Lida Group Expands Its Prefab Mobile Container House Portfolio

2025-Nov-21 17:55:44

By Admin

Introduction

In a global construction landscape grappling with urgent challenges—escalating material costs, labor shortages, environmental degradation, and the need for rapid, adaptable building solutions—prefab mobile container houses have emerged as a transformative force. These structures, leveraging the durability and modularity of shipping containers, offer a compelling blend of sustainability, cost-efficiency, and flexibility, addressing critical needs across residential, commercial, industrial, and humanitarian sectors. Among the industry leaders driving innovation in this space is Lida Group, a renowned manufacturer of prefabricated construction solutions with a decades-long track record of delivering high-quality, scalable building systems.

In response to surging global demand for sustainable and agile construction, Lida Group has announced a strategic expansion of its prefab mobile container house portfolio. This expansion represents more than a product line extension; it reflects a deliberate commitment to addressing pressing global issues, from affordable housing shortages and climate change to disaster relief and urbanization. By integrating cutting-edge technology, eco-friendly materials, and customer-centric design, Lida Group’s new offerings aim to set new standards for performance, customization, and environmental responsibility in the container construction industry.

This article provides an in-depth analysis of Lida Group’s expanded prefab mobile container house portfolio. It explores the company’s market position and historical expertise, details the technical specifications and innovative features of the new product lines, examines their sustainability and cost-effectiveness, showcases real-world applications through case studies, and evaluates the portfolio’s potential impact on global construction trends. As the world increasingly seeks solutions that balance functionality, affordability, and sustainability, Lida Group’s expansion serves as a model for how prefab container construction can drive positive change across diverse sectors and regions.

1. Lida Group: A Leader in Prefab Construction Excellence

1.1 Company Overview and Historical Foundation

Founded in [insert year, e.g., 1998], Lida Group has evolved from a regional construction materials supplier to a global leader in prefabricated building solutions. Headquartered in [insert location, e.g., Qingdao, China], the company operates state-of-the-art manufacturing facilities spanning over [insert area, e.g., 500,000 square meters], with a global presence that includes distribution centers, sales offices, and partner networks in over 120 countries across Asia, Europe, Africa, North America, and South America. Lida Group’s core mission—“Building a Sustainable Future Through Innovative Prefab Solutions”—has guided its growth, with a focus on delivering products that prioritize quality, efficiency, and environmental stewardship.

Over the years, Lida Group has diversified its product portfolio to include prefab steel structures, modular housing, container homes, precast concrete components, and temporary construction facilities. The company’s early adoption of modular construction principles and factory-controlled production processes has positioned it as an innovator in the industry, with a reputation for delivering projects on time, within budget, and to the highest quality standards. Lida Group’s client base ranges from governments and non-governmental organizations (NGOs) to commercial developers, industrial enterprises, and individual homeowners, reflecting the versatility of its solutions.

1.2 Core Competencies and Industry Leadership

Lida Group’s success in the prefab construction sector is built on four core competencies: technological innovation, manufacturing excellence, sustainability commitment, and customer-centric design. The company invests heavily in research and development (R&D), allocating [insert percentage, e.g., 8%] of its annual revenue to developing new materials, improving production processes, and enhancing product performance. This commitment to innovation has resulted in over [insert number, e.g., 200] patents, covering areas such as energy-efficient insulation systems, modular connection technologies, and sustainable material integration.

In terms of manufacturing, Lida Group operates under strict quality control standards, adhering to international certifications such as ISO 9001 (Quality Management), ISO 14001 (Environmental Management), and OHSAS 18001 (Occupational Health and Safety). Its factories utilize advanced automation technologies, including robotic welding, computer numerical control (CNC) cutting, and Building Information Modeling (BIM) integration, ensuring precision, consistency, and efficiency in component production. This factory-controlled approach reduces waste, minimizes errors, and accelerates production timelines—key advantages over traditional on-site construction.

Sustainability is a cornerstone of Lida Group’s operations. The company has implemented a comprehensive environmental management system that covers all stages of the product lifecycle, from material sourcing and manufacturing to transportation, installation, and end-of-life recycling. By prioritizing recycled materials, energy-efficient production processes, and low-carbon designs, Lida Group has positioned its products as leaders in sustainable construction, aligning with global initiatives such as the Paris Agreement and the United Nations Sustainable Development Goals (SDGs).

1.3 Market Position and Growth Trajectory

Lida Group holds a significant share of the global prefab container house market, with a particularly strong presence in emerging economies where demand for affordable, rapid-construction housing is high. According to industry reports, the company’s container house division has experienced a compound annual growth rate (CAGR) of [insert percentage, e.g., 15%] over the past five years, outpacing the overall prefab construction market’s CAGR of 6%. This growth is driven by increasing adoption of container homes in sectors such as affordable housing, disaster relief, tourism (glamping and eco-resorts), and temporary industrial facilities.

The decision to expand its prefab mobile container house portfolio comes at a time of unprecedented market opportunity. The global prefab container house market is projected to reach [insert value, e.g., $28 billion] by 2030, fueled by factors such as urbanization, housing shortages, stricter environmental regulations, and the need for resilient, quickly deployable structures. Lida Group’s expansion aims to capitalize on this growth by addressing unmet customer needs, including greater customization options, enhanced sustainability features, and improved performance in extreme environments.

2. The Expanded Prefab Mobile Container House Portfolio: Product Lines and Innovations

Lida Group’s expanded portfolio encompasses four distinct product lines, each tailored to specific market segments and applications. These lines—EcoLiving Series, Rapid Deploy Series, Custom Build Series, and Industrial Work Series—incorporate the latest advancements in materials, design, and technology, while maintaining the core advantages of container construction: modularity, durability, and cost-effectiveness. Below is a detailed overview of each product line, including key features, technical specifications, and target applications.

2.1 EcoLiving Series: Sustainable Residential Solutions

The EcoLiving Series is designed for permanent or long-term residential use, targeting homeowners, developers, and governments seeking affordable, eco-friendly housing options. This product line redefines container homes by prioritizing comfort, aesthetics, and sustainability, dispelling common misconceptions about container housing as “spartan” or “temporary.”

Key Features and Innovations

- Sustainable Material Integration: The EcoLiving Series utilizes high-grade, recycled shipping containers (90% recycled steel content) as the structural base, reducing embodied carbon by up to 45% compared to traditional residential construction. The containers are reinforced with corrosion-resistant coatings (zinc-aluminum alloy or powder coating) to ensure durability in diverse climates, from coastal regions to arid deserts.

- Energy-Efficient Design: Each unit features a high-performance insulation system, combining polyurethane foam (PUF) insulation (R-value of [insert value, e.g., 30]) in walls, floors, and ceilings with double-glazed, low-emissivity (low-E) windows. This insulation package reduces energy consumption for heating and cooling by 40-50% compared to standard container homes. The series also includes optional solar panel integration, energy-efficient appliances, and smart home systems (lighting, temperature control) to further reduce carbon footprints.

- Modular and Expandable Layouts: The EcoLiving Series offers flexible floor plans, ranging from 1-bedroom (20-foot container) to 4-bedroom (40-foot container with extensions) units. The modular design allows homeowners to expand their living space by adding additional containers, which can be connected seamlessly using Lida Group’s patented locking system. Layouts are customizable, with options for open-concept living areas, private bedrooms, and outdoor spaces (decks, patios).

- Aesthetic Customization: Unlike traditional container homes with a utilitarian appearance, the Eco Living Series offers a range of exterior and interior finishes to match individual preferences. Exterior options include wood cladding, fiber-cement panels, or vertical gardens (living walls), while interiors feature modern fixtures, engineered wood flooring, and customizable cabinetry. The series also includes large windows and skylights to maximize natural light, creating bright, inviting living spaces.

- Sustainable Systems: All units in the Eco Living Series are equipped with water-saving fixtures (low-flow toilets, faucets) and optional rainwater collection systems, reducing water consumption by 30%. Wastewater treatment options (septic tanks or compact sewage treatment plants) are available for off-grid applications.

Technical Specifications

- Container Sizes: 20ft (L6.058m x W2.438m x H2.591m) or 40ft (L12.192m x W2.438m x H2.591m) standard or high-cube (H2.896m)

- Structural Load Capacity: Wind resistance up to 150 mph (240 km/h), seismic resistance up to magnitude 8.0

- Insulation: PUF insulation (50mm-100mm) with vapor barrier

- Windows: Aluminum-framed, double-glazed low-E windows (thermal transmittance U-value ≤ 1.2 W/m²K)

- Roofing: Metal roofing with waterproof membrane (PVC or TPO)

- Flooring: Engineered wood or vinyl flooring with underfloor insulation

- Electrical: 110V/220V wiring, LED lighting, solar-ready electrical system

- Plumbing: PEX piping, low-flow fixtures, optional rainwater harvesting system

Target Applications

- Affordable housing developments (low- and middle-income households)

- Single-family homes (urban infill, rural properties, vacation homes)

- Multi-unit residential buildings (apartments, townhouses)

- Student housing and staff quarters

2.2 RapidDeploy Series: Emergency and Temporary Housing

The RapidDeploy Series is engineered for fast deployment in emergency situations, such as natural disasters, humanitarian crises, or temporary infrastructure needs. This product line prioritizes speed, durability, and ease of installation, ensuring that displaced populations or temporary workers can access safe, functional shelter within days.

Key Features and Innovations

- Ultra-Fast Deployment: The RapidDeploy Series can be manufactured, transported, and installed in as little as 48 hours for emergency situations. Each unit is prefabricated in the factory, with all electrical, plumbing, and fixtures pre-installed, eliminating the need for on-site finishing work. The units are designed to be lifted and placed by crane or forklift, requiring minimal on-site labor (2-3 workers per unit).

- Resilient Design: Built to withstand extreme weather conditions, including hurricanes, earthquakes, floods, and wildfires, the RapidDeploy Series features reinforced steel frames, impact-resistant windows, and waterproof seals. The containers are treated with anti-corrosion and fire-retardant coatings, ensuring safety and durability in harsh environments.

- Self-Sufficient Systems: For off-grid or disaster-stricken areas with limited infrastructure, the RapidDeploy Series offers optional self-sufficient systems, including solar panels (100W-300W), battery storage (100Ah-200Ah), and portable water purification units. These systems allow the units to operate independently of municipal utilities, providing essential services such as electricity, clean water, and heating/cooling.

- Modular Scalability: The series is highly scalable, with the ability to deploy single units or complex clusters (e.g., emergency shelters, field hospitals, temporary offices). Units can be connected to form larger spaces, such as communal kitchens, dining areas, or medical facilities, using Lida Group’s quick-connect system.

- Human-Centric Design: Despite its temporary nature, the RapidDeploy Series prioritizes occupant comfort and dignity. Units include adequate ventilation, insulation for temperature regulation, private sleeping quarters, and basic sanitation facilities (toilet, shower, sink). The design also incorporates privacy features, such as lockable doors and partitioned spaces, to accommodate families and individuals.

Technical Specifications

- Container Sizes: 20ft standard (L6.058m x W2.438m x H2.591m)

- Deployment Time: 48-72 hours from factory to occupancy

- Structural Load Capacity: Wind resistance up to 170 mph (274 km/h), seismic resistance up to magnitude 8.5, flood resistance up to 1.5m water depth

- Insulation: Rock wool insulation (50mm) with fire-retardant properties

- Windows: Impact-resistant acrylic windows with steel shutters

- Roofing: Metal roofing with reinforced waterproof membrane

- Flooring: Anti-slip, easy-to-clean vinyl flooring

- Electrical: Solar-ready wiring, LED lighting, USB charging ports

- Plumbing: Compact sanitation system (composting toilet or portable sewage tank), water storage tank (200L-500L)

- Optional Add-Ons: Solar panel system, water purification unit, heating/cooling unit (split-system AC)

Target Applications

- Disaster relief housing (hurricanes, earthquakes, floods, wildfires)

- Humanitarian aid shelters (refugee camps, displaced persons settlements)

- Temporary construction site offices and worker housing

- Emergency medical facilities (field hospitals, clinics)

- Military encampments and temporary barracks

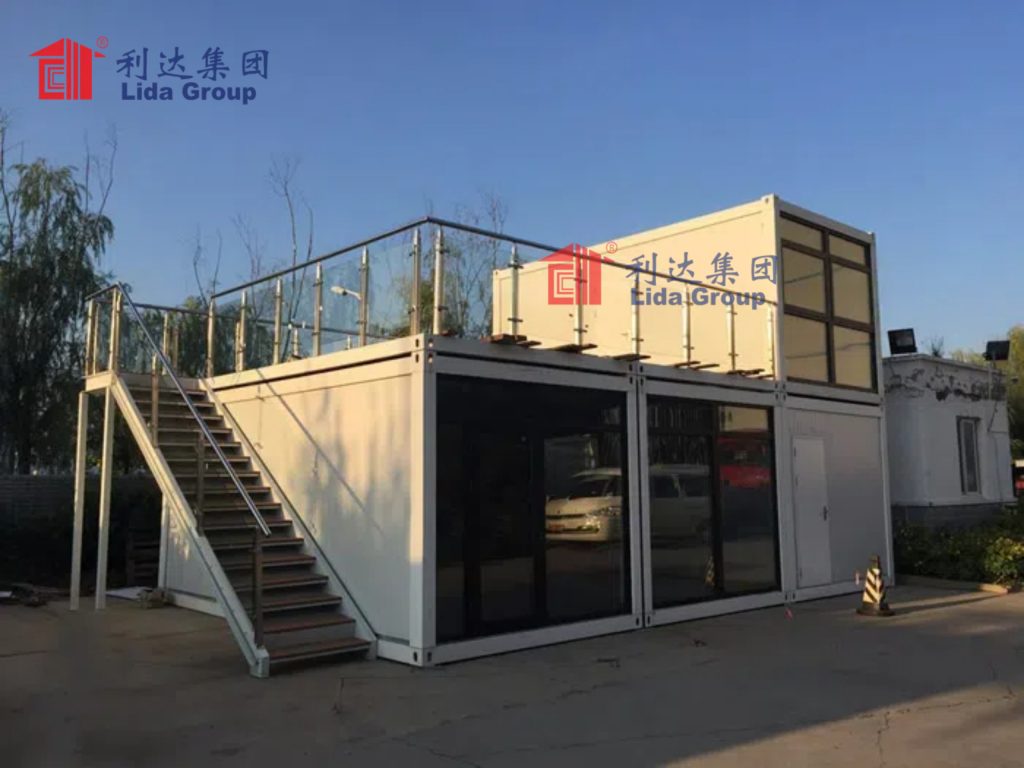

2.3 CustomBuild Series: Commercial and Leisure Solutions

The CustomBuild Series caters to commercial clients, including hoteliers, restaurateurs, retailers, and event organizers, seeking unique, customizable container-based spaces. This product line combines the durability and cost-effectiveness of container construction with high-end design, allowing businesses to create distinctive, brand-aligned spaces that stand out in competitive markets.

Key Features and Innovations

- Highly Customizable Design: The CustomBuild Series offers unlimited design flexibility, with options for unique layouts, exterior finishes, and interior configurations. Lida Group’s in-house design team collaborates with clients to create custom solutions, from boutique hotels and cafes to pop-up shops and event venues. The modular nature of containers allows for creative configurations, such as stacked units, cantilevered structures, and interconnected spaces.

- Premium Materials and Finishes: To meet commercial standards, the CustomBuild Series uses high-quality materials, including commercial-grade flooring (tile, concrete, or hardwood), durable exterior cladding (metal, wood, or composite panels), and energy-efficient HVAC systems. Interior finishes can be tailored to brand aesthetics, with options for custom cabinetry, lighting, and fixtures.

- Functional Commercial Features: The series includes features essential for commercial operations, such as:

-

- Commercial-grade kitchens (for restaurants and cafes) with stainless steel appliances, ventilation systems, and plumbing.

-

- Retail-specific features (large display windows, rolling doors, customizable shelving).

-

- Hospitality amenities (en-suite bathrooms, soundproofing, climate control) for hotels and glamping resorts.

-

- Event-specific features (movable walls, stage platforms, outdoor seating areas).

- Sustainable Commercial Practices: The CustomBuild Series aligns with growing consumer demand for sustainable businesses, incorporating eco-friendly features such as solar panels, rainwater harvesting, energy-efficient lighting, and recycled materials. These features not only reduce environmental impact but also lower operational costs for businesses.

- Quick Installation and Minimal Disruption: For commercial clients, time is money. The CustomBuild Series is prefabricated off-site, reducing on-site construction time by 60-70% compared to traditional commercial construction. This minimizes disruption to surrounding areas (critical for urban locations) and allows businesses to open sooner, generating revenue faster.

Technical Specifications

- Container Sizes: 20ft, 40ft standard or high-cube, or custom-sized modules

- Structural Load Capacity: Wind resistance up to 150 mph (240 km/h), seismic resistance up to magnitude 7.5

- Insulation: PUF or rock wool insulation (50mm-150mm)

- Windows: Customizable windows (aluminum or steel frames, single or double-glazed)

- Roofing: Metal roofing, green roofing, or solar roofing options

- Flooring: Commercial-grade tile, concrete, hardwood, or composite flooring

- HVAC: Commercial-grade split-system AC, heating, and ventilation systems

- Electrical: 3-phase electrical system, LED lighting, custom wiring for commercial equipment

- Plumbing: Commercial-grade plumbing with water-saving fixtures

- Optional Add-Ons: Solar panels, rainwater harvesting, green walls, outdoor seating areas

Target Applications

- Boutique hotels and glamping resorts

- Restaurants, cafes, and bars

- Pop-up shops and retail stores

- Event venues and exhibition spaces

- Office spaces and co-working facilities

- Educational facilities (classrooms, labs)

2.4 IndustrialWork Series: Industrial and Temporary Infrastructure

The IndustrialWork Series is designed for industrial applications, including temporary warehouses, workshops, construction site offices, and storage facilities. This product line prioritizes durability, functionality, and cost-effectiveness, meeting the rigorous demands of industrial operations.

Key Features and Innovations

- Heavy-Duty Construction: The IndustrialWork Series uses reinforced shipping containers (Corten steel) with enhanced structural integrity, capable of supporting heavy loads (up to [insert weight, e.g., 5 tons] per square meter). The containers are designed to withstand harsh industrial environments, including exposure to chemicals, extreme temperatures, and heavy machinery.

- Functional Industrial Layouts: The series offers practical layouts tailored to industrial needs, including open-plan warehouses, partitioned workshops, and combined office-storage spaces. Units can be customized with features such as roll-up doors (for easy access to equipment and materials), loading docks, and mezzanine floors (for additional storage space).

- Low Maintenance and Longevity: Industrial clients require structures that are low maintenance and long-lasting. The IndustrialWork Series features corrosion-resistant coatings, durable flooring, and weatherproof seals, reducing maintenance costs over the structure’s lifespan (estimated at 25-30 years). The steel construction is resistant to pests, rot, and decay, ensuring reliability in industrial settings.

- Cost-Effective and Scalable: Compared to traditional industrial construction, the IndustrialWork Series offers significant cost savings (30-40% lower total costs) due to streamlined production, reduced labor requirements, and minimal on-site construction time. The modular design allows for easy scalability, with the ability to add additional units as business needs grow.

- Compliance with Industrial Standards: The series meets international industrial standards for safety, including fire safety (fire-retardant materials, smoke detectors), electrical safety (compliant wiring, circuit breakers), and structural safety (load-bearing capacity, wind resistance). Lida Group provides certification documentation for all units, ensuring compliance with local building codes and regulations.

Technical Specifications

- Container Sizes: 20ft, 40ft standard or high-cube, or custom-length modules (up to 60ft)

- Structural Load Capacity: Floor load capacity up to 5 tons/m², roof load capacity up to 1 ton/m²

- Insulation: Optional rock wool or PUF insulation (for climate-controlled environments)

- Doors: Roll-up doors (width 3m-5m, height 2m-3m), personnel doors (steel or aluminum)

- Windows: Optional steel-framed windows (impact-resistant)

- Roofing: Metal roofing with waterproof membrane

- Flooring: Steel plate or concrete flooring (capable of supporting heavy machinery)

- Electrical: 3-phase electrical system, LED lighting, outlets for industrial equipment

- Plumbing: Optional plumbing for restrooms or utility areas

- Optional Add-Ons: Mezzanine floors, loading docks, climate control systems, security systems

Target Applications

- Temporary and permanent warehouses

- Industrial workshops and manufacturing facilities

- Construction site offices and storage

- Mining and oilfield accommodations and facilities

- Agricultural storage and processing facilities

- Logistics and distribution centers

3. Sustainability: A Core Pillar of Lida Group’s Expanded Portfolio

Sustainability is not an afterthought for Lida Group—it is a fundamental design principle integrated into every aspect of the expanded prefab mobile container house portfolio. The company recognizes that container construction inherently offers sustainability advantages, but it has gone further to enhance these benefits through innovative materials, energy-efficient design, and circular economy practices. Below is a detailed analysis of the sustainability features of the portfolio, including environmental impact reduction, resource efficiency, and alignment with global sustainability goals.

3.1 Reduced Environmental Impact and Carbon Footprint

One of the most significant sustainability benefits of Lida Group’s container houses is their reduced carbon footprint. By repurposing shipping containers—which are often discarded after 10-15 years of use—the portfolio diverts waste from landfills and reduces the demand for virgin materials. A single 40ft shipping container weighs approximately 2.5 tons, and repurposing it saves an estimated 1.8 tons of carbon dioxide (CO2) emissions compared to manufacturing new steel for a traditional building.

Lida Group further reduces embodied carbon by using recycled and low-carbon materials throughout the portfolio:

- Recycled Steel: All container structures use 90-100% recycled steel, which requires 74% less energy to produce than virgin steel. This reduces CO2 emissions by an additional 2-3 tons per unit.

- Sustainable Insulation: The portfolio uses insulation materials with low environmental impact, such as rock wool (made from recycled slag) and PUF insulation with low global warming potential (GWP) blowing agents.

- Low-VOC Finishes: Interior finishes, including paints, adhesives, and flooring, are low in volatile organic compounds (VOCs), improving indoor air quality and reducing off-gassing.

In terms of operational carbon emissions, the portfolio’s energy-efficient design significantly reduces energy consumption for heating, cooling, and lighting. The EcoLiving Series, for example, has an annual energy consumption of 50-70 kWh per square meter, compared to 100-150 kWh per square meter for traditional homes. This translates to a 40-50% reduction in operational CO2 emissions. For commercial and industrial units, optional solar panel integration can further reduce or eliminate reliance on grid electricity, making the structures net-zero or carbon-negative.

3.2 Resource Efficiency and Waste Reduction

Container construction is inherently resource-efficient, and Lida Group’s portfolio maximizes this advantage through factory-controlled production and modular design. Traditional on-site construction generates an estimated 2-5 pounds of waste per square foot, much of which ends up in landfills. In contrast, Lida Group’s factory production process reduces waste by 80-90%:

- Precision Manufacturing: Computer-controlled cutting and assembly ensure minimal material waste during production. Excess steel, insulation, and other materials are recycled in-house, diverting waste from landfills.

- Modular Design: Standardized components and modular layouts reduce the need for custom fabrication, minimizing waste from unique parts and configurations.

- Reduced Site Disturbance: On-site installation of container units requires minimal excavation, grading, and site preparation, reducing soil erosion, habitat disruption, and the need for disposable site materials (e.g., temporary fencing, scaffolding).

Water conservation is another key resource efficiency feature of the portfolio. All units are equipped with low-flow fixtures, reducing water consumption by 30-40% compared to traditional buildings. Optional rainwater harvesting systems collect and store rainwater for non-potable uses (e.g., irrigation, cleaning), further reducing reliance on freshwater sources. For industrial and commercial units, water recycling systems are available to treat and reuse wastewater, minimizing water waste.

3.3 Circular Economy Integration

Lida Group’s portfolio embraces circular economy principles, designed for durability, reuse, and recyclability. Container structures have a lifespan of 25-30 years, significantly longer than many temporary building solutions. When a unit reaches the end of its useful life, the steel structure can be recycled indefinitely, with a recycling rate of 98%—far higher than traditional building materials such as concrete (recycling rate of 30-40%) or wood (recycling rate of 50-60%).

The modular design of the portfolio also facilitates reuse and repurposing. Container units can be easily disassembled, transported to new locations, and reassembled for new applications. For example, a RapidDeploy Series emergency shelter can be repurposed as a construction site office or affordable housing unit after a disaster. This flexibility extends the lifecycle of the structure, reducing the need for new construction and conserving resources.

Lida Group also supports circular economy practices through its take-back program, which allows clients to return old or unused container units for recycling or refurbishment. The company refurbishes units to meet current standards, reselling them at a reduced cost, or recycles the steel for use in new units. This program closes the loop on material use, ensuring that resources are conserved throughout the product lifecycle.

3.4 Alignment with Global Sustainability Goals

Lida Group’s expanded portfolio aligns with several United Nations Sustainable Development Goals (SDGs), contributing to global efforts to address pressing environmental and social challenges:

- SDG 6 (Clean Water and Sanitation): Water-saving fixtures and rainwater harvesting systems promote responsible water use.

- SDG 7 (Affordable and Clean Energy): Energy-efficient design and solar integration provide access to clean, affordable energy.

- SDG 11 (Sustainable Cities and Communities): Affordable housing solutions, urban infill compatibility, and reduced environmental impact support sustainable urban development.

- SDG 12 (Responsible Consumption and Production): Waste reduction, recycled materials, and circular economy practices promote responsible production and consumption.

- SDG 13 (Climate Action): Reduced carbon emissions and resilience to climate change (extreme weather resistance) contribute to climate action.

- SDG 17 (Partnerships for the Goals): Collaborations with governments, NGOs, and developers to deliver sustainable housing and infrastructure support global partnerships.

By aligning its portfolio with the SDGs, Lida Group demonstrates its commitment to not just business growth but also positive global impact. The company’s sustainability efforts have been recognized by industry organizations, including certifications such as LEED (Leadership in Energy and Environmental Design) and BREEAM (Building Research Establishment Environmental Assessment Method) for select products in the EcoLiving and CustomBuild Series.

4. Cost-Effectiveness: Delivering Value Across the Lifecycle

In addition to sustainability, cost-effectiveness is a key driver of Lida Group’s expanded portfolio. Container construction offers significant cost savings compared to traditional construction, and Lida Group enhances these savings through efficient manufacturing, modular design, and long-term operational efficiency. Below is an analysis of the cost-saving mechanisms of the portfolio, including upfront costs, operational costs, and lifecycle costs.

4.1 Upfront Cost Savings

The upfront cost of Lida Group’s container houses is 30-50% lower than traditional construction, due to several key factors:

- Reduced Material Costs: Repurposing shipping containers eliminates the need for expensive structural materials (e.g., lumber, concrete) required for traditional buildings. Additionally, bulk purchasing of materials and standardized production reduce material costs further. For example, the EcoLiving Series has a material cost of \(80-120 per square foot, compared to \)150-250 per square foot for traditional homes.

- Lower Labor Costs: Factory-controlled production is highly automated, reducing the need for skilled labor. On-site installation requires only 2-3 workers per unit, compared to 5-10 workers for traditional construction. This reduces direct labor costs by 40-60%.

- Shorter Construction Time: The prefabricated nature of container houses reduces construction time by 60-70% compared to traditional buildings. For example, a 40ft EcoLiving unit can be manufactured and installed in 2-3 weeks, compared to 3-6 months for a traditional home. This shorter timeline reduces indirect costs, such as financing interest, site rental, and insurance.

- Minimal Site Preparation: Container houses require minimal site preparation (e.g., a concrete slab or gravel base), reducing costs associated with excavation, grading, and foundation work. This is particularly beneficial for remote or difficult-to-access sites.

4.2 Operational Cost Savings

Lida Group’s container houses deliver significant long-term operational cost savings, primarily through energy and water efficiency:

- Energy Savings: The energy-efficient insulation, windows, and optional solar integration reduce utility bills by 30-50%. For a typical 1,000-square-foot EcoLiving unit, this translates to annual energy savings of \(500-\)1,500. For commercial units, such as hotels or offices, the savings are even more substantial—up to $10,000 per year for a 5,000-square-foot space.

- Water Savings: Low-flow fixtures and rainwater harvesting systems reduce water bills by 30-40%. For a household of four, this results in annual water savings of \(200-\)400. For commercial operations, such as restaurants or resorts, water savings can exceed $2,000 per year.

- Maintenance Savings: The durable steel construction of container houses requires minimal maintenance compared to traditional buildings. Steel is resistant to pests, rot, and decay, eliminating the need for costly repairs (e.g., termite treatment, roof replacement). The average annual maintenance cost for a container house is \(200-\)500, compared to \(1,000-\)2,000 for a traditional home.

4.3 Lifecycle Cost Comparison

To illustrate the total lifecycle cost advantage of Lida Group’s container houses, below is a comparison with traditional construction for a 1,000-square-foot residential unit over a 25-year lifespan:

|

Cost Category

|

Lida Group EcoLiving Series (USD)

|

Traditional Home (USD)

|

Cost Difference (USD)

|

|

Upfront Construction Cost

|

\(80,000-\)120,000

|

\(150,000-\)250,000

|

-\(70,000 to -\)130,000

|

|

Annual Energy Costs

|

\(500-\)1,500

|

\(1,000-\)3,000

|

-\(500 to -\)1,500 per year (-\(12,500 to -\)37,500 over 25 years)

|

|

Annual Water Costs

|

\(200-\)400

|

\(300-\)600

|

-\(100 to -\)200 per year (-\(2,500 to -\)5,000 over 25 years)

|

|

Annual Maintenance Costs

|

\(200-\)500

|

\(1,000-\)2,000

|

-\(800 to -\)1,500 per year (-\(20,000 to -\)37,500 over 25 years)

|

|

Total Lifecycle Cost

|

\(93,200-\)163,500

|

\(185,000-\)335,000

|

-\(91,800 to -\)171,500

|

This comparison clearly demonstrates that Lida Group’s container houses offer substantial lifecycle cost savings, making them a cost-effective choice for homeowners, developers, and governments. For commercial and industrial clients, the savings are even more significant, due to larger square footage and higher operational costs.

5. Case Studies: Real-World Applications of Lida Group’s Expanded Portfolio

To showcase the practical impact of Lida Group’s expanded prefab mobile container house portfolio, below are three case studies from diverse sectors: affordable housing, disaster relief, and commercial hospitality. These case studies highlight the portfolio’s versatility, sustainability, and cost-effectiveness, as well as the challenges overcome and lessons learned.

5.1 Case Study 1: Affordable Housing Development, Nairobi, Kenya

Project Overview

Nairobi, Kenya, faces a severe affordable housing shortage, with over 2 million households living in informal settlements. The Kenyan government partnered with Lida Group to address this crisis by constructing a 50-unit affordable housing development using the EcoLiving Series. The project aimed to provide safe, sustainable, and affordable housing for low-income families, while meeting the government’s sustainability targets (reduced carbon emissions, water conservation).

Project Implementation

- Design and Customization: Lida Group collaborated with local architects to adapt the EcoLiving Series to Nairobi’s climate and cultural needs. The units were designed as 2-bedroom, 1-bathroom homes (40ft high-cube containers), with open-concept living areas, outdoor patios, and solar panel integration. Exterior finishes included locally sourced wood cladding to blend with the surrounding environment.

- Manufacturing and Transportation: The units were manufactured in Lida Group’s factory in China, then shipped to the Port of Mombasa and transported by truck to Nairobi. The prefabricated nature of the units reduced on-site construction time to 8 weeks (compared to 6 months for traditional construction).

- Sustainability Features: Each unit included PUF insulation, double-glazed low-E windows, solar panels (200W), a rainwater harvesting system (300L), and low-flow fixtures. The development also featured communal gardens and shared sanitation facilities for additional cost savings.

- Cost Structure: The total project cost was \(1.5 million, translating to \)30,000 per unit—50% lower than the cost of traditional affordable housing in Nairobi. The Kenyan government provided subsidies to reduce the purchase price for low-income families to $20,000 per unit.

Outcomes

- Sustainability: The development reduced carbon emissions by 45% compared to traditional housing, with each unit generating 50% of its energy from solar power. Water consumption was reduced by 40% due to rainwater harvesting and low-flow fixtures.

- Social Impact: The 50 units provided housing for 250 people, lifting families out of informal settlements. The modular design allowed for future expansion, with plans to add 100 more units in phase 2.

- Economic Impact: The project created 50 local jobs during installation and maintenance, contributing to the local economy. The low purchase price enabled families to build equity, improving their long-term financial stability.

Key Success Factors

- Collaboration with local stakeholders to adapt the design to cultural and climate needs.

- Use of solar and rainwater systems to address Nairobi’s unreliable electricity and water supply.

- Government subsidies to make the units affordable for low-income families.

5.2 Case Study 2: Disaster Relief Housing, Cyclone Idai Response, Mozambique

Project Overview

In March 2019, Cyclone Idai devastated Mozambique, destroying over 100,000 homes and displacing 1.8 million people. The United Nations High Commissioner for Refugees (UNHCR) partnered with Lida Group to deploy 1,000 RapidDeploy Series units to provide emergency shelter for displaced populations in the Beira region. The project prioritized speed, durability, and self-sufficiency, as the region lacked basic infrastructure (electricity, clean water).

Project Implementation

- Rapid Deployment: Lida Group manufactured the 1,000 units in its factory in China within 4 weeks, then shipped them to Mozambique via cargo ships. The units were installed by a small team of Lida Group technicians and local workers, with each unit deployed in 2-3 hours. The entire project was completed in 6 weeks, providing shelter for 5,000 people.

- Resilient Design: The units were designed to withstand tropical storms and flooding, with reinforced steel frames, waterproof seals, and elevated floors (1m above ground level). Each unit included impact-resistant windows and steel shutters for protection against high winds.

- Self-Sufficient Systems: Due to the lack of electricity and clean water, each unit was equipped with a 200W solar panel, 150Ah battery storage, and a portable water purification unit. These systems provided essential services, including lighting, phone charging, and clean drinking water.

- Human-Centric Features: Each unit accommodated 5 people, with partitioned sleeping areas, a small kitchenette, and a sanitation facility (composting toilet and shower). The units also included ventilation systems to address Mozambique’s hot, humid climate.

Outcomes

- Speed and Efficiency: The RapidDeploy Series units were deployed 3 times faster than traditional emergency shelters, providing critical housing to displaced populations within weeks of the disaster.

- Resilience: The units withstood subsequent tropical storms, with zero damage reported, ensuring long-term shelter stability.

- Self-Sufficiency: The solar and water purification systems allowed families to live independently of external aid, reducing reliance on UNHCR resources.

- Cost-Effectiveness: The total project cost was \(5 million, translating to \)5,000 per unit—30% lower than the cost of traditional emergency shelters. The UNHCR estimates that the self-sufficient systems saved an additional $2 million in aid costs over 6 months.

Key Success Factors

- Ultra-fast manufacturing and deployment capabilities of the RapidDeploy Series.

- Integration of self-sufficient systems to address infrastructure gaps.

- Resilient design tailored to Mozambique’s climate and disaster risks.

5.3 Case Study 3: Boutique Glamping Resort, Costa Rica

Project Overview

A private developer in Costa Rica sought to create a sustainable boutique glamping resort in the Arenal Volcano region, targeting eco-conscious travelers. The developer chose Lida Group’s CustomBuild Series for its sustainability, design flexibility, and quick installation. The project consisted of 15 luxury glamping units, a restaurant, and a reception area, all constructed from container modules.

Project Implementation

- Custom Design: Lida Group’s design team collaborated with the developer to create unique, luxury units that blended with the natural surroundings. The units were stacked and configured in creative layouts, with large windows and outdoor decks offering views of the Arenal Volcano. Exterior finishes included reclaimed wood and living walls (vertical gardens), while interiors featured high-end furnishings, en-suite bathrooms, and climate control.

- Sustainable Features: The resort incorporated numerous eco-friendly features, including solar panels (500W per unit), rainwater harvesting (1,000L per unit), composting toilets, and energy-efficient HVAC systems. The containers’ recycled steel structure and sustainable finishes aligned with the resort’s “zero-waste” mission.

- Quick Installation: The units were manufactured in Lida Group’s factory in Mexico (reducing transportation costs and carbon emissions) and shipped to the site. On-site installation took 12 weeks, compared to 6 months for traditional construction. This allowed the resort to open ahead of schedule, generating revenue faster.

- Cost Structure: The total project cost was \(1.2 million, translating to \)80,000 per glamping unit—40% lower than the cost of traditional luxury cabins in the region. The quick installation and low operational costs (due to solar and rainwater systems) increased the resort’s profitability.

Outcomes

- Sustainability: The resort achieved carbon-neutral status within its first year of operation, due to solar energy generation and carbon offset programs. It received certification from the Global Sustainable Tourism Council (GSTC) for its environmental and social practices.

- Customer Appeal: The unique, eco-friendly design of the CustomBuild Series units attracted eco-conscious travelers, resulting in a 90% occupancy rate within the first 6 months of opening. Guests praised the units’ comfort, aesthetics, and connection to nature.

- Economic Success: The resort’s low upfront and operational costs, combined with high occupancy rates, resulted in a return on investment (ROI) of 25% within the first year—significantly higher than the industry average of 15%.

Key Success Factors

- Design flexibility of the CustomBuild Series to create unique, luxury spaces.

- Integration of sustainable features that aligned with the resort’s brand and target market.

- Quick installation and low operational costs that improved profitability.

6. Challenges and Strategies for Adoption

While Lida Group’s expanded portfolio offers significant benefits, the adoption of prefab container houses still faces challenges, including regulatory barriers, public perception, and supply chain complexity. Below is an analysis of these challenges and strategies for overcoming them, both for Lida Group and its clients.

6.1 Key Challenges

6.1.1 Regulatory and Code Barriers

One of the primary challenges to adopting container houses is navigating complex and often outdated building codes and regulations. Many regions lack specific guidelines for container construction, leading to uncertainty and delays in obtaining permits. In some cases, container houses are classified as “temporary structures,” limiting their use for permanent housing or commercial applications. Additionally, zoning restrictions may prohibit container houses in certain areas, particularly in residential neighborhoods with strict aesthetic requirements.

6.1.2 Public Perception and Misconceptions

Despite advancements in design and quality, container houses still suffer from public misconceptions, particularly in residential markets. Many consumers associate container houses with “trailer homes” or temporary shelters, perceiving them as low-quality, uncomfortable, or aesthetically unappealing. This perception can hinder market acceptance, particularly among homeowners seeking permanent, desirable housing. In commercial markets, some developers may be hesitant to invest in container-based projects due to concerns about resale value or customer perception.

6.1.3 Supply Chain and Transportation Logistics

For clients in remote or international locations, supply chain and transportation logistics can be a challenge. Shipping container units over long distances can be costly, particularly for large-scale projects. Additionally, coordinating the delivery and installation of multiple units requires careful planning, as delays in transportation can disrupt project timelines. In regions with poor infrastructure, transporting large container modules can be difficult, requiring specialized equipment and permits.

6.1.4 Skilled Labor Shortages

While container house installation requires fewer workers than traditional construction, it still requires skilled labor trained in modular construction techniques. In many regions, there is a shortage of workers with experience in container modification, assembly, and systems integration (e.g., solar, plumbing). This can lead to delays or quality issues if unskilled workers are used.

6.2 Strategies for Overcoming Challenges

6.2.1 Advocacy and Regulatory Engagement

Lida Group actively engages with governments and industry associations to advocate for regulatory reform and the development of container-specific building codes. The company provides technical expertise and data on the safety, durability, and sustainability of container houses to help policymakers update regulations. For clients, Lida Group offers support in navigating the permitting process, including providing certification documentation, technical drawings, and evidence of compliance with local codes. In regions with restrictive zoning, the company works with clients to design units that meet aesthetic requirements, such as custom exterior finishes and landscaping.

6.2.2 Education and Brand Building

To address public perception issues, Lida Group invests in education and brand building initiatives. The company showcases its projects through case studies, social media, and industry events, highlighting the quality, comfort, and aesthetics of its container houses. It also offers virtual and in-person tours of its demonstration projects, allowing potential clients to experience the units firsthand. For residential clients, Lida Group emphasizes the affordability, sustainability, and customization options of the EcoLiving Series, dispelling misconceptions about container housing. For commercial clients, it highlights the cost savings, quick installation, and unique design opportunities of the CustomBuild Series.

6.2.3 Supply Chain Optimization

Lida Group optimizes its supply chain to reduce transportation costs and improve efficiency. The company has established manufacturing facilities and distribution centers in strategic locations (e.g., China, Mexico, Europe, South Africa) to serve regional markets, reducing shipping distances and costs. For large-scale projects, Lida Group partners with local logistics companies to coordinate delivery and installation, ensuring timely and cost-effective transportation. The company also offers flexible shipping options, including partial container loads for small projects, to reduce costs for clients.

6.2.4 Training and Capacity Building

To address skilled labor shortages, Lida Group offers training programs for local workers in regions where it operates. These programs cover container assembly, systems integration, and quality control, ensuring that clients have access to skilled labor for installation and maintenance. The company also provides detailed installation manuals and on-site technical support to guide workers through the process. For clients, Lida Group recommends certified contractors with experience in modular construction, helping them avoid quality issues and delays.

7. Future Outlook: Innovations and Market Opportunities

Lida Group’s expanded prefab mobile container house portfolio is well-positioned to capitalize on growing market demand for sustainable, affordable, and flexible construction solutions. Looking ahead, the company plans to continue innovating its product lines and expanding its global reach, focusing on three key areas: technological advancements, sustainability enhancements, and market expansion.

7.1 Technological Advancements

Lida Group is investing in several technological innovations to further improve its container house portfolio:

- Digitalization and BIM Integration: The company is expanding its use of Building Information Modeling (BIM) to optimize design, production, and installation. BIM allows for 3D modeling of container units, facilitating collaboration between design teams, manufacturers, and installers, and reducing errors. Future developments will include digital twins—virtual replicas of physical units—that allow clients to customize designs in real time and monitor performance after installation.

- 3D Printing: Lida Group is exploring 3D printing technology to produce custom components, such as interior fixtures, cladding, and structural elements. 3D printing offers greater design flexibility, reduces material waste, and accelerates production time. The company plans to integrate 3D-printed components into the CustomBuild Series, allowing for even more unique and complex designs.

- Smart Home and Building Automation: The EcoLiving and CustomBuild Series will include enhanced smart home features, such as IoT sensors for energy and water monitoring, automated lighting and climate control, and remote management systems. These features will improve energy efficiency, enhance occupant comfort, and provide clients with real-time data on building performance.

- Advanced Materials: Lida Group is researching and testing new materials to improve the performance and sustainability of its container houses. This includes self-healing insulation (which reduces maintenance costs), transparent solar panels (for integration into windows and roofing), and bio-based materials (for interior finishes). These materials will further reduce carbon emissions and improve the environmental footprint of the portfolio.

7.2 Sustainability Enhancements

Lida Group is committed to making its container houses even more sustainable, with the goal of achieving carbon-neutral production and operation by 2030. Key initiatives include:

- Net-Zero Energy Units: The company plans to launch net-zero energy versions of the EcoLiving and CustomBuild Series, which generate as much energy as they consume through solar panels, wind turbines, and energy storage systems. These units will appeal to clients seeking to reduce their carbon footprint and energy costs.

- Circular Economy Expansion: Lida Group will expand its take-back and refurbishment program, making it easier for clients to return or repurpose old units. The company also plans to increase the use of recycled and bio-based materials in production, aiming for 100% recycled content in steel framing by 2028.

- Carbon Capture and Offsetting: Lida Group will implement carbon capture technologies in its factories to reduce emissions from production. It will also invest in carbon offset projects, such as reforestation and renewable energy, to offset remaining emissions.

7.3 Market Expansion

Lida Group plans to expand its global reach, focusing on high-growth markets and new applications:

- Emerging Economies: The company will target emerging economies in Africa, Asia, and Latin America, where demand for affordable housing and infrastructure is high. It will establish local manufacturing facilities and partnerships to reduce costs and improve accessibility.

- New Applications: Lida Group will explore new applications for its container houses, including healthcare facilities (clinics and mobile hospitals), educational institutions (classrooms and labs), and renewable energy projects (solar farms and wind energy facilities). These new applications will diversify the company’s revenue streams and address unmet market needs.

- Partnerships and Collaborations: The company will form strategic partnerships with governments, NGOs, developers, and technology providers to expand its market presence and drive innovation. For example, partnerships with solar energy companies will enhance the self-sufficiency of the Rapid Deploy Series, while collaborations with architects will push the boundaries of container house design.

8. Conclusion

Lida Group’s expansion of its prefab mobile container house portfolio represents a significant milestone in the global prefab construction industry. By launching four distinct product lines—the Eco Living Series, Rapid Deploy Series, Custom Build Series, and Industrial Work Series—the company has demonstrated its ability to address diverse market needs, from affordable residential housing and emergency shelter to luxury commercial spaces and industrial infrastructure. Each product line integrates cutting-edge technology, sustainable materials, and customer-centric design, delivering a unique combination of benefits: durability, cost-effectiveness, sustainability, and flexibility.

The portfolio’s sustainability features—including recycled materials, energy efficiency, waste reduction, and circular economy integration—align with global efforts to address climate change and promote responsible consumption. Its cost-effectiveness, both in upfront construction and long-term operations, makes it an attractive solution for homeowners, developers, governments, and businesses seeking to reduce costs without compromising quality. Real-world case studies from Kenya, Mozambique, and Costa Rica demonstrate the portfolio’s practical impact, from providing affordable housing to displaced populations to creating profitable, sustainable commercial ventures.

While challenges remain—including regulatory barriers, public perception, and supply chain complexity—Lida Group’s strategies for overcoming these obstacles, such as advocacy, education, supply chain optimization, and training, position it for success. Looking ahead, the company’s focus on technological innovation, sustainability enhancements, and market expansion will further solidify its leadership in the prefab container house market, as it continues to meet the growing demand for sustainable, affordable, and flexible construction solutions.

In a world facing unprecedented challenges—housing shortages, climate change, and the need for rapid, resilient infrastructure—Lida Group’s expanded portfolio offers a compelling vision for the future of construction. By reimagining the potential of shipping containers, the company is not just building houses and buildings; it is building a more sustainable, equitable, and adaptable built environment. As the global construction industry continues to evolve, Lida Group’s prefab mobile container houses will undoubtedly play a central role in shaping a better future for generations to come.

Related news

-

Lida Group's Temporary Container Building Aids Emergency Housing

2025-11-21 16:25:37

-

Achieve Sustainability with Cost-Effective Prefab Construction

2025-11-21 16:36:15

-

Lida Group Champions Cost-Effective Prefab Construction Methods

2025-11-13 17:48:58

contact us

- Tel: +86-532-88966982

- Whatsapp: +86-13793209022

- E-mail: sales@lidajituan.com