Lida Group: A Leader in Innovative Steel Structure Building

2025-Nov-26 17:06:37

By Admin

In the contemporary construction landscape, steel structure buildings have emerged as a cornerstone of sustainable, efficient, and resilient development. Driven by urbanization acceleration, environmental regulations, and the demand for large-span, adaptable spaces, the global steel structure market is projected to reach $320.7 billion by 2030, with a compound annual growth rate (CAGR) of 6.8% from 2024 to 2030 . This growth is fueled by steel’s inherent advantages—high strength-to-weight ratio, recyclability, rapid construction capabilities, and design flexibility—coupled with ongoing innovations in material science and engineering. Among the pioneers shaping this industry, Lida Group (officially Weifang Henglida Steel Structure Co., Ltd.) stands out as a global leader, redefining the boundaries of steel structure building through cutting-edge technology, comprehensive product solutions, and a relentless commitment to innovation.

Founded in 1993 and headquartered in Weifang, Shandong, China, Lida Group has evolved from a specialized steel structure engineering firm into a fully integrated provider of innovative steel structure solutions. With over 30 years of dedicated experience, the company has established itself as one of China’s largest manufacturers of steel structure buildings, prefabricated modular units, steel villas, and industrial warehouses, complemented by a robust portfolio of steel pipes and components . Lida Group’s global footprint spans more than 90 countries, with its steel structures deployed in iconic projects—from the Olympic Sailing Center in Qingdao to industrial complexes in the Middle East and emergency shelters in Africa . What distinguishes Lida Group from competitors is its holistic approach to innovation: integrating advanced materials, intelligent design, precision manufacturing, and sustainable practices to deliver steel structure buildings that meet the evolving needs of diverse industries and environments.

This article explores Lida Group’s journey as an innovator in steel structure building, delving into its technological breakthroughs, comprehensive product portfolio, engineering excellence, global project successes, and vision for the future of sustainable construction. By examining the company’s core capabilities and industry impact, we uncover why Lida Group is the preferred partner for clients seeking reliable, innovative, and future-ready steel structure solutions.

1. Company Overview: 30 Years of Pioneering Excellence in Steel Structure Engineering

1.1 From Specialization to Global Leadership: A Journey of Innovation

Lida Group’s story begins in 1993, when it was founded with a singular focus on steel structure engineering. In the early years, the company concentrated on mastering the fundamentals of steel fabrication and structural design, serving local construction projects in China. As the demand for efficient, durable building solutions grew, Lida Group expanded its expertise, investing in research and development (R&D) to pioneer new applications for steel structures—from industrial warehouses to residential villas and modular prefabricated units .

Today, Lida Group operates as a one-stop provider of steel structure solutions, with an 83,000-square-meter state-of-the-art manufacturing facility equipped with 14 advanced production lines: 3 dedicated to heavy steel structures, 5 for light steel framing, 3 for steel structure warehouses/workshops, and 3 for specialized steel components . This extensive infrastructure enables the company to handle high-volume orders with precision, boasting a monthly production capacity of 50,000 square meters of steel structure space and 3,000 sets of prefabricated steel modules .

The company’s growth is underpinned by a team of 750 professionals, including 50 senior engineers, 200 overseas project supervisors, and a dedicated R&D team of 35 specialists . These experts bring deep expertise in structural engineering, material science, intelligent manufacturing, and cross-border project management, ensuring that every Lida Group solution meets the highest standards of quality, safety, and performance.

1.2 Global Reach and International Certification: Building Trust Across Borders

Lida Group’s commitment to excellence is validated by its compliance with global quality and safety standards, earning certifications including ISO 9001:2015 (quality management), CE EN 1090 (steel structure fabrication), API 5L and API 5CT (oil and gas pipeline steel), BV, and SGS . These certifications ensure that Lida Group’s steel structures adhere to rigorous international norms, making them compatible with local building codes in over 90 countries across Asia, Europe, Africa, North America, and Oceania .

The company’s global presence is supported by a strategic logistics network and regional offices, enabling it to deliver timely solutions even in remote or challenging locations—from the Arctic’s permafrost to the Middle East’s desert landscapes . Lida Group’s steel structures have been trusted by international organizations, government agencies, and private enterprises, including partnerships with global mining companies, energy giants, and leading construction firms.

1.3 Core Values: Innovation, Quality, and Sustainability

At the heart of Lida Group’s operations are three unwavering core values: innovation, quality, and sustainability. These values guide every aspect of the company’s business, from R&D to manufacturing, project execution, and after-sales service.

- Innovation: Lida Group invests 5% of its annual revenue in R&D, focusing on advancing steel structure technology, improving material performance, and integrating intelligent systems . The company’s innovation lab collaborates with leading universities and research institutions to develop breakthrough solutions, such as high-strength steel frames, fire-resistant coatings, and smart monitoring systems for steel structures.

- Quality: Lida Group adheres to a strict quality control system covering every stage of production—from raw material selection to final inspection. The company uses only premium steel (Q235, Q355, and high-strength alloy steel) sourced from certified suppliers, and employs advanced testing methods including ultrasonic testing, X-ray inspection, and load-bearing simulations to ensure structural integrity .

- Sustainability: As a leader in green construction, Lida Group leverages steel’s inherent sustainability (100% recyclability, reduced material waste, and energy efficiency) to minimize environmental impact. The company’s steel structures are designed to support net-zero energy goals, with features such as solar panel integration, thermal insulation, and rainwater harvesting systems, aligning with the United Nations’ Sustainable Development Goals (SDGs) .

2. Technological Innovation: Redefining Steel Structure Building

Lida Group’s leadership in steel structure building is rooted in its relentless pursuit of technological innovation. The company has pioneered numerous advancements in design, materials, and manufacturing, setting new standards for performance, efficiency, and sustainability in the industry.

2.1 Advanced Design and Engineering Technologies

Lida Group revolutionizes steel structure design through the adoption of cutting-edge software and methodologies, enabling precise, efficient, and customizable solutions:

2.1.1 Building Information Modeling (BIM) Integration

Lida Group is an early adopter of BIM technology, using it to create digital twins of steel structure projects. This 3D modeling approach allows for:

- Multidisciplinary Collaboration: Architects, engineers, and contractors can collaborate in real time, identifying and resolving design conflicts before construction begins.

- Precision Calculation: BIM software (including Autodesk Revit and Tekla Structures) enables accurate calculation of steel quantities, load-bearing capacities, and structural performance, reducing material waste by up to 15% .

- Lifecycle Management: The digital twin serves as a foundation for ongoing maintenance and monitoring, allowing clients to track the condition of steel structures throughout their lifespan.

For example, in the design of a 50,000-square-meter steel structure warehouse in Germany, Lida Group’s BIM team optimized the frame layout to reduce steel usage by 10% while maintaining the required load-bearing capacity, resulting in significant cost savings for the client .

2.1.2 Finite Element Analysis (FEA) for Extreme Conditions

Lida Group uses FEA software to simulate the performance of steel structures under extreme conditions—including seismic activity, hurricane-force winds, extreme temperatures, and heavy snow loads. This advanced analysis ensures that structures are engineered to withstand local environmental challenges, from the -40°C cold of northern Canada to the seismic zones of Southeast Asia .

The FEA process involves:

- Creating detailed 3D models of steel components (beams, columns, connections)

- Applying simulated loads (wind, snow, seismic forces) to test structural response

- Optimizing designs to enhance durability and safety while minimizing material usage

This approach has enabled Lida Group to deliver steel structures with a service lifespan of 50+ years, significantly exceeding industry averages .

2.1.3 Customization Through Parametric Design

Lida Group leverages parametric design tools to create highly customizable steel structures that meet the unique needs of each client. This technology allows engineers to adjust key parameters (e.g., span length, height, load capacity) and generate optimized designs in minutes, rather than days. Whether designing a small steel villa or a large-span industrial workshop, parametric design ensures that every Lida Group structure is tailored to the client’s specific requirements—without compromising on performance or efficiency.

2.2 Innovative Materials and Components

Lida Group drives innovation through the development and integration of advanced materials, enhancing the performance, durability, and sustainability of its steel structures:

2.2.1 High-Strength and Weather-Resistant Steel

Lida Group utilizes a range of advanced steel materials, including:

- Q355 High-Strength Steel: Offering 20% higher yield strength than standard Q235 steel, Q355 reduces the weight of steel structures by up to 25% while maintaining structural integrity. This not only lowers material costs but also simplifies transportation and installation .

- Weathering Steel (Corten A/B): Designed to resist corrosion in harsh environments (e.g., coastal regions, industrial areas), weathering steel forms a protective patina over time, eliminating the need for regular painting and reducing maintenance costs by 30% .

- Fire-Resistant Steel: Treated with intumescent coatings, Lida Group’s fire-resistant steel maintains structural stability for up to 4 hours in high temperatures, exceeding international fire safety standards (EN 13381-4) .

2.2.2 Advanced Connection Technologies

Steel structure performance depends heavily on the quality of connections between components. Lida Group has developed proprietary connection technologies that enhance strength, durability, and ease of installation:

- High-Strength Bolted Connections: These prefabricated connections use grade 10.9 high-strength bolts, ensuring secure, rigid joints that can withstand dynamic loads. The bolted design eliminates the need for on-site welding, reducing construction time by 20% .

- Prefabricated Node Connections: Lida Group manufactures complex node connections in its factory, ensuring precision and consistency. These prefabricated nodes are shipped to the site and assembled quickly, minimizing on-site labor and errors.

2.2.3 Sustainable Material Integration

Lida Group prioritizes sustainability by integrating eco-friendly materials into its steel structures:

- Recycled Steel: Over 70% of the steel used in Lida Group’s structures is recycled, reducing carbon emissions by up to 50% compared to virgin steel production .

- Eco-Friendly Coatings: The company uses low-VOC (volatile organic compound) paints and coatings, minimizing environmental pollution and improving indoor air quality for occupied structures.

- Insulation Materials: For enclosed steel structures (e.g., warehouses, villas), Lida Group integrates high-performance insulation (rock wool, fiber glass wool, or PU) to enhance energy efficiency, reducing heating and cooling costs by 30-40% .

2.3 Intelligent Manufacturing and Precision Production

Lida Group’s manufacturing facility is a hub of intelligent technology, ensuring that steel structures are produced with unparalleled precision, efficiency, and quality:

2.3.1 Automated Production Lines

The company’s production lines feature advanced automation technologies, including:

- CNC Cutting Machines: High-precision plasma and laser cutting machines (with a tolerance of ±0.5mm) ensure accurate fabrication of steel components, reducing waste and improving assembly efficiency.

- Robotic Welding Systems: Automated welding robots (from Fanuc and KUKA) deliver consistent, high-quality welds, with ultrasonic testing to ensure integrity. These robots increase welding productivity by 30% and reduce human error .

- Automated Painting Lines: Conveyor-based painting systems apply primer and finish coats evenly, with controlled drying environments to ensure coating adhesion and durability.

2.3.2 Digital Quality Control

Lida Group implements a digital quality control system that tracks every steel component from raw material to finished product:

- Barcode Tracking: Each component is assigned a unique barcode, allowing for real-time monitoring of production progress and quality checks.

- 3D Scanning Inspection: After fabrication, components are scanned using 3D laser scanners to verify dimensions against the BIM model, ensuring compliance with design specifications.

- Third-Party Testing: Critical projects undergo independent testing by SGS, BV, or TÜV, validating structural performance and material quality .

2.3.3 Modular Prefabrication

Lida Group specializes in modular prefabrication of steel structures, where components are manufactured in the factory and assembled on-site. This approach offers numerous advantages:

- Faster Construction: Modular components can be assembled on-site in days or weeks, compared to months for traditional construction. For example, a 10,000-square-meter steel structure warehouse can be installed in just 4 weeks .

- Reduced On-Site Labor: Modular assembly requires fewer on-site workers, lowering labor costs and minimizing safety risks.

- Consistent Quality: Factory-controlled production ensures that every module meets the same high standards, eliminating the variability of on-site fabrication.

3. Comprehensive Product Portfolio: Innovative Steel Structure Solutions

Lida Group offers a diverse range of steel structure products, each designed to meet the unique needs of different industries and applications. From industrial warehouses to residential villas, every product line emphasizes innovation, durability, and customization.

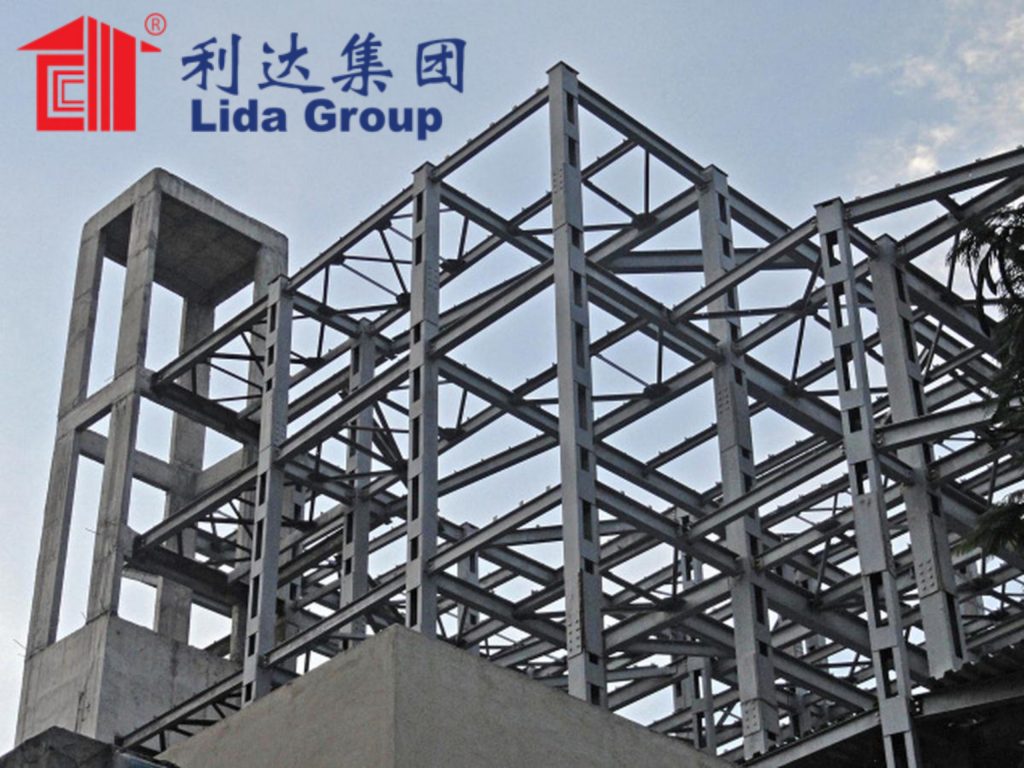

3.1 Heavy Steel Structure Buildings

Lida Group’s heavy steel structures are engineered for large-span, high-load applications, providing reliable solutions for industrial and commercial projects:

3.1.1 Industrial Warehouses and Workshops

These large-scale steel structures are ideal for manufacturing facilities, logistics centers, and storage warehouses. Key specifications include:

- Span Capacity: Up to 100 meters of clear span without internal columns, maximizing usable space.

- Frame Structure: H-beam girders and columns (Q235/Q355 steel), with rigid connections for stability.

- Roof/Walls: Corrugated steel sheets or sandwich panels (with insulation options), offering weather resistance and energy efficiency.

- Customization: Adjustable height (up to 30 meters), door sizes (roll-up, sliding, or overhead doors), and ventilation systems (natural or mechanical).

Lida Group’s heavy steel warehouses have a load-bearing capacity of up to 20 kN/m², making them suitable for storing heavy equipment, raw materials, and finished goods . They are also designed for rapid expansion, allowing clients to add additional bays as their needs grow.

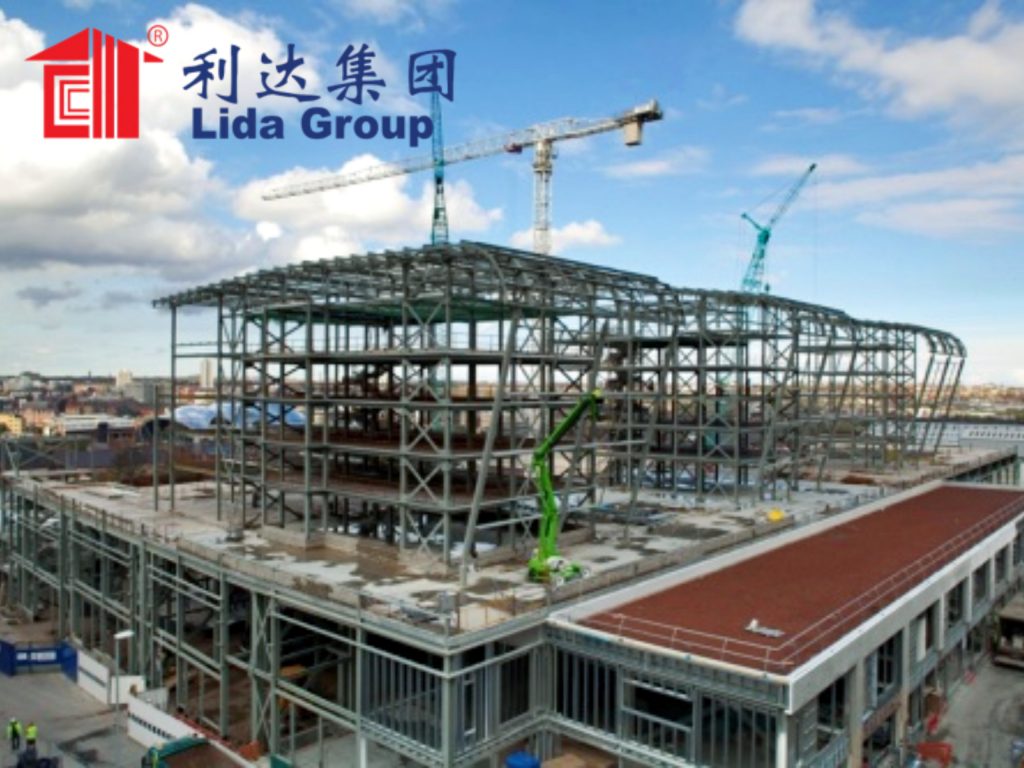

3.1.2 Commercial and Public Buildings

Lida Group delivers steel structure solutions for commercial complexes, exhibition halls, sports stadiums, and public facilities. These structures offer:

- Architectural Flexibility: Steel’s strength-to-weight ratio enables creative designs, including curved roofs, cantilevered structures, and large open spaces.

- Speed of Construction: Accelerated project timelines, critical for commercial projects seeking to open quickly and generate revenue.

- Sustainability: Recyclable steel and energy-efficient design support green building certifications (LEED, BREEAM).

A standout example is the design and construction of a 15,000-square-meter exhibition center in Dubai, where Lida Group’s heavy steel structure featured a 60-meter clear span and a curved roof, creating a striking architectural landmark while ensuring rapid construction (completed in 6 months) .

3.2 Light Steel Structure Buildings

Lida Group’s light steel structures are designed for residential, small commercial, and temporary applications, offering a balance of efficiency, affordability, and sustainability:

3.2.1 Steel Villas and Residential Buildings

Lida Group’s light steel villas are a popular choice for homeowners seeking durable, energy-efficient, and customizable residences. Key features include:

- Frame Structure: Light steel C-sections and U-sections (Q235 steel), with a lightweight design that reduces foundation costs.

- Insulation: Rock wool or PU insulation in walls and roofs, ensuring thermal efficiency and soundproofing.

- Design Flexibility: Single-story, two-story, or multi-story configurations, with customizable layouts, exterior finishes (wood, stone, or vinyl siding), and interior fixtures.

- Sustainability: 100% recyclable steel, low-VOC materials, and compatibility with solar panels and other renewable energy systems.

These villas have a service lifespan of 50+ years and can withstand wind speeds of up to 250 km/h (Category 5 hurricanes) and seismic activity up to magnitude 8.0 .

3.2.2 Small Commercial and Agricultural Buildings

Lida Group’s light steel structures are also used for small offices, retail stores, farm sheds, and greenhouses. These structures offer:

- Cost Efficiency: Lower material and construction costs compared to traditional concrete buildings.

- Quick Installation: Assembled in days, minimizing downtime for businesses and farmers.

- Durability: Resistance to rot, termites, and weather damage, ensuring long-term performance with minimal maintenance.

3.3 Modular Steel Structure Units

Lida Group’s modular steel units are prefabricated, portable solutions ideal for temporary or semi-permanent applications, including:

3.3.1 Container-Based Steel Structures

Based on standard shipping container sizes (20FT, 40FT), these modular units are modified into offices, dormitories, ablution facilities, and emergency shelters. Key features include:

- Steel Frame: Reinforced container steel (Q235) for durability and portability.

- Customization: Expandable designs, insulation options, and interior finishes tailored to client needs.

- Portability: Can be transported by ship, truck, or plane, making them ideal for remote locations or emergency response.

3.3.2 Prefabricated Steel Modules

Lida Group’s prefabricated steel modules are designed for rapid assembly into larger structures, such as labor camps, military barracks, and temporary hospitals. These modules:

- Are manufactured in the factory with pre-installed electrical, plumbing, and fixtures.

- Can be assembled on-site in hours or days, depending on the size of the project.

- Are reusable and relocatable, offering a sustainable alternative to traditional temporary buildings.

3.4 Steel Structure Components and Pipes

Lida Group complements its complete building solutions with a range of high-quality steel components and pipes, ensuring consistency and reliability across projects:

3.4.1 Structural Components

- Beams and Columns: H-beams, I-beams, square tubes, and angle steel, available in various sizes and grades (Q235, Q355, high-strength steel).

- Purlins and Girts: C-sections and Z-sections, used to support roofs and walls.

- Connections: High-strength bolts, nuts, washers, and prefabricated nodes.

3.4.2 Steel Pipes

Lida Group manufactures a range of steel pipes for industrial and construction applications, including:

- High-Frequency Welded Pipes: Used for water, gas, and oil transportation, compliant with GB/T 3091-2008 standards.

- Hot-Dipped Galvanized Pipes: Corrosion-resistant, ideal for outdoor and marine applications.

- Steel-Plastic Composite Pipes: Combines the strength of steel with the corrosion resistance of plastic, suitable for drinking water and chemical transportation .

These pipes are certified to API 5L and API 5CT standards, ensuring quality and compatibility with global oil and gas projects .

4. Project Case Studies: Innovation in Action

Lida Group’s innovative steel structure solutions have been deployed in diverse projects worldwide, showcasing the company’s ability to adapt to unique challenges, environments, and client needs. Below are four standout case studies:

4.1 Case Study 1: Large-Span Steel Structure Warehouse, Germany

Client: A global logistics company

Challenge: Need for a 50,000-square-meter warehouse with a 40-meter clear span, capable of supporting heavy forklift traffic and automated storage systems, with a tight 6-month construction timeline.

Solution: Heavy steel structure with BIM-optimized design

- Design: Lida Group used BIM technology to optimize the steel frame layout, reducing material usage by 10% while maintaining a load-bearing capacity of 15 kN/m². The structure featured H-beam columns (Q355 steel) and girders, with a corrugated steel roof and sandwich panel walls for energy efficiency.

- Manufacturing: Prefabricated components were produced in Lida Group’s factory using automated welding and cutting systems, ensuring precision and consistency.

- Installation: Modular assembly reduced on-site construction time to 4 months, meeting the client’s timeline.

- Outcome: The warehouse is now operational, handling 50,000+ shipments monthly. The steel structure’s durability and flexibility allow for future expansion, and the energy-efficient design has reduced utility costs by 25% compared to the client’s existing facilities .

4.2 Case Study 2: Seismic-Resistant Steel Villa Community, Indonesia

Client: A local real estate developer

Challenge: Design and construct a 100-unit villa community in a seismic zone (magnitude 7.0+), with strict sustainability requirements and a budget constraint.

Solution: Light steel structure with FEA-optimized seismic design

- Design: Lida Group used FEA software to simulate seismic forces, engineering light steel frames (Q235 steel) with reinforced connections and flexible joints to absorb seismic energy. The villas featured rock wool insulation and solar panels for energy efficiency.

- Materials: Recycled steel accounted for 75% of the structure, supporting the developer’s sustainability goals.

- Construction: Modular prefabrication reduced on-site labor costs by 30%, and the lightweight steel frames minimized foundation requirements, lowering overall project costs.

- Outcome: The villa community was completed on time and within budget. During a 6.2-magnitude earthquake in 2023, the structures remained intact with no structural damage, validating the seismic design. The community has since been certified as a green building by the Indonesian Green Building Council .

4.3 Case Study 3: Arctic Steel Structure Mining Camp, Canada

Client: A global mining company

Challenge: Provide a 200-person labor camp with steel structure buildings capable of withstanding -40°C temperatures, strong winds (120 km/h), and remote location logistics.

Solution: Customized steel structure camp with weather-resistant materials

- Design: Lida Group’s FEA team simulated extreme cold and wind conditions, engineering steel frames with anti-corrosion coatings and triple-glazed windows. The camp included dormitories, a cafeteria, and maintenance facilities, all with enhanced insulation (150mm rock wool) to maintain internal temperatures of 22°C.

- Materials: Weathering steel (Corten A) was used for exterior components, eliminating the need for regular painting in the harsh Arctic environment.

- Logistics: Prefabricated components were shipped in flat-pack containers, reducing transportation costs by 40%. On-site assembly was completed in 8 weeks by a small team of Lida Group supervisors and local workers.

- Outcome: The camp has been operational for 3 years, with no structural issues reported. The steel structures’ durability and low maintenance requirements have reduced operational costs by 30% compared to traditional wooden camps .

4.4 Case Study 4: Emergency Steel Structure Hospital, Kenya

Client: An international humanitarian organization

Challenge: Deploy a 50-bed emergency hospital in 4 weeks to respond to a health crisis, with steel structures capable of withstanding monsoon rains and termite infestations.

Solution: Modular steel structure hospital with rapid deployment design

- Design: Lida Group’s modular steel modules (20FT and 40FT) were customized into operating rooms, patient wards, and medical storage facilities. The structures featured elevated foundations to avoid flooding and termite-resistant steel frames.

- Manufacturing: Components were prefabricated in China with pre-installed electrical, plumbing, and medical fixtures, reducing on-site assembly time.

- Deployment: Modules were shipped to Kenya and assembled in 3 weeks, with Lida Group’s on-site team providing technical support.

- Outcome: The hospital treated over 10,000 patients during the crisis. The steel structures withstood monsoon rains and termite attacks, and the modular design allowed for relocation to another region after the crisis subsided ..

5. Key Advantages of Lida Group’s Innovative Steel Structure Solutions

Lida Group’s steel structure buildings offer numerous advantages over traditional construction materials (concrete, wood) and generic steel structures, making them the preferred choice for clients worldwide:

5.1 Superior Performance and Durability

- High Strength-to-Weight Ratio: Steel’s strength allows for large-span designs with minimal material usage, maximizing usable space while reducing structural weight.

- Long Lifespan: Lida Group’s steel structures have a service lifespan of 50+ years, compared to 20-30 years for traditional concrete buildings .

- Weather and Corrosion Resistance: Advanced coatings and weathering steel materials ensure resistance to rust, termites, extreme temperatures, and harsh environments.

- Seismic and Wind Resistance: FEA-optimized designs and flexible joints make Lida Group’s steel structures highly resilient to seismic activity and strong winds.

5.2 Efficiency and Cost Savings

- Rapid Construction: Modular prefabrication and automated manufacturing reduce project timelines by 30-50% compared to traditional construction, enabling clients to start using the structure sooner .

- Reduced Labor Costs: Factory-controlled production minimizes on-site labor requirements, lowering labor costs by 20-30%.

- Material Efficiency: BIM and FEA optimization reduce steel waste by up to 15%, lowering material costs.

- Low Maintenance: Steel structures require minimal maintenance (e.g., no painting for weathering steel), reducing long-term operational costs by 30% .

5.3 Sustainability and Environmental Responsibility

- 100% Recyclability: Steel is the most recycled material globally, and Lida Group’s structures are designed for disassembly and recycling, reducing landfill waste.

- Reduced Carbon Footprint: Using recycled steel reduces carbon emissions by up to 50% compared to virgin steel, and the energy-efficient design of Lida Group’s structures lowers operational carbon emissions .

- Minimal On-Site Pollution: Prefabrication reduces on-site dust, noise, and waste, minimizing environmental impact during construction.

- Green Building Certification: Lida Group’s steel structures support LEED, BREEAM, and other green building certifications, helping clients meet sustainability goals.

5.4 Flexibility and Customization

- Design Flexibility: Steel’s versatility allows for unlimited design possibilities, from large-span warehouses to curved commercial buildings and customizable residential villas.

- Modular Expansion: Steel structures can be easily expanded or modified, adapting to changing client needs without major reconstruction.

- Global Adaptability: Lida Group’s structures are engineered to meet local building codes and environmental conditions, from seismic zones to extreme climates.

6. Industry Trends and Lida Group’s Future Vision

The global steel structure building industry is evolving rapidly, driven by technological advancements, sustainability mandates, and changing market demands. Key trends shaping the industry include:

6.1 Key Industry Trends

- Smart Steel Structures: Integration of IoT (Internet of Things) sensors for real-time monitoring of structural health, temperature, and energy usage.

- Net-Zero Energy Buildings: Steel structures designed to generate as much energy as they consume, through solar panels, wind turbines, and energy-efficient systems.

- 3D Printing of Steel Components: Additive manufacturing is enabling the production of complex steel components with reduced material waste and faster lead times.

- Circular Economy Practices: Increased focus on recycling and reusing steel structures, minimizing environmental impact and maximizing resource efficiency.

- Urbanization and Vertical Construction: Steel’s strength-to-weight ratio makes it ideal for high-rise buildings and urban development, as cities become more densely populated.

6.2 Lida Group’s Future Vision and Strategy

Lida Group is well-positioned to capitalize on these trends, with a clear strategy for future growth and innovation:

6.2.1 Investing in Smart Steel Technology

Lida Group is developing smart steel structures integrated with IoT sensors and AI-powered monitoring systems. These systems will allow clients to:

- Track structural health in real time, identifying potential issues before they become critical.

- Optimize energy usage through smart thermostats, lighting, and ventilation.

- Predict maintenance needs, reducing downtime and extending the lifespan of structures.

The company’s first smart steel warehouse, deployed in Singapore in 2024, features sensors that monitor temperature, humidity, and structural vibration, with data analyzed by AI to optimize operations .

6.2.2 Advancing Net-Zero Energy Solutions

Lida Group is expanding its focus on net-zero energy steel structures, integrating:

- High-efficiency solar panels (including building-integrated photovoltaics)

- Wind turbines for suitable locations

- Energy storage systems (batteries) to store excess energy

- Passive design principles (natural ventilation, daylighting) to reduce energy demand

The company aims to have 50% of its steel structure projects meet net-zero energy standards by 2027 .

6.2.3 Adopting 3D Printing Technology

Lida Group is investing in 3D printing (additive manufacturing) for steel components, with a focus on:

- Producing complex, custom-shaped components that are difficult to fabricate with traditional methods.

- Reducing material waste by up to 30% compared to subtractive manufacturing (cutting, welding).

- Shortening lead times for custom components, enabling faster project delivery.

6.2.4 Expanding in Emerging Markets

Lida Group plans to strengthen its presence in emerging markets, including Africa, Southeast Asia, and Latin America, where urbanization and infrastructure development are driving demand for steel structure buildings. The company will focus on:

- Affordable housing solutions using light steel structures.

- Industrial warehouses and logistics centers to support economic growth.

- Emergency shelters and infrastructure for disaster-prone regions.

6.2.5 Leading Sustainable Construction Practices

Lida Group is committed to becoming a global leader in sustainable steel structure building, with goals to:

- Reduce carbon emissions from manufacturing by 40% by 2030.

- Increase the use of recycled steel to 90% by 2028.

- Develop fully recyclable steel structure systems that can be disassembled and reused without loss of performance.

7. Conclusion: Lida Group—Shaping the Future of Steel Structure Building

Lida Group’s 30-year journey from a specialized steel structure engineering firm to a global leader in innovative steel structure building is a testament to its unwavering commitment to innovation, quality, and sustainability. The company has redefined the industry through its adoption of advanced technologies (BIM, FEA, automation), development of high-performance materials, and delivery of comprehensive, customizable solutions that meet the diverse needs of clients worldwide.

What sets Lida Group apart is its holistic approach to steel structure building: integrating design, manufacturing, and construction to deliver end-to-end solutions that are efficient, durable, and sustainable. The company’s technical expertise, global reach, and customer-centric focus have made it a trusted partner for projects of all sizes—from small residential villas to large-span industrial warehouses and emergency infrastructure.

Lida Group’s innovative steel structure solutions offer numerous advantages over traditional construction, including superior performance, cost savings, sustainability, and flexibility. These advantages, combined with the company’s commitment to technological advancement, position it to lead the industry into the future, addressing global challenges such as urbanization, climate change, and the need for resilient infrastructure.

As the global steel structure market continues to grow, Lida Group remains at the forefront of innovation, investing in smart technology, net-zero energy solutions, and sustainable practices to deliver cutting-edge solutions that meet the evolving needs of clients. Whether you’re a logistics company seeking a large-span warehouse, a developer building seismic-resistant homes, or a humanitarian organization responding to a crisis, Lida Group’s innovative steel structure solutions offer the perfect balance of performance, efficiency, and sustainability.

In a world where construction must be faster, greener, and more resilient, Lida Group is not just building steel structures—they’re building the foundation for a sustainable future.

Related news

-

Lida Group's Prefab House Offers Superior Energy Efficiency

2025-11-25 17:34:03

-

Lida Group Champions Cost-Effective Prefab Construction Methods

2025-11-13 17:48:58

-

Lida Group Redefines Cost-Effective Prefab Construction

2025-11-07 17:35:21

contact us

- Tel: +86-532-88966982

- Whatsapp: +86-13793209022

- E-mail: sales@lidajituan.com