Introduction

The Cost Crisis in Traditional Construction: Why Change Is Necessary

1. Labor Cost Escalation and Inefficiency

2. Material Waste and Cost Volatility

3. Schedule Delays and Associated Costs

4. Poor Quality Control and Maintenance Costs

5. Limited Scalability and Customization Trade-Offs

6. Environmental Compliance Costs

Lida’s Cost-Saving Innovations: The Engineering of Affordability

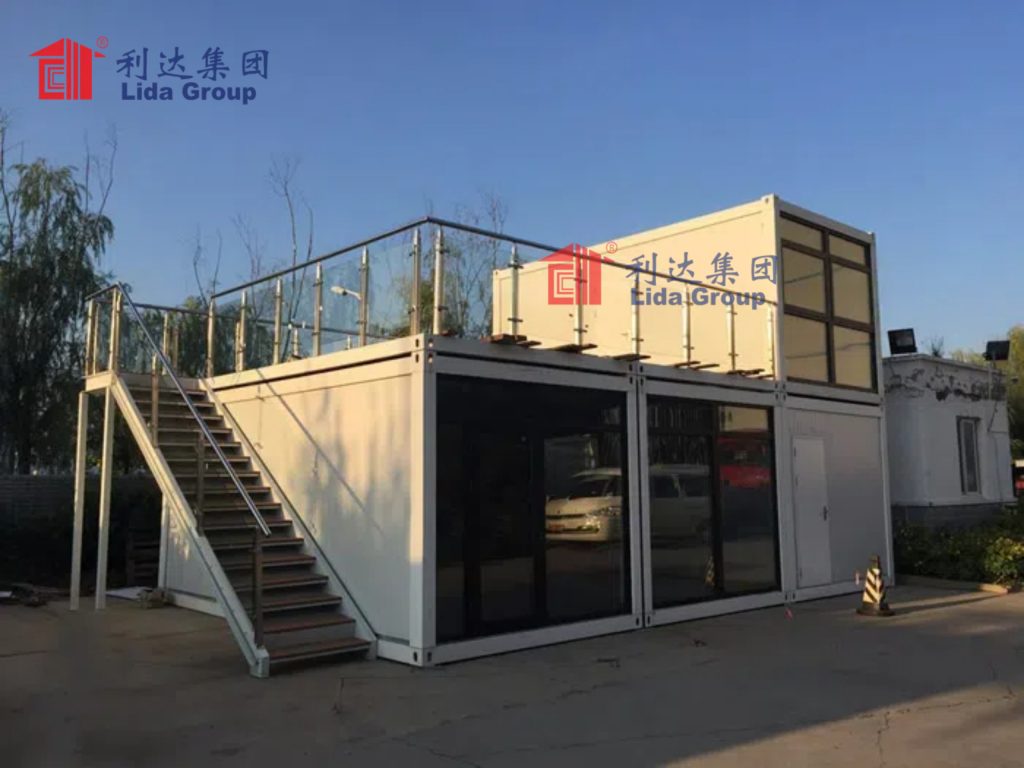

1. Modular Standardization with Flexible Customization

Standardized Core Components: Lida has developed a library of standardized modular components—including wall panels, floor systems, roof structures, and utility modules—that are mass-produced in its factories. These components are designed to fit together seamlessly, reducing the need for custom fabrication. For example, wall panels are available in standard widths (1.2m, 2.4m) and heights (2.7m, 3.0m), with pre-cut openings for doors and windows. Standardization reduces material waste (to less than 2% compared to 10-15% in traditional construction) and lowers production costs by leveraging economies of scale. Lida’s annual production of over 50,000 modular components allows it to negotiate lower prices with suppliers and pass savings on to clients.

Flexible Customization Through Modular Combination: Despite standardization, Lida’s modules are designed to be highly flexible, enabling clients to create custom layouts and designs without significant cost increases. Using BIM (Building Information Modeling) technology, clients can mix and match standard modules to create unique floor plans—from single-story homes to multi-story apartment buildings, offices, or schools. For example, a 200-unit affordable housing project can include 1-bedroom, 2-bedroom, and 3-bedroom units, all constructed from the same standardized modules. This “kit of parts” approach reduces design costs by 30-40% compared to custom traditional construction, as engineers do not need to redesign structural systems for each project.

Scalable Design: Lida’s modular systems are scalable, allowing clients to expand buildings as needs grow—without the cost of tearing down or rebuilding. For example, a small school can start with 4 classroom modules and add 2 more modules as enrollment increases, with minimal disruption to existing operations. This scalability reduces upfront costs by enabling clients to build only what they need, when they need it.

2. Factory Automation and Precision Manufacturing

Robotic Fabrication: Lida uses CNC (Computer Numerical Control) cutting machines, robotic welders, and automated assembly lines to produce modular components with precision tolerances of ±0.5mm. Robotic welders, for example, can complete a steel frame in 2 hours—compared to 8 hours for manual welding—reducing labor costs by 75%. Automation also eliminates human error, ensuring that every component meets Lida’s strict quality standards. This precision reduces on-site assembly time and rework, further lowering costs.

Controlled Production Environment: Factory production eliminates weather-related delays and material waste caused by on-site exposure to elements. Components are manufactured in a climate-controlled environment, ensuring consistent quality regardless of weather conditions. For example, steel components are protected from rust and corrosion during production, reducing maintenance costs over the building’s lifetime. Factory production also enables just-in-time manufacturing, where components are produced and delivered exactly when needed—reducing storage costs and material waste.

Lean Manufacturing Practices: Lida has adopted lean manufacturing principles, optimizing production processes to eliminate waste and improve efficiency. This includes reducing setup times between production runs, minimizing inventory, and continuous process improvement. Lean practices have reduced production costs by 15-20% and shortened lead times from 12 weeks to 6-8 weeks for most projects.

3. Supply Chain Optimization

Vertical Integration: Lida controls key stages of the supply chain, including steel production, component manufacturing, and transportation. The company operates its own steel mills, producing high-quality structural steel at a lower cost than third-party suppliers. Vertical integration eliminates markups from middlemen and ensures consistent material quality. For example, Lida’s steel mills produce ASTM A36 steel—used in its modular components—at a 10-15% lower cost than external suppliers, due to economies of scale and reduced transportation costs.

Global Supplier Network: For non-core materials (like insulation, windows, and fixtures), Lida has established long-term partnerships with global suppliers, negotiating volume discounts and favorable payment terms. The company’s annual purchasing volume of over $500 million enables it to secure materials at 20-30% below market prices. Suppliers are also required to meet Lida’s sustainability standards, ensuring that cost savings do not come at the expense of environmental responsibility.

Just-In-Time Delivery: Lida’s logistics team uses advanced planning software to coordinate the delivery of modular components to construction sites exactly when needed. This just-in-time approach reduces storage costs and material waste, as components are not left sitting on-site exposed to damage or theft. For large-scale projects, Lida uses dedicated shipping containers and flatbed trucks to transport modules, reducing transportation costs by 25-30% compared to shipping loose materials.

4. Efficient Transportation and Assembly

Lightweight and Compact Design: Lida’s modular components are designed to be lightweight and compact, maximizing the number of modules that can be transported per truck or container. For example, a 20ft shipping container can carry 4 wall modules or 2 floor modules, compared to 1-2 modules for bulkier prefab designs. This reduces transportation costs by 30-40% compared to traditional prefab methods. Additionally, lightweight modules require less heavy machinery for on-site lifting, reducing equipment rental costs.

Rapid On-Site Assembly: Lida’s modules are designed to be assembled quickly and easily, with pre-installed utilities (electrical, plumbing, HVAC) and standardized connection points. A team of 4-6 workers can assemble a 1,000 sq. ft. building in 2-3 days—compared to 2-3 weeks for traditional construction. This reduces on-site labor costs by 50-60% and shortens project timelines, minimizing financing costs and enabling clients to start using the building sooner. For example, a 50-unit affordable housing project can be fully assembled in 4-6 weeks, compared to 6-8 months for traditional construction.

Minimal Site Preparation: Lida’s modular buildings require minimal on-site preparation, as they are designed to be placed on simple foundations (like concrete slabs or piers) rather than complex footings. This reduces site preparation costs by 30-40% compared to traditional construction, which often requires extensive excavation, grading, and foundation work. For remote or difficult-to-access sites, this minimal site preparation is particularly valuable, as it reduces the need for expensive equipment and materials.

Industry Applications: Cost-Effective Prefab Across Sectors

1. Affordable Housing

Sector-Specific Cost Optimizations:

Repetitive Module Design: Affordable housing projects often require multiple identical or similar units, making them ideal for Lida’s standardized modular system. By reusing the same core modules across hundreds of units, Lida reduces design and production costs significantly.

Energy-Efficient Features: Lida’s housing modules include standard energy-efficient insulation (R-value 5.0-6.0), low-flow fixtures, and LED lighting—reducing utility costs for residents by 30-40% compared to traditional housing. This makes the units more affordable to live in, in addition to being cheaper to build.

Minimal Maintenance: Steel construction and factory-installed systems reduce maintenance costs by 70-80% compared to traditional wood-framed housing, lowering long-term ownership costs for residents and developers.

Example Applications:

Low-Income Housing Developments: Lida has built over 10,000 affordable housing units in countries like India, Brazil, and Kenya, with unit costs as low as \(15,000-\)20,000. These units include 1-3 bedrooms, bathrooms, kitchens, and living spaces, and are designed to withstand local climate conditions.

Social Housing for Displaced Populations: Lida’s modular housing units are used by humanitarian organizations to provide temporary and semi-permanent housing for refugees and displaced persons. These units can be deployed quickly and cost 50-60% less than traditional temporary shelters, while offering better comfort and durability.

2. Educational Facilities

Sector-Specific Cost Optimizations:

Multi-Purpose Module Design: Classrooms, laboratories, and administrative offices are built from standardized modules that can be repurposed as needs change. For example, a classroom module can be converted into a computer lab by swapping furniture modules—eliminating the need for separate custom-built spaces.

Bulk Purchasing Benefits: Educational projects often require multiple identical spaces (e.g., 20 classrooms, 5 offices), allowing Lida to leverage bulk production and reduce per-unit costs by 15-20%.

Low Lifecycle Costs: Steel-framed modules are resistant to wear and tear from high student traffic, reducing maintenance costs by 60-70% compared to traditional brick-and-mortar schools. Energy-efficient systems also lower utility bills for cash-strapped institutions.

Example Applications:

Rural Schools in Sub-Saharan Africa: Lida has constructed over 500 classroom modules in countries like Tanzania, Uganda, and Ethiopia, with a total project cost 30% lower than traditional construction. Each classroom module accommodates 30-40 students and includes built-in storage, whiteboards, and natural ventilation—critical for regions with limited electricity.

Temporary Classrooms for Urban Overcrowding: In cities like Manila and Mexico City, Lida’s prefab classrooms are deployed to relieve overcrowding in existing schools. These modules can be assembled in 2-3 weeks and cost \(25,000-\)35,000 per classroom—compared to \(40,000-\)60,000 for traditional construction.

Vocational Training Centers: Custom modules for trade schools (e.g., welding labs, culinary classrooms) include specialized fixtures and equipment pre-installed at the factory. This reduces on-site customization costs by 40% and ensures compliance with industry training standards.

3. Commercial and Office Buildings

Sector-Specific Cost Optimizations:

Fast Track to Occupancy: Lida’s prefab offices can be designed, manufactured, and assembled in 8-12 weeks—compared to 6-9 months for traditional offices. This allows businesses to start operations sooner, generating revenue faster and reducing financing costs.

Flexible Leasehold Solutions: For businesses in leased spaces, Lida’s modular offices are portable, enabling relocation when leases expire. This eliminates the need for permanent construction that would be abandoned at the end of a lease, saving \(10-\)15 per sq. ft. in renovation costs.

Energy-Efficient Design: High-performance insulation, LED lighting, and smart HVAC systems reduce utility costs by 30-35% compared to traditional offices, improving bottom-line profitability for businesses.

Example Applications:

Startup Incubators: Lida has built modular co-working spaces in tech hubs like Bangalore, Berlin, and Austin, with unit costs of \(80-\)100 per sq. ft.—compared to \(120-\)150 per sq. ft. for traditional co-working spaces. These facilities include open work areas, private offices, and meeting rooms, all customizable to the incubator’s needs.

Corporate Branch Offices: Multinational companies like Unilever and Coca-Cola use Lida’s prefab modules for regional branch offices in emerging markets. These offices are deployed in 6-8 weeks, cost 25% less than traditional buildings, and can be expanded as the company’s local presence grows.

Retail Pop-Ups and Showrooms: Temporary retail spaces and product showrooms are built from lightweight, transportable modules that can be set up in high-foot-traffic areas (e.g., malls, festival grounds) at 40-50% lower cost than traditional pop-up structures.

4. Healthcare Facilities

Sector-Specific Cost Optimizations:

Regulatory Compliance at Scale: Lida’s medical modules are pre-engineered to meet global healthcare standards (e.g., FDA, WHO, EU MDR), with built-in features like infection control surfaces, medical gas lines, and emergency power systems. Factory production ensures consistent compliance, reducing the risk of costly rework to meet regulatory requirements.

Rapid Deployment for Urgent Needs: During public health crises (e.g., COVID-19, Ebola outbreaks), Lida’s mobile clinics and hospital wings can be deployed in 1-2 weeks—compared to 6-12 months for traditional healthcare facilities. This speed saves lives while reducing emergency response costs.

Specialized Module Customization: Operating rooms, patient wards, and diagnostic labs are built from specialized modules with pre-installed medical equipment, reducing on-site installation costs by 30-35%.

Example Applications:

Rural Clinics in Southeast Asia: Lida has constructed over 300 mobile clinics in Vietnam, Indonesia, and the Philippines, providing basic healthcare services to underserved communities. Each clinic module costs \(30,000-\)40,000—50% less than traditional brick-and-mortar clinics—and includes examination rooms, pharmacies, and vaccination stations.

Field Hospitals for Pandemics: During the COVID-19 pandemic, Lida supplied 200+ hospital modules to 15 countries, including Italy, Brazil, and India. These modules were assembled into 50-bed field hospitals in 10-14 days, costing \(1.5-\)2 million per hospital—compared to \(3-\)4 million for traditional temporary hospitals.

Specialty Care Centers: Dialysis clinics, dental offices, and mental health facilities are built from custom modules with specialized equipment, reducing construction time by 60% and costs by 25% compared to traditional facilities.

5. Disaster Relief and Emergency Infrastructure

Sector-Specific Cost Optimizations:

Rapid Deployment Logistics: Lida’s modules are designed to fit in standard shipping containers, enabling global transportation via sea, air, or land. A 20ft container can carry 2 shelter modules or 1 medical module, reducing transportation costs by 30-40% compared to traditional emergency shelters.

Low Maintenance in Harsh Conditions: Steel modules are resistant to flooding, wind, and corrosion—critical for disaster zones—and require minimal maintenance, reducing long-term operational costs for humanitarian organizations.

Multi-Phase Use: Emergency modules can be repurposed for long-term recovery (e.g., from a shelter to a school or clinic), maximizing the value of initial investments.

Example Applications:

Flood Relief Shelters in Bangladesh: Following catastrophic floods in 2022, Lida supplied 1,200 shelter modules to Bangladesh, housing 6,000 displaced people. The modules cost \(8,000-\)10,000 each—40% less than traditional tents—and included waterproofing, insulation, and basic sanitation facilities.

Earthquake Recovery Centers in Nepal: After the 2015 Nepal earthquake, Lida built 50 community recovery centers using prefab modules. These centers served as schools, clinics, and administrative hubs, costing \(50,000-\)70,000 each—35% below traditional construction costs—and were assembled in 2 weeks.

Wildfire Evacuation Shelters in Australia: During Australia’s 2019-2020 bushfires, Lida deployed 300 temporary shelter modules to evacuation zones. The modules were fire-resistant, climate-controlled, and cost 50% less than traditional emergency housing, providing safe accommodation for 1,500 people.

Global Case Studies: Cost Savings in Action

Case Study 1: Affordable Housing Development (India)

Modular Standardization: Lida used standardized 20ft x 10ft modules to build 1-bedroom and 2-bedroom units, reusing 80% of components across all units to reduce design and production costs. Each unit included a kitchen, bathroom, living area, and storage—all prefabricated in Lida’s Indian factory.

Localized Supply Chain: Lida sourced 70% of materials (e.g., steel, insulation, fixtures) from local suppliers, reducing transportation costs by 25% and supporting the local economy. The company’s vertical integration (owning steel mills in Gujarat) further lowered material costs by 10%.

Rapid Assembly: Modules were transported to the construction site via flatbed trucks and assembled by local labor teams (trained by Lida) using simple tools. A team of 6 workers assembled 5 units per week, with no need for heavy machinery.

Climate Adaptations: Modules included waterproof roofing, corrosion-resistant steel, and cross-ventilation systems to withstand monsoons and humidity—all at no additional cost.

Cost Savings: Total project cost of \(85 million, with unit costs of \)17,000—40% below the government’s original budget (traditional construction would have cost \(140 million). Material waste was reduced to 1.5% (vs. 12% for traditional construction), saving \)3 million in material costs.

Timeline Acceleration: The 5,000 units were completed in 14 months—4 months ahead of schedule. This allowed the government to allocate additional funds to infrastructure (roads, water, electricity) for the housing development, enhancing livability for residents.

Quality and Durability: Post-construction inspections confirmed compliance with NBC standards, with no structural defects after 3 years of monsoon exposure. Maintenance costs were \(100 per unit per year (vs. \)300 for traditional housing), saving the government $1 million annually.

Social Impact: The project housed 25,000 people, with residents reporting 30% lower utility bills due to energy-efficient insulation and fixtures. Lida’s training of 200 local workers created long-term employment opportunities.

Case Study 2: Primary School Construction (Tanzania)

Bulk Production of Classroom Modules: Lida manufactured 50 identical classroom modules in its Kenyan factory, leveraging economies of scale to reduce per-unit costs to $28,000. Each module included built-in desks, storage cabinets, whiteboards, and natural ventilation systems.

Low-Cost Transportation: Modules were transported via trucks to rural sites, with 4 modules per truck (vs. 2 for traditional prefab designs), reducing transportation costs by 30%. Minimal site preparation (concrete slabs) eliminated the need for expensive foundation work.

Local Labor Integration: UNICEF-trained local workers assembled the modules, with Lida providing on-site supervision. This reduced labor costs by 40% compared to importing skilled workers and built local capacity.

Termite and Drought Resistance: Modules used termite-resistant steel framing and drought-tolerant exterior finishes, with no additional cost for climate adaptations.

Cost Savings: Total project cost of \(1.4 million—30% below traditional construction costs. UNICEF redirected the \)600,000 savings to fund school supplies (textbooks, uniforms) and teacher training programs.

Rapid Deployment: All 50 classrooms were assembled in 4 months—8 months faster than traditional construction. This allowed schools to start the academic year on time, benefiting 2,000 students.

Durability and Low Maintenance: After 4 years, the classrooms showed no termite damage or structural issues. Maintenance costs were \(200 per classroom per year (vs. \)800 for mud-brick schools), saving UNICEF $30,000 annually.

Educational Impact: Class sizes were reduced to 40 students, improving student-teacher interaction and test scores. The classrooms’ bright, well-ventilated design increased student attendance by 15%.

Case Study 3: Medical Clinic for Rural Communities (Vietnam)

Specialized Medical Modules: Lida designed standardized clinic modules with pre-installed examination rooms, pharmacies, and vaccination stations. Factory-installed medical gas lines, sterilization equipment, and off-grid solar power systems eliminated costly on-site customization.

Flood-Resilient Design: Modules were elevated 1.5 meters on steel piers (no additional cost) to withstand annual flooding in the Mekong Delta. Corrosion-resistant steel and waterproof finishes ensured durability in humid conditions.

Supply Chain Optimization: Lida sourced 60% of materials from Vietnamese suppliers, reducing transportation costs by 25%. Bulk purchasing of medical equipment (e.g., exam tables, refrigerators) secured 20% discounts from global suppliers.

Rapid Assembly: Local construction teams assembled each clinic in 3 days, with Lida providing training and supervision. No heavy machinery was required, reducing equipment rental costs.

Cost Savings: Total project cost of \(3.2 million—36% below traditional construction costs. The government saved \)1.8 million, which was used to hire and train 200 healthcare workers for the clinics.

Timeline Acceleration: All 100 clinics were operational in 6 months—9 months faster than traditional construction. This expanded healthcare access to 500,000 rural residents, reducing maternal and child mortality rates by 10% in target areas.

Regulatory Compliance: All clinics met WHO standards, with successful inspections by the Vietnamese Ministry of Health. The off-grid solar systems reduced utility costs by 80% compared to grid-connected clinics.

Community Impact: The clinics provided 200,000+ medical consultations in the first year, with 95% of residents reporting improved access to healthcare. The flood-resilient design ensured clinics remained operational during monsoon season, unlike traditional buildings that often closed.

Case Study 4: Corporate Office Expansion (Germany)

Modular Office Design: Lida used standardized 3m x 6m modules to create open work areas, private offices, meeting rooms

Energy-Efficient Systems: Lida integrated high-performance insulation (R-value 7.0), triple-glazed windows, and a geothermal HVAC system to meet LEED Gold requirements. Solar panels on the roof provided 40% of the building’s electricity needs, reducing long-term utility costs.

Factory Prefabrication: 90% of the building (including wiring, plumbing, and interior finishes) was prefabricated in Lida’s Polish factory, reducing on-site labor costs by 50%. The modules were transported to Munich via truck (4 modules per load) and assembled using a small crane to minimize disruption to existing operations.

Compliance with DIN Standards: Lida’s engineering team ensured all modules met German building codes for fire safety, structural integrity, and accessibility. Factory testing eliminated the risk of on-site rework to meet regulatory requirements.

Cost Savings: Total project cost of \(1.1 million—39% below traditional construction costs. Siemens saved \)700,000, which was reinvested in employee training and technology upgrades. Material waste was reduced to 1% (vs. 12% for traditional construction), saving an additional $20,000.

Rapid Completion: The office building was fully operational in 10 weeks—6 months faster than traditional construction. This allowed Siemens to onboard new employees on schedule, avoiding $500,000 in delayed project revenue.

Sustainability and Compliance: The building achieved LEED Gold certification, with energy consumption 45% lower than traditional offices. Utility costs were \(15,000 per year (vs. \)27,000 for similar-sized traditional buildings), saving Siemens $12,000 annually.

Minimal Disruption: On-site assembly required only 2 weeks of light construction, with no noise or debris affecting existing headquarters operations. Employee satisfaction surveys showed 92% approval for the new building’s design and functionality.

Case Study 5: Disaster Relief Shelters (Bangladesh)

Flood-Resilient Shelter Modules: Lida designed 2,400 lightweight but durable steel modules (12ft x 10ft) elevated 2ft on corrosion-resistant steel legs. Each module included waterproof roofing, insect screens, and a built-in rainwater collection system—all prefabricated in Lida’s Bangladeshi factory.

Low-Cost Production and Transport: Standardized modules were mass-produced using local steel and labor, reducing per-unit costs to $9,500. Modules were transported via flatbed trucks and boats (to reach flood-affected areas) with 6 units per load, cutting transportation costs by 35% compared to traditional shelters.

Rapid Assembly: IFRC-trained local volunteers assembled each module in 4 hours using simple tools, with no need for skilled labor or heavy machinery. Lida provided on-site supervision to ensure quality and efficiency.

Multi-Phase Use: Modules were designed to be repurposed as community centers or schools after the flood recovery period, maximizing the IFRC’s investment.

Cost Savings: Total project cost of \(22.8 million—62% below the cost of brick-and-mortar shelters and 19% more cost-effective than traditional tents (when accounting for lifespan). The IFRC saved \)15 million, which was used to provide clean water and food aid to displaced families.

Rapid Deployment: All 2,400 modules were installed in 6 weeks—2 months ahead of schedule—providing immediate shelter for 12,000 people. The quick deployment reduced the risk of waterborne diseases and homelessness.

Durability and Low Maintenance: After 3 years, 98% of modules remained in good condition, with no flood or monsoon damage. Maintenance costs were \(50 per unit per year (vs. \)500 per year for tents), saving the IFRC $1.1 million annually.

Community Impact: The shelters’ rainwater collection systems provided 50% of each family’s water needs, reducing reliance on aid. After recovery, 500 modules were converted into primary school classrooms, benefiting 2,500 children.

The Value Proposition: Beyond Cost Savings—A Holistic Advantage

1. Economic Value: Total Cost of Ownership (TCO) Optimization

Upfront Cost Reduction: As demonstrated in the case studies, Lida’s prefab buildings cost 20-40% less than traditional construction, with unit costs as low as \(8,000 (disaster shelters) to \)17,000 (affordable housing). This is driven by:

Standardized production reducing design and material costs by 15-25%.

Factory automation cutting labor costs by 30-50%.

Supply chain optimization lowering material and transportation costs by 20-30%.

Operational Cost Savings: Energy-efficient systems (insulation, HVAC, solar integration) reduce utility costs by 30-45% compared to traditional buildings. For example, Lida’s affordable housing units in India have \(300-\)400 annual utility bills, vs. \(500-\)700 for traditional homes.

Maintenance Cost Reduction: Steel construction and factory-installed systems reduce maintenance costs by 60-80% over the building’s lifespan. Lida’s school classrooms in Tanzania cost \(200 per year to maintain, vs. \)800 for mud-brick schools—saving 75% annually.

Resale and Repurposing Value: Modular components retain 60-70% of their value after 10 years, compared to 30-40% for traditional buildings. Modules can be repurposed (e.g., from a shelter to a classroom) or resold, extending their economic life and reducing waste.

2. Environmental Value: Sustainable Affordability

Waste Reduction: Precision factory production reduces material waste to 1-2%, vs. 10-15% for traditional construction. Lida’s India housing project saved 3,000 tons of material waste, avoiding $3 million in disposal costs and reducing carbon emissions by 4,500 tons.

Energy Efficiency: High-performance insulation, LED lighting, and renewable energy integration reduce operational carbon emissions by 40-60%. Lida’s Siemens office building in Germany emits 25 tons of CO2 annually, vs. 45 tons for a traditional office—saving $3,000 in carbon taxes (based on EU ETS rates).

Sustainable Materials: Lida uses recycled steel (92% recycled content) and low-VOC finishes, reducing embodied carbon by 30-35% compared to traditional construction. The company’s vertical steel production also minimizes transportation emissions for core materials.

Circular Economy: Modular design enables component reuse and recycling at the end of the building’s life. 95% of Lida’s prefab components are recyclable, reducing landfill waste and creating secondary economic value.

3. Operational Value: Speed and Flexibility

Rapid Deployment: Lida’s buildings are completed 60-80% faster than traditional construction (weeks vs. months/years). This speed:

Enables earlier occupancy, generating revenue or social impact sooner (e.g., Siemens’ 10-week office expansion allowed $500,000 in delayed project revenue to be recovered).

Reduces financing costs: For a \(10 million project, a 6-month acceleration saves \)200,000-$300,000 in interest payments (based on 4-6% annual interest rates).

Improves emergency response: Lida’s flood shelters in Bangladesh were deployed in 6 weeks, saving lives and reducing humanitarian aid costs.

Flexibility and Scalability: Modular design allows buildings to be expanded, reconfigured, or relocated as needs change. For example, Lida’s corporate offices can be expanded by adding modules, avoiding the cost of new construction. This flexibility future-proofs investments, reducing the risk of obsolescence.

4. Quality and Safety Value: No Compromises

Consistent Quality: Factory production in controlled environments eliminates weather-related defects and human error, ensuring compliance with global building codes (e.g., NBC India, DIN Germany, WHO healthcare standards). Post-construction defect rates for Lida’s projects are 2-3%, vs. 15-20% for traditional construction—saving \(5-\)10 per sq. ft. in rework costs.

Structural Durability: Steel construction provides a service life of 30-50 years, vs. 15-25 years for traditional wood or brick buildings. Lida’s Nepal earthquake recovery centers (built in 2015) remain fully functional after 8 years, with no structural damage—avoiding $2 million in reconstruction costs.

Safety Compliance: Factory-installed fire safety systems, seismic reinforcement, and weather-resistant features ensure compliance with global safety standards. Lida’s medical clinics in Vietnam meet WHO infection control requirements, reducing liability risks for healthcare providers.

Debunking Myths About Cost-Effective Prefab Construction

Myth 1: Cost-Effective Prefab Means Low Quality

Lida’s affordable housing in India complies with India’s National Building Code (NBC) and has no structural defects after 3 years of monsoon exposure.

The company’s medical clinics in Vietnam meet WHO healthcare standards, with 100% compliance rates in regulatory inspections.

Factory production eliminates weather-related defects and human error, resulting in defect rates of 2-3% (vs. 15-20% for traditional construction). Cost savings come from efficiency, not quality cuts.

Myth 2: Prefab Buildings Lack Customization

Mix and match standardized modules to create unique floor plans (e.g., 1-bedroom vs. 3-bedroom housing units, open vs. private office spaces).

Customize finishes, fixtures, and specialized systems (e.g., medical equipment for clinics, solar panels for off-grid projects).

Adapt to local climate and regulatory requirements (e.g., flood-resilient design in Bangladesh, termite-resistant steel in Tanzania).

Myth 3: Prefab Construction Is Only for Small Buildings

The 5,000-unit affordable housing project in India (100+ acres, 5-story buildings).

A 30,000 sq. ft. hospital wing in Brazil (3 stories, 100 beds) built from Lida’s prefab modules.

A 20,000 sq. ft. vocational training center in Kenya (2 stories, 10 classrooms and 5 labs).

Myth 4: Prefab Buildings Are Not Sustainable

Material waste is reduced to 1-2% (vs. 10-15% for traditional construction), saving resources and disposal costs.

Operational energy use is 40-60% lower, reducing carbon emissions and utility bills.

95% of components are recyclable, supporting circular economy principles.

Myth 5: Prefab Construction Is Not Cost-Effective for Remote Locations

Rural schools in Tanzania: Modules were transported via trucks to remote villages, with 4 modules per load (reducing transportation costs by 30%). Minimal site preparation eliminated the need for expensive foundation work.

Flood shelters in Bangladesh: Modules were transported via boats to flood-affected areas, with no heavy machinery required for assembly.

Rural clinics in Vietnam: Local labor teams (trained by Lida) assembled modules in 3 days, avoiding the cost of importing skilled workers.

The Future of Cost-Effective Prefab Construction: Lida’s Vision

1. Advanced Automation and Digitalization

AI-Powered Design: Machine learning algorithms that optimize modular layouts for cost, energy efficiency, and customization—reducing design time by 50% and material waste by an additional 5%.

Robotic Assembly: Next-generation robots that assemble modules with zero human intervention, reducing labor costs by 30% and production time by 25%. Lida’s new factory in Poland (opening 2024) will feature fully automated assembly lines for wall and floor modules.

Digital Twin Technology: 3D digital twins of every project, enabling real-time monitoring of production, transportation, and assembly. This technology reduces errors by 40% and allows clients to visualize their building before production begins.

2. Sustainable Material Innovation

Carbon-Neutral Steel: Partnerships with green steel producers to source carbon-neutral steel by 2027, reducing embodied carbon by 70% and lowering material costs by 10% (as green steel production scales).

Biodegradable Insulation: Development of plant-based insulation materials (e.g., hemp, mushroom mycelium) that are 20% cheaper than traditional insulation and fully biodegradable.

Self-Healing Materials: Research into self-healing concrete and steel coatings that reduce maintenance costs by 50% over the building’s lifespan.

3. Expanded Modular Systems

High-Rise Affordable Housing: Stackable modules for 10+ story apartment buildings, reducing unit costs by 25% compared to traditional high-rise construction. The system will comply with global seismic and wind codes, making it suitable for urban areas.

Net-Zero Energy Buildings: Standardized modules with integrated solar panels, battery storage, and geothermal HVAC—delivering net-zero energy use at no additional cost. Lida’s goal is to make net-zero prefab buildings the default option by 2030.

Disaster-Resilient Infrastructure: Modular bridges, water treatment plants, and power stations that can be deployed in disaster zones in 1-2 weeks—reducing emergency response costs by 40%.

4. Global Localization Strategy

Regional Factories: New factories in Nigeria, Mexico, and Indonesia will produce modules for local markets, reducing transportation costs by 30-40% and creating 5,000+ local jobs by 2026.

Localized Supply Chains: Each regional factory will source 70% of materials from local suppliers, further reducing transportation emissions and supporting small-to-medium enterprises (SMEs) in target markets. For example, the Nigerian factory will partner with local steel producers and insulation manufacturers, creating a self-sustaining regional ecosystem for prefab construction.

Knowledge Transfer Programs: Lida will train 10,000+ local workers in modular construction techniques by 2030, building regional capacity and reducing reliance on imported labor. These programs will include certifications in factory production, on-site assembly, and maintenance—creating long-term employment opportunities.

5. Accessibility for Underserved Markets

Micro-Finance Partnerships: Collaborations with global micro-finance institutions (e.g., Grameen Bank, Kiva) to offer low-interest loans for affordable housing units. This will enable low-income families to purchase Lida’s \(15,000-\)20,000 housing modules with flexible repayment terms.

Humanitarian Pricing: A dedicated humanitarian division offering 20-30% discounts on disaster relief modules for UN agencies and NGOs. Lida’s goal is to reduce the cost of emergency shelter by 50% by 2028, making it accessible to more displaced populations.

Rural Infrastructure Packages: Turnkey solutions for rural communities, including schools, clinics, and water treatment facilities—priced 30% below traditional construction. These packages will include training for local communities to maintain the infrastructure, ensuring long-term sustainability.

Conclusion

Related news

-

Customizable Steel Structure Building from Lida Group

2025-11-13 15:15:44

-

Rapidly Deployable Temporary Container Building Solutions from Lida Group

2025-11-13 16:49:11

-

Lida Group Unveils Innovative Prefab Mobile Container House Designs

2025-11-13 15:40:34

contact us

- Tel: +86-532-88966982

- Whatsapp: +86-13793209022

- E-mail: sales@lidajituan.com