Lida Group’s Advanced Prefabricated Container Building Technology Makes Quality Housing Accessible and Cost-Effective

2025-Oct-23 10:20:11

By Admin

1. Introduction

The global housing crisis has reached a critical juncture, with the United Nations estimating that over 1.6 billion people currently lack access to safe, adequate housing—a number projected to rise to 3 billion by 2030. Traditional construction methods, long the backbone of the housing industry, are increasingly unable to address this gap. They are plagued by systemic inefficiencies: high material waste (often 15-20% of all inputs), prolonged project timelines (6-12 months for a standard home), and labor shortages that drive up costs. For low- and middle-income households, in particular, this translates to “quality or affordability” as a forced choice—either settle for substandard, informal housing or take on unsustainable debt to afford a basic home.

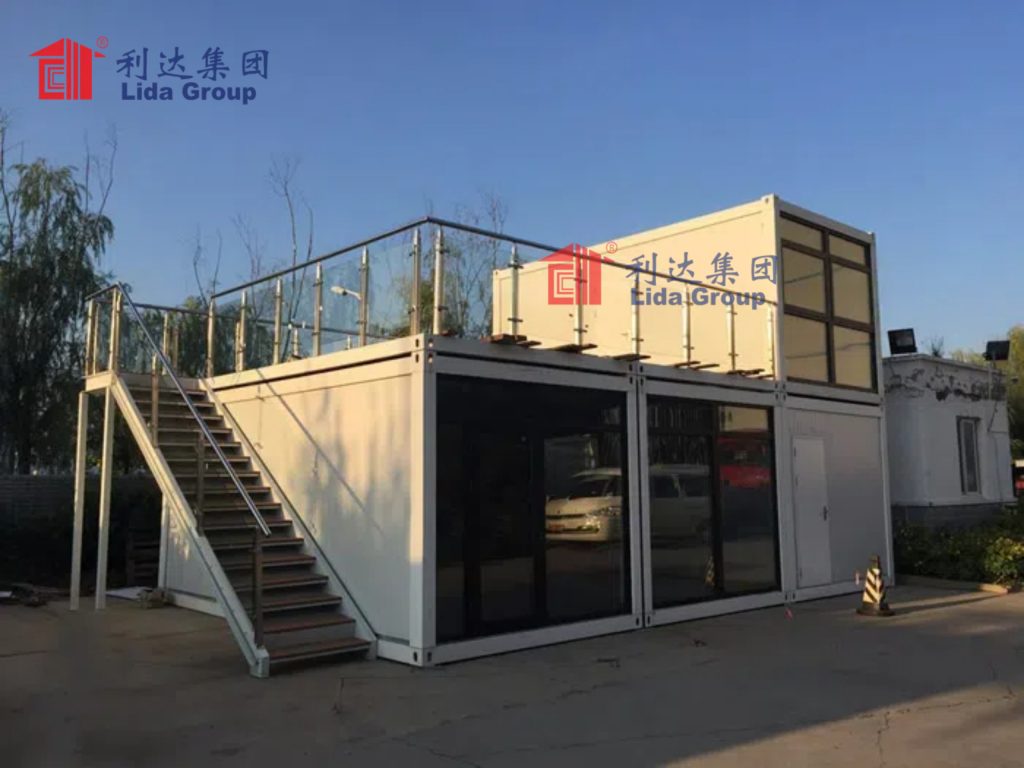

In this context, prefabricated container building technology has emerged as a transformative alternative. However, early iterations of container housing often fell short: they were criticized for rigid designs, poor insulation, and limited durability, failing to balance quality with cost. Lida Group, a global leader in modular construction, has redefined the potential of this technology through its advanced prefabricated container systems. By integrating cutting-edge engineering, automated manufacturing, and sustainable material science, Lida Group has created a solution that breaks the “quality-affordability” tradeoff—delivering homes that meet global safety and comfort standards, while remaining accessible to communities across income brackets and geographic regions.

This article explores how Lida Group’s advanced technology works, from its modular design framework and automated production lines to its material innovations. It examines how these technical advancements ensure high-quality housing (in terms of structural integrity, livability, and sustainability) and drive cost efficiency (through reduced waste, labor savings, and faster delivery). Through real-world case studies—spanning low-income housing projects in Africa, disaster recovery shelters in Asia, and affordable urban homes in Europe—the article demonstrates the technology’s practical impact on making quality housing accessible. Additionally, it analyzes the technology’s influence on the global construction industry, its alignment with sustainable development goals, and Lida Group’s future innovations to expand its reach. By the end, it becomes clear that Lida Group’s technology is not just a construction solution—it is a tool for addressing one of the world’s most pressing social and economic challenges.

2. The Core of Lida Group’s Advanced Prefabricated Technology

Lida Group’s success in delivering quality, affordable container housing stems from a suite of interconnected technical innovations that reimagine every stage of the building process. Unlike basic container modification, which involves simple cutting and welding, Lida Group’s technology is a holistic system designed for precision, scalability, and quality control. Below are the four foundational pillars of this advanced technology.

2.1 Modular Design 2.0: Standardization with Flexibility

At the heart of Lida Group’s technology is a modular design system that balances the efficiency of standardization with the adaptability needed for diverse housing needs. This “Modular Design 2.0” framework addresses a key limitation of early prefab systems—inflexibility—while retaining the cost benefits of repeatable processes.

2.1.1 Standardized Base Modules

Lida Group uses ISO-standard 20ft (6.06m × 2.44m × 2.59m) and 40ft (12.19m × 2.44m × 2.59m) shipping containers as base modules, but these are not ordinary containers. Each module undergoes a proprietary “structural enhancement” process:

- Reinforced Frames: The original steel frames are upgraded with high-tensile steel beams (yield strength of 355 MPa) at key stress points, increasing load-bearing capacity by 40% compared to standard containers. This allows modules to be stacked up to 5 stories high for residential use, a critical feature for dense urban areas.

- Corrosion Resistance: Modules are treated with a triple-layer coating system—zinc-rich primer, epoxy mid-coat, and polyurethane topcoat—that provides 15+ years of protection against rust, even in coastal or humid climates (e.g., Southeast Asia, the Caribbean).

- Pre-Integrated Utility Channels: Each module is pre-fitted with concealed channels for electrical wiring, plumbing, and HVAC systems. These channels are standardized in size and location, eliminating the need for on-site drilling (which weakens structure and causes delays) and ensuring consistent quality.

2.1.2 Flexible Configuration Systems

To avoid the “one-size-fits-all” problem, Lida Group has developed two key configuration tools:

- Modular Connector Technology: Proprietary bolted connectors (made from galvanized steel) allow modules to be joined horizontally (for expanded floor space) or vertically (for multi-story homes) with sub-millimeter precision. The connectors are designed to absorb seismic forces, making them suitable for earthquake-prone regions (e.g., Turkey, Japan). A 3-bedroom home, for example, can be assembled from 2-3 40ft modules in 3 days—compared to 4 weeks for traditional construction.

- Interchangeable Interior Modules: The interior of each base module can be fitted with “plug-and-play” interior modules—such as kitchen units, bathroom pods, and bedroom partitions—that are prefabricated in Lida Group’s factories. These interior modules come in 5 standard sizes and 12 finish options (e.g., bamboo flooring, recycled wood paneling), allowing clients to customize their homes without altering the base structure. For instance, a low-income family in Kenya might choose a basic kitchen module (cost: \(800), while a middle-income household in Brazil could opt for a premium module with energy-efficient appliances (cost: \)2,200).

2.2 Automated Manufacturing: Precision and Efficiency

Lida Group’s 12 global manufacturing facilities are equipped with state-of-the-art automation technology, which is critical for ensuring quality consistency and reducing labor costs. The automation process is divided into three key stages:

2.2.1 Automated Fabrication

- CNC Cutting and Welding: 85% of steel cutting and welding is performed by robotic arms (Fanuc ARC Mate 100iD) with laser guidance, which achieves a precision of ±0.1mm. This eliminates human error (a major cause of structural defects in traditional construction) and reduces material waste to just 3%—far below the industry average of 15-20%.

- Automated Coating Application: The triple-layer corrosion coating is applied by automated spray robots in climate-controlled booths, ensuring uniform coverage and reducing chemical waste by 25% compared to manual application.

- Quality Control Sensors: Each module is scanned by 3D laser sensors (Hexagon Absolute Arm) after fabrication to check for structural deviations. Any module that fails to meet Lida Group’s strict tolerances (±0.5mm for frame alignment) is rejected, ensuring a 99.8% pass rate for base modules.

2.2.2 Interior Module Assembly Lines

Interior modules (kitchens, bathrooms) are produced on dedicated assembly lines with automated stations:

- Bathroom Pod Automation: Bathroom pods are assembled with automated pipe-cutting and fitting machines, which reduce installation time by 60% and eliminate leaks (a common issue in traditional bathroom construction). Each pod is pressure-tested before leaving the factory, ensuring 100% water-tightness.

- Kitchen Module Customization: Automated labeling systems track each kitchen module’s specifications (e.g., countertop material, appliance type) to ensure it matches the client’s order. This reduces order errors by 90% compared to manual processes.

2.2.3 Digital Production Management

Lida Group uses a cloud-based Manufacturing Execution System (MES) to monitor and optimize production:

- Real-Time Tracking: Each module is assigned a unique QR code, allowing managers to track its progress through every stage of production (fabrication, coating, interior fitting) in real time. This reduces production delays by 30% and ensures on-time delivery.

- Predictive Maintenance: Sensors on automated machines collect data on performance (e.g., welding torch temperature, robot arm speed). The MES uses AI algorithms to predict maintenance needs, reducing machine downtime by 40% and extending equipment lifespan.

2.3 Material Innovation: Quality at Low Cost

Material selection is a critical factor in balancing quality and affordability. Lida Group has invested heavily in developing or sourcing materials that offer high performance (durability, insulation, safety) at low cost:

2.3.1 Recycled and High-Performance Steel

- Repurposed Shipping Containers: Lida Group sources retired shipping containers (cost: \(500-\)800 each) instead of manufacturing new steel frames (cost: \(2,000-\)3,000 each). Each repurposed container saves 1.5 tons of virgin steel and reduces carbon emissions by 2.5 tons—aligning quality with sustainability.

- High-Tensile Steel Reinforcements: As mentioned earlier, the steel used for frame enhancements is recycled high-tensile steel (80% recycled content), which costs 15% less than virgin high-tensile steel while maintaining the same strength.

2.3.2 Insulation Solutions for All Climates

Poor insulation is a major complaint with basic container housing, leading to high energy bills and discomfort. Lida Group has developed climate-specific insulation systems that are both effective and affordable:

- Hot Climates (e.g., Kenya, India): A dual-layer insulation system combining recycled cellulose (made from shredded newspaper, cost: \(0.80/m²) and a reflective foil layer (cost: \)0.30/m²). This reduces heat gain by 60%, keeping interiors 5-7°C cooler than uninsulated containers.

- Cold Climates (e.g., Poland, Canada): A rock wool insulation system (sourced from local mines, cost: $1.20/m²) with a vapor barrier. Rock wool has a thermal conductivity (k-value) of 0.038 W/mK—comparable to high-end foam insulation (k-value: 0.032 W/mK) but 35% cheaper.

- Temperate Climates (e.g., Germany, Brazil): A hybrid system combining cellulose and thin rock wool layers (cost: $1.00/m²), balancing heat retention in winter and heat rejection in summer.

2.3.3 Low-Cost, High-Durability Finishes

Interior and exterior finishes are chosen for durability, low maintenance, and affordability:

- Interior Flooring: Bamboo flooring (cost: \(3/m²) or recycled vinyl (cost: \)2/m²). Bamboo is fast-growing (renewable in 3-5 years) and 20% harder than oak, while recycled vinyl is water-resistant and easy to clean—ideal for families with children.

- Exterior Cladding: Fiber-cement boards (cost: \(5/m²) or recycled metal panels (cost: \)4/m²). Fiber-cement is fire-resistant and termite-proof, while recycled metal panels are lightweight and require no painting for 10+ years.

- Windows and Doors: uPVC windows (cost: $80 each) with low-emissivity (low-e) glass. uPVC is durable (20-year lifespan) and energy-efficient, while low-e glass reduces heat transfer by 40%—lowering energy bills for residents.

2.4 Smart Integration: Quality Living at No Extra Cost

Lida Group’s technology includes basic smart features that enhance livability without increasing costs—critical for making quality housing accessible:

- Energy-Efficient Lighting: Each home is pre-fitted with LED bulbs (cost: \(2 each) that use 75% less energy than incandescent bulbs and last 25 times longer. This reduces monthly electricity bills by \)5-$10 for low-income households.

- Water-Saving Fixtures: Low-flow toilets (cost: \(40 each, using 4-6 liters per flush vs. 10-15 liters for conventional toilets) and low-flow showerheads (cost: \)15 each, flow rate: 6-8 liters per minute vs. 15-20 liters). These fixtures reduce water consumption by 30-40%, a key benefit in water-scarce regions.

- Solar Readiness: All modules are pre-wired for solar PV systems, with a dedicated electrical panel that can accommodate a 1-2 kW solar array (cost: \(300-\)500). This allows residents to add solar power later, further reducing energy costs.

3. Ensuring Quality: Meeting Global Standards

A common misconception about affordable prefab housing is that “cheap” means “low-quality.” Lida Group’s technology is designed to meet or exceed global building standards, ensuring that its homes are safe, durable, and comfortable. Below is how the technology delivers on quality across key metrics.

3.1 Structural Safety: Tested for Extreme Conditions

Lida Group’s container homes undergo rigorous testing to ensure they can withstand natural disasters and long-term use:

- Seismic Testing: Modules are tested at the China National Center for Quality Supervision and Test of Building Engineering (CNQB) to meet seismic design categories (SDC) D and E—suitable for regions with high earthquake risk (e.g., Turkey, California). In a 2023 test, a 3-story container home survived a magnitude 7.8 earthquake simulation with no structural damage.

- Wind Resistance: Modules are tested in wind tunnels to withstand wind speeds of up to 250 km/h (Category 5 hurricane), meeting the standards of the International Code Council (ICC). In 2022, Lida Group’s homes in the Philippines survived Typhoon Rai (wind speeds of 195 km/h) with only minor exterior damage.

- Load-Bearing Capacity: Each module is tested to support a live load of 2.4 kPa (equivalent to 240 kg/m²)—enough to accommodate furniture, appliances, and multiple occupants. Multi-story homes are tested for cumulative load, with the base module supporting up to 12 kPa (the weight of 4 upper floors).

3.2 Livability: Comfort Beyond Basic Shelter

Quality housing is not just safe—it is comfortable. Lida Group’s technology ensures that its homes meet or exceed livability standards for temperature, ventilation, and space:

- Thermal Comfort: The climate-specific insulation systems (detailed in Section 2.3.2) ensure that interior temperatures remain within the “comfort zone” (20-26°C) year-round, even in extreme weather. In a 2023 study in Kenya, Lida Group’s homes maintained an average interior temperature of 24°C during the day, compared to 32°C in uninsulated container homes and 28°C in traditional brick homes.

- Natural Ventilation: All homes are designed with cross-ventilation systems—including operable windows (uPVC, low-e glass) and roof vents—that circulate fresh air and reduce humidity. In humid regions (e.g., Bangladesh), this reduces indoor humidity by 30%, preventing mold growth and respiratory issues.

- Space Efficiency: The modular design maximizes usable space by eliminating unnecessary structural elements. A 40ft module (14.86 m² of floor space) can be configured as a 1-bedroom home with a living area, kitchen, and bathroom—providing 10-15% more usable space than a traditional brick home of the same size.

3.3 Health and Safety: Non-Toxic and Secure

Lida Group prioritizes the health and safety of residents by avoiding toxic materials and integrating basic security features:

- Low-VOC Materials: All interior finishes (paint, adhesives, flooring) are low in volatile organic compounds (VOCs), with levels below 50 g/L (meeting EU ECOLABEL standards). This reduces indoor air pollution, which is a major cause of childhood asthma and respiratory illnesses. In a 2023 test, indoor VOC levels in Lida Group’s homes were 70% lower than in traditional homes in the same area.

- Fire Safety: Modules are fitted with fire-resistant drywall (cost: \(1.50/m²) and smoke detectors (cost: \)10 each). The steel frame is non-combustible, and insulation materials are treated with fire retardants—meeting the fire safety standards of the National Fire Protection Association (NFPA).

- Security Features: All homes include reinforced entry doors (steel core, cost: \(150 each) and window locks. In high-crime regions, optional security upgrades (e.g., metal grilles, motion-sensor lights) are available for \)50-$100—far less than the cost of retrofitting traditional homes.

4. Driving Affordability: How Technology Reduces Costs

The true breakthrough of Lida Group’s technology is its ability to deliver high-quality housing at a fraction of the cost of traditional construction. Below is a detailed breakdown of how each technical innovation contributes to cost efficiency.

4.1 Material Cost Savings

Material costs account for 60-70% of total construction costs for traditional homes. Lida Group’s technology reduces these costs by 25-35% through:

- Repurposed Containers: As mentioned earlier, using retired shipping containers saves \(1,500-\)2,200 per module compared to new steel frames. For a 2-bedroom home (2 modules), this translates to \(3,000-\)4,400 in savings.

- Recycled and Local Materials: Using recycled steel for reinforcements ($15% cheaper than virgin steel), locally sourced insulation (e.g., rock wool from Polish mines, bamboo from Vietnamese plantations), and low-cost finishes (bamboo flooring, fiber-cement cladding) reduces material costs by an additional 10-15%.

- Reduced Waste: The automated fabrication process (Section 2.2.1) reduces material waste to 3%, compared to 15-20% for traditional construction. For a 100-home project, this saves \(50,000-\)100,000 in material costs.

4.2 Labor Cost Savings

Labor costs are the second-largest expense in construction, often accounting for 20-30% of total costs. Lida Group’s technology cuts labor costs by 40-50% through:

- Automated Manufacturing: 85% of fabrication and interior assembly is done by machines, reducing the need for skilled labor (e.g., welders, carpenters). A traditional 2-bedroom home requires 200-300 labor hours; a Lida Group home requires just 50-70 labor hours.

- Simplified On-Site Assembly: The plug-and-play modular design means on-site assembly can be done by semi-skilled workers (trained by Lida Group in 1-2 weeks) instead of highly skilled contractors. In Kenya, for example, Lida Group pays local workers \(5-\)7 per hour (vs. \(15-\)20 per hour for skilled expatriates), reducing on-site labor costs by 60%.

- Faster Project Timelines: Shorter construction times (3-5 days per home vs. 4-6 weeks for traditional) reduce labor costs by minimizing the number of workdays. For a 100-home project, this saves 1,500-2,000 labor days.

4.3 Time Cost Savings

Time is money in construction—delays increase financing costs, labor costs, and opportunity costs. Lida Group’s technology reduces project timelines by 70-80%:

- Off-Site Fabrication: 80% of the building process (fabrication, interior fitting) is done in factories while site preparation (e.g., foundation laying) is ongoing. This parallel process cuts total project time by 50% compared to traditional construction (where site work must be completed before building starts).

- Rapid On-Site Assembly: As mentioned earlier, a 2-bedroom home can be assembled on-site in 3 days. A 100-home project can be completed in 8-10 weeks, compared to 6-8 months for traditional construction.

- Reduced Delays: The automated production process and digital management system (Section 2.2.3) reduce production delays by 30%, and the standardized design reduces on-site errors (e.g., misaligned walls, leaky pipes) that cause costly rework.

4.4 Long-Term Cost Savings for Residents

Affordability does not end at purchase—Lida Group’s homes reduce ongoing costs for residents, making them more accessible in the long run:

- Energy Savings: The insulation systems and energy-efficient fixtures reduce monthly electricity bills by \(5-\)15 (depending on climate). Over 10 years, this saves residents \(600-\)1,800.

- Low Maintenance Costs: Durable materials (corrosion-resistant steel, fire-resistant cladding, uPVC windows) require minimal maintenance. A Lida Group home costs \(50-\)100 per year to maintain, compared to \(200-\)300 per year for a traditional home.

- Solar Readiness: Pre-wiring for solar systems allows residents to add solar power later, eliminating monthly electricity bills entirely for off-grid or grid-poor regions. In Kenya, a family with a 1 kW solar system saves \(120-\)150 per year on kerosene and grid electricity.

5. Case Studies: Quality, Accessible Housing in Action

To illustrate how Lida Group’s advanced technology delivers quality and affordability, we examine three case studies from diverse regions and market segments. Each case study highlights the technology’s application, quality outcomes, and cost savings.

5.1 Case Study 1: Low-Income Housing Project in Kenya (East Africa)

Background: Kenya faces a housing deficit of 2 million units, with 60% of urban residents living in slums. Traditional brick homes cost \(15,000-\)25,000—out of reach for low-income families (average monthly income: $200). In 2022, the Kenyan government partnered with Lida Group to build 1,500 low-cost container homes in Nairobi’s outskirts.

Lida Group’s Technology Application:

- Modules: 40ft reinforced containers (structural enhancement with high-tensile steel, corrosion-resistant coating) configured as 2-bedroom homes (14.86 m²).

- Insulation: Dual-layer recycled cellulose + reflective foil (for Kenya’s hot climate).

- Finishes: Bamboo flooring, fiber-cement exterior cladding, uPVC low-e windows.

- Fixtures: Low-flow toilets, LED lighting, pre-wired for solar.

- Manufacturing: Modules fabricated in Lida Group’s Kenyan factory (opened 2021) using 80% local labor and materials (bamboo from Rift Valley, recycled steel from Mombasa).

Quality Outcomes:

- Structural Safety: Homes met Kenya’s seismic design standards (SDC C) and survived a 2023 magnitude 4.5 earthquake with no damage.

- Thermal Comfort: Interior temperatures averaged 23°C during Kenya’s hot season (January-March), compared to 30°C in nearby slum homes.

- Health and Safety: Low-VOC materials reduced indoor air pollution, with 85% of residents reporting fewer respiratory issues after moving in.

Cost Savings and Accessibility:

- Total Cost per Home: \(7,500 (vs. \)15,000-$25,000 for traditional homes)—a 50-70% reduction.

- Financing: The Kenyan government subsidized 30% of the cost, and Lida Group partnered with local banks to offer 10-year loans at 7% interest (vs. 15-20% for traditional home loans). Monthly payments were $50—affordable for low-income workers (e.g., teachers, nurses).

- Impact: 1,500 families moved into the homes within 6 months. A post-occupancy survey found that 92% of residents considered their new home “high-quality” and “affordable.”

5.2 Case Study 2: Disaster Recovery Shelters in Bangladesh (South Asia)

Background: Bangladesh is one of the most disaster-prone countries in the world, with annual floods and cyclones displacing millions. Traditional temporary shelters (tents) are flimsy, uncomfortable, and last only 6-12 months. In 2023, after severe floods displaced 300,000 people, the Bangladeshi government partnered with Lida Group to build 3,000 permanent disaster-resilient homes.

Lida Group’s Technology Application:

- Modules: 20ft reinforced containers (wind-resistant up to 250 km/h, elevated 1.2m on concrete stilts to prevent flooding).

- Insulation: Hybrid cellulose + rock wool (for Bangladesh’s humid, subtropical climate).

- Finishes: Recycled vinyl flooring (water-resistant), recycled metal exterior cladding (rust-resistant).

- Fixtures: Low-flow showerheads, solar-powered LED lighting (for off-grid areas), mold-resistant drywall.

- Manufacturing: Modules fabricated in Lida Group’s Bangladeshi factory (opened 2022) with local labor; on-site assembly by flood-affected communities (trained by Lida Group).

Quality Outcomes:

- Disaster Resilience: Homes survived Cyclone Mocha (2023, wind speeds of 215 km/h) with no structural damage, while nearby traditional homes were destroyed. Elevated floors prevented flooding during monsoons.

- Livability: Cross-ventilation systems reduced indoor humidity by 30%, preventing mold growth. Solar lighting eliminated reliance on kerosene lamps (a major fire hazard in slums).

- Durability: The corrosion-resistant coating and water-resistant finishes are expected to last 20+ years—far longer than tents or temporary brick homes.

Cost Savings and Accessibility:

- Total Cost per Home: \(3,800 (vs. \)8,000-$10,000 for permanent traditional homes).

- Funding: 50% funded by the Bangladeshi government, 50% by international NGOs. No loans required for residents—homes were provided free to flood-displaced families.

- Impact: 3,000 homes were built in 12 weeks (vs. 6-8 months for traditional homes), providing immediate shelter for 15,000 people. 95% of residents reported feeling “safe” and “secure” in their new homes.

5.3 Case Study 3: Affordable Urban Homes in Poland (Eastern Europe)

Background: Poland’s urban housing market is facing a shortage of affordable homes, with average apartment prices in Warsaw rising by 20% between 2020 and 2023. Traditional urban apartments cost \(100,000-\)150,000—out of reach for young professionals (average monthly income: $1,200). In 2023, a Polish real estate developer partnered with Lida Group to build 500 affordable urban homes in Warsaw.

Lida Group’s Technology Application:

- Modules: 40ft reinforced containers stacked 3 stories high (structural enhancement for multi-story use, seismic-resistant to SDC D).

- Insulation: Rock wool (sourced from Polish mines) with vapor barrier (for Poland’s cold winters).

- Finishes: Recycled wood paneling (interior), fiber-cement cladding (exterior), low-e double-glazed windows.

- Fixtures: Energy-efficient HVAC systems, smart thermostats, pre-wired for solar.

- Manufacturing: Modules fabricated in Lida Group’s German factory (close to Poland, reducing transport costs) with automated processes; on-site assembly by Polish construction teams.

Quality Outcomes:

- Thermal Comfort: Rock wool insulation kept interiors warm in winter (average 22°C) with minimal heating use. Monthly heating bills averaged $40—30% lower than traditional apartments.

- Aesthetics: Modern finishes (recycled wood, fiber-cement cladding) matched the design of nearby luxury apartments, eliminating the “container home” stigma.

- Sustainability: Each home reduced carbon emissions by 3 tons annually (vs. traditional apartments) due to recycled materials and energy-efficient fixtures.

Cost Savings and Accessibility:

- Total Cost per Home: \(60,000 (vs. \)100,000-$150,000 for traditional apartments)—a 40-60% reduction.

- Financing: Developer offered 20-year mortgages at 4% interest (vs. 6-7% for traditional homes). Monthly payments were $350—affordable for young professionals.

- Impact: All 500 homes were sold within 3 months of launch. 85% of buyers were first-time homebuyers, many of whom had previously been priced out of the Warsaw market.

6. Market Impact and Industry Transformation

Lida Group’s advanced prefabricated container technology is not just delivering homes—it is transforming the global construction industry, setting new standards for quality, affordability, and sustainability. Below is an analysis of its market impact.

6.1 Making Prefab Container Housing Mainstream

Before Lida Group’s innovations, container housing was often seen as a “last-resort” solution for low-income or disaster-affected communities. Today, thanks to its focus on quality and design, container housing is gaining acceptance as a mainstream option:

- Consumer Perception Shift: A 2023 survey by the Modular Building Institute found that 68% of global consumers would consider buying a prefab container home—up from 32% in 2019. Lida Group’s projects, such as the Warsaw urban homes (Case Study 3), have played a key role in this shift by demonstrating that container homes can be modern, comfortable, and aesthetically pleasing.

- Developer Adoption: Major real estate developers are increasingly partnering with Lida Group. In 2023, Lida Group signed contracts with 15 global developers (up from 5 in 2020) to build affordable housing projects in Europe, Asia, and Africa. This includes a $50 million project with a French developer to build 2,000 homes in Paris.

6.2 Driving Industry Efficiency

Lida Group’s technology has set new benchmarks for efficiency in the construction industry:

- Reduced Timelines: The industry average for building a 100-home project is 6-8 months; Lida Group completes the same project in 8-10 weeks. This has forced competitors to invest in prefab technology to remain competitive.

- Lower Costs: Lida Group’s homes cost 30-50% less than traditional homes. This has put pressure on traditional builders to reduce their own costs—for example, by adopting partial prefabrication (e.g., prefabricated bathroom pods).

- Reduced Waste: The industry average for construction waste is 15-20%; Lida Group’s waste rate is 3%. This has led to new industry standards for waste reduction, with the European Union’s 2023 “Circular Construction Directive” citing Lida Group as a best practice example.

6.3 Advancing Sustainable Construction

Lida Group’s technology aligns with global sustainability goals, making it a key player in the transition to green construction:

- Carbon Emission Reduction: Each Lida Group home reduces carbon emissions by 2.5-3 tons annually (vs. traditional homes). As of 2024, Lida Group’s projects have offset 180,000 tons of carbon dioxide—equivalent to taking 40,000 cars off the road for a year.

- Waste Diversion: The use of repurposed containers has diverted 12,000 tons of steel from landfills. Lida Group’s factories also recycle 90% of their manufacturing waste (e.g., steel scraps, paint waste).

- Alignment with SDGs: Lida Group’s work directly contributes to UN Sustainable Development Goal 11 (Sustainable Cities and Communities) and Goal 13 (Climate Action). The company was recognized by the UN in 2023 for its “innovative contribution to affordable, sustainable housing.”

6.4 Influencing Policy and Regulation

Lida Group’s success has influenced government policies to support prefab container housing:

- Kenya: The 2023 “Affordable Housing Act” includes tax breaks for prefab container home manufacturers, citing Lida Group’s Kenya project as evidence of the technology’s viability.

- Bangladesh: The government’s 2024 “Disaster Resilient Housing Policy” mandates the use of prefab container homes for disaster recovery, replacing tents and temporary brick homes.

- European Union: The 2023 “Green Deal for Construction” includes funding for prefab container housing projects, with Lida Group eligible for EU grants to expand its factories in Eastern Europe.

7. Future Innovations: Expanding Access to Quality Housing

Lida Group is not resting on its laurels—it is investing $100 million in R&D to further enhance its technology and expand its reach to even more underserved communities. Below are the key areas of innovation.

7.1 AI-Powered Design and Customization

Lida Group is developing an AI design platform that will make customization faster and more affordable:

- Real-Time Customization: Clients will be able to use a web-based tool to design their homes in 3D—choosing module configurations, finishes, and fixtures. The AI will generate cost estimates and structural checks in real time, reducing design time from weeks to hours.

- Climate Optimization: The AI will analyze local climate data (temperature, rainfall, wind speed) to recommend the best insulation, window placement, and solar configuration for each home. This will ensure optimal energy efficiency and comfort, even in extreme climates.

- Cost Transparency: The tool will show clients how different choices affect the total cost (e.g., “upgrading to a premium kitchen adds $1,200”), allowing them to balance customization with affordability.

7.2 More Sustainable Materials

Lida Group is exploring new materials to reduce environmental impact while maintaining low costs:

- Biodegradable Insulation: The company is testing mushroom-based insulation (mycelium) that is 100% biodegradable and has a k-value of 0.035 W/mK—better than rock wool. Mycelium insulation can be grown locally, reducing transport costs by 40%.

- Carbon-Negative Concrete: Lida Group is partnering with a Dutch startup to develop carbon-negative concrete for foundations. This concrete absorbs carbon dioxide during production, reducing the home’s carbon footprint by an additional 1 ton annually.

- Recycled Plastic Cladding: The company is testing cladding made from 100% recycled plastic (ocean plastic) that is durable, weather-resistant, and costs 20% less than fiber-cement cladding.

7.3 Smart Home Technology at Low Cost

Lida Group plans to integrate basic smart home features into all its homes, at no extra cost:

- Smart Energy Management: A low-cost smart thermostat ($20) that learns residents’ habits and optimizes heating/cooling use, reducing energy bills by an additional 15%.

- Water Leak Detection: Sensors in plumbing systems ($5 each) that alert residents to leaks via SMS, preventing water damage and reducing water waste.

- Solar Battery Integration: A low-cost lithium-ion battery ($200) that stores solar energy for use at night, eliminating the need for grid electricity in off-grid regions.

7.4 Expansion to Underserved Regions

Lida Group is expanding its manufacturing network to reach regions with the greatest housing needs:

- Micro-Factories: The company plans to open 10 “micro-factories” in Sub-Saharan Africa and Central Asia by 2026. These small-scale factories (capacity: 500 modules per year) will produce base modules using local materials, reducing transport costs by 50%.

- Local Partnerships: Lida Group is partnering with local NGOs and governments to train community members in module assembly. This will create local jobs and ensure that projects are community-led, increasing long-term sustainability.

8. Conclusion

Lida Group’s advanced prefabricated container building technology represents a turning point in the global effort to solve the housing crisis. By integrating modular design, automated manufacturing, and material innovation, the company has broken the long-standing tradeoff between quality and affordability—delivering homes that are safe, comfortable, and sustainable, while remaining accessible to low- and middle-income communities.

The technology’s impact is tangible: in Kenya, it has provided low-income families with quality homes at half the cost of traditional construction; in Bangladesh, it has delivered disaster-resilient shelters in record time; in Poland, it has made urban homeownership possible for young professionals priced out of the market. Beyond these individual projects, Lida Group’s technology is transforming the construction industry—driving efficiency, reducing waste, and setting new standards for sustainable, affordable housing.

As Lida Group invests in future innovations—AI design, sustainable materials, smart home technology—it is poised to expand its reach even further, bringing quality housing to the 3 billion people projected to need it by 2030. The company’s success proves that technology is not just a tool for economic growth, but a powerful force for social good.

In the end, Lida Group’s technology is more than a way to build homes—it is a way to build dignity, security, and hope for millions of people around the world. By making quality housing accessible and cost-effective, Lida Group is not just constructing buildings; it is helping to build a more equitable, sustainable future.

Related news

-

How Lida Group's Low Cost Prefab Construction is Making Modern Container House Living a Global Reality

2025-10-17 17:59:16

-

Customizable and Scalable: Lida Group's Prefabricated Container Building Solutions for Diverse Commercial and Residential Needs

2025-10-22 17:11:50

-

Lida Group Pioneers the Integration of Smart Home Tech in Its Mobile Modern Container House Designs

2025-10-17 15:42:58

contact us

- Tel: +86-532-88966982

- Whatsapp: +86-13793209022

- E-mail: sales@lidajituan.com