prefab Mobile Container House Series

2025-10-29 15:32:45

-

Lida Group Achieves the Ideal Balance with Cost-Effective Steel Structure Construction for High Quality Metal Building Projects

2025-10-29 15:26:28

-

Discover Cost-Effective Prefab Construction with Lida Group

2025-10-29 15:48:16

contact us

- Tel: +86-532-88966982

- Whatsapp: +86-13793209022

- E-mail: sales@lidajituan.com