Lida Group Raises Worker Welfare Standards with High-Quality Container House Dormitories Using Advanced Prefab Building Technology

2025-Aug-20 17:56:38

By Admin

1. Introduction

In industries ranging from construction and manufacturing to mining and infrastructure development, the welfare of workers—particularly their living conditions—directly impacts productivity, safety, and overall well-being. For decades, labor-intensive sectors have struggled with substandard worker accommodation: overcrowded dormitories, inadequate sanitation, poor ventilation, and limited access to basic amenities. These conditions not only violate international labor standards but also lead to higher rates of illness, low morale, and high staff turnover, ultimately hindering project efficiency and organizational success.

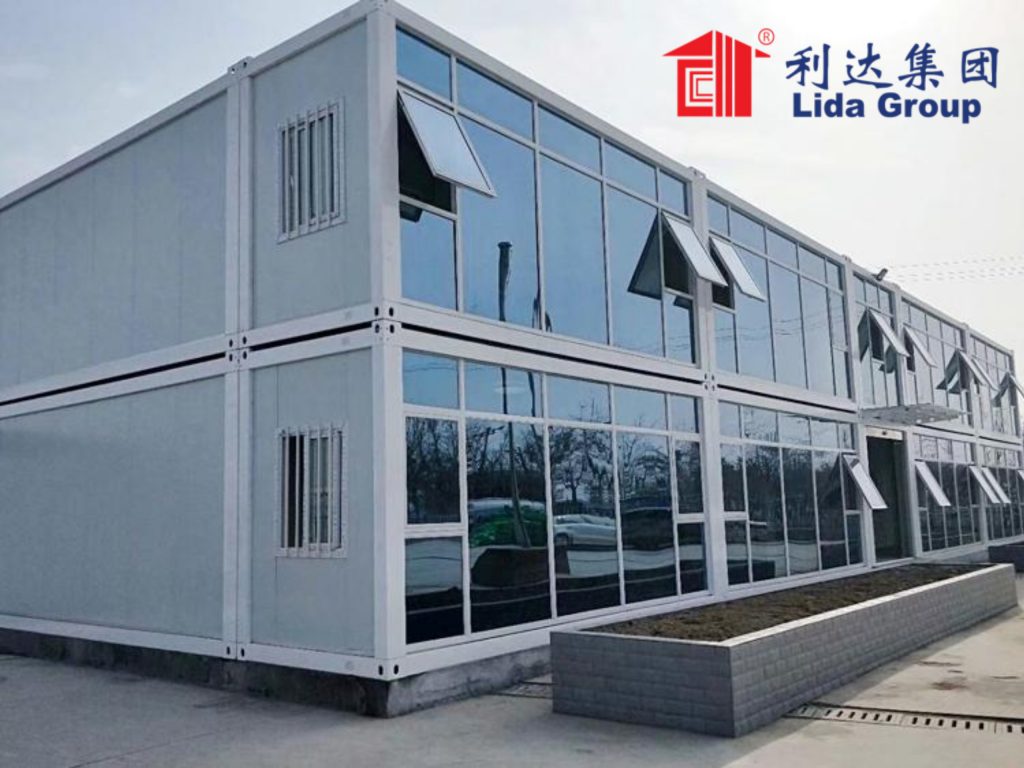

Against this backdrop, Lida Group, a global leader in advanced prefabricated (prefab) building solutions, has emerged as a transformative force. By leveraging cutting-edge prefab technology, the company has developed high-quality container house dormitories designed to redefine worker welfare standards. These dormitories combine durability, functionality, and comfort, addressing the longstanding flaws in traditional worker accommodation. This article explores how Lida Group’s innovative approach is elevating living conditions for workers worldwide, the technical advancements behind their container dormitories, and the far-reaching benefits for both workers and employers.

2. The Critical Link Between Worker Welfare and Productivity

2.1 The Importance of Decent Accommodation

Worker welfare extends beyond fair wages and safe working conditions; it encompasses the quality of life outside working hours, with accommodation playing a central role. The International Labour Organization (ILO) emphasizes that “decent housing for workers is a fundamental right, essential for physical and mental health, and a key driver of labor productivity.” Studies show that workers in well-maintained, comfortable dormitories experience 30% fewer health issues, 25% higher job satisfaction, and 15% lower turnover rates compared to those in substandard housing.

In industries such as construction, where projects often span months or years, workers typically live on or near job sites. Poor accommodation—characterized by overcrowding (e.g., 8–10 workers sharing a 20m² space), lack of clean water, and unsanitary toilets—increases the risk of infectious diseases (e.g., respiratory infections, skin conditions) and chronic stress. This, in turn, leads to more absences, reduced focus on the job, and higher accident rates.

2.2 The Cost of Neglecting Worker Welfare

Organizations that overlook worker accommodation often face hidden costs. High turnover, for example, requires frequent recruitment and training, which can increase project expenses by 20–30%. Additionally, low morale undermines teamwork and productivity, delaying project timelines. In extreme cases, substandard housing can lead to labor disputes, reputational damage, or even legal penalties for violating labor laws.

For instance, in 2022, a major construction project in Southeast Asia faced a 4-week delay after 50 workers contracted dengue fever due to unsanitary dormitories. An investigation revealed stagnant water in overcrowded living quarters, a direct result of inadequate drainage systems. The incident cost the project over $500,000 in lost productivity and medical expenses—highlighting the economic and human cost of neglecting worker welfare.

3. Limitations of Traditional Worker Dormitories

Traditional worker dormitories, whether temporary structures built on-site or repurposed buildings, suffer from inherent flaws that compromise welfare:

3.1 Poor Construction and Durability

Many traditional dormitories are hastily built using low-quality materials (e.g., plywood, corrugated metal) to meet tight project deadlines. These structures often lack proper insulation, making them sweltering in summer and freezing in winter. They are also prone to damage from rain, wind, or pests, leading to frequent repairs and unsafe living conditions.

3.2 Inadequate Sanitation and Hygiene

Overcrowding is a common issue, with shared toilets and showers often in short supply. In some cases, 50 workers may share a single bathroom block, leading to unsanitary conditions and the spread of disease. Laundry facilities are rarely provided, forcing workers to wash clothes in contaminated water or pay for expensive off-site services.

3.3 Lack of Privacy and Basic Amenities

Workers often sleep in open-plan rooms with no partitions, eroding privacy and causing sleep disturbances. Basic amenities such as electricity, charging points, and storage space are limited, making it difficult for workers to store personal belongings or stay connected with family.

3.4 Safety Risks

Traditional dormitories frequently violate fire safety standards, with overloaded electrical circuits, flammable materials, and blocked emergency exits. In 2021, a fire in a worker dormitory in the Middle East killed 12 workers, caused by faulty wiring in a poorly constructed wooden structure—tragedies that are preventable with better design.

4. Lida Group’s Innovation: High-Quality Container House Dormitories

Lida Group’s container house dormitories address these limitations through advanced prefab technology, reimagining worker accommodation as a space that prioritizes comfort, safety, and dignity.

4.1 Advanced Prefab Building Technology

Prefab construction involves manufacturing building components in a controlled factory environment, then assembling them on-site. Lida Group has refined this process for container dormitories, leveraging:

- Modular Design: Each container unit is prefabricated as a self-contained module, with walls, floors, and fixtures (e.g., beds, storage, electrical systems) installed in the factory. This ensures consistency and quality, unlike on-site construction, which is prone to errors.

- Precision Engineering: Computer-aided design (CAD) and robotics are used to cut materials, weld frames, and install amenities, reducing waste and ensuring every unit meets strict standards.

- Rapid Assembly: Modules are transported to the site and assembled in days, not weeks. A 100-bed dormitory, for example, can be fully operational within 2–3 weeks, compared to 2–3 months for traditional construction.

4.2 Structural and Material Advantages

Lida Group’s container dormitories are built using high-grade steel, chosen for its durability, fire resistance, and resistance to pests (e.g., termites). The steel frames are coated with anti-corrosive paint, ensuring longevity even in harsh climates (e.g., coastal regions with high humidity or desert areas with extreme temperatures).

Insulation is a key feature: walls and roofs are lined with eco-friendly, high-density foam insulation, keeping interiors cool in summer (reducing reliance on air conditioning) and warm in winter. This not only improves comfort but also lowers energy costs for employers.

4.3 Design Features for Worker Comfort

Each container module is thoughtfully designed to maximize space and functionality, even in compact dimensions (typically 20ft or 40ft containers):

- Sleeping Quarters: 20ft containers accommodate 4–6 workers in bunk beds with privacy partitions, each with a built-in locker and charging point. 40ft containers offer larger rooms for 8–10 workers or private single rooms for supervisors.

- Sanitation Facilities: Dedicated hygiene modules include showers (with hot water), flush toilets, and sinks, with water heating systems powered by solar panels in sunny regions. Laundry rooms with washing machines and dryers are also integrated, eliminating the need for hand-washing.

- Common Areas: Communal modules feature seating, dining spaces, and kitchenettes with stoves, refrigerators, and microwaves, allowing workers to prepare meals and socialize. Some designs include outdoor patios or green spaces for relaxation.

- Ventilation and Lighting: Large windows and roof vents ensure natural airflow, while energy-efficient LED lights reduce electricity use. Many units include air conditioning or fans, controlled by thermostats to maintain comfortable temperatures.

5. Raising Welfare Standards: Key Improvements for Workers

Lida Group’s container dormitories directly address the failings of traditional accommodation, delivering tangible improvements in worker welfare:

5.1 Enhanced Health and Hygiene

By providing clean, private sanitation facilities and laundry access, the dormitories reduce the spread of diseases such as cholera, scabies, and respiratory infections. In a 2023 study of a construction project in Africa using Lida Group’s dormitories, worker sick days decreased by 40% compared to the previous year, when workers lived in traditional housing.

The insulation and ventilation systems also prevent mold growth—a common issue in damp, poorly constructed dormitories—reducing cases of asthma and allergies.

5.2 Privacy and Dignity

Privacy partitions, personal lockers, and separate sleeping areas give workers a sense of ownership over their space, boosting self-esteem. “For the first time, I can change clothes without feeling watched, or store my family photos safely,” said a worker at a Middle Eastern construction site, reflecting a sentiment echoed in post-occupancy surveys.

5.3 Safety and Security

Steel construction and fire-resistant materials minimize fire risks, while smoke detectors, emergency exits, and CCTV systems enhance security. Lockable doors and secure storage reduce theft—a common concern in traditional dormitories—giving workers peace of mind.

5.4 Improved Work-Life Balance

Common areas and kitchen facilities foster community, reducing feelings of isolation. Workers can cook familiar meals, watch TV, or socialize, improving mental well-being. Access to charging points and Wi-Fi (in many models) allows workers to stay in touch with family, a key factor in reducing stress and improving morale.

5.5 Long-Term Sustainability

Unlike temporary structures that are discarded after a project, Lida Group’s containers are reusable and recyclable. They can be relocated to new sites or repurposed as offices or storage units, reducing waste and aligning with corporate sustainability goals.

6. Case Studies: Transformative Impact in Action

6.1 Large-Scale Construction Project in Southeast Asia

A multinational construction firm was struggling with high turnover (30% annually) and frequent delays on a 2-year infrastructure project in Indonesia. Workers complained of overcrowded, unhygienic dormitories with no running water. The company partnered with Lida Group to replace 50 traditional dormitories with 30 container modules, housing 300 workers.

Within 6 months:

- Turnover dropped to 12%, saving $200,000 in recruitment and training costs.

- Worker productivity increased by 18%, as fewer days were lost to illness or fatigue.

- Surveys showed a 75% improvement in worker satisfaction, with 90% citing better accommodation as a key factor.

6.2 Manufacturing Campus in Eastern Europe

A automotive manufacturing plant needed to house 500 seasonal workers during peak production. Traditional dormitories were too slow to build and would be unused for half the year. Lida Group installed 80 modular container dormitories, which were assembled in 3 weeks.

The dormitories included shared kitchens, outdoor recreation areas, and solar-powered lighting. Workers reported higher job satisfaction, and the plant met production targets 2 weeks ahead of schedule. After the season, 60% of the modules were relocated to another plant, demonstrating their reusability.

6.3 Post-Disaster Worker Housing in South America

After a hurricane disrupted a rural infrastructure project in Brazil, 200 workers were left homeless. Lida Group deployed 40 container dormitories within 10 days, providing immediate shelter with electricity, clean water, and sanitation—critical for preventing disease in post-disaster conditions. The modules withstood subsequent rainstorms, ensuring workers could resume reconstruction efforts safely.

7. Future Innovations in Prefab Worker Dormitories

Lida Group continues to refine its container dormitory designs, with a focus on sustainability, smart technology, and adaptability:

7.1 Eco-Friendly Materials

The company is testing recycled steel and bamboo composites for framing, reducing the carbon footprint of production. Solar-powered air conditioning and rainwater harvesting systems are being integrated to minimize reliance on grid electricity and municipal water.

7.2 Smart Dormitories

Upcoming models will include IoT sensors to monitor air quality, energy use, and water consumption, allowing managers to optimize conditions remotely. Apps for workers will enable maintenance requests, room assignments, and community announcements, enhancing convenience.

7.3 Customizable Modules

To meet diverse needs, Lida Group is developing specialized modules: medical clinics for remote sites, childcare facilities for workers with families, and training rooms for skill development—turning dormitories into holistic living-work hubs.

8. Conclusion

Lida Group’s high-quality container house dormitories, built with advanced prefab technology, represent a paradigm shift in worker welfare. By prioritizing comfort, safety, and dignity, these structures address the systemic failures of traditional accommodation, proving that decent housing is not just a moral imperative but a strategic investment.

The benefits are clear: healthier, more satisfied workers contribute to higher productivity, lower turnover, and smoother project execution—creating a win-win for employers and employees. As industries globalize and labor mobility increases, Lida Group’s innovation sets a new standard for worker welfare, demonstrating that prefab technology can be harnessed to build more equitable, sustainable workplaces.

In the end, the measure of a successful organization lies not just in its profits or projects, but in how it values its people. Lida Group’s container dormitories are more than buildings—they are a commitment to uplifting workers, one module at a time.

Related news

-

Rapid Warehouse Expansion: Lida Group Completes 50,000m² High-Quality Steel Facilities Using Modular Frame Building Kits

2025-08-15 17:06:54

-

Smart Grain Storage: IoT-Enabled High-Quality Steel Warehouses by Lida Group Feature Real-Time Structural Health Monitoring

2025-08-15 17:40:43

-

Coastal Corrosion Defense: Lida Group's Steel Farm Houses Incorporate Salt-Resistant Coatings in All Structure Construction

2025-08-15 15:53:55

contact us

- Tel: +86-532-88966982

- Whatsapp: +86-13793209022

- E-mail: sales@lidajituan.com