The global construction industry is perpetually locked in a battle against the “Iron Triangle” – the longstanding principle that dictates a trade-off between a project’s cost, speed, and quality. The conventional wisdom suggests that you can have a project fast and cheap, but not high-quality; cheap and high-quality, but not fast; or fast and high-quality, but certainly not cheap. This paradigm has led to budget overruns, protracted timelines, and variable quality for generations. However, a transformative shift is underway, championed by innovators like Lida Group, who are proving that this triangle is not a rigid law but a challenge to be solved. Through the strategic application of prefabricated construction methodologies, Lida Group consistently delivers projects that are not only rapid and high-quality but also remarkably cost-effective. This article provides a comprehensive examination of the mechanisms, strategies, and integrated processes that enable Lida to achieve this trifecta, using a hypothetical but representative case study to illustrate the journey from conception to completion.

**Part 1: Deconstructing the Cost Drivers in Traditional Construction**

To appreciate the cost-effectiveness of Lida’s model, one must first understand the inherent financial inefficiencies of traditional cast-in-situ construction.

**1.1 The High Cost of Time**

In traditional construction, time is literally money. Projects often span months or years, during which significant costs accumulate beyond direct labour and materials. These include:

* **Financing Costs:** Construction loans carry interest. Every day added to the project timeline increases the total interest paid, a substantial and often underestimated expense.

* **Site Overheads:** Temporary utilities, site security, fencing, site management trailers, and portable sanitation represent ongoing costs that persist for the duration of the build.

* **Equipment Rental:** Cranes, scaffolding, and other heavy machinery are rented for extended periods. Delays directly inflate these rental costs.

* **Opportunity Cost:** For commercial projects, every day of delayed completion is a day of lost revenue. A delayed apartment building cannot house tenants; a late factory cannot start production. This lost potential income is a critical component of the true project cost.

**1.2 Labor Inefficiency and Variability**

On-site construction is notoriously labor-intensive and prone to inefficiency.

* **Skilled Labor Shortages:** Dependence on multiple skilled trades (carpenters, masons, welders) can lead to bottlenecks if one trade is delayed, creating a domino effect that idles other teams.

* **Weather Disruptions:** Rain, extreme heat, or cold can halt outdoor work for days or weeks, directly impacting the schedule and budget.

* **Quality Variability:** The quality of work is directly tied to the skill and diligence of individual workers on any given day. Inconsistent workmanship can lead to rework, which is one of the most significant and avoidable cost overruns in construction.

**1.3 Material Waste and Logistics**

Traditional sites are often scenes of significant waste.

* **Ordering Inefficiencies:** Materials are often ordered with a buffer to account for errors, leading to surplus that becomes waste.

* **On-Site Damage:** Materials stored on-site are vulnerable to weather damage, theft, and mishandling.

* **Cutting Waste:** The process of cutting materials like lumber, steel rebar, and pipes to fit specific on-site needs generates substantial off-cuts that are rarely recyclable and end up in landfills, representing wasted expenditure.

It is against this backdrop of inherent financial risk and inefficiency that Lida Group’s prefabricated model shines, systematically addressing and mitigating each of these cost drivers.

**Part 2: The Lida Group Prefab Model: A Blueprint for Cost-Effectiveness**

Lida’s approach is not merely about building components in a factory; it is a holistic, integrated system designed for financial efficiency at every stage.

**2.1 The Foundational Principle: Parallel Processing**

The single most significant time and cost saver is the shift from a linear to a parallel workflow.

* **Traditional (Linear):** Site preparation -> Foundation -> On-site framing -> Enclosure -> Interior finishes. Each step must be largely completed before the next begins.

* **Lida (Parallel):** While the site is being prepared and the foundation is being poured, the building’s superstructure—walls, floors, roof trusses—is being manufactured simultaneously in a controlled factory environment. This parallel process can reduce the overall project timeline by 30% to 50%, directly slashing financing costs, overheads, and opportunity costs.

**2.2 Factory-Based Fabrication: The Epicenter of Efficiency**

The controlled factory environment is where major cost savings are engineered.

* **Economies of Scale and Bulk Purchasing:** Lida purchases raw materials like steel, insulation, and fasteners in massive quantities, securing them at a significantly lower unit cost than a single project could.

* **Precision Manufacturing:** Using Computer-Aided Design (CAD) and Computer-Aided Manufacturing (CAM), components are cut, drilled, and assembled with millimeter precision. This eliminates the material waste endemic to on-site “measure-and-cut” practices.

* **Reduced Labor Costs:** Factory work is more efficient. A smaller, specialized workforce can produce more in a day than a larger on-site crew, as they are not hindered by weather, site logistics, or trade sequencing. This optimized labor model reduces total man-hours required.

* **Zero Weather Delays:** Factory production is immune to the elements, ensuring a predictable and uninterrupted manufacturing schedule.

* **Enhanced Quality Control:** Every component is fabricated and inspected under strict quality assurance protocols. This consistency prevents the costly rework that plagues traditional sites due to human error or subpar workmanship.

**2.3 Streamlined On-Site Assembly: From Construction to Installation**

Once factory-made components arrive on site, the process shifts to rapid assembly.

* **Reduced On-Site Labor:** The need for large crews of skilled framers and welders is drastically reduced. The site crew functions more as an assembly team, following precise instructions to connect the pre-engineered parts.

* **Speed of Erection:** With components designed to fit together perfectly, the building envelope can be raised in a matter of days or weeks, not months. This rapid “drying-in” of the structure protects the interior from the elements much sooner.

* **Safer Construction:** A more predictable and organized site with less manual handling of raw materials and fewer complex tasks leads to a safer working environment, reducing the risk and potential cost of accidents.

**Part 3: A Case Study in Action: The “Innovate Corporate Campus”**

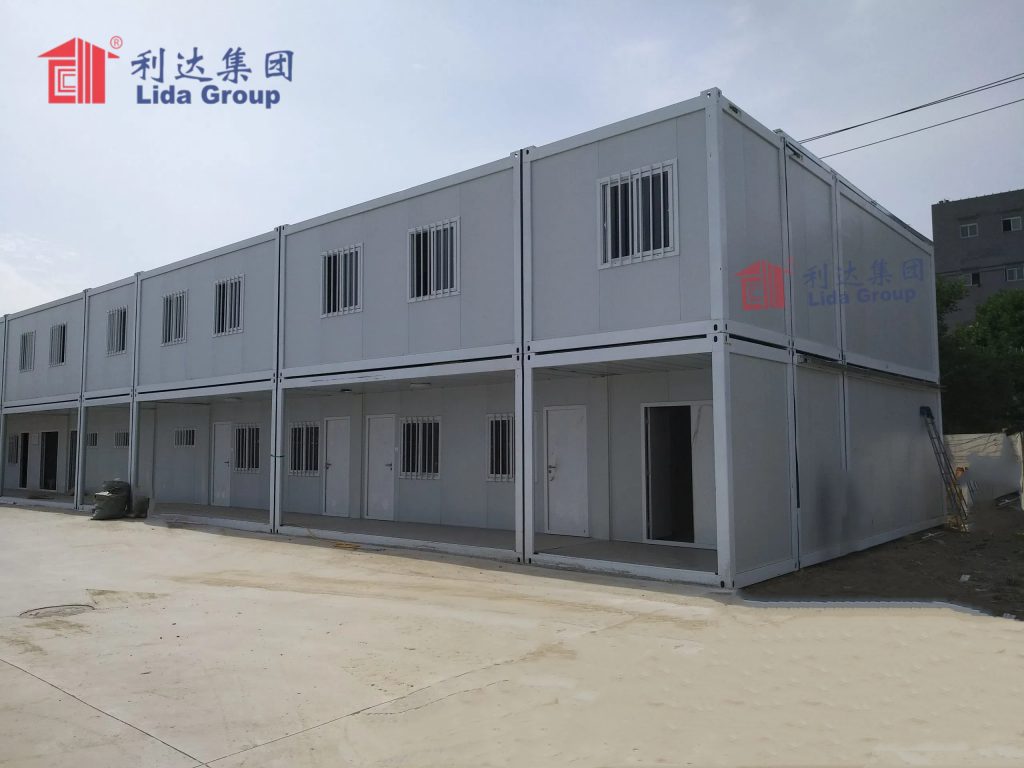

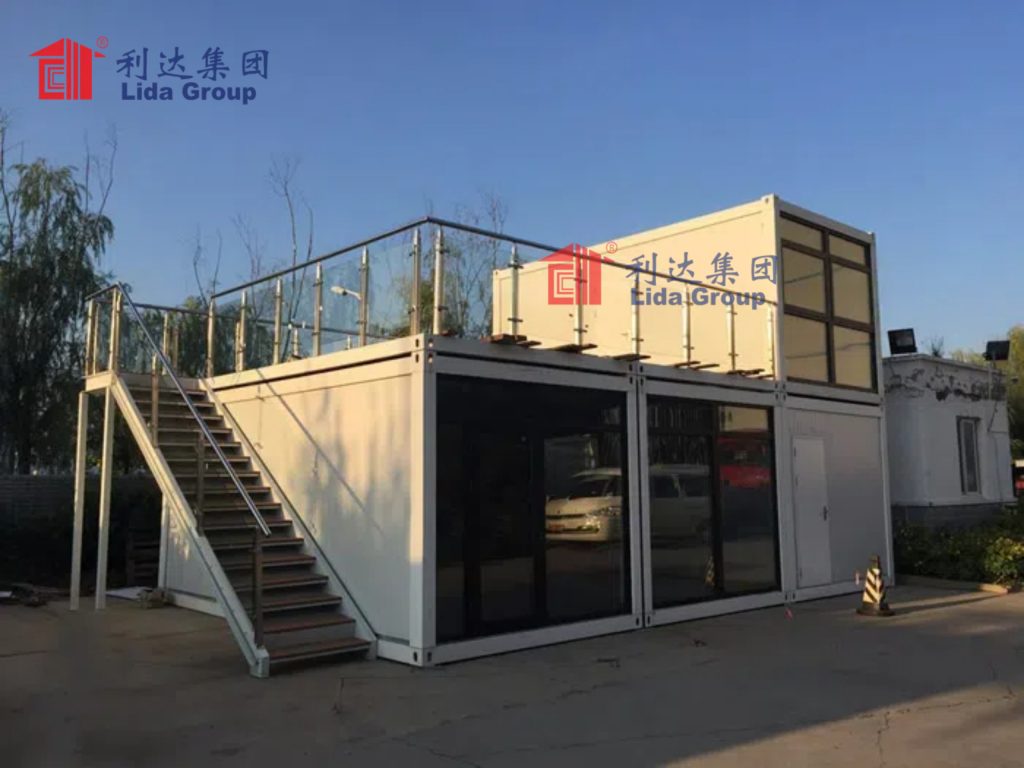

To illustrate these principles, let’s follow a hypothetical but highly representative project: the “Innovate Corporate Campus,” a two-story, 20,000-square-meter office complex.

**Phase 1: Integrated Planning and Design (The Cornerstone of Savings)**

The project begins not with a shovel, but with a deep, collaborative design process involving Lida’s engineers, architects, and the client.

* **Value Engineering:** From day one, the team designs for cost-effectiveness. This involves selecting the most efficient structural systems, optimizing panel sizes to minimize waste, and choosing materials that offer the best balance of performance, durability, and cost.

* **Building Information Modeling (BIM):** A digital twin of the entire building is created. This 3D model integrates architecture, structure, and MEP (Mechanical, Electrical, Plumbing) systems. The software performs “clash detection,” identifying where, for example, a pipe might run through a steel beam *before* it reaches the factory floor. Resolving these conflicts digitally eliminates incredibly expensive on-site modifications and delays.

* **Fixed-Price Contracting:** Because the project is 80% manufactured in a factory, Lida can provide a much more accurate and fixed price early on. The risk of unforeseen cost variations, a hallmark of traditional projects, is massively reduced.

**Phase 2: Factory Fabrication**

While the site is being graded and the concrete slab is being poured, the campus comes to life in Lida’s factory.

* **The Assembly Line:** Light gauge steel frames for walls and floors move along production lines. Insulation is precisely fitted, and pre-wiring for electrical and data is installed within the wall panels.

* **Integrated Components:** Windows and external door frames are pre-installed into wall panels in the factory, ensuring a perfect fit and superior weather sealing compared to on-site installation.

* **Quality Checks:** Each completed module, from a wall panel to a complex mechanical unit, undergoes rigorous inspection. This ensures that only defect-free components are shipped to the site.

**Phase 3: Just-in-Time Logistics and Assembly**

* **Sequenced Delivery:** Components are not dumped on-site in a pile. They are loaded onto trucks in the reverse order of their assembly. The first components needed are the last loaded and first off the truck. This “just-in-time” delivery eliminates on-site clutter and handling, further speeding up the process.

* **Rapid Erection:** With the foundation ready, cranes lift the prefabricated wall panels into place. The steel structure is bolted together. The speed is breathtaking; the skeletal structure of the entire campus is up within two weeks.

* **Follow-On Trades:** With the building enclosed quickly, interior trades like drywall installers, electricians, and painters can begin their work in a protected environment, unaffected by external weather, and can work concurrently in different sections.

**The Financial Outcome for the Innovate Campus:**

* **A 40% Reduction in Construction Time** compared to a traditional build, leading to massive savings on interest and overheads.

* **A 25% Reduction in Overall Project Cost** when factoring in hard construction costs, financing, and overheads.

* **Less than 5% Material Waste** sent to landfill, compared to the industry average of 25-30%.

* **A Predictable Budget** with no costly change orders or surprises.

**Part 4: Beyond Initial Cost: The Life-Cycle Cost Advantage**

Lida’s cost-effectiveness extends far beyond the construction phase. Their buildings are designed for low total cost of ownership.

* **Energy Efficiency:** The precision manufacturing allows for exceptionally tight building envelopes and seamless integration of high-performance insulation. This drastically reduces energy loss, leading to significantly lower heating and cooling bills for the life of the building.

* **Durability and Low Maintenance:** The use of galvanized steel frames eliminates concerns about rot, termites, or warping. The high-quality, factory-applied finishes on wall panels are more uniform and durable than many on-site applications, reducing repainting and maintenance frequency.

* **Adaptability:** The structural systems often allow for easy future modifications. Interior walls can be reconfigured, and mezzanines can be added with minimal disruption and cost, future-proofing the client’s investment.

**Part 5: Addressing Common Misconceptions**

It is crucial to dispel myths that might obscure the value proposition.

* **Myth 1: Prefab is Low-Quality.** The reality is the opposite. Factory control ensures a consistently higher and more predictable quality than variable on-site construction.

* **Myth 2: Prefab Lacks Design Flexibility.** As demonstrated in the previous article, Lida’s model is built on a platform of customizable components, allowing for vast aesthetic and functional variety.

* **Myth 3: The Savings Come from Cheap Materials.** The savings are primarily derived from the *process*—reduced time, waste, and labor. Lida often uses superior, engineered materials like structural steel and high-performance composites.

**Conclusion: Redefining Value in the Built Environment**

Lida Group’s delivery of a cost-effective prefab construction project is not a matter of chance; it is the direct result of a meticulously engineered system that fundamentally rethinks how buildings are created. By transferring the bulk of the construction process from a chaotic, weather-dependent site to a controlled, efficient factory, Lida systematically dismantles the primary cost drivers of traditional building.

The cost-effectiveness achieved is multi-faceted. It is realized through **dramatic time savings** that reduce financing and overheads; through **unparalleled material and labor efficiency** that minimizes waste and optimizes productivity; and through **superior planning and integration** that eliminates costly errors and rework. Furthermore, this initial affordability is compounded by long-term value, embodied in energy-efficient, durable, and adaptable structures that promise a low total cost of ownership for decades to come.

The case of the “Innovate Corporate Campus” is a testament to this model’s power. It demonstrates that the old “Iron Triangle” is obsolete. Clients no longer need to choose between cost, speed, and quality. Lida Group’s prefabricated approach delivers on all three fronts simultaneously, offering a smarter, more resilient, and profoundly more economical path forward for the construction industry. In doing so, they are not just building projects; they are building a compelling case for the future of construction itself—a future that is faster, higher quality, and unequivocally more cost-effective.

Related news

-

Innovative Prefab Mobile Container House for Flexible Living

2025-11-27 11:53:34

-

Discover Our Modern Free Design Container Building Concepts

2025-11-27 13:18:29

-

Lida Group Champions Cost-Effective Prefab Construction

2025-11-27 11:39:07

contact us

- Tel: +86-532-88966982

- Whatsapp: +86-13793209022

- E-mail: sales@lidajituan.com