Lida Group Delivers Cost-Effective Durable Construction Solutions

2025-Nov-26 17:30:46

By Admin

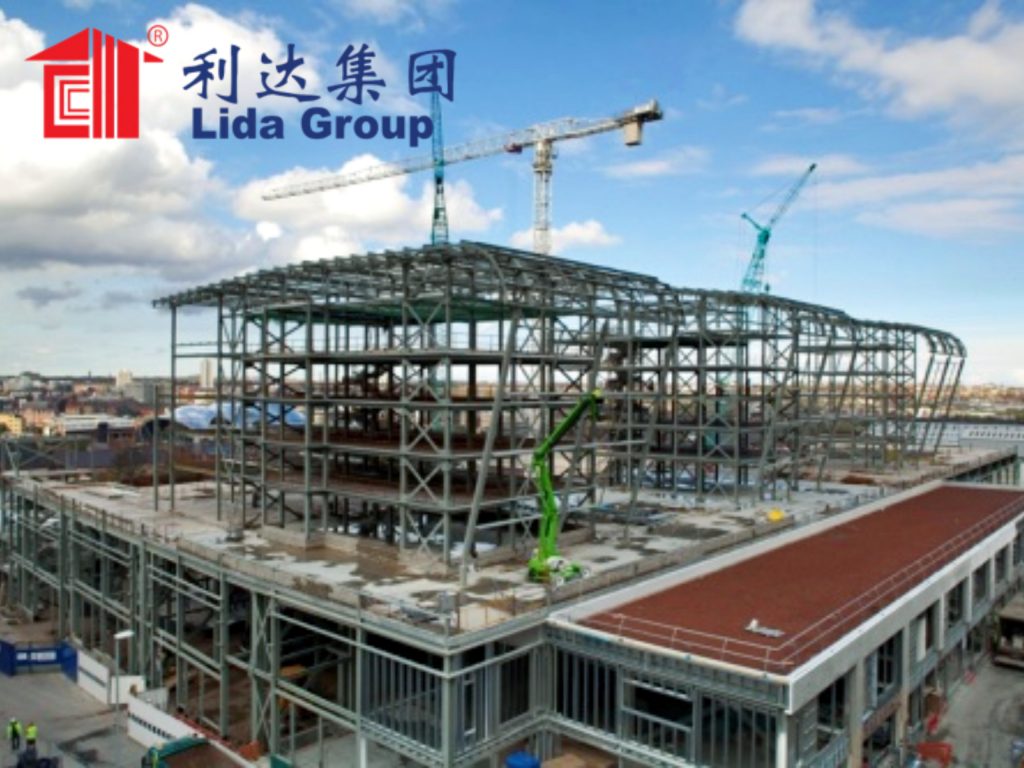

The global construction industry stands at a crossroads, grappling with interconnected challenges that demand innovative solutions. From skyrocketing material costs and skilled labor shortages to increasingly stringent environmental regulations and the need for rapid project delivery, stakeholders across sectors—industrial, commercial, energy, and infrastructure—are seeking alternatives to traditional building methods that often fall short in efficiency, durability, and cost-effectiveness. In this complex ecosystem, Lida Group has emerged as a transformative force, redefining construction standards through its cost-effective, durable, and sustainable prefabricated solutions. Founded in 1993 as a small steel workshop in Shandong Province, China, Lida Group has evolved into a national high-tech enterprise and global leader, delivering modular buildings, steel structure facilities, and integrated construction services to over 80 countries worldwide. With a comprehensive portfolio spanning industrial warehouses, offshore energy modules, mining camps, and civil constructions, the company has demonstrated that durability and affordability need not be mutually exclusive. This article explores how Lida Group’s three decades of engineering expertise, advanced manufacturing capabilities, and customer-centric approach have positioned it as a trusted partner for organizations seeking to build smarter, stronger, and more economically.

The Case for Cost-Effective Durability: Addressing Industry Pain Points

Before delving into Lida Group’s specific solutions, it is critical to understand the pressing need for construction methods that balance cost efficiency with long-term durability. Traditional brick-and-mortar and concrete construction, while time-tested, suffer from inherent limitations that have become increasingly problematic in today’s fast-paced global economy.

First, cost overruns are rampant in conventional construction. A 2023 industry report found that 78% of large-scale projects exceed their initial budgets, driven by material waste (up to 30% of resources in typical builds), labor inefficiencies, and weather-related delays. For industrial clients—such as manufacturing plants, logistics companies, and energy firms—these delays can translate to millions in lost revenue, as facilities fail to come online on schedule. Second, durability concerns plague structures in harsh environments. From hurricane-prone coastal regions to corrosion-prone offshore platforms and seismic zones, traditional buildings often require expensive maintenance or replacement within decades. Third, sustainability has become a non-negotiable factor. The construction sector accounts for 39% of global carbon emissions, with embodied energy (the energy consumed during material production and construction) and operational energy use being major contributors. Regulators and investors alike are demanding greener solutions, forcing companies to prioritize low-carbon construction without sacrificing performance or budget.

Lida Group’s core value proposition—cost-effective durability—directly addresses these pain points. By leveraging prefabrication, advanced materials, and precision engineering, the company delivers structures that are not only more affordable to build and maintain but also engineered to withstand extreme conditions, reducing lifecycle costs and environmental impact. This dual focus has resonated with global giants, from automotive manufacturers in Europe to oil and gas companies in the North Sea, who recognize that short-term savings must be balanced with long-term resilience.

Lida Group’s Technical Foundations: Engineering for Affordability and Longevity

At the heart of Lida Group’s success lies a commitment to technical innovation and manufacturing excellence. The company’s solutions are built on four interconnected pillars—advanced material science, precision engineering, modular design, and efficient manufacturing—that work in tandem to deliver cost-effective durability.

1. Advanced Material Science: Strength Without the Premium

Lida Group’s choice of materials is a cornerstone of its cost and durability advantages. The company specializes in steel structure solutions, leveraging the unique properties of steel to create structures that are both strong and economical. Unlike concrete, which requires extensive curing time and heavy transportation, steel offers exceptional strength-to-weight ratio, allowing for lighter frames that reduce foundation costs while maintaining structural integrity. Lida Group primarily uses high-strength steel alloys such as S550MC and Q235B, which offer superior load-bearing capacity compared to traditional steel grades, enabling the design of lighter, more material-efficient structures.

A key innovation in material durability is Lida’s use of corrosion-resistant coatings and alloys. For offshore and coastal projects, the company employs Corten steel (weathering steel), which forms a protective oxide layer when exposed to air and water, eliminating the need for constant repainting and reducing maintenance costs. For more extreme environments—such as offshore oil rigs or chemical plants—Lida applies nano-ceramic coatings or galvanized finishes (75 μm anti-corrosion coating, ISO 1461 certified) that extend the structure’s lifespan to 25+ years with minimal upkeep. These materials not only enhance durability but also reduce lifecycle costs: a study of Lida’s offshore modules found that clients saved up to 40% on maintenance expenses over a 15-year period compared to conventional structures.

Sustainability is another critical aspect of Lida’s material selection. The company’s steel components have a recycled content exceeding 92%, significantly reducing embodied carbon compared to virgin materials. For insulation, Lida uses aerogel-enhanced composite panels and bio-based materials (such as seaweed-based insulation with an R-value of 5.2 per inch), which improve energy efficiency while minimizing environmental impact. These sustainable materials not only meet global ESG (Environmental, Social, Governance) mandates but also reduce operational costs by lowering heating and cooling expenses—an important consideration for long-term durability and affordability.

2. Precision Engineering: Minimizing Waste, Maximizing Performance

Lida Group’s engineering processes are designed to eliminate inefficiencies that drive up costs in traditional construction. The company has invested heavily in digitalization and automation, using Building Information Modeling (BIM) to create 3D models of entire structures, allowing for clash detection and design optimization before production begins. This virtual prototyping ensures that all mechanical, electrical, and structural systems integrate seamlessly, reducing rework and material waste on-site. For example, in a European automotive workshop project, BIM integration helped Lida optimize the steel frame design, reducing material usage by 22% while maintaining the required load-bearing capacity for 20-ton robotic assembly lines.

Precision manufacturing is another key element. Lida’s state-of-the-art factories—including a 30,000-square-meter facility in Weifang dedicated to heavy steel structures—are equipped with robotic welding arms that achieve tolerances of 0.1–0.2 mm, ensuring consistent quality and structural integrity. Computer-controlled laser cutting systems use nesting algorithms to maximize material utilization, reducing scrap generation by up to 75% compared to traditional fabrication methods. This level of precision not only enhances durability—by ensuring perfect component alignment that distributes loads evenly—but also lowers costs by minimizing material waste and the need for on-site adjustments.

Lida’s engineering team also tailors solutions to meet regional building codes and environmental challenges. The company’s structures comply with design specifications from China, Australia, the United States, Europe, and the United Kingdom, ensuring regulatory compliance across global markets. For seismic zones, engineers reinforce steel frames with shock-absorbing joints and rigid connections, while for hurricane-prone areas, they design aerodynamic sloped roofs that reduce wind load by 40% and interlocking foundation anchors that secure units during Category 5 storms. This localized engineering approach ensures that structures are durable in their specific environment, avoiding costly retrofits or failures.

3. Modular Design: Speed, Scalability, and Cost Efficiency

Modular construction is the linchpin of Lida Group’s cost-effective solutions. Unlike traditional construction, where most work is done on-site, Lida’s structures are prefabricated in climate-controlled factories as modular units, which are then shipped to the site for assembly. This approach offers multiple cost and durability benefits.

First, modular construction drastically reduces project timelines. A 50,000-square-foot steel warehouse, for example, can be completed in 12–16 weeks with Lida’s prefab approach, compared to 12+ months for concrete construction. For clients in time-sensitive industries—such as automotive manufacturing or oil and gas exploration—this speed-to-market translates to significant cost savings. In one case, a European car manufacturer needed a 150,000-square-foot workshop to launch a new electric vehicle model within 8 months; Lida delivered by prefabricating 500+ steel modules in China and shipping them to Europe, where on-site assembly took just 6 weeks. The client avoided millions in lost revenue by meeting its launch deadline, demonstrating how speed directly contributes to cost-effectiveness.

Second, modular design enhances scalability and reusability. Lida’s container-based and light steel modules are stackable (up to 8 stories) and interchangeable, allowing clients to expand or reconfigure structures as their needs change. For example, Chevron’s modular office in Texas expanded from 20 to 80 workspaces in 3 weeks during a shale gas boom, simply by adding more modules. Additionally, modules can be disassembled and redeployed to other projects, eliminating the need for costly new construction. A mining company in Kazakhstan, for instance, reused Lida’s dormitory modules across three different sites, saving 35% on accommodation costs over five years. This reusability not only lowers upfront costs but also reduces environmental impact, aligning with circular economy principles.

Third, modular construction minimizes on-site labor requirements. Traditional construction relies heavily on skilled labor, which is in short supply globally—85% of contractors report difficulty filling craft positions. Lida’s prefabricated modules require only a small team of workers for on-site assembly (6 workers can install 10 units per day using bolt-and-nut connections), reducing labor costs by 30–40% compared to conventional builds. Moreover, factory-based production eliminates weather-related delays, which account for 28% of schedule overruns in traditional construction, further reducing labor and overhead costs.

4. End-to-End Services: Reducing Risk and Ensuring Accountability

Lida Group’s cost-effective durability extends beyond product design to its comprehensive service offering. The company provides end-to-end solutions, from initial design and engineering to manufacturing, logistics, on-site assembly, and post-construction support. This turnkey approach reduces risk for clients by ensuring accountability across the entire project lifecycle, avoiding the cost overruns and delays that often result from coordinating multiple contractors.

Lida’s in-house logistics team is a key component of this service. The company uses AI-powered route optimization and nesting algorithms to maximize container space utilization, reducing freight costs by 35% compared to traditional material transportation. For remote or challenging locations—such as arctic mining sites or offshore platforms—Lida coordinates specialized shipping, including helicopter delivery of modular units and just-in-sequence delivery of components to minimize on-site storage costs. The company’s global network of subsidiaries, including MF Real Estate Investment LLC and Lida International Building System Co. in the United States, ensures local support and compliance with regional regulations, reducing logistical headaches and potential fines.

On-site assembly is another area where Lida adds value. The company’s trained teams use standardized installation processes, ensuring that modules are assembled correctly and efficiently. For complex projects—such as offshore oil rig crew quarters—Lida provides 24/7 on-site supervision to address any issues promptly, avoiding costly downtime. Post-construction, the company offers multilingual 24/7 support and maintenance services, helping clients extend the lifespan of their structures and address any issues before they escalate into major expenses. This comprehensive support ensures that clients get the most out of their investment, enhancing the long-term cost-effectiveness of Lida’s solutions.

Case Studies: Proving Cost-Effective Durability in Real-World Applications

Lida Group’s technical capabilities are best demonstrated through its global project portfolio. The following case studies highlight how the company’s solutions have delivered cost savings and durability in diverse industries and extreme environments.

Case Study 1: Offshore Oil & Gas—Typhoon-Proof Crew Quarters for CNOOC

Client: China National Offshore Oil Corporation (CNOOC)

Challenge: CNOOC needed to protect 200 workers on a semi-submersible rig in the South China Sea, an area prone to annual typhoons with winds up to 250 km/h. The client required a structure that could withstand extreme weather, ensure worker safety, and reduce long-term maintenance costs.

Solution: Lida designed an 8-story stackable container building using ASTM A588 corrosion-resistant steel frames. The structure featured aerodynamic sloped roofs to reduce wind load, interlocking foundation anchors to secure units to the rig deck, and watertight bulkheads rated for 15m wave submersion. Emergency features included helicopter-evacuation-ready rooftop pads and fire-resistant cladding.

Results: The modules survived Super Typhoon Saola in 2023 unscathed, while adjacent traditional modules sustained $6 million in damage. The corrosion-resistant materials eliminated the need for annual repainting, reducing maintenance costs by 33% over five years. The rapid deployment (factory production: 45 days; on-site assembly: 10 days) allowed CNOOC to avoid costly downtime, ensuring the rig remained operational during the typhoon season. The structure also achieved DNV GL-OS-C301 offshore certification, demonstrating compliance with global safety standards.

Case Study 2: Industrial Manufacturing—Cost-Effective Workshop for European Automotive Giant

Client: Major European electric vehicle (EV) manufacturer

Challenge: The client needed a 150,000-square-foot workshop to house robotic assembly lines for a new EV model. Key requirements included vibration resistance for precision machinery, an 8-month deadline to meet production targets, and compliance with EU environmental regulations.

Solution: Lida designed a light steel structure with reinforced foundations and shock-absorbing joints to minimize vibration. The structure used BIM modeling to optimize the steel frame, reducing material usage by 22% while maintaining the required load-bearing capacity. Prefabricated modules were produced in China and shipped to Europe, where on-site assembly was completed in 6 weeks. The workshop integrated energy-efficient lighting, solar panels, and rainwater harvesting systems to meet EU sustainability mandates.

Results: The client met its 8-month launch deadline, avoiding an estimated $20 million in lost revenue from delayed production. The prefabricated approach reduced construction costs by 35% compared to traditional concrete construction, and the energy-efficient design cut operational costs by 20% annually. The vibration-resistant structure ensured the robotic assembly lines operated with precision, reducing product defects and further lowering costs. The workshop’s 92% recycled steel content also helped the client achieve its ESG goals, enhancing its brand reputation in the sustainable mobility sector.

Case Study 3: Remote Mining—Arctic Camp for International Mining Company

Client: Global mining firm operating in the Arctic

Challenge: The client needed to establish a 200-person camp in a roadless Arctic region with temperatures as low as -45°C. The camp required durable, energy-efficient accommodation, offices, and facilities that could be deployed quickly without permanent foundations.

Solution: Lida delivered volumetric modular house units that were flown to the site by helicopter. The modules featured galvanized steel frames with 75 μm anti-corrosion coating, PU-insulated walls (100 mm thickness, U-value 0.28 W/m²K) to maintain indoor temperatures of 22°C, and foundation-free screw pile systems that adapted to uneven terrain. The units were pre-equipped with HVAC systems, electrical wiring, and plumbing, enabling plug-and-play utility connections.

Results: The camp was fully operational in 6 weeks, compared to 6+ months for traditional construction. The energy-efficient insulation reduced heating costs by 40% in the extreme cold, while the corrosion-resistant materials withstood the harsh Arctic conditions with zero maintenance required over three years. The modular design allowed the client to scale the camp from 200 to 350 persons as the mining operation expanded, avoiding the need for new construction. The camp’s low environmental impact—including minimal site disturbance and 90% recyclable materials—complied with strict Arctic conservation regulations.

Case Study 4: Offshore Energy—Net-Zero Emission Offices for Equinor (North Sea)

Client: Equinor, Norwegian energy company

Challenge: Equinor needed to reduce carbon emissions by 50% on an aging North Sea oil platform to comply with the EU’s Offshore Safety Directive 2025. The client required offshore offices that were energy-efficient, durable, and aligned with circular economy principles.

Solution: Lida designed hybrid office containers with Solar Skin™ roofs (thin-film PV generating 180 W/m²) and 200 kW hydrogen fuel cells for backup power, replacing diesel generators. The modules used 92% recycled aluminum cladding from decommissioned rigs and bio-based seaweed insulation. An AI energy manager balanced consumption across 30+ units, optimizing energy use. The structure was engineered to withstand North Sea storms and corrosion, with blast-resistant walls and EMI-shielded control rooms.

Results: The offices achieved net-zero energy status in 2024, saving 640 tons of CO2e annually—equivalent to 1,500 flights from Oslo to London. The use of recycled materials reduced embodied carbon by 45% compared to conventional offshore offices, helping Equinor meet its ESG targets. The durable design withstood 150 km/h winds and corrosive saltwater, requiring no major maintenance over two years. The project became the first offshore container building certified under the EU Taxonomy for Sustainable Activities, setting a new standard for green offshore construction.

Sustainability: A Synergy of Cost-Effectiveness and Durability

In today’s business environment, sustainability is no longer an optional add-on but a critical component of cost-effective and durable construction. Lida Group has integrated sustainability into every aspect of its operations, recognizing that eco-friendly practices often align with long-term cost savings and enhanced durability.

Lida’s prefabricated approach inherently reduces environmental impact. Factory-based production generates 75% less waste than traditional construction, as scrap materials are recycled on-site rather than discarded in landfills. The company’s use of recycled steel (92% content) and bio-based insulation reduces embodied carbon, while energy-efficient designs (such as solar-integrated modules and high-performance insulation) lower operational energy use and costs. For example, Lida’s net-zero offshore offices for Equinor not only reduced carbon emissions but also cut energy costs by 50% compared to diesel-powered facilities.

Sustainability also enhances durability. Corrosion-resistant materials, such as Corten steel and nano-ceramic coatings, not only extend the lifespan of structures but also reduce the need for toxic paints and chemicals that harm the environment. Energy-efficient insulation not only lowers utility bills but also prevents moisture buildup, which can cause mold and structural damage over time. By prioritizing sustainable materials and designs, Lida creates structures that are both environmentally friendly and more resilient, reducing lifecycle costs for clients.

Lida Group’s sustainability credentials have been recognized by industry bodies. The company is a prefabricated construction industry base in Shandong Province, a “specialized and special new” enterprise in Shandong, and an invisible champion enterprise in Weifang City. It has also been awarded the title of Top 10 Enterprise in the Integrated Housing Industry for three consecutive years (2020–2022) by the China Construction Metal Association and designated as a national emergency enterprise for its role in earthquake relief. These certifications validate Lida’s commitment to sustainability and provide clients with confidence that their projects meet global environmental standards.

Competitive Advantages: Why Lida Group Stands Out in the Global Market

Lida Group’s success in delivering cost-effective durable solutions stems from several competitive advantages that set it apart from other construction firms and modular suppliers.

First, the company’s three decades of experience and technical expertise. Founded in 1993, Lida has refined its engineering and manufacturing processes over time, adapting to global trends and client needs. Its team of engineers—specializing in steel structures, modular design, and sustainability—has a deep understanding of the technical challenges of building in diverse environments, from Arctic deserts to offshore platforms. This expertise allows Lida to deliver tailored solutions that balance cost, durability, and performance, rather than one-size-fits-all products.

Second, Lida’s vertical integration. Unlike many modular suppliers that outsource manufacturing or logistics, Lida controls every step of the process—from R&D and design to production, shipping, and assembly. This vertical integration ensures quality control, reduces lead times, and lowers costs by eliminating middlemen. The company’s in-house factories produce over 1,000 tons of steel monthly, ensuring a steady supply of materials and reducing reliance on external vendors.

Third, Lida’s global reach and local compliance. With operations in 80+ countries and subsidiaries in the United States, Europe, and Asia, the company has the logistical capability to deliver projects anywhere in the world. Its structures comply with regional building codes and environmental regulations, ensuring that clients avoid costly delays or fines. For example, Lida’s offshore modules meet DNV GL and API standards for oil and gas projects, while its civil constructions comply with EU and US building codes.

Fourth, Lida’s commitment to innovation. The company invests heavily in R&D, continuously developing new materials, designs, and technologies to improve cost-effectiveness and durability. Recent innovations include Solar Skin™ roofs, hydrogen fuel cell integration, and AI-powered energy management systems, which have helped clients reduce costs and carbon emissions. Lida’s status as a national high-tech enterprise and technology center in Weifang City reflects its focus on innovation and technical excellence.

Finally, Lida’s customer-centric approach. The company works closely with clients to understand their specific needs, offering OEM customization that includes modifying door placements, adding fireproof cladding, integrating solar panels, or reconfiguring layouts to meet changing requirements. This flexibility ensures that clients get exactly what they need, rather than compromising on functionality to save costs. Lida’s 24/7 multilingual support and post-construction maintenance services further demonstrate its commitment to customer satisfaction, building long-term relationships with clients across industries.

Challenges and Future Outlook

While Lida Group has achieved significant success, it faces several challenges in the global construction market. One key challenge is the perception of prefabricated construction in some regions, where traditional methods are still preferred due to cultural or regulatory barriers. To address this, Lida must continue to educate clients about the benefits of modular solutions—through case studies, certifications, and pilot projects—that demonstrate cost savings and durability.

Another challenge is the volatility of steel prices, which can impact the cost-effectiveness of Lida’s solutions. The company mitigates this risk by maintaining strategic stockpiles of steel, negotiating long-term supply contracts, and optimizing material usage through precision engineering. Additionally, Lida’s investment in recycled steel helps reduce reliance on virgin materials, which are more prone to price fluctuations.

Looking ahead, Lida Group is well-positioned to capitalize on growing global demand for cost-effective, durable, and sustainable construction solutions. The prefabricated construction market is projected to grow at a CAGR of 12.5% from 2023 to 2030, driven by urbanization, industrialization, and the need for rapid infrastructure development. Lida’s focus on offshore energy, industrial manufacturing, and remote infrastructure aligns with these growth trends, as these sectors require the company’s specialized expertise in extreme environments.

The company’s future plans include expanding its manufacturing capacity to meet growing demand, investing in new technologies such as 3D printing for modular components, and strengthening its presence in emerging markets in Africa, Southeast Asia, and Latin America. Lida also aims to further enhance its sustainability credentials by developing fully circular modular solutions—where 100% of materials can be recycled or reused—and integrating more renewable energy technologies into its structures.

Conclusion

Lida Group’s three-decade journey from a small steel workshop to a global leader in cost-effective durable construction solutions is a testament to its commitment to innovation, quality, and customer satisfaction. By leveraging advanced materials, precision engineering, modular design, and end-to-end services, the company has redefined what is possible in construction—delivering structures that are faster to build, more affordable, and more resilient than traditional alternatives.

The case studies presented in this article—from typhoon-proof offshore modules to net-zero energy offices—demonstrate that Lida’s solutions are not just theoretical but proven in real-world applications. Clients across industries have benefited from significant cost savings (30–50% compared to traditional construction), reduced project timelines (up to 80% faster), and enhanced durability (25+ year lifespans with minimal maintenance). Moreover, Lida’s focus on sustainability ensures that these benefits are achieved without compromising the environment, aligning with global ESG mandates and long-term planetary health.

As the global construction industry continues to evolve, Lida Group is well-positioned to lead the way. Its technical expertise, vertical integration, global reach, and customer-centric approach make it a trusted partner for organizations seeking to build smarter, stronger, and more economically. Whether it’s a remote mining camp in the Arctic, an offshore oil rig in the North Sea, or a manufacturing facility in Europe, Lida Group delivers solutions that stand the test of time—proving that cost-effectiveness and durability are not opposing goals but complementary pillars of modern construction.

In a world where efficiency, resilience, and sustainability are more important than ever, Lida Group’s commitment to cost-effective durable solutions is not just a business strategy but a contribution to building a better, more sustainable future. As the company continues to innovate and expand, it will undoubtedly remain at the forefront of the construction revolution, shaping the way we build for decades to come.

Related news

-

Discover the Advantages of Our Metal Frame Construction

2025-11-26 17:12:49

-

Lida Group: A Leader in Innovative Steel Structure Building

2025-11-26 17:06:37

-

Customizable Prefab House Solutions from Lida Group

2025-11-26 16:57:51

contact us

- Tel: +86-532-88966982

- Whatsapp: +86-13793209022

- E-mail: sales@lidajituan.com