Lida Group’s Cost-Effective Prefab House Balances Quality & Value

2026-Jan-22 17:51:36

By Admin

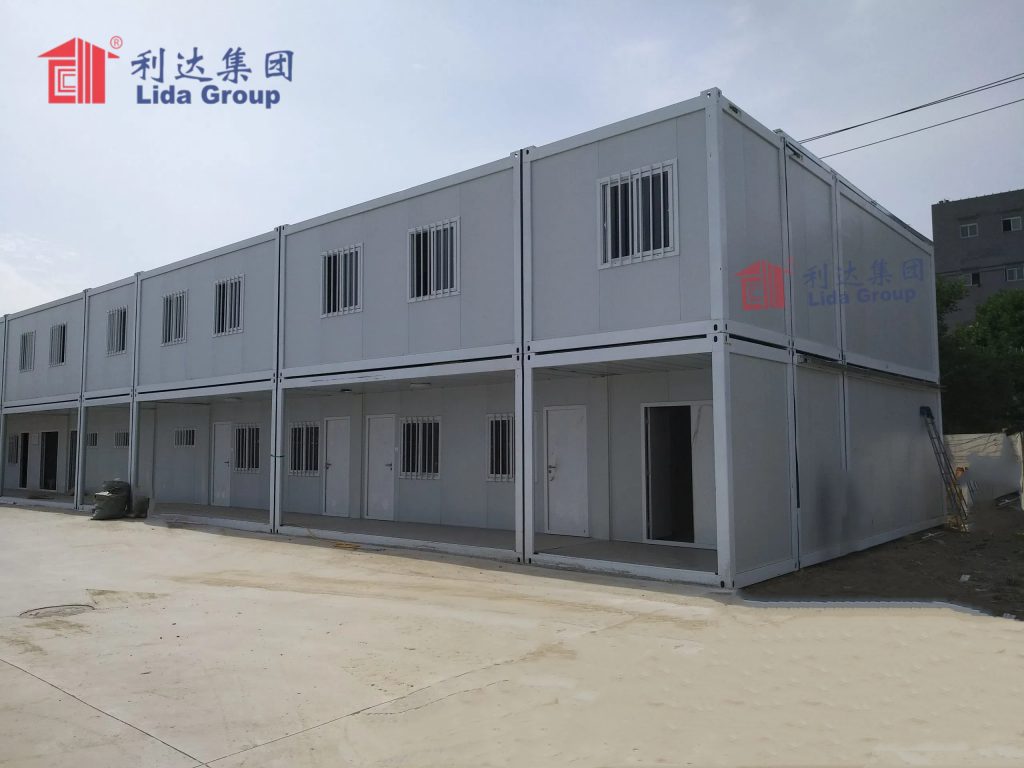

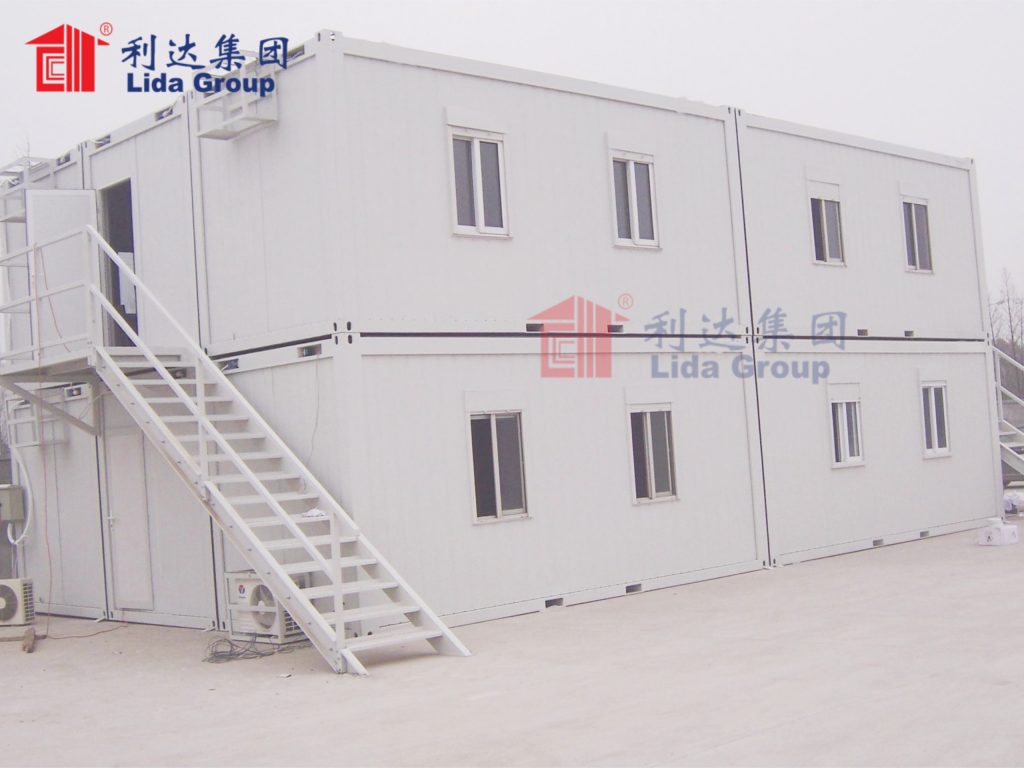

In the global construction industry, where cost pressures, quality demands, and sustainability goals often stand in tension, Lida Group has carved a unique niche by mastering the art of balancing cost-effectiveness, uncompromising quality, and long-term value in its prefabricated (prefab) house solutions. With over three decades of expertise in modular construction, the company has shattered the misconception that affordable prefab housing must sacrifice durability, safety, or livability. Instead, Lida Group integrates precision engineering, streamlined production processes, and customer-centric design to deliver prefab houses that meet rigorous quality standards while optimizing costs at every stage—from factory fabrication to on-site assembly and lifecycle maintenance. Serving clients across 152 countries, from governments and developers to nonprofits and enterprises, Lida’s prefab solutions adapt to diverse scenarios, including urban affordable housing, rural revitalization, infrastructure camps, and emergency shelters, all while delivering tangible value beyond upfront savings. This article explores how Lida Group achieves this delicate balance, details the quality control systems and cost-optimization strategies that underpin its success, showcases real-world projects, and analyzes the company’s impact on the global prefab market, demonstrating why it stands as a model for merging quality, cost, and value.

1. Market Context: The Growing Demand for Balanced Prefab Solutions

The global prefab housing market is experiencing robust growth, driven by a universal quest for solutions that reconcile cost efficiency with quality performance. Industry data indicates the global residential container market reached 914.96 billion yuan in 2025 and is projected to surpass 1751 billion yuan by 2032, with a compound annual growth rate (CAGR) of 9.72% . In China alone, the container house market scaled to 128.6 billion yuan in 2024 and is expected to grow to 150.2 billion yuan in 2025, a year-on-year increase of 16.8% . This growth is not merely quantitative but reflects a critical market shift: clients are no longer willing to choose between affordability and quality—they demand both, along with long-term value that extends beyond initial construction costs.

1.1 Industry Pain Points: The Quality-Cost-Value Triangle

Traditional construction and low-end prefab solutions often fail to balance the three pillars of the quality-cost-value triangle. On one end, conventional brick-and-mortar buildings deliver durability but suffer from prolonged timelines (12-18 months for mid-rise projects), high labor costs, and material waste (15-20%), inflating total ownership expenses . On the other end, budget prefab houses cut costs through shoddy materials, simplified structures, and minimal quality control, leading to frequent maintenance, safety risks, and shortened lifespans—ultimately eroding value. Additionally, the global skilled labor shortage (a deficit of over 10 million workers) exacerbates these challenges, as limited expertise drives up costs for quality craftsmanship while compromising consistency . Lida Group addresses these pain points by reengineering the prefab lifecycle to eliminate inefficiencies without compromising quality, creating a sustainable balance that delivers lasting value.

1.2 Policy Drivers for Balanced Prefab Adoption

Governments worldwide are reinforcing the demand for balanced prefab solutions through policies that prioritize both affordability and quality. China’s 14th Five-Year Plan for Construction Industry Development mandates that prefabricated buildings account for over 30% of new constructions by 2025, with the central government allocating 38.7 billion yuan in 2024 to support high-quality, cost-effective container-based housing . Local policies further incentivize this balance: Guangdong Province requires 100% of temporary housing for large infrastructure projects to use container systems that meet strict seismic and fire safety standards, while Jiangsu Province offers subsidies of 300 yuan per square meter for prefab buildings that achieve both cost targets and quality certifications . In the European Union, the Green Deal funds modular construction solutions that merge energy efficiency (a quality metric) with cost savings, and the U.S. Federal Emergency Management Agency (FEMA) prioritizes prefab units that deliver rapid deployment, durability, and affordability for disaster relief. These policies create a favorable ecosystem for Lida Group’s balanced approach.

2. Lida Group’s Core Strategy: Balancing Quality, Cost, and Value

Lida Group’s success stems from a holistic strategy that embeds quality into every cost-optimization measure and aligns both with long-term value creation. This strategy is built on three integrated pillars: precision quality control systems, lean cost-optimization processes, and value-centric design—each reinforcing the others to avoid trade-offs.

2.1 Precision Quality Control: Building Durability into Every Component

Quality is non-negotiable for Lida Group, and the company has established a multi-layered quality control (QC) system that spans from raw material sourcing to post-installation monitoring. This system ensures that every prefab house meets or exceeds global standards, including ISO, CE, TÜV, and GB 8624-2012 (A-class fire resistance), while remaining cost-competitive.

At the sourcing stage, Lida implements strict material validation protocols. The company’s steel frames—crafted from Q235 galvanized steel with a 40 g/m² zinc coating—undergo tensile strength, corrosion resistance, and durability testing, ensuring a service life of over 20 years with minimal maintenance . Recycled steel (accounting for 65% of frame materials) is rigorously inspected to match the performance of virgin steel, balancing sustainability, cost savings, and quality. Insulation materials, including 75mm rock wool (for high-performance projects) and 50mm fiberglass (for cost-sensitive applications), are tested for thermal conductivity (0.038 W/(m·K) for fiberglass) and fire resistance, ensuring energy efficiency without compromising safety.

Factory production integrates automated QC technologies to maintain consistency. Lida’s six smart factories use robotic welding (with precision tolerance of ±0.5mm), digital twin simulation, and 3D-printed custom components to eliminate human error . Each module undergoes 12 rigorous inspections before shipment, including structural load testing, waterproofing checks (IP65-level certification), and electrical system validation. For example, wall panels are pressure-tested to ensure they withstand level 12 wind resistance (220 km/h) and grade 8 seismic activity, meeting global safety standards for diverse climates and geographies.

Post-installation, Lida provides a comprehensive quality assurance package, including a 10-year structural warranty and 5-year warranty on mechanical systems. The company also deploys IoT sensors in select projects to monitor structural integrity, temperature, and humidity in real time, enabling proactive maintenance and extending the building’s lifespan—further enhancing long-term value.

2.2 Lean Cost-Optimization: Cutting Waste, Not Quality

Lida Group’s cost-effectiveness is rooted in lean principles that eliminate waste across the prefab lifecycle, rather than reducing quality. The company leverages scale, standardization, and process efficiency to drive down costs while preserving durability and performance.

规模化生产 (Scale Production) is a cornerstone of Lida’s cost strategy. With eight steel structure manufacturing lines and an annual capacity of 24,000 prefab units, the company achieves economies of scale in material procurement (securing 15-25% lower costs from suppliers) and production . Standardized modular designs (20ft, 40ft, and custom sizes) reduce研发 (R&D) costs and enable mass production of components, while interchangeability simplifies inventory management and reduces waste from custom fabrication.

Factory-integrated prefabrication shifts 90% of construction work to controlled environments, eliminating weather delays, on-site waste (reduced to 3% vs. 15-20% in traditional construction), and rework . Automated production lines cut labor costs by 40% compared to on-site construction, and the “parallel workflow” model—where modules are fabricated in factories while on-site foundations are prepared—shortens project timelines by 60-70%, reducing financing and overhead costs for clients.

Logistics optimization further reduces costs. Lida’s modular units are designed for compact transportation: standard 20ft units can be stacked 4-6 per 40ft shipping container, and folding models (such as the LD-CH-016) can be stacked 10 units per container, cutting logistics costs by 50% . Lightweight components (2.5-3 tons per 20ft unit) enable delivery to remote areas with limited infrastructure, avoiding the high costs of specialized transportation.

Customization without excess is another key cost-saving measure. Lida offers modular customization (e.g., adjusting room layouts, adding fixtures) using pre-engineered components, avoiding the high costs of fully custom designs. Clients can choose from predefined packages tailored to their needs—from basic rural housing to luxury urban apartments—ensuring they pay only for the features they require, without compromising quality.

2.3 Value-Centric Design: Beyond Cost and Quality

Lida Group defines value broadly, encompassing not just upfront cost savings and quality, but also usability, adaptability, sustainability, and long-term operational efficiency. The company’s prefab houses are designed to deliver value across their entire lifecycle, making them a smart investment for clients.

Adaptability is a core value driver. Lida’s modular designs allow for horizontal and vertical expansion, enabling clients to scale their buildings as needs change—from a single-family home to a multi-unit complex, or from a construction camp to a permanent community center. This reusability extends the building’s value beyond its initial purpose; for example, modules used as worker dormitories can be relocated and repurposed as student housing or emergency shelters, eliminating demolition costs and reducing environmental impact.

Sustainability enhances both environmental and economic value. Lida’s use of recycled materials and energy-efficient components reduces carbon emissions by 65% compared to traditional concrete buildings, helping clients meet sustainability goals and qualify for green building subsidies . Energy-efficient insulation, UPVC windows, and optional solar panels lower operational costs (utility bills reduced by 20-30% annually), while low-maintenance materials (galvanized steel, moisture-resistant panels) minimize upkeep expenses over the building’s lifespan.

User-centric design further amplifies value. Lida’s prefab houses prioritize livability, with soundproof partitions (60dB noise reduction), optimized space layouts, and pre-installed fixtures that meet daily needs. For example, residential units include pre-fitted kitchens, bathrooms, and storage solutions, while commercial units can be configured for offices, retail, or healthcare—ensuring the building delivers immediate utility and functional value.

3. Technical Innovations: Enabling the Quality-Cost-Value Balance

Lida Group’s ability to balance quality, cost, and value is underpinned by cutting-edge technical innovations that optimize performance while controlling expenses. These innovations span structural engineering, production technology, and smart integration, creating a synergistic system that avoids trade-offs.

3.1 Structural Engineering: Strength and Efficiency in Harmony

Lida’s structural designs merge superior strength with material efficiency, reducing costs without compromising durability. The company’s optimized steel frame system uses 15% less material than conventional prefab frames while maintaining structural integrity—achieved through computer-aided design (CAD) simulations that identify load-bearing critical points and minimize excess material . Corner pillars (210×150×30mm with a 2.75mm thickness) support vertical stacking up to 3 levels, while bolted connections (replacing welding) enable easy assembly and disassembly, reducing labor costs and preserving structural integrity for reuse.

Integrated sandwich panels further enhance this balance. These panels combine insulation, weatherproofing, and structural support in a single prefabricated component, eliminating the need for multiple materials and on-site installation. The panels are lightweight yet durable, reducing transportation costs while delivering thermal efficiency and fire resistance—addressing quality, cost, and sustainability goals simultaneously.

3.2 Smart Production: Automation and Precision

Lida’s smart factories integrate 83 cutting-edge technologies to automate production, improve precision, and reduce costs . Robotic welding systems ensure consistent joint quality, eliminating rework and reducing labor expenses. Digital twin technology creates virtual models of each module, enabling real-time production monitoring and optimization—identifying inefficiencies before they lead to waste. 3D printing is used for custom components, such as connectors and fixtures, reducing lead times and costs compared to traditional manufacturing.

A centralized digital management system connects design, production, logistics, and on-site assembly, enabling end-to-end visibility and control. This system optimizes production schedules, minimizes inventory, and ensures timely delivery—reducing overhead costs and avoiding delays that erode client value. For example, the system uses predictive analytics to forecast material needs, ensuring just-in-time delivery and reducing storage costs.

3.3 Smart Integration: Enhancing Value Without Added Cost

Lida integrates smart technologies into its prefab houses to enhance value without significant cost increases. Pre-installed IoT sensors monitor structural health, energy usage, and environmental conditions, enabling proactive maintenance and reducing long-term operational costs. AI-powered energy management systems optimize heating, ventilation, and lighting, cutting utility bills by 20-30% while improving user comfort.

For international projects, Lida’s adaptive technology ensures compliance with local standards without custom redesign. Modular electrical and plumbing systems can be configured to meet regional voltage and plumbing codes, reducing adaptation costs and ensuring quality across global markets. This flexibility enables Lida to deliver consistent quality and value worldwide, regardless of local regulations.

4. Real-World Projects: Balancing Quality, Cost, and Value in Action

Lida Group’s balanced approach is validated by its global portfolio of projects, spanning diverse sectors and geographies. These projects demonstrate how the company’s prefab houses deliver on the promise of affordability, quality, and long-term value.

4.1 Rural Revitalization in Chengdu, China

Lida partnered with local governments in Yunlong Town, Chengdu, to deliver 147 prefab houses as part of China’s rural revitalization initiative. Each 260-square-meter house features Western Sichuan-style architecture, grade 8 seismic resistance, and energy-efficient insulation—meeting high quality and cultural design standards. The project cost $45,000 per unit, 30% lower than traditional construction, thanks to Lida’s standardized production and logistics optimization.

Post-occupancy, residents reported 20-30% lower utility bills due to energy-efficient components, and the houses’ durability (tested against local climate conditions) has eliminated the need for frequent maintenance. The modular design allows for future expansion, enabling families to add rooms as needed—extending the building’s value. Local officials noted that the project balanced affordability with quality, delivering lasting value to rural communities.

4.2 Affordable Housing in the United States

In response to the U.S. housing crisis, Lida supplied 50 modular prefab units for an affordable housing complex in Texas. The units were designed to meet U.S. building codes (including wind resistance for hurricane-prone regions) and feature 3 bedrooms, 2 bathrooms, and energy-efficient appliances—delivering quality comparable to traditional homes at 25% lower cost.

The project was completed in 8 weeks (vs. 6 months for traditional construction), reducing financing costs for the developer. Tenants praised the houses’ comfort, durability, and low utility costs, with one resident noting, “This home is just as sturdy and comfortable as my previous house, but my monthly expenses are much lower.” The complex’s success has led to additional partnerships with U.S. developers, demonstrating Lida’s ability to balance quality and cost in competitive markets.

4.3 Mining Camp in Indonesia

Lida supplied 40 prefab units for a mining camp in Indonesia, housing 200 workers. The units were customized for high humidity and temperatures, with enhanced insulation, air conditioning, and corrosion-resistant materials—ensuring quality performance in harsh conditions. The project cost 22% less than traditional worker dormitories, thanks to Lida’s local labor training program (avoiding imported labor costs) and compact logistics.

The modular design allowed the units to be relocated to another mine site after the project’s completion, maximizing reuse and return on investment. The client reported improved worker productivity due to the comfortable living conditions, and the units’ durability reduced maintenance costs by 40% compared to previous temporary housing. This project exemplifies how Lida’s balance of quality, cost, and adaptability delivers value for industrial clients.

4.4 Emergency Relief in Kenya

Lida partnered with NGOs to deliver 50 prefab shelters for drought-displaced communities in Kenya. The units were lightweight, portable, and designed to withstand extreme heat and dust storms—meeting quality standards for emergency housing. Each unit cost $2,500, 50% lower than conventional emergency shelters, thanks to recycled materials and standardized production.

The shelters were deployed in 48 hours, providing immediate protection for displaced families. After the crisis, the units were repurposed as community centers and schools, extending their value beyond emergency relief. Local NGOs noted that the shelters balanced affordability with durability, delivering lasting value to vulnerable communities.

5. Industry Impact and Future Trends

Lida Group’s balanced approach is reshaping the global prefab housing market, driving a shift from trade-offs between quality and cost to integrated solutions that deliver comprehensive value. The company’s success has set new industry standards, influencing competitors, policies, and client expectations.

5.1 Redefining Industry Standards

Lida’s model has challenged the low-cost, low-quality perception of prefab housing, proving that affordable solutions can meet or exceed traditional construction quality. The company’s collaboration with Shanghai Construction Engineering Group to develop national standards for box-type steel structure housing has influenced design, production, and quality control practices across China . Globally, Lida’s success has accelerated the mainstream adoption of prefab housing, moving it from “temporary” to “permanent” solutions in urban development plans and disaster relief strategies.

5.2 Future Innovations to Strengthen the Balance

Lida Group continues to invest in innovations that enhance the quality-cost-value balance. Key focus areas include: AI-Powered Design Optimization: AI tools will generate tailored modular layouts based on client needs, further reducing waste and customization costs while preserving quality. Carbon-Negative Materials: The company is developing recycled ocean plastic insulation and carbon-negative steel frames to enhance sustainability, reduce material costs, and meet global climate goals. Robotic On-Site Assembly: Autonomous robots will handle module connection and placement, reducing labor costs to near-zero while improving precision and safety.

Lida is also expanding its digital twin capabilities to enable remote monitoring and maintenance of global projects, further extending the lifespan of its prefab houses and enhancing long-term value.

6. Conclusion

Lida Group’s cost-effective prefab houses represent a paradigm shift in the construction industry—proving that quality, affordability, and value can coexist and reinforce one another. By integrating precision quality control, lean cost-optimization, and value-centric design, the company has eliminated the false choice between “cheap” and “durable,” delivering solutions that meet rigorous global standards while optimizing costs at every stage of the lifecycle. Lida’s approach goes beyond upfront savings: its prefab houses deliver lasting value through adaptability, sustainability, and operational efficiency, making them a smart investment for clients across sectors and geographies.

Real-world projects—from rural homes in China and affordable housing in the U.S. to mining camps in Indonesia and emergency shelters in Kenya—validate the strength of Lida’s model. These projects demonstrate that balanced prefab solutions can address pressing global challenges, including housing shortages, labor gaps, and climate change, while delivering tangible benefits to clients and communities.

As the global prefab market continues to grow, Lida Group stands as a leader and innovator, shaping the industry’s future by prioritizing balance over trade-offs. For governments, developers, and nonprofits seeking to build smarter, more sustainably, and more affordably, Lida’s prefab houses offer a proven solution that delivers on the promise of quality, cost-effectiveness, and lasting value. In an era where efficiency and sustainability are paramount, Lida Group’s balanced approach is not just a business strategy—it is a blueprint for a more inclusive, resilient, and value-driven built environment.

Related news

-

Flexible Design in Modern Mobile Container Dormitory Solutions

2026-01-22 17:37:24

-

Lida Group Delivers Affordable Cost-Effective Prefab House Projects

2026-01-22 17:22:03

-

Streamline Housing with Easy Assembly Container Apartment Systems

2026-01-22 16:50:35

contact us

- Tel: +86-532-88966982

- Whatsapp: +86-13793209022

- E-mail: sales@lidajituan.com