Lida Group’s Easy Install Container House Saves Time and Labor

2026-Feb-14 14:56:21

By Admin

In the fast-paced world of construction, emergency response, temporary accommodation, and infrastructure development, time and labor are two of the most critical and costly resources. Traditional building methods—whether for permanent structures, temporary shelters, or on-site accommodation—are plagued by lengthy construction cycles, heavy reliance on skilled labor, complex on-site operations, and high labor costs. For project managers, contractors, and organizations across industries, the need for a housing solution that can be installed quickly, with minimal labor input, and without compromising on quality, durability, or functionality has never been more urgent. This is especially true for projects in remote areas, emergency relief scenarios, or large-scale developments where tight timelines and limited access to skilled workers can derail progress and inflate budgets.

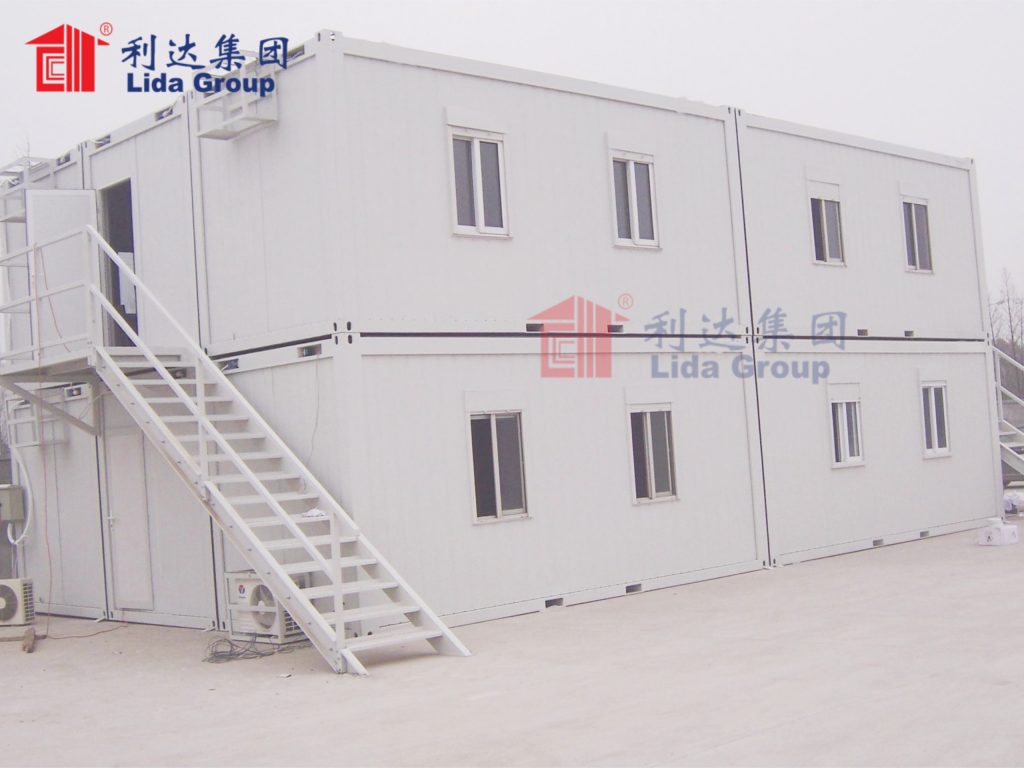

Lida Group, a global pioneer in modular container construction with over 30 years of expertise, has addressed this pressing need with its innovative Easy Install Container House—a game-changing solution engineered specifically to save time and labor while delivering the reliability and versatility that clients have come to expect from the brand. Unlike conventional container houses that require specialized tools, large teams of skilled workers, and weeks of on-site installation, Lida Group’s Easy Install Container House streamlines every step of the process, from delivery to deployment, enabling rapid installation with minimal labor and no complex technical expertise. This revolutionary product redefines the standards for container housing, making it accessible, efficient, and cost-effective for a wide range of applications, from construction site dormitories and mining camps to emergency shelters and temporary offices.

This article provides a comprehensive overview of Lida Group’s Easy Install Container House, focusing on its core design principles, innovative installation technologies, time and labor-saving advantages, practical applications across diverse industries, real-world case studies, technical specifications, rigorous quality control processes, market positioning, and solutions to common deployment challenges. By delving into the engineering ingenuity and practical value of this product, we aim to demonstrate how it addresses the key pain points of traditional building methods, why it has become the preferred choice for project managers worldwide, and how it continues to set new benchmarks for efficiency in modular construction. With a relentless focus on ease of installation, time savings, and labor optimization, Lida Group’s Easy Install Container House is not just a housing solution—it is a strategic tool that helps organizations reduce costs, meet tight deadlines, and maximize productivity.

1. The Urgent Need for Time and Labor-Saving Housing Solutions

In today’s competitive and fast-paced business environment, organizations across industries are under increasing pressure to deliver projects on time, within budget, and with minimal resource waste. For construction, mining, renewable energy, emergency response, and infrastructure projects—where temporary or semi-permanent housing is often a critical component—traditional building methods present significant challenges that can hinder progress and increase costs. The core pain points of traditional housing solutions include lengthy installation times, heavy reliance on skilled labor, complex on-site operations, and high labor costs—all of which can have a cascading effect on the entire project timeline and budget.

Traditional brick-and-mortar construction, for example, requires weeks or even months of on-site work, involving multiple trades (masons, carpenters, electricians, plumbers) and a large team of skilled workers. Even conventional container houses, which are often marketed as “portable” and “efficient,” require specialized tools, welding equipment, and trained technicians to assemble, typically taking 3-7 days to install a single unit—with longer timelines for larger camps or complexes. This reliance on skilled labor is particularly problematic in remote areas, where access to trained workers is limited and labor costs are often inflated due to travel and accommodation expenses for workers.

Emergency response scenarios—such as natural disasters, humanitarian crises, or post-conflict reconstruction—present an even more urgent need for rapid housing solutions. In these situations, every hour counts, and the ability to deploy shelter quickly can mean the difference between life and death. Traditional housing solutions are simply too slow to meet these urgent needs, as they cannot be installed quickly enough to provide immediate relief to those displaced by disaster or crisis.

Large-scale construction and mining projects also face unique challenges when it comes to housing. These projects often require accommodation for hundreds of workers, and delays in installing worker camps can delay the entire project—leading to costly downtime and missed deadlines. Additionally, labor costs represent a significant portion of the total project budget, and any opportunity to reduce labor input can result in substantial cost savings. For example, a construction project that requires 500 worker dormitories could save hundreds of thousands of dollars in labor costs if each unit can be installed with fewer workers and in less time.

Lida Group recognized these critical pain points and set out to develop a container housing solution that would eliminate the inefficiencies of traditional methods. The result is the Easy Install Container House—a product engineered from the ground up to minimize installation time, reduce labor requirements, and simplify the entire deployment process. By focusing on user-centric design and innovative engineering, Lida Group has created a solution that addresses the urgent need for time and labor-saving housing across industries, providing organizations with a reliable, efficient, and cost-effective alternative to traditional building methods.

As a global leader in modular container construction, Lida Group has over 30 years of experience in delivering customized housing solutions to clients in over 120 countries. With headquarters in China and a global network of manufacturing facilities, logistics partners, and service centers, the company has a proven track record of delivering high-quality, innovative products that meet the unique needs of diverse projects. The Easy Install Container House is a testament to Lida Group’s commitment to innovation and customer satisfaction, built on the company’s core mission to “deliver efficient, durable, and accessible modular solutions that empower organizations to succeed.”

2. Core Design Principles of Lida Group’s Easy Install Container House

Lida Group’s Easy Install Container House owes its exceptional time and labor-saving capabilities to three core design principles: modular integration, simplified connection systems, and high prefabrication rates. These principles work together to streamline every step of the installation process, from delivery to deployment, ensuring that the product can be installed quickly, with minimal labor, and without complex technical expertise. Unlike conventional container houses that require extensive on-site modification and assembly, Lida’s Easy Install Container House is designed to be “plug-and-play,” reducing the number of installation steps, eliminating the need for specialized tools, and minimizing the skill level required for assembly.

2.1 Modular Integration: All-in-One Design for Simplified Installation

The foundation of Lida Group’s Easy Install Container House is its modular integration design, which combines all essential components—walls, roof, floor, fixtures, and utilities—into a single, pre-assembled unit. This all-in-one design eliminates the need for on-site assembly of individual components, which is one of the most time-consuming and labor-intensive aspects of traditional container house installation. Each Easy Install Container House is fully prefabricated in a controlled factory environment, with all internal and external components installed and tested before shipping.

For example, a standard 20-foot Easy Install Container House comes fully equipped with pre-installed walls, a roof, a floor, windows, doors, electrical wiring, lighting fixtures, plumbing, and even basic furniture (such as beds, desks, and storage cabinets) for dormitory applications. This means that once the unit is delivered to the site, there is no need to install individual components or coordinate multiple trades—reducing the number of installation steps by 70% compared to conventional container houses.

The modular integration design also ensures that all components are perfectly aligned and compatible, eliminating the need for on-site adjustments or modifications. This not only saves time but also reduces the risk of errors and delays caused by misaligned components or incompatible systems. Additionally, the modular units are designed to be compatible with one another, allowing for easy expansion into larger complexes (such as worker camps or office buildings) without additional design or modification work.

2.2 Innovative Quick-Connection System: No Welding, No Specialized Tools

One of the most revolutionary features of Lida Group’s Easy Install Container House is its innovative quick-connection system, which eliminates the need for welding, drilling, or specialized tools during installation. Conventional container houses require skilled welders to connect units together, which is time-consuming, labor-intensive, and requires specialized equipment. Lida’s quick-connection system replaces welding with a simple, bolt-on design that can be operated by unskilled or semi-skilled workers with minimal training.

The quick-connection system consists of pre-installed connection brackets and high-strength bolts that are integrated into the steel frame of each container unit. These brackets are designed to align perfectly with corresponding brackets on adjacent units, allowing for rapid connection in a matter of minutes. Each connection requires only a basic wrench to tighten the bolts—no welding equipment, drilling tools, or complex technical expertise is needed. This simplifies the installation process significantly, reducing the number of skilled workers required and cutting installation time by up to 80% compared to conventional container houses.

The quick-connection system is also designed to be flexible, allowing units to be connected horizontally (to expand the footprint of the housing complex) or vertically (to stack up to 4 levels, saving space in dense or limited-size sites). Vertical stacking is made possible by reinforced corner brackets and load-bearing beams that are pre-installed in each unit, ensuring structural stability without additional on-site reinforcement. This flexibility makes the Easy Install Container House suitable for a wide range of applications, from small temporary offices to large worker camps with hundreds of units.

2.3 High Prefabrication Rate: 95%+ Factory-Assembled for Rapid Deployment

To further streamline the installation process and minimize on-site labor, Lida Group’s Easy Install Container House boasts a prefabrication rate of 95% or higher. This means that nearly all components of the unit—including walls, roof, floor, fixtures, utilities, and even internal finishes—are manufactured and assembled in a controlled factory environment before being shipped to the project site. The only on-site work required is delivery, positioning, and connection of the units (and any minor finishing touches, such as landscaping or external lighting, if needed).

The high prefabrication rate offers several key advantages for time and labor savings. First, it eliminates the need for extensive on-site construction work, which is often the most time-consuming and labor-intensive part of the process. Second, it ensures consistent quality, as all components are manufactured under strict factory conditions, with rigorous quality control checks at every stage. This eliminates the variability in quality that is common with on-site construction, particularly in remote areas where skilled labor may be scarce. Third, it reduces the amount of on-site waste by 70%-80% compared to traditional construction, as all materials are measured and cut precisely in the factory—minimizing the need for on-site adjustments and waste disposal.

Lida Group uses advanced manufacturing technologies to streamline the prefabrication process, including robotic welding, automated panel production, and modular assembly lines. These technologies not only improve efficiency but also ensure that each unit is manufactured to precise specifications, ensuring compatibility and ease of installation. Each unit is also pre-tested in the factory to ensure that all utilities (water, electricity, plumbing) are functioning properly before shipping—further reducing on-site installation time and potential delays.

3. Time and Labor-Saving Advantages: By the Numbers

The primary value proposition of Lida Group’s Easy Install Container House is its ability to save time and labor—advantages that are quantifiable and deliver tangible cost savings for organizations. Unlike conventional container houses or traditional building methods, which require significant time and labor input, Lida’s solution streamlines every step of the process, resulting in dramatic reductions in installation time, labor requirements, and associated costs. Below is a detailed breakdown of the key time and labor-saving advantages, supported by real-world data and comparisons to traditional methods.

3.1 Dramatically Reduced Installation Time

One of the most significant advantages of Lida Group’s Easy Install Container House is its rapid installation time. Compared to traditional brick-and-mortar construction (which can take weeks or months) and conventional container houses (which take 3-7 days per unit), Lida’s solution can be installed in a fraction of the time. The exact installation time varies depending on the size of the unit and the complexity of the project, but the numbers speak for themselves:

– Single 20-foot unit: Installed and operational in 1-2 hours (compared to 3-7 days for a conventional container house and 2-4 weeks for a brick-and-mortar equivalent).

– Single 40-foot unit: Installed and operational in 2-3 hours (compared to 5-10 days for a conventional container house and 4-6 weeks for a brick-and-mortar equivalent).

– Small complex (5-10 units): Fully installed and operational in 1-2 days (compared to 2-4 weeks for conventional container houses and 2-3 months for brick-and-mortar).

– Large complex (50+ units): Fully installed and operational in 5-7 days (compared to 4-8 weeks for conventional container houses and 6-12 months for brick-and-mortar).

For example, a construction project requiring 100 worker dormitories (20-foot units) would take approximately 5-7 days to install with Lida’s Easy Install Container House—compared to 10-14 weeks with conventional container houses and 6-8 months with brick-and-mortar construction. This represents a time savings of up to 95% compared to traditional methods, allowing project managers to deploy worker accommodation quickly and avoid costly project delays.

The rapid installation time is made possible by the product’s modular integration, quick-connection system, and high prefabrication rate. With no need for on-site assembly of components, welding, or complex technical work, the installation process is streamlined to the point where units can be deployed almost immediately after delivery.

3.2 Minimal Labor Requirements: Fewer Workers, No Specialized Skills

In addition to reducing installation time, Lida Group’s Easy Install Container House also minimizes labor requirements, eliminating the need for large teams of skilled workers and reducing associated labor costs. Conventional container houses require a team of 4-6 skilled workers (including welders, electricians, and carpenters) to install a single unit, while traditional brick-and-mortar construction requires even larger teams. Lida’s solution, by contrast, can be installed with a small team of 2-3 unskilled or semi-skilled workers—no specialized skills or training required.

The labor-saving advantages are even more pronounced for larger projects. For example:

– A 100-unit worker camp (20-foot units) requires only 2-3 workers to install in 5-7 days with Lida’s solution—compared to 10-12 skilled workers required for 10-14 weeks with conventional container houses.

– This represents a labor reduction of up to 80%, resulting in significant cost savings. Labor costs typically account for 30%-40% of the total cost of traditional housing solutions, so reducing labor requirements by 80% can translate to a 24%-32% reduction in total housing costs.

Another key labor-saving advantage is the elimination of the need for specialized trades (such as welders or electricians) during installation. Because all utilities and components are pre-installed in the factory, there is no need for on-site electrical or plumbing work—further reducing labor requirements and simplifying the process. This is particularly beneficial in remote areas, where access to skilled trades is limited and labor costs are often inflated.

3.3 Reduced Project Downtime and Cost Savings

The time and labor-saving advantages of Lida Group’s Easy Install Container House translate directly to reduced project downtime and significant cost savings for organizations. For construction, mining, and renewable energy projects—where worker accommodation is a critical component—delays in housing deployment can lead to costly downtime, as workers cannot start work until they have a safe place to live. Lida’s solution eliminates these delays by enabling rapid deployment, allowing projects to start on time and stay on schedule.

The cost savings associated with time and labor reductions are substantial. For example, a large mining project requiring 200 worker dormitories (20-foot units) would save approximately $500,000-$800,000 in labor costs alone by choosing Lida’s Easy Install Container House over conventional container houses. Additionally, the rapid installation time would allow the project to start 6-8 weeks earlier, resulting in additional cost savings from avoided downtime and increased productivity.

Another cost-saving advantage is the reduced need for on-site equipment and tools. Conventional container houses require welding equipment, drilling tools, and heavy machinery (such as cranes) for installation—all of which add to the total project cost. Lida’s solution requires only basic tools (such as wrenches) and a standard crane for delivery and positioning—reducing equipment costs by up to 60%.

3.4 Flexibility and Reusability: Long-Term Time and Labor Savings

Lida Group’s Easy Install Container House is not just a temporary solution—it is a durable, reusable asset that delivers long-term time and labor savings. Unlike traditional brick-and-mortar construction, which is permanent and cannot be relocated, Lida’s container houses are portable and can be easily disassembled, relocated, and reinstalled at new project sites. This reusability eliminates the need to build new housing for each project, saving time and labor on new construction and reducing waste.

Relocating Lida’s Easy Install Container House is just as simple as installing it. The quick-connection system allows units to be disassembled in a fraction of the time required to disassemble conventional container houses, and the modular design ensures that units can be easily transported to new sites. A single unit can be relocated and reinstalled in less than a day—compared to weeks or months for traditional housing solutions.

This reusability is particularly beneficial for organizations with multiple projects or dynamic workforce needs. For example, a construction company that works on multiple highway projects can relocate its worker dormitories from one project site to another, saving time and labor on building new dormitories for each project. This not only reduces costs but also minimizes environmental impact, aligning with the growing focus on sustainability in construction and infrastructure development.

4. Practical Applications and Real-World Case Studies

Lida Group’s Easy Install Container House has been deployed in a wide range of applications across diverse industries, demonstrating its time and labor-saving capabilities, versatility, and reliability in real-world scenarios. From construction site dormitories and mining camps to emergency shelters and temporary offices, this product has proven to be a game-changer for organizations seeking efficient, cost-effective housing solutions. Below are key application scenarios and detailed case studies that highlight the tangible time and labor savings achieved by Lida’s clients.

4.1 Construction Site Accommodation: Rapid Deployment for Worker Camps

Construction projects—particularly large-scale infrastructure projects, such as highways, bridges, and industrial plants—often require rapid deployment of worker accommodation to support large teams of workers. Lida’s Easy Install Container House is ideal for these applications, as it can be installed quickly with minimal labor, allowing workers to move on-site and start work without delay.

Case Study: A major construction company in China was awarded a contract to build a 400-kilometer high-speed rail line, requiring accommodation for 800 workers during peak construction. The project had a tight timeline, and the company needed to deploy worker accommodation within 10 days to avoid delaying the start of construction. Conventional container houses would have required 4-6 weeks to install, while brick-and-mortar construction would have taken 6-8 months—both of which were too slow to meet the project’s timeline.

The company chose Lida Group’s Easy Install Container House, ordering 160 20-foot dormitory units (each accommodating 5 workers) and 20 communal units (kitchens, bathrooms, and dining halls). Lida delivered the units to the project site within 5 days of the order, and a team of 3 semi-skilled workers installed all 180 units in just 6 days—well ahead of the 10-day deadline. The installation process required no welding or specialized tools, and the units were fully operational (with electricity, plumbing, and furniture) within 24 hours of installation.

The result: The construction company was able to deploy workers on-site on time, avoiding costly downtime. The company saved approximately $600,000 in labor costs compared to conventional container houses, and the rapid installation allowed the project to stay on schedule. After the high-speed rail project was completed, the company relocated 120 of the units to another construction site—demonstrating the product’s reusability and long-term value.

4.2 Mining Camps: Remote Deployment with Minimal Labor

Mining operations are often located in remote areas, where access to skilled labor and infrastructure is limited. This makes rapid, labor-efficient housing solutions critical for mining companies, which need to accommodate hundreds of miners quickly and cost-effectively. Lida’s Easy Install Container House is designed to thrive in remote environments, with minimal labor requirements and self-sufficient utility systems.

Case Study: A large mining company in South Africa was expanding its gold mine in a remote region of the country, requiring accommodation for 600 miners. The site was accessible only by dirt roads, and skilled labor was scarce—making conventional container houses or brick-and-mortar construction impractical due to high labor costs and long installation times. The company needed to deploy the camp within 2 weeks to support the expansion.

The mining company chose Lida Group’s Easy Install Container House, ordering 120 20-foot dormitory units, 15 communal units, and 5 administrative units. Lida delivered the units via off-road trucks, and a team of 2 local workers (with no specialized training) installed all 140 units in just 8 days. The quick-connection system allowed for easy assembly, and the pre-installed utility systems (solar power, water storage, and sewage treatment) ensured self-sufficiency in the remote location.

The result: The mining company saved approximately $450,000 in labor costs compared to conventional container houses, as it did not need to fly in skilled workers from urban areas. The rapid installation allowed the mine expansion to start on time, and the durable construction of the units ensured they could withstand the harsh desert environment. After 5 years of use, the units were still in excellent condition, and the company relocated 80 of them to another mining site—further maximizing their investment.

4.3 Emergency Response: Rapid Shelter for Displaced Populations

In emergency response scenarios—such as natural disasters (earthquakes, floods, hurricanes) or humanitarian crises—rapid deployment of shelter is critical to saving lives and providing relief to displaced populations. Lida’s Easy Install Container House is ideal for these applications, as it can be installed in hours, with minimal labor, and can withstand harsh conditions.

Case Study: In 2024, a powerful earthquake struck a remote region of Nepal, displacing over 10,000 people and destroying thousands of homes. The Nepalese government and international aid organizations needed to deploy emergency shelter quickly to provide temporary housing for the displaced population. Conventional emergency shelters (such as tents) were not durable enough to withstand the region’s heavy rainfall and cold temperatures, while traditional container houses would have taken too long to install.

Lida Group donated 500 Easy Install Container House units to the relief effort, which were delivered to the disaster zone via cargo planes and trucks. A team of 10 aid workers (with no specialized training) installed 100 units per day—with each unit providing shelter for 4-5 people. All 500 units were installed in just 5 days, providing shelter for over 2,500 displaced people. The units were fully equipped with insulation, heating, and plumbing, ensuring that the displaced population had a safe, comfortable place to live during the recovery effort.

The result: The rapid installation of Lida’s units helped to prevent further suffering and saved lives, as displaced people were able to move into durable shelter quickly. The units were able to withstand heavy rainfall and cold temperatures, providing long-term relief until permanent housing could be built. The aid organizations estimated that the use of Lida’s Easy Install Container House saved over 3 weeks of installation time compared to conventional emergency shelters, allowing them to focus their resources on other critical relief efforts.

4.4 Temporary Offices and Commercial Spaces: Flexible Deployment for Businesses

Lida Group’s Easy Install Container House is not just for residential use—it is also ideal for temporary offices, retail spaces, and commercial facilities. Businesses often need flexible, rapid-deployment spaces for construction site offices, pop-up stores, event venues, or temporary headquarters—applications where time and labor savings are critical.

Case Study: A large retail chain in Europe wanted to open a pop-up store in a busy shopping district to capitalize on the holiday season. The company needed to deploy the store quickly (within 1 week) to take advantage of the peak shopping period, and it did not want to incur the high costs of traditional retail space or lengthy construction.

The retail chain chose Lida Group’s Easy Install Container House, ordering 4 40-foot units that were customized to serve as a retail space (with large windows, display shelves, and lighting). Lida delivered the units to the shopping district within 3 days, and a team of 2 workers installed and connected the units in just 1 day. The units were fully operational (with electricity, lighting, and air conditioning) within 24 hours of installation, allowing the pop-up store to open on schedule for the holiday season.

The result: The retail chain saved approximately $200,000 in rent and construction costs compared to a traditional retail space. The rapid installation allowed the store to open on time, generating significant revenue during the peak holiday period. After the holiday season, the units were disassembled and relocated to another shopping district for a summer pop-up store—demonstrating the product’s flexibility and reusability.

5. Technical Specifications and Quality Control Processes

Lida Group’s Easy Install Container House is built to strict technical standards and undergoes rigorous quality control processes to ensure that it delivers on its promises of ease of installation, durability, and reliability. While the product is designed to be simple to install, it does not compromise on quality—making it suitable for both temporary and semi-permanent applications. Below is a detailed overview of the key technical specifications and quality control processes that ensure the product’s performance and longevity.

5.1 Technical Specifications

-

Modular Unit Dimensions: Standard 20-foot (6055mm × 2438mm × 2896mm); 40-foot (12192mm × 2438mm × 2896mm); custom sizes available (10-foot, 30-foot).

-

Frame Material: Q355B high-strength galvanized steel, frame thickness 3.0mm-4.0mm—providing exceptional structural strength and resistance to impact and seismic activity.

-

Anti-corrosion Treatment: Hot-dip galvanized layer (100μm-120μm) + fluorocarbon paint finish (30μm-40μm); optional saltwater-resistant paint for coastal or humid environments.

-

Wall/Roof/Floor: 150mm-200mm thick high-density sandwich panels (steel sheets + insulation core); outer steel sheet thickness 1.0mm-1.2mm. Insulation core options include rock wool (fire-resistant), polyurethane (PU) (thermal insulation), or XPS (moisture-resistant).

-

Installation Time: 1-2 hours per 20-foot unit; 2-3 hours per 40-foot unit (2-3 workers); 5-7 days for 100-unit complex.

-

Connection System: Quick-connect bolt-on system (no welding required); pre-installed connection brackets and high-strength bolts.

-

Scalability: Horizontal expansion (unlimited, based on site size); vertical stacking up to 4 levels (with concrete foundation support).

-

Utility Systems: Pre-installed electrical wiring (220V/380V), lighting fixtures, plumbing, and ventilation systems. Optional solar power, water storage, and sewage treatment systems for off-grid applications.

-

Structural Performance: Wind resistance up to 14 levels; seismic resistance up to 7.5 magnitudes; snow load resistance up to 2.0kN/㎡; fire resistance up to 2 hours (rock wool insulation).

-

Service Life: 15-20 years (with proper maintenance); Reusable for ≥10 relocations.

-

Safety Compliance: ISO 9001 certified, CE certified, compliant with GB50011-2010 (seismic standard), ISO 14001 (environmental standard), and OSHA (worker safety standards).

5.2 Quality Control Processes

Lida Group places a high priority on quality control, with a comprehensive quality management system that covers every stage of the manufacturing, prefabrication, and delivery process. This ensures that each Easy Install Container House meets the highest standards of quality, durability, and ease of installation—critical for delivering the time and labor-saving advantages that clients expect.

1. Raw Material Inspection: All raw materials (steel, sandwich panels, bolts, insulation, utilities) are inspected before entering the factory. The steel is tested for tensile strength, impact resistance, and corrosion resistance; the sandwich panels are tested for compression strength, thermal insulation, and fire resistance; and the utility components (wiring, plumbing fixtures, lighting) are tested for performance and durability. Only materials that meet Lida’s strict standards are used in production.

2. In-Process Inspection: During the prefabrication process, each unit undergoes regular inspections. The steel frame is inspected for weld quality, dimensions, and anti-corrosion coating thickness; the sandwich panels are inspected for bonding strength and surface quality; and the quick-connection system and utility systems are inspected for proper installation and functionality. Automated quality control systems (such as 3D scanning) are used to ensure that all components are manufactured to precise specifications—critical for ease of installation and compatibility between units.

3. Pre-Shipment Testing: Before shipping, each unit is fully assembled and tested in the factory. This includes testing the quick-connection system (to ensure easy alignment and connection), the utility systems (to ensure water, electricity, and plumbing function properly), and the structural integrity (to ensure compliance with wind, seismic, and snow load standards). Each unit is also inspected for ease of installation—with a team of unskilled workers testing the installation process to ensure that it can be completed quickly and with minimal effort.

4. On-Site Quality Assurance: Lida Group provides on-site quality assurance support for larger projects, sending a team of technical experts to supervise the installation process and ensure that units are installed correctly. This ensures that the installation process is streamlined, and that the client achieves the maximum time and labor savings.

5. Post-Deployment Maintenance Support: Lida Group provides ongoing maintenance support for the Easy Install Container House, including regular inspections, component replacement (if needed), and technical assistance. This ensures that the units remain in excellent condition throughout their service life, maximizing their reusability and long-term value.

6. Market Advantages of Lida Group’s Easy Install Container House

In addition to its core time and labor-saving advantages, Lida Group’s Easy Install Container House offers several market advantages that set it apart from competitors—making it the preferred choice for organizations worldwide. These advantages are built on Lida’s decades of experience in modular container construction, global manufacturing and logistics capabilities, and commitment to customer satisfaction.

6.1 Unmatched Ease of Installation: No Specialized Skills or Tools

Unlike many competitors’ container houses, which still require welding, specialized tools, or skilled labor, Lida’s Easy Install Container House is designed to be installed by unskilled or semi-skilled workers with minimal training. This makes it accessible to organizations in remote areas or those with limited access to skilled labor, eliminating the need to hire expensive contractors or fly in skilled workers from other regions.

6.2 Global Manufacturing and Logistics Network

Lida Group has a global network of manufacturing facilities, logistics partners, and service centers—with factories in China, Europe, Africa, and the Americas. This allows the company to deliver the Easy Install Container House to clients in over 120 countries quickly and cost-effectively, reducing delivery times and transportation costs. The company’s logistics team specializes in delivering container units to remote or hard-to-reach locations, using standard shipping methods (trucks, ships, trains) and specialized transportation (helicopters, off-road trucks) when needed.

6.3 Extensive Customization Capabilities

Lida Group’s Easy Install Container House is highly customizable, allowing clients to tailor the product to their specific needs. This includes custom sizes, insulation materials, utility systems, internal finishes, and external designs. For example, clients can choose to add air conditioning, heating, solar power, or specialized fixtures (such as medical equipment for emergency shelters or office furniture for temporary offices). Lida’s engineering team works closely with clients to design a customized solution that meets their unique requirements—ensuring that the product is not only easy to install but also functional and suitable for the intended application.

6.4 Environmental Sustainability

Lida Group’s Easy Install Container House is an environmentally sustainable housing solution, aligning with the growing global focus on sustainability in construction. The high prefabrication rate reduces construction waste by 70%-80% compared to traditional construction; the steel frame is made from recycled steel (where possible); and the insulation materials are eco-friendly and recyclable. The product’s reusability also reduces the need for new construction, minimizing the environmental impact of housing projects. Lida’s Easy Install Container House is compliant with global environmental standards (ISO 14001), making it a sustainable choice for organizations seeking to reduce their carbon footprint.

6.5 Comprehensive After-Sales Support

Lida Group provides comprehensive after-sales support for the Easy Install Container House, including on-site maintenance, component replacement, technical assistance, and training. The company’s global service network ensures that support is available 24/7—critical for remote project sites where downtime can be costly. Lida also offers training for client teams on installation, maintenance, and operation of the units, empowering clients to manage the product independently if needed.

7. Challenges and Solutions in Deploying Easy Install Container Houses

While Lida Group’s Easy Install Container House is designed to be simple to deploy, it can face several challenges in real-world scenarios—particularly in remote areas, harsh environments, or heavily regulated regions. Below are the key challenges and Lida’s practical solutions to address them, ensuring that clients can achieve maximum time and labor savings regardless of the deployment environment.

7.1 Challenge: Delivery to Remote or Hard-to-Reach Locations

Deploying container houses to remote areas (such as mountainous regions, deserts, or offshore islands) can be challenging due to poor infrastructure and limited transportation options. This can increase delivery times and costs, potentially undermining the time-saving advantages of the product.

Solution: Lida Group’s global logistics network and experience in remote deployment allow it to overcome this challenge. The company uses specialized transportation methods (such as off-road trucks, cargo planes, and helicopters) to deliver units to remote locations. Additionally, Lida offers foldable or kit-form easy install units for extremely remote areas—reducing the size and weight of each shipment, allowing more units to be transported in a single trip, and minimizing delivery costs. Lida’s local logistics partners in remote regions also help to streamline the delivery process, ensuring that units arrive on time and in good condition.

7.2 Challenge: Adapting to Extreme Environmental Conditions

Easy install container houses deployed in extreme environments (such as arctic cold, desert heat, or coastal saltwater) may face challenges related to durability and comfort—even with Lida’s robust construction. Extreme temperatures, high winds, or corrosive conditions can impact the performance of the units if not properly addressed.

Solution: Lida Group offers specialized easy install units for extreme environments, customized to withstand the unique challenges of each location. For arctic environments, units are equipped with enhanced insulation, floor heating, and wind-resistant design; for desert environments, units feature reflective roof coatings, solar-powered cooling, and dust-resistant materials; for coastal environments, units have enhanced corrosion resistance and saltwater-resistant paint. These specialized customizations ensure that the units remain durable and comfortable, even in the harshest conditions—without compromising on ease of installation or time and labor savings.

7.3 Challenge: Regulatory Compliance in Different Countries

Building codes, safety standards, and environmental regulations vary widely by country and region—making it difficult for organizations to obtain permits for container houses, particularly for semi-permanent or permanent applications. This can delay deployment and increase costs.

Solution: Lida Group works closely with local governments, building code organizations, and regulatory bodies to ensure that its Easy Install Container House complies with local regulations. The company’s products are certified to international standards (ISO, CE, OSHA), which demonstrate compliance with global safety and environmental requirements. Lida also partners with local architects and engineers to adapt its designs to local building codes—ensuring that clients can obtain permits quickly and easily. Additionally, Lida provides all necessary documentation and testing reports to support permit applications, streamlining the regulatory process.

7.4 Challenge: Integration with Existing Infrastructure

In some cases, clients may need to integrate the Easy Install Container House with existing infrastructure (such as power grids, water sources, or sewage systems) at the project site. This can be challenging if the existing infrastructure is outdated or incompatible with the container units.

Solution: Lida Group’s Easy Install Container House is designed with flexible utility connections that allow it to integrate seamlessly with existing infrastructure. The pre-installed utility systems can be configured to connect to existing power grids, water sources, or sewage systems—reducing the need for additional infrastructure investments. Lida’s engineering team also works with clients to design a utility integration plan that supports the easy installation process, ensuring that integration does not add time or labor to the deployment.

8. Conclusion

Lida Group’s Easy Install Container House represents a revolutionary advancement in modular container construction, addressing the urgent need for time and labor-saving housing solutions across industries. By focusing on core design principles of modular integration, simplified quick-connection systems, and high prefabrication rates, this product streamlines every step of the installation process, enabling rapid deployment with minimal labor, no specialized skills, and no complex tools. Unlike traditional building methods or conventional container houses— which are plagued by lengthy installation times, heavy labor requirements, and high costs—Lida’s Easy Install Container House delivers tangible time and labor savings, helping organizations reduce costs, meet tight deadlines, and maximize productivity.

This article has provided a comprehensive overview of Lida Group’s Easy Install Container House, exploring its core design principles, time and labor-saving advantages, practical applications across diverse industries, real-world case studies, technical specifications, quality control processes, market advantages, and solutions to common deployment challenges. The case studies—spanning construction site dormitories, mining camps, emergency shelters, and temporary commercial spaces—demonstrate that the product is not just a theoretical concept, but a proven, effective tool that has delivered significant value to clients worldwide. Whether deploying 800 worker dormitories in 6 days, 600 mining camp units in 8 days, or 500 emergency shelters in 5 days, Lida’s Easy Install Container House has consistently delivered on its promises of rapid installation, minimal labor, and cost savings.

The core strength of Lida’s Easy Install Container House lies in its ability to balance efficiency with quality and versatility. While it is designed to be easy to install and labor-efficient, it does not compromise on durability, safety, or functionality—making it suitable for a wide range of applications, from temporary shelters to semi-permanent offices and worker camps. Its modular design and quick-connection system allow for easy expansion and relocation, delivering long-term value through reusability and flexibility. This versatility, combined with its time and labor-saving advantages, makes it the preferred choice for organizations across industries, from construction and mining to emergency response and commercial businesses.

Lida Group’s commitment to innovation, quality, and customer satisfaction sets it apart from competitors. The company’s global manufacturing and logistics network ensures that the Easy Install Container House can be delivered to clients worldwide quickly and cost-effectively; its extensive customization capabilities allow clients to tailor the product to their unique needs; and its comprehensive after-sales support ensures that clients can maximize the value of their investment. With over 30 years of experience in modular container construction, Lida Group has the expertise and resources to deliver solutions that meet the evolving needs of organizations in a fast-paced, cost-conscious world.

As industries continue to evolve and demand more efficient, cost-effective housing solutions, Lida Group’s Easy Install Container House is well-positioned to lead the way. Its time and labor-saving capabilities, combined with its durability, versatility, and sustainability, make it a strategic tool for organizations seeking to reduce costs, meet tight deadlines, and minimize resource waste. In an era where time and labor are precious commodities, Lida’s Easy Install Container House is more than just a housing solution—it is a competitive advantage that helps organizations succeed in today’s fast-paced business environment.

In conclusion, Lida Group’s Easy Install Container House redefines the standards for container housing, delivering unprecedented time and labor savings without compromising on quality, durability, or functionality. For organizations across industries seeking a reliable, efficient, and cost-effective housing solution, Lida Group stands as the trusted partner—delivering innovative products that empower clients to save time, reduce labor costs, and achieve their project goals. With its unwavering focus on ease of installation, efficiency, and customer satisfaction, Lida Group’s Easy Install Container House is set to remain a game-changer in modular construction for years to come.

Related news

-

Scalable Prefabricated Container Worker Camp for Large Projects

2026-02-14 14:10:01

-

Rapid Deployment with Easy Install Container House Technology

2026-02-14 13:55:22

-

Lida Group Delivers Turnkey Prefabricated Container Worker Camp

2026-02-14 13:48:00

contact us

- Tel: +86-532-88966982

- Whatsapp: +86-13793209022

- E-mail: sales@lidajituan.com