For decades, the construction industry has been shackled by a seemingly unbreakable triad of constraints: projects could be fast, cheap, or high-quality, but never all three simultaneously. This conventional wisdom has dictated that cost-effectiveness often comes at the expense of durability, and that robust, long-lasting structures inherently demand a premium in both time and capital. Lida Group, a global leader in prefabricated and modular construction, is systematically dismantling this outdated paradigm. Through a synergistic integration of innovative engineering, advanced manufacturing, and strategic material science, Lida is not merely participating in the market; it is actively redefining the very standards of what constitutes cost-effective and durable construction. This article delves into the core methodologies and philosophies that enable Lida Group to deliver buildings that are simultaneously affordable, exceptionally durable, and rapidly deployable, setting a new benchmark for the entire industry.

**I. The Flawed Foundation of Traditional Construction**

To fully appreciate Lida’s revolution, one must first understand the inherent inefficiencies and compromises of traditional building methods.

**A. The Cost-Durability Dilemma**

In conventional construction, the pursuit of lower initial costs often leads to decisions that undermine long-term durability. This includes:

* **Use of Cost-Sensitive Materials:** Opting for lower-grade materials that are more susceptible to environmental degradation, pest infestation, and wear-and-tear.

* **Compressed Timelines Leading to Craftsmanship Deficits:** Rushing on-site labor can result in poor workmanship, improper installation of weather barriers, and inadequate sealing, creating latent defects that manifest as major durability issues years later.

* **Reactive Maintenance Cycles:** The “build-cheap-now, pay-more-later” model forces owners into a cycle of constant repairs and premature replacements, dramatically increasing the total cost of ownership.

**B. The Inefficiencies of On-Site Building**

The traditional construction site is a hotbed of unpredictability and waste.

* **Weather Dependency:** Projects are routinely delayed by rain, wind, and extreme temperatures, increasing labor costs and extending financing periods.

* **Material Waste:** On-site cutting and fitting generate an enormous amount of waste—often 15-30% of all materials delivered—which represents a direct financial loss and an environmental burden.

* **Inconsistent Quality Control:** Supervising the quality of work across a large, dynamic site with multiple trades is incredibly challenging. Variations in skill and oversight lead to inconsistencies in the final product, compromising both performance and longevity.

Lida Group’s entire operational model is engineered to surgically address and eliminate these foundational flaws.

**II. The Core Pillars of Lida’s Methodology**

Lida’s redefinition of standards rests on three interdependent pillars: Precision Manufacturing, Integrated Durability-by-Design, and a Holistic Life-Cycle Cost Approach.

**A. Pillar 1: Precision Manufacturing in a Controlled Environment**

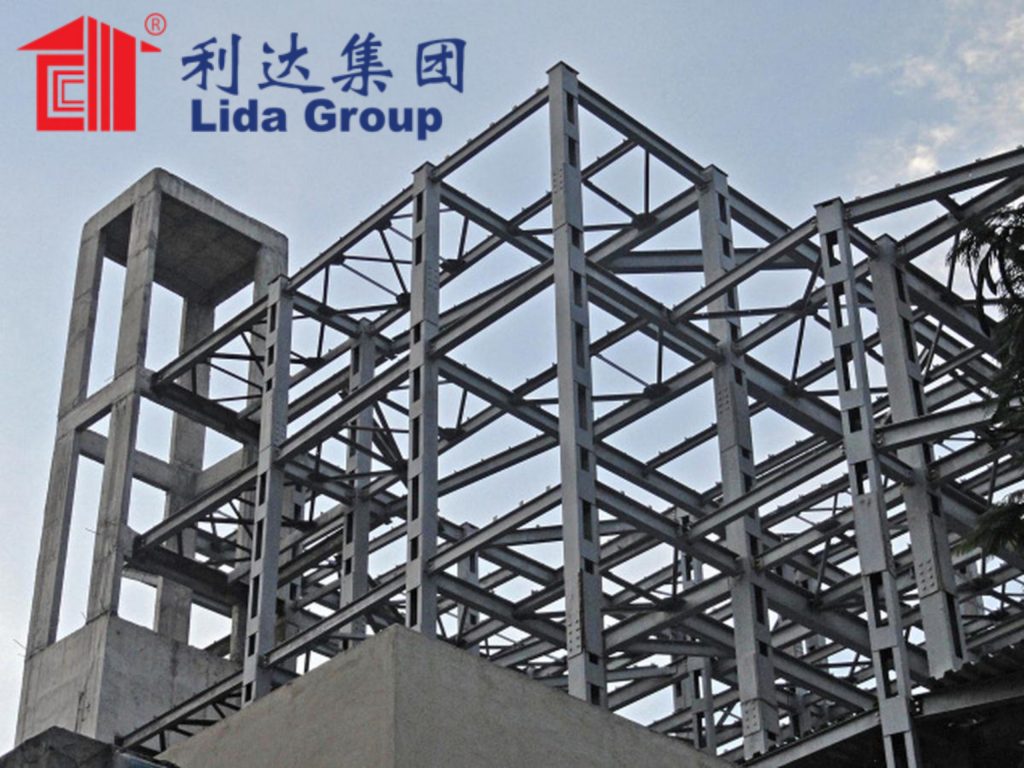

The most significant departure from tradition is Lida’s shift of value-added activities from the construction site to a controlled factory environment.

* **Building Information Modeling (BIM):** Every project begins with a comprehensive digital prototype. This 3D model integrates architectural, structural, and mechanical details, allowing engineers to optimize every component, identify and resolve conflicts virtually, and generate precise fabrication data. This digital rehearsal eliminates costly on-site errors and rework.

* **Computer-Aided Manufacturing (CAM):** Structural components, wall panels, and roof systems are fabricated using automated machinery. This ensures millimeter-perfect accuracy for every steel stud, panel, and connector. Such precision is unattainable with manual on-site cutting and assembly.

* **Assembly Line Production:** Buildings are assembled as modular units or panelized systems in a factory setting. This jig-based assembly guarantees consistency, squareness, and conformity to specifications for every single module that leaves the facility.

**The Impact on Cost and Durability:**

* **Cost Reduction:** Factory efficiency slashes labor hours, minimizes material waste to less than 5%, and reduces on-site supervision costs. The accelerated timeline also lowers financing costs and allows the client to generate revenue from the asset much sooner.

* **Durability Enhancement:** By building indoors, materials are protected from weather damage during construction. The controlled environment ensures that insulation is kept dry, air and vapor barriers are installed correctly and sealed continuously, and all connections are made to exact specifications. This results in a building that is fundamentally sounder and more resilient from day one.

**B. Pillar 2: Integrated Durability-by-Design**

Durability is not an afterthought or a result of using expensive materials; it is an intrinsic characteristic engineered into Lida’s building systems from the outset.

**1. The Structural Skeleton: Light Gauge Steel Framing**

Lida extensively uses high-tensile, light-gauge steel frames, which form a supremely durable core.

* **Strength and Resilience:** Steel offers an exceptional strength-to-weight ratio, capable of withstanding heavy snow loads, high winds, and seismic activity. Its inorganic nature makes it impervious to rot, mold, and pests like termites—a leading cause of structural failure in wood-framed buildings.

* **Dimensional Stability:** Unlike wood, which warps, twists, and shrinks over time, steel remains dimensionally stable. This eliminates problems like cracked drywall, sticking doors, and uneven floors, preserving the building’s integrity and appearance for decades.

**2. The Building Envelope: Advanced Sandwich Panel Systems**

For many projects, Lida employs structural insulated sandwich panels for walls and roofs. These panels are a masterpiece of integrated design.

* **Composite Action:** A high-density insulating core (such as PIR or Rockwool) is permanently bonded to durable facing materials (like galvanized or galvalume steel). This creates a single component that provides structure, insulation, and cladding simultaneously.

* **Superior Thermal and Airtight Performance:** The continuous insulation layer eliminates thermal bridging—the weak points in a building envelope where heat escapes. Combined with factory-applied seals at the joints, these panels create an exceptionally airtight envelope. This not only slashes energy costs by up to 50-60% but also prevents the moisture drive and condensation that can lead to structural decay and mold growth within walls.

* **Corrosion Protection:** The steel skins are typically given a multi-layer coating system, including a galvanized anti-corrosion layer and a durable color-finish coat (e.g., PVDF), providing exceptional resistance to rust and UV degradation.

**3. Long-Lasting Integrated Systems**

Durability extends to the building’s systems. Lida designs for ease of maintenance and longevity in MEP (Mechanical, Electrical, Plumbing) systems. The precision of the structure allows for perfectly laid-out and accessible utility chases, while the high-performance envelope reduces the strain and runtime on HVAC equipment, extending its service life.

**C. Pillar 3: Holistic Life-Cycle Cost Analysis**

Lida Group shifts the client’s perspective from the narrow focus on *initial construction cost* to the more meaningful metric of *Total Cost of Ownership (TCO)*.

* **Initial Capital Expenditure (CapEx):** While already competitive, Lida’s methods often lead to lower initial costs due to speed and efficiency.

* **Operational Expenditure (OpEx):** This is where Lida buildings deliver immense value. The superior energy efficiency of the building envelope leads to dramatically lower monthly utility bills. The durability of the materials and systems results in minimal repair and maintenance costs.

* **Reinvestment and Replacement Costs:** With a longer functional lifespan and reduced need for major renovations, the cost of capital reinvestment is pushed far into the future.

By demonstrating that a slightly higher initial investment (or often, a lower one) yields massive savings over 10, 20, or 50 years, Lida makes a compelling case for true cost-effectiveness.

**III. Case in Point: The “Apex Logistics Hub” Revisited**

A practical example illuminates these principles. The Apex Logistics Hub, a 15,000 sqm distribution center, was completed using Lida’s sandwich panel and steel frame system.

* **Timeline:** Completed in under four months, versus an estimated 12-14 months for a conventional build. This saved the client over eight months of financing costs and allowed them to capture peak-season revenue.

* **Durability Performance:** The steel structure and panels are designed for a 50+ year service life with minimal maintenance. The building is resistant to the impact from loading operations and is entirely immune to the pest problems that plague traditional warehouses.

* **Energy Efficiency:** The PIR-cored sandwich panels achieved a U-value that reduced the building’s heating and cooling load by over 60% compared to a standard insulated metal building, slashing its operational carbon footprint and utility expenses.

* **TCO:** While the initial cost was competitive, the client’s financial analysis projected that the combined savings from accelerated occupancy, lower energy bills, and eliminated pest control and high maintenance would result in a TCO reduction of more than 30% over 25 years.

**IV. Redefining Standards Across Sectors**

Lida’s approach is not limited to a single building type. It is redefining standards across the spectrum:

* **Commercial and Industrial:** Warehouses, factories, and office buildings benefit from the clear-span spaces, low operating costs, and durability.

* **Residential:** Multi-story apartment complexes and housing developments achieve higher quality, better acoustics, and faster occupancy.

* **Institutional:** Schools and clinics are built faster, providing crucial community services sooner, with healthier indoor environments and lower public operating budgets.

* **Agricultural:** Buildings for livestock and crop storage offer superior climate control and sanitation, improving operational outcomes.

**V. The Sustainable Imperative**

This new paradigm is inherently more sustainable. The massive reduction in construction waste, the superior energy efficiency in operation, the use of recyclable steel, and the longer building lifespan all contribute to a drastically reduced environmental footprint. Lida proves that the most cost-effective and durable path is also the most ecologically responsible one.

**Conclusion: A Lasting Legacy of Value and Resilience**

Lida Group is not simply selling buildings; it is advocating for and delivering a superior model of value creation. By fundamentally re-engineering the construction process, the company has successfully decoupled cost from compromise and durability from extravagance. The old triad of “fast, cheap, or good—pick two” has been rendered obsolete.

Through the triumvirate of **precision manufacturing, integrated durability-by-design, and a holistic life-cycle cost perspective,** Lida delivers assets that are capital-efficient to erect, inexpensive to operate, and built to endure for generations. They have shifted the industry’s focus from the myopic view of upfront price to the intelligent metric of long-term value.

In doing so, Lida Group is setting a new global standard. They demonstrate that the future of construction is not about finding cheaper ways to build the same fragile structures, but about leveraging innovation to create buildings that are inherently better, smarter, and more resilient. For any project stakeholder seeking to maximize return on investment, minimize risk, and build a legacy of quality, the choice is clear. Lida Group has redefined the playing field, proving that true cost-effectiveness is measured not in the first cost, but in the lasting value of a durable, high-performing, and efficient building.

Related news

-

Efficient and Robust Metal Frame Construction by Lida Group

2025-11-26 17:42:59

-

Why Choose a Steel Structure Building for Your Project?

2025-11-26 17:36:50

-

Lida Group Delivers Cost-Effective Durable Construction Solutions

2025-11-26 17:30:46

contact us

- Tel: +86-532-88966982

- Whatsapp: +86-13793209022

- E-mail: sales@lidajituan.com