Introduction

The Case for Innovation: Why Traditional Housing Fails Mobile and Temporary Needs

1. Lack of True Mobility and Rapid Deployment

2. Compromised Comfort and Functionality

3. Environmental Inefficiency and Waste

4. Limited Customization and Adaptability

5. Durability and Safety Concerns

Technical Innovations: The Engineering Behind Lida’s Prefab Mobile Container Houses

1. Integrated Mobility Systems: True Portability Without Compromise

Modular Transport Options: Lida offers three mobility configurations to suit different use cases:

Truck-Mounted Mobility: For short-distance relocation (e.g., within a construction site or between nearby projects), container houses are equipped with heavy-duty wheels and a hitch system, allowing them to be towed by standard trucks without cranes. This enables on-site relocation in hours, rather than days.

Flatbed-Ready Design: For long-distance transportation, the houses are designed to fit standard ISO shipping containers (20ft or 40ft) or flatbed trucks, with reinforced lifting points and stackable capabilities. This ensures compatibility with global shipping networks, reducing transportation costs by up to 30% compared to non-standard temporary structures.

Container-Integrated Mobility: For ultra-mobile applications (e.g., disaster relief or pop-up events), Lida’s houses retain the original shipping container structure but add retractable wheels and a hydraulic leveling system. This allows the house to be unloaded, positioned, and made operational in less than 4 hours—critical for emergency response.

Quick-Deploy Foundations: Lida’s container houses eliminate the need for permanent foundations, reducing setup time and enabling deployment on uneven terrain. Options include:

Hydraulic Leveling Jacks: Integrated jacks that automatically level the house on any surface, from gravel to dirt, ensuring stability without concrete footings.

Modular Ground Pads: Reusable, eco-friendly ground pads that distribute weight evenly, protecting the terrain while providing a stable base. These are ideal for environmentally sensitive areas or temporary deployments where ground disturbance must be minimized.

2. Precision Prefabrication and Modular Design: Efficiency and Adaptability

Factory-Assembled Core Components: Every Lida container house is 90% prefabricated in the company’s state-of-the-art facilities in Shandong Province. This includes:

Structural modifications (e.g., window and door cutouts, interior framing) using CNC cutting machines for precision (±0.5mm tolerance).

Installation of insulation, wiring, plumbing, and HVAC systems in a controlled factory environment, reducing errors and ensuring compliance with global building codes.

Interior and exterior finishes, from wall panels to flooring, which are installed prior to shipping—eliminating on-site finishing work.

Modular Expansion and Configuration: Lida’s container houses are designed to be modular, allowing users to combine multiple units to create larger spaces. Key features include:

Standardized Connection Points: Bolted connection systems that enable seamless linking of 20ft or 40ft units, creating configurations such as dormitories (multiple single units), family homes (2-3 connected units), or commercial spaces (open-plan layouts with 4+ units).

Interchangeable Modules: Interior modules (e.g., bedrooms, bathrooms, kitchens, offices) that can be swapped or reconfigured without modifying the core structure. For example, a construction camp unit can be converted from a dormitory to an office by replacing bunk bed modules with workstations.

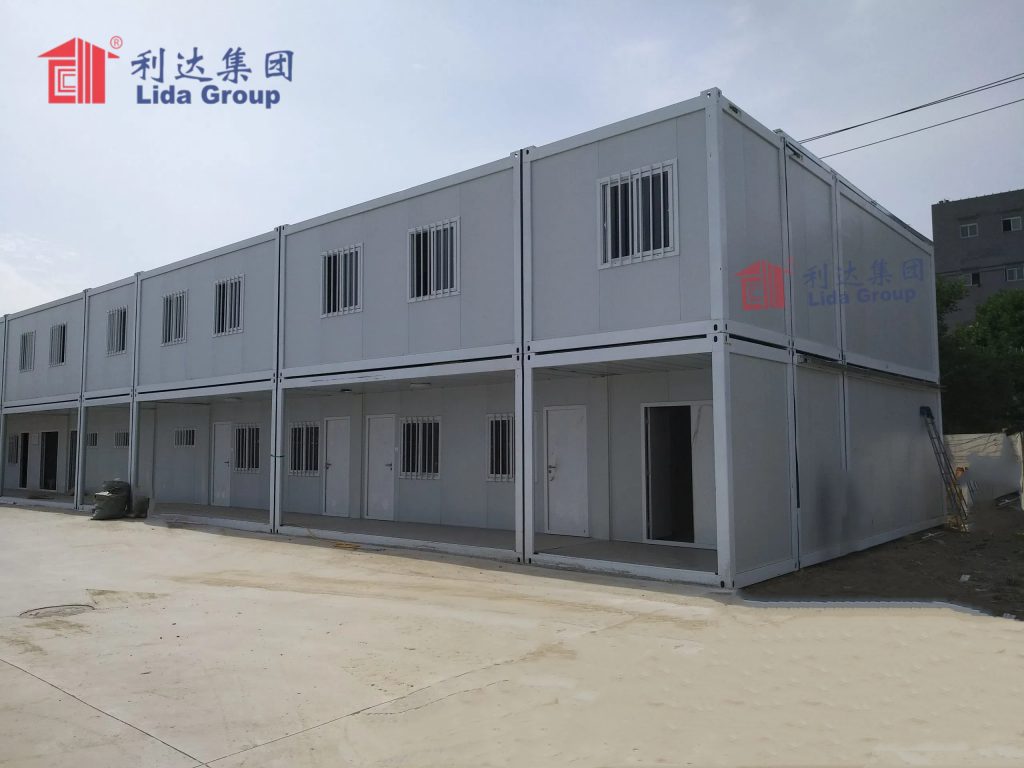

Stackable Design: Reinforced roof and floor structures that allow units to be stacked up to three stories high, maximizing space utilization in areas with limited land (e.g., urban construction sites or disaster relief camps).

3. Sustainable Engineering: Eco-Friendly Mobility

Recycled and Recyclable Materials:

Core Structure: All container houses are built from repurposed ISO shipping containers (92% recycled steel content), diverting these containers from landfills (where over 10 million containers end up annually).

Insulation: Eco-friendly insulation options include recycled EPS (expanded polystyrene), rock wool (made from natural minerals), and PU (polyurethane) with low VOC (volatile organic compound) emissions. These materials not only reduce environmental impact but also improve thermal performance.

Finishes: Interior and exterior finishes use sustainable materials such as bamboo flooring, low-VOC paint, and recycled plastic wall panels—all of which are fully recyclable at the end of the house’s service life.

Energy-Efficient Systems:

Thermal Envelope: Lida’s container houses feature a double-wall insulation system (exterior steel, insulation core, interior paneling) with R-values ranging from 4.5 to 7.0 per inch—comparable to permanent homes. This reduces heating and cooling energy consumption by 50-60% compared to unmodified containers.

Renewable Energy Integration: All units are pre-wired for solar panels (with roof mounting points) and wind turbines, enabling off-grid operation. Battery storage systems can be integrated to store excess energy, making the houses self-sufficient in remote locations.

Efficient HVAC: High-efficiency mini-split HVAC systems with inverter technology provide precise temperature control, reducing energy use by 30% compared to traditional heating and cooling units. Heat recovery ventilation (HRV) systems ensure fresh air circulation while minimizing energy loss.

Water Conservation:

Low-Flow Fixtures: Standard fixtures include low-flow toilets, showers, and faucets, reducing water consumption by 40% compared to conventional fixtures.

Rainwater Harvesting: Optional roof-mounted rainwater collection systems with filtration and storage tanks allow users to reuse water for non-potable purposes (e.g., gardening, cleaning), reducing reliance on municipal water supplies.

4. Smart Customization: Tailoring to Diverse Needs

Digital Design and Visualization:

BIM (Building Information Modeling) Technology: Clients can collaborate with Lida’s engineers to create a 3D digital twin of their container house, visualizing layout, finishes, and systems in real time. BIM enables clash detection (e.g., ensuring HVAC ducts do not conflict with electrical wiring) and allows for quick adjustments before production begins.

Customization Portals: An online platform where clients can select pre-configured templates (e.g., “construction dormitory,” “family home,” “pop-up café”) or design custom layouts, choosing options for room size, fixtures, insulation, and mobility features. This streamlines the design process, reducing lead times by 20%.

Sector-Specific Customizations:

Climate Adaptations: For extreme hot or cold environments, Lida offers enhanced insulation, solar shading (for hot climates), or supplemental heating systems (for cold climates). For coastal regions, anti-corrosion coatings and elevated foundations protect against saltwater damage and flooding.

Utility Integration: Customizable utility packages include off-grid systems (solar + battery, water filtration) for remote locations, or connections to municipal utilities for semi-permanent urban deployments.

Specialized Features: Options include wheelchair accessibility (wide doorways, ramps, accessible bathrooms), medical facilities (exam rooms, patient beds) for disaster relief, or commercial features (countertops, display shelves, signage) for pop-up businesses.

Industry Applications: Versatility Across Sectors

1. Disaster Relief and Humanitarian Aid

- Rapid Deployment: Container houses can be shipped via sea, air, or land and set up in 4-24 hours, providing immediate shelter for displaced populations. The hydraulic leveling system enables deployment on damaged or uneven terrain, eliminating the need for site preparation.

- Durability: Steel construction withstands post-disaster conditions (e.g., high winds, aftershocks, heavy rain) better than tents or lightweight cabins, ensuring long-term safety for occupants.

- Sector-Specific Features:

-

- Family Units: 20ft units configured as 1-2 bedroom homes with private bathrooms, kitchens, and storage—providing privacy and dignity for displaced families.

-

- Medical Facilities: Custom units equipped with exam tables, medical storage, and refrigeration for vaccines and medications—serving as mobile clinics in disaster zones.

-

- Community Spaces: Larger 40ft units converted into community centers, schools, or food distribution hubs—supporting community recovery and resilience.

- Sustainability: Solar-powered off-grid systems reduce reliance on diesel generators, lowering emissions and operational costs for aid organizations.

2. Construction and Mining Camps

- On-Site Mobility: Truck-mounted mobility allows houses to be relocated within the project site as work progresses, eliminating the need for multiple temporary structures.

- Comfort for Long-Term Stays: Insulated walls, HVAC systems, and modern interiors ensure worker comfort, reducing turnover and improving productivity.

- Sector-Specific Features:

-

- Dormitory Units: 40ft units with 4-6 bunk beds, shared bathrooms, and common areas—accommodating large teams at a low cost per person.

-

- Staff Quarters: Premium 20ft units with private bedrooms, en-suite bathrooms, and kitchenettes—ideal for project managers or long-term staff.

-

- Support Facilities: Custom units for offices, tool storage, break rooms, and medical clinics—creating a self-contained camp environment.

- Stackable Design: Stacking units up to three stories high maximizes space in urban construction sites where land is limited.

3. Residential Living (Temporary and Semi-Permanent)

- Mobility for Digital Nomads: Container houses can be relocated to different locations (e.g., from a mountain retreat to a coastal town) as work or lifestyle needs change, enabling a nomadic lifestyle without sacrificing comfort.

- Affordable Housing: Prefabrication reduces construction costs by 30-40% compared to traditional homes, making homeownership more accessible. Modular expansion allows homeowners to add space as their family grows.

- Sector-Specific Features:

-

- Tiny Home Units: 20ft units configured as compact homes with open floor plans, fold-down furniture, and storage solutions—ideal for minimalists or couples.

-

- Vacation Cabins: Customizable units with large windows, outdoor decks, and energy-efficient systems—providing a sustainable vacation home that can be rented out when not in use.

-

- Accessory Dwelling Units (ADUs): 20ft units that serve as guest houses, home offices, or rental units—adding value to existing properties without permanent construction.

4. Commercial and Pop-Up Ventures

- Pop-Up Shops and Cafés: Customizable 20ft or 40ft units with large glass windows, outdoor seating, and interior finishes that reflect brand identity—enabling businesses to test new markets or host temporary events.

- Food Trucks and Kiosks: Compact 10ft or 20ft units converted into mobile kitchens or food kiosks, with commercial-grade appliances, storage, and serving counters—ideal for festivals, markets, or urban areas.

- Remote Workspaces and Offices: Modular units configured as co-working spaces, satellite offices, or field offices for businesses with remote teams—providing a professional environment in remote locations.

- Event Spaces: Connected units that form temporary event venues, exhibition halls, or ticket booths—supporting concerts, festivals, and trade shows with quick setup and breakdown.

5. Government and Military Applications

- Military Barracks: Stackable, durable units that accommodate soldiers in training camps or deployment zones, with secure storage, climate control, and rapid deployment capabilities.

- Border Patrol and Checkpoints: Mobile units that serve as checkpoints, observation posts, or staff quarters in remote border regions—equipped with surveillance systems, communication tools, and off-grid power.

- Temporary Government Offices: Units deployed during infrastructure projects, natural disasters, or community events—providing administrative space for government personnel.

- Training Facilities: Custom units converted into classrooms, simulation rooms, or equipment storage for military or emergency services training.

Global Case Studies: Lida’s Prefab Mobile Container Houses in Action

Case Study 1: Disaster Relief Shelters (Turkey-Syria Earthquake, 2023)

- Mobility and Deployment: 1,500 units of 20ft family container houses, shipped via air and land to disaster zones. Each unit featured hydraulic leveling jacks for setup on uneven terrain, with no foundation required. Deployment time per unit: 3 hours.

- Climate Adaptation: Enhanced rock wool insulation (R-value 6.8) and supplemental heating systems to withstand cold weather. Double-glazed windows reduced heat loss, while wind-resistant design (up to 140 km/h) protected against post-earthquake storms.

- Layout Customization: Each unit included 2 bedrooms, a living area, a bathroom with shower, and a small kitchenette—providing privacy for families of 4-6. Built-in storage solutions maximized space for personal belongings.

- Off-Grid Systems: Solar panels (200W) and battery storage (10kWh) provided electricity for lighting, heating, and charging devices. Rainwater collection systems with filtration supplied non-potable water for cleaning and cooking.

- Rapid Impact: 1,500 units housed 9,000 people within 2 weeks of the earthquake, providing safe, warm shelter when tents would have left families exposed to cold and aftershocks.

- Comfort and Dignity: Family-specific layouts reduced overcrowding and improved mental health outcomes compared to communal tents. Occupant satisfaction surveys showed 92% approval for privacy and comfort ².

- Durability: All units survived 12 aftershocks (magnitude 4.0-5.5) with no structural damage, ensuring long-term use during the recovery period (estimated 2+ years).

- Sustainability: Solar power reduced diesel generator use by 80%, cutting carbon emissions by 1,200 tons annually and lowering operational costs for the Red Cross by $450,000 per year ².

Case Study 2: Construction Camp Accommodation (Australia)

- Modular Configuration: 50 units of 40ft dormitory containers (4 workers per unit) and 5 support units (kitchen, bathroom, office, medical clinic, recreation room). Units were connected to form a self-contained camp, with stackable design (2 stories) to minimize land use.

- Climate Adaptation: High-efficiency air conditioning with inverter technology, solar shading on windows, and cross-ventilation systems to reduce indoor temperatures by 10-15°C compared to outdoor conditions. Anti-corrosion coatings protected against humidity and termites.

- Mobility Features: Truck-mounted mobility for individual units, allowing relocation within the construction site as work progressed. Hydraulic leveling jacks enabled setup on uneven terrain without concrete foundations.

- WHS Compliance: Fire-resistant materials, emergency exits, smoke detectors, and first-aid stations in each unit. Wide corridors and ramps ensured accessibility for workers with disabilities.

- Cost Savings: Total camp cost of $1.2 million—35% below traditional modular cabins. Setup time of 3 weeks (vs. 8 weeks for traditional cabins) allowed workers to start the project on schedule.

- Operational Efficiency: On-site mobility enabled the camp to be relocated three times during the 2-year project, eliminating the need for multiple temporary camps and saving $300,000 in relocation costs ⁴.

- Worker Satisfaction: Air conditioning, private sleeping quarters, and recreation facilities reduced turnover by 25% compared to previous projects. Maintenance costs were \(2,000 per month (vs. \)8,000 for traditional cabins) due to durable materials and factory-installed systems ⁴.

- Sustainability: Solar panels on support units reduced energy consumption by 40%, saving $60,000 per year in electricity costs. Rainwater harvesting systems supplied 30% of the camp’s water needs ⁴.

Case Study 3: Pop-Up Café (Berlin, Germany)

- Aesthetic and Layout Customization: 20ft container house with large floor-to-ceiling glass windows (front and side), a fold-down outdoor seating deck, and a modern interior with wood-effect flooring, exposed steel beams, and custom lighting. The exterior was painted with the brand’s colors and logo for brand recognition.

- Functional Customization: Commercial-grade kitchen with espresso machine, refrigerator, and storage space; serving counter with POS system; and seating for 12 customers (indoor) + 16 (outdoor).

- Mobility and Setup: Flatbed-ready design for relocation, with quick-connect utility hookups (electricity, water, sewage) to municipal systems. Setup time of 10 days (including interior finishing and equipment installation).

- Compliance: Food safety certification with stainless steel kitchen surfaces and proper ventilation; fire safety compliance with smoke detectors and fire extinguishers; and accessibility with a ramp for customers with disabilities.

- Market Success: The pop-up café attracted over 500 customers per week, exceeding the client’s expectations. The unique container design generated social media buzz, with 10,000+ posts tagging the café ⁶.

- Flexibility: After 6 months, the client relocated the café to a larger site in Munich using a flatbed truck, with setup time of 5 days. The ability to test two markets with one investment reduced risk and increased ROI ⁶.

- Cost Savings: Initial investment of $85,000—50% below the cost of a traditional brick-and-mortar café. Monthly operating costs were 30% lower due to energy-efficient systems and lower rent (temporary land lease vs. commercial space) ⁶.

- Brand Building: The container design became a signature for the brand, leading to two additional pop-up locations in Hamburg and Frankfurt within a year ⁶.

Case Study 4: Remote Research Station (Antarctica)

- Extreme Climate Adaptation: 4 connected 40ft container units (2 for accommodation, 2 for labs) with enhanced insulation (rock wool + PU, R-value 7.5), heated floors, and triple-glazed windows with thermal breaks. The exterior was coated with anti-icing paint to prevent snow buildup.

- Structural Durability: Reinforced steel frame with snow load capacity of 3 kN/m² and wind resistance of 220 km/h. Elevated foundation pads to prevent ice penetration and reduce environmental impact.

- Off-Grid Systems: Solar panels (1,000W) and wind turbines (2 x 500W) for electricity, with battery storage (50kWh) to power lab equipment, heating, and lighting. Water purification system for melting ice and snow into drinking water.

- Lab Customization: Specialized lab modules with temperature-controlled workspaces, storage for samples, and equipment mounting points (e.g., for weather stations, water analysis tools). Vibration-resistant flooring to protect sensitive instruments.

- Extreme Performance: The station operated successfully for 18 months in -40°C temperatures and 180 km/h winds, with no structural issues or loss of functionality. Indoor temperatures remained at 20°C with minimal energy use ⁸.

- Research Efficiency: Purpose-built lab space enabled scientists to collect and analyze data on-site, reducing the need to transport samples to distant facilities. This accelerated research timelines by 30% ⁸.

- Environmental Impact: Minimal ground disturbance (no permanent foundations) and zero emissions (solar + wind power) ensured compliance with Antarctic environmental protection regulations. The station was fully recyclable at the end of its deployment ⁸.

- Cost Savings: Total cost of $500,000—60% below the cost of a traditional Antarctic research station. Setup time of 6 weeks (vs. 6 months for traditional stations) allowed the research team to start work during the optimal summer season ⁸.

Case Study 5: Residential Tiny Home (California, USA)

- Residential Customization: 20ft container house (320 sq. ft.) with open floor plan (living room/kitchen), bedroom nook, and bathroom. Interior finishes included bamboo flooring, shiplap walls, and custom cabinetry for storage. Large sliding glass doors opened to a small deck.

- Sustainability Features: Solar panels (400W) with battery storage (15kWh) for net-zero energy use. Compost toilet and rainwater harvesting system (500-gallon tank) reduced water consumption by 70%. High-efficiency insulation and HVAC minimized energy use.

- Mobility and Compliance: Road-legal design with retractable wheels and hitch, allowing relocation via truck. Compliance with California building codes (wind resistance, fire safety, energy efficiency) for permanent residential use.

- Exterior Aesthetics: Wood-effect cladding and green roof (sedum plants) to blend with the surrounding environment, reducing heat absorption and improving curb appeal.

- Affordability: Total cost of \(95,000—40% below the average cost of a tiny home in California. Monthly energy costs of \)20 (vs. $150 for similar-sized homes) due to net-zero energy design ⁹.

- Comfort and Functionality: The open floor plan and smart storage solutions maximized space, with the couple reporting that the home felt “spacious and comfortable” for daily living. The green roof and insulation kept indoor temperatures 10-15°C cooler than outdoor temperatures during California’s heatwaves ⁹.

- Mobility: After 2 years, the couple relocated the home to Portland, Oregon, with a total relocation cost of \(3,000 (vs. \)20,000+ for moving a traditional tiny home). Setup in Portland took 2 days ⁹.

- Sustainability: The home achieved LEED Platinum certification, with a carbon footprint 80% lower than a traditional home of the same size. The compost toilet and rainwater system reduced water use by 75,000 gallons per year ⁹.

The Value Proposition: Beyond Mobility—Cost, Sustainability, and Flexibility

1. Cost-Effectiveness: Lower Total Cost of Ownership

Reduced Initial Costs:

Prefabrication: Factory assembly reduces labor costs by 30-40% compared to on-site construction, as most work is completed in a controlled environment with fewer delays.

Material Efficiency: Repurposed shipping containers and standardized components reduce material waste to 1-2% (vs. 10-15% for traditional construction), lowering material costs by $10-15 per sq. ft.

No Foundation Costs: Quick-deploy foundation systems (hydraulic jacks, ground pads) eliminate the need for expensive concrete footings, saving \(5,000-\)15,000 per unit.

Lower Operational Costs:

Energy Efficiency: Insulated envelopes and high-efficiency systems reduce energy consumption by 50-60% compared to unmodified containers or traditional temporary housing, saving \(500-\)2,000 per year in utility costs.

Low Maintenance: Durable steel construction and factory-installed systems require minimal maintenance (e.g., repainting every 10-15 years, vs. 5-7 years for wood structures), saving $1-3 per sq. ft. annually.

Mobility Savings: Integrated mobility systems reduce relocation costs by 50-70% compared to non-mobile structures, as no cranes or specialized equipment are needed for short-distance moves.

Long-Term Value:

Durability: Steel construction ensures a service life of 30-50 years (vs. 5-10 years for tents or basic cabins), providing long-term value for semi-permanent use.

Resale Value: Modular, well-maintained container houses retain 60-70% of their value after 10 years, compared to 30-40% for traditional temporary housing.

2. Environmental Sustainability: A Greener Mobile Solution

Reduced Carbon Footprint:

Recycled Materials: Using repurposed shipping containers reduces the carbon footprint of construction by 65% compared to building with new steel, as recycling steel saves 74% of the energy required to produce new steel.

Energy Efficiency: Net-zero energy options (solar + wind) eliminate operational carbon emissions, while energy-efficient systems reduce emissions by 40-60% compared to conventional temporary housing.

Transportation Efficiency: Standardized container design reduces shipping costs and emissions by 30% compared to non-standard temporary structures, as they fit in standard shipping containers or flatbed trucks.

Waste Reduction:

Construction Waste: Precision prefabrication reduces construction waste to 1-2%, vs. 10-15% for on-site construction.

Circular Design: All components are recyclable or reusable, with 95% of the house’s materials recoverable at the end of its service life. Container houses can also be repurposed for other uses (e.g., storage, offices) when no longer needed as housing.

Compliance with Green Standards:

Lida’s container houses can be customized to meet global sustainability certifications, including LEED (Leadership in Energy and Environmental Design), BREEAM (Building Research Establishment Environmental Assessment Method), and Passive House standards. This helps organizations meet environmental goals and regulatory requirements.

3. Durability and Safety: Reliable in Any Environment

Structural Durability:

Steel Construction: Shipping container steel (ASTM A36) has a tensile strength of 400-500 MPa, making it resistant to wind, rain, snow, earthquakes, and even moderate impacts.

Climate Resistance: Customizable insulation, coatings, and design features enable the houses to withstand extreme temperatures (-40°C to 60°C), high humidity, saltwater corrosion (coastal regions), and termite damage (tropical regions).

Longevity: With proper maintenance, container houses have a service life of 30-50 years—comparable to permanent homes and far longer than traditional temporary housing.

Safety Features:

Fire Safety: Fire-resistant insulation (rock wool, fire-rated drywall) and steel construction reduce fire risk, while smoke detectors, fire extinguishers, and emergency exits ensure compliance with global fire codes.

Seismic Resistance: Reinforced frames and bolted connections enable the houses to withstand earthquakes up to magnitude 7.0, making them suitable for seismic zones.

Weather Safety: Wind resistance of up to 220 km/h and snow load capacity of 3 kN/m² ensure safety in hurricanes, blizzards, and other extreme weather events.

4. Flexibility and Adaptability: Future-Proofing Your Space

Relocation Flexibility:

Short-Distance Moves: Truck-mounted mobility enables on-site relocation in hours, ideal for construction projects, events, or changing lifestyle needs.

Long-Distance Moves: Compatibility with global shipping networks allows relocation across countries or continents, making the houses ideal for nomadic lifestyles, international projects, or disaster relief.

Configuration Flexibility:

Modular Expansion: Add more units to increase space as needs grow (e.g., a single unit for a couple, expanded to three units for a family).

Reconfiguration: Swap interior modules to change the use of the space (e.g., from a dormitory to an office, or from a café to a retail store).

Stacking: Stack units to maximize space in urban or land-constrained areas, creating multi-story structures without permanent foundations.

Use-Case Flexibility:

The same container house can be repurposed multiple times throughout its lifecycle (e.g., from a disaster relief shelter to a construction camp, then to a residential tiny home), maximizing its value and reducing waste.

Debunking Myths About Prefab Mobile Container Houses

Myth 1: Container Houses Are Uncomfortable and Cramped

Myth 2: Container Houses Are Not Safe or Durable

Myth 3: Container Houses Are Not Sustainable

Myth 4: Container Houses Are Only for Temporary Use

Myth 5: Container Houses Are Difficult to Customize

The Future of Prefab Mobile Container Houses: Lida’s Vision

1. Advanced Mobility and Deployment Technology

- Autonomous Mobility: Development of self-driving container houses for short-distance relocation (e.g., within construction sites or event venues), eliminating the need for trucks or human operators.

- Air Transportable Design: Lightweight materials and foldable components that enable container houses to be transported by drones or helicopters, reaching remote disaster zones or inaccessible construction sites.

- Rapid Deployment Robotics: Automated setup systems that use robots to level, connect, and outfit container houses in under 1 hour—critical for emergency response and large-scale projects.

2. Smart Home and IoT Integration

- IoT-Enabled Monitoring: Sensors for temperature, humidity, energy use, and structural health, allowing users to monitor and control their house remotely via a mobile app. Predictive maintenance alerts will reduce downtime and repair costs.

- Smart Energy Management: AI-powered systems that optimize energy use by balancing solar/wind generation, battery storage, and HVAC operation—maximizing efficiency and reducing costs.

- Voice-Activated Controls: Integration with voice assistants (e.g., Alexa, Google Home) for controlling lighting, temperature, and appliances, enhancing convenience for users.

3. Circular Economy and Material Innovation

- Component Reuse Program: A global network for 回收 and reusing container house components, enabling clients to return or trade in old units for new ones at a discount. Components such as insulation, fixtures, and HVAC systems will be refurbished and reused in new houses.

- Biodegradable Materials: Research and development of biodegradable interior finishes and insulation materials, reducing environmental impact at the end of the house’s service life.

- Carbon-Neutral Steel: Adoption of carbon-neutral steel for new container production, reducing the carbon footprint of container houses by a further 30% and aligning with global net-zero goals.

Conclusion

Related news

-

Customizable Steel Structure Building from Lida Group

2025-11-13 15:15:44

-

Lida Group Redefines Cost-Effective Construction for Warehouses

2025-11-13 14:13:06

-

Rapid Assembly with Lida Group's Metal Frame Building

2025-11-13 11:24:23

contact us

- Tel: +86-532-88966982

- Whatsapp: +86-13793209022

- E-mail: sales@lidajituan.com