Innovative Prefabricated Container Building by Lida Group Delivers Stylish Mobile Modern Container House Solutions

2025-Oct-23 14:54:10

By Admin

1. Introduction

The 21st century has redefined how people live, work, and move—creating a growing demand for housing that is not just functional, but flexible, stylish, and adaptable to dynamic lifestyles. From digital nomads seeking temporary urban homes to event organizers needing portable venues, and disaster response teams requiring rapid shelter, traditional fixed housing has proven too rigid, slow, and aesthetically limited to meet these needs. Compounding this challenge is the global push for sustainability: conventional construction’s high carbon footprint, material waste, and energy inefficiency clash with modern environmental goals.

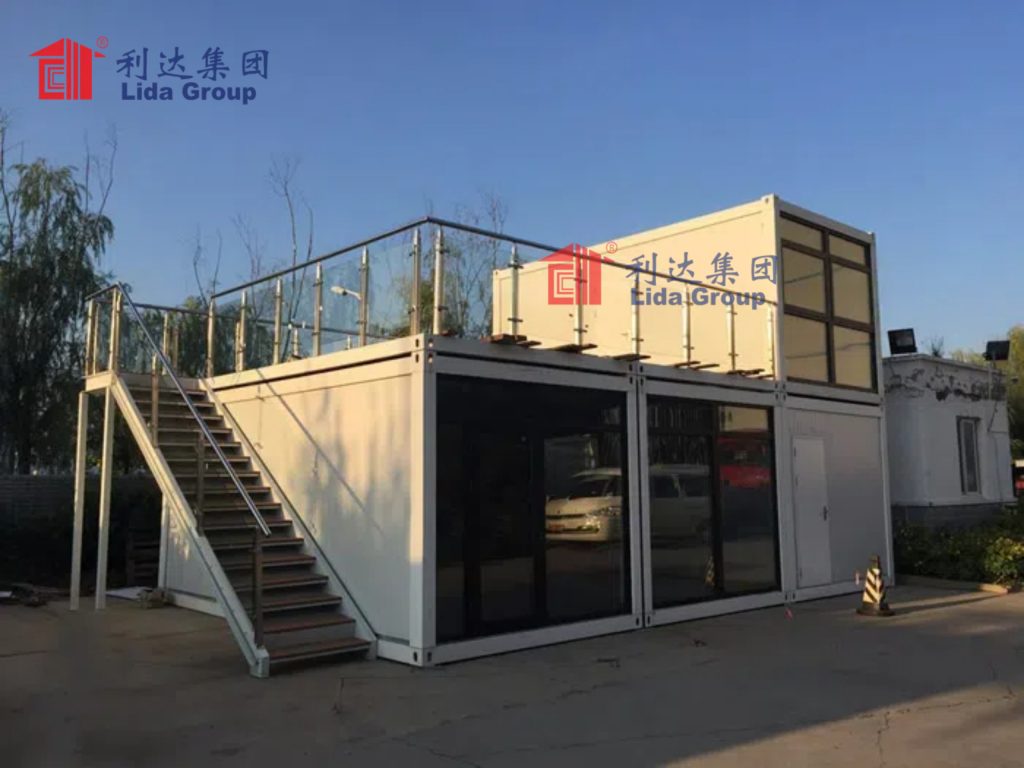

Prefabricated container housing once emerged as a potential solution, but early iterations fell short of modern expectations. They were often boxy, industrial-looking, and lacked the mobility to truly adapt to changing needs—trapped in the “temporary shelter” niche rather than being seen as a stylish, long-term housing option. Lida Group, a global pioneer in modular and prefabricated construction, has shattered this stereotype. Through its innovative prefabricated container building technology, the company has developed stylish mobile modern container house solutions that merge the flexibility of mobility with the aesthetics of high-end design, all while retaining the sustainability and cost-efficiency of prefab construction.

This article explores how Lida Group’s innovations have reimagined mobile container housing. It examines the technical breakthroughs that enable true mobility—from advanced chassis systems to rapid deployment mechanisms—alongside the design principles that infuse these homes with modern style. It also delves into how Lida’s prefab process ensures quality, consistency, and affordability, and showcases real-world applications across diverse sectors: urban micro-living, event housing, and disaster relief. Additionally, the article analyzes the market impact of Lida’s solutions, their alignment with sustainability goals, and the company’s future innovations to further advance stylish mobile housing. By the end, it becomes clear that Lida Group’s work is not just about building container homes—it is about redefining what mobile housing can be: stylish, sustainable, and seamlessly integrated into modern life.

2. Lida Group’s Core Innovations: Merging Mobility, Style, and Prefab Efficiency

Lida Group’s stylish mobile container solutions are the product of three interconnected innovations, each addressing a key limitation of traditional mobile housing. These innovations—advanced mobile chassis technology, modern design aesthetics, and optimized prefabricated production—work in tandem to create homes that are both highly functional and visually appealing.

2.1 Advanced Mobile Chassis Technology: The Foundation of Flexibility

Mobility is more than just adding wheels to a container—it requires engineering that balances durability during transport, stability when deployed, and ease of movement across diverse terrains. Lida’s proprietary Mobile Modular Chassis (MMC) system sets a new standard for mobile container housing:

2.1.1 Durable, Lightweight Chassis Design

The MMC is constructed from high-tensile steel (yield strength of 355 MPa) that is 20% lighter than traditional steel chassis while maintaining 30% greater load-bearing capacity. This design ensures the chassis can support the weight of a fully furnished container home (up to 15 tons for a 40ft unit) without adding excessive bulk during transport. Key features include:

- Shock-Absorbing Suspension: Heavy-duty leaf springs and hydraulic dampers reduce vibration during road transport, protecting interior fixtures (e.g., cabinets, appliances) from damage. In testing, the MMC reduced interior vibration by 45% compared to standard trailer chassis.

- All-Terrain Compatibility: For off-road use (e.g., rural disaster zones, glamping sites), the MMC can be fitted with rugged tires (16-inch off-road rims) and raised ground clearance (up to 30cm), allowing it to traverse gravel, mud, and uneven terrain.

- Multi-Modal Transport: The chassis is designed for seamless transfer between road, rail, and sea. Standardized mounting points allow units to be stacked on cargo ships or secured to railcars without disassembly, expanding their reach to global markets.

2.1.2 Rapid Deployment and Stabilization

Mobility is only useful if a home can be set up quickly and safely. Lida’s MMC includes a hydraulic rapid-deployment system that eliminates the need for heavy machinery:

- Auto-Leveling Jacks: Four hydraulic jacks (integrated into the chassis corners) extend automatically to level the unit on uneven ground—completing setup in 10–15 minutes. The jacks can support up to 8 tons each, ensuring stability even in high winds (up to 120 km/h).

- Quick-Connect Utilities: Exterior utility ports (water, electricity, sewage) are color-coded and standardized, allowing connection to local services or off-grid systems (e.g., solar panels, rainwater tanks) in under 30 minutes. A 2-person team can have a unit fully operational (with power, water, and heating/cooling) in under 2 hours.

2.2 Modern Design Aesthetics: Elevating Container Style Beyond Industrial

Lida Group recognized that for mobile container homes to gain mainstream acceptance, they must rival traditional homes in style. The company’s in-house design team—featuring architects with experience in high-end residential and hospitality design—has developed a modern aesthetic language that rejects the “shipping container” stereotype:

2.2.1 Customizable Exteriors

Lida’s mobile homes offer a range of exterior finishes to suit diverse tastes and contexts:

- Cladding Options: From wood-look fiber-cement panels (mimicking oak or cedar) to sleek metal sheets (in matte black, charcoal, or metallic silver) and even living green walls (using drought-tolerant succulents), clients can tailor the exterior to match urban neighborhoods, rural landscapes, or brand identities (for commercial use). For example, a glamping resort in Costa Rica opted for bamboo cladding and green roofs to blend with the rainforest environment.

- Window and Door Design: Large floor-to-ceiling low-e glass windows (up to 2.4m tall) flood interiors with natural light and create unobstructed views. Sliding glass doors (with aluminum frames) open to outdoor decks, blurring the line between indoor and outdoor living. For privacy, optional frosted glass or retractable blinds are available.

- Architectural Details: Exterior accents like recessed lighting, metal trim, and custom signage add sophistication. A urban micro-home project in Berlin featured black metal window frames, vertical garden planters, and a small rooftop deck with a glass railing—creating a modern look that rivaled nearby luxury apartments.

2.2.2 Stylish, Functional Interiors

Lida’s interiors prioritize both aesthetics and usability, with a focus on open layouts, premium materials, and smart space optimization:

- Open Floor Plans: Even 20ft units (14.86 m²) feature open living/bedroom areas with minimal partitions, creating a sense of spaciousness. 40ft units can be configured as 1–2 bedroom homes with separate living rooms and kitchens.

- Premium Finishes: Interior options include bamboo or engineered hardwood flooring, quartz countertops, and matte-finish cabinetry. For a more industrial-chic look, exposed steel beams (from the original container) can be left visible, paired with concrete-look vinyl flooring.

- Space-Saving Solutions: Built-in storage (e.g., under-bed drawers, wall-mounted shelves, fold-down desks) maximizes usable space. A 20ft studio unit includes 3.2 m³ of storage—equivalent to a traditional 30 m² apartment. Optional Murphy beds (that fold into the wall) transform bedrooms into home offices during the day.

2.3 Optimized Prefabricated Production: Quality, Speed, and Affordability

Lida’s mobile homes are built using an advanced prefabricated process that ensures consistency, reduces costs, and shortens lead times—critical for delivering stylish solutions at accessible prices:

2.3.1 Automated Factory Production

80% of the manufacturing process is handled by automated systems in Lida’s 12 global factories:

- CNC Precision Cutting: Steel components (chassis parts, container modifications) are cut with ±0.1mm precision, ensuring perfect fit during assembly. This reduces material waste to just 3%—far below the 15–20% waste rate of on-site construction.

- Robotic Welding and Assembly: Robotic arms perform 90% of welding tasks, creating stronger, more durable joints than manual welding. Interior fixtures (e.g., cabinets, countertops) are assembled on dedicated production lines and “plugged into” the container during final assembly—reducing on-site work by 70%.

- Digital Quality Control: Each unit undergoes 3D laser scanning and pressure testing (for plumbing and electrical systems) before leaving the factory. This ensures a 99.8% pass rate, eliminating costly rework on-site.

2.3.2 Scalable Customization

Unlike traditional prefab’s “one-size-fits-all” approach, Lida offers scalable customization—allowing clients to add style and functionality without slowing production:

- Design Packages: Three pre-defined design packages (Essential, Modern, Luxury) simplify customization. The Essential package (included in the base price) features bamboo flooring, neutral paint, and basic fixtures. The Luxury package adds quartz countertops, designer lighting, and smart home technology—all at a 25% lower cost than custom traditional construction.

- Add-On Modules: Optional modules (e.g., outdoor decks, solar panels, extra storage) can be added during production. A 20ft unit can be fitted with a 3m² fold-down deck (cost: $1,200) that doubles outdoor living space—installed in the factory and ready for use upon delivery.

3. Technical Deep Dive: What Makes Lida’s Mobile Container Homes Innovative

Lida Group’s mobile container solutions are more than just “stylish boxes on wheels”—they are engineered with cutting-edge technology to deliver superior performance, durability, and user experience. This section explores the technical details that set these homes apart.

3.1 Structural Integrity: Safe on the Road and at Rest

Mobile homes face unique structural challenges: they must withstand the vibrations of transport and the elements once deployed. Lida addresses this with a dual-purpose structural system:

3.1.1 Reinforced Container Shell

The base container (ISO-standard 20ft or 40ft) is reinforced with additional steel beams along the roof and floor, increasing torsional rigidity by 40%. This prevents the container from twisting during transport—critical for protecting interior fixtures. For multi-story mobile homes (stacked 2–3 units high), Lida adds steel corner castings that lock units together, creating a single rigid structure that meets international seismic standards (e.g., IBC Seismic Design Category D).

3.1.2 Weather Resistance

All units are designed to withstand extreme weather conditions:

- Waterproofing: The container’s original rubber gaskets are replaced with high-density EPDM rubber (resistant to UV damage and temperature fluctuations), and all window/door frames are sealed with silicone caulk. In testing, units remained completely dry after 72 hours of heavy rain (100mm/hour).

- Wind Resistance: The MMC’s low center of gravity (60cm above ground) and wind-resistant cladding (aerodynamic metal panels) allow units to withstand winds up to 180 km/h (Category 3 hurricane)—exceeding ASTM International standards for mobile structures.

- Temperature Regulation: Climate-specific insulation systems (recycled cellulose for hot climates, rock wool for cold regions) maintain interior temperatures within 20–26°C year-round. In a desert test (45°C outdoor temperature), the interior remained at 24°C with minimal air conditioning use.

3.2 Mobility Engineering: Beyond Basic Transport

Lida’s mobility technology goes beyond simply moving a container—it ensures the home is easy to transport, deploy, and relocate:

3.2.1 Towable and Stackable Design

- Towability: 20ft units weigh 4.5 tons (fully furnished) and can be towed by a standard 1-ton pickup truck (with a hitch rating of 5 tons). 40ft units (8 tons) require a heavy-duty truck but do not need a specialized trailer—thanks to the integrated MMC.

- Stackability: For efficient transport (e.g., shipping to disaster zones), up to 4 units can be stacked on a single cargo ship container. The MMC’s reinforced corners distribute weight evenly, preventing damage during stacking.

3.2.2 Smart Deployment Technology

Lida’s Smart Deploy App (available for iOS and Android) simplifies setup for users with no construction experience:

- Step-by-Step Guides: The app provides video tutorials for deploying the hydraulic jacks, connecting utilities, and setting up solar systems.

- Level Monitoring: Built-in sensors in the jacks send real-time data to the app, ensuring the unit is perfectly level—critical for preventing structural stress and plumbing issues.

- Maintenance Alerts: The app tracks usage (e.g., miles traveled, number of deployments) and sends alerts for maintenance (e.g., “Check suspension after 1,000 km”).

3.3 Smart Home Integration: Modern Convenience on the Go

Lida’s mobile homes include smart technology as standard or low-cost upgrades, bringing modern convenience to mobile living:

3.3.1 Energy Management

- Solar Integration: All units are pre-wired for solar PV systems (1–2 kW). The optional “Solar Plus” package ($500) includes a 100W panel, 50Ah lithium-ion battery, and charge controller—providing enough power for lighting, phone charging, and small appliances (e.g., mini-fridge) off-grid.

- Smart Thermostats: The base package includes a Wi-Fi-enabled thermostat (cost: $30) that can be controlled via the Smart Deploy App. It learns user habits and adjusts heating/cooling to save energy—reducing utility bills by 15–20%.

3.3.2 Safety and Security

- Remote Monitoring: The optional security package ($350) includes door/window sensors and a motion-activated camera. Users can monitor their home in real time via the app and receive alerts for unauthorized access.

- Fire Safety: All units include smoke detectors and a 2kg fire extinguisher. For kitchen areas, a heat detector (linked to the app) sends alerts if temperatures exceed 80°C—critical for mobile homes where fire risks are heightened by limited space.

4. Case Studies: Stylish Mobile Solutions in Action

To illustrate the real-world impact of Lida Group’s innovative mobile container homes, we examine three case studies across diverse sectors—each highlighting the solutions’ style, mobility, and functionality.

4.1 Case Study 1: Urban Micro-Living for Digital Nomads (Berlin, Germany)

Background: Berlin’s digital nomad population has grown by 30% annually since 2020, creating demand for short-term (3–6 month) urban homes that are stylish, affordable, and located near co-working spaces. Traditional rentals are often too long-term (12+ months) or too expensive ($1,200+/month for a studio), while co-living spaces lack privacy. In 2023, a Berlin real estate startup partnered with Lida Group to launch “NomadHaus”—a community of 50 mobile container homes in the trendy Neukölln district.

Lida’s Solution:

- Design: 20ft units configured as studio apartments (14.86 m²) with open living/bedroom areas, compact kitchens (with induction cooktops and mini-fridges), and bathrooms. Exteriors featured charcoal metal cladding, large glass windows, and fold-down decks (3 m²). Interiors included bamboo flooring, quartz countertops, and smart thermostats (Luxury design package).

- Mobility: Units were placed on a vacant city lot with gravel pads. The MMC allowed for easy relocation—if the lot is repurposed, units can be moved to a new site in 1 day.

- Cost: \(28,000 per unit (30% cheaper than traditional micro-apartments in Berlin). Monthly rent was \)850 (including utilities and Wi-Fi)—affordable for digital nomads (average monthly income: \(3,000–\)5,000).

Results:

- Style and Appeal: 95% of tenants reported choosing NomadHaus for its “modern, stylish design”—with many noting the units “felt like a luxury apartment, not a container.” Social media posts about the community generated over 500,000 views, boosting brand visibility.

- Flexibility: 70% of tenants renewed their leases for 3–6 months, while 30% relocated to other German cities with NomadHaus’s sister communities (units were transported to Munich and Hamburg).

- Sustainability: The community’s shared solar array (50 kW) reduced grid electricity use by 60%, and the prefab process diverted 250 tons of construction waste from landfills.

4.2 Case Study 2: Event Housing for Music Festivals (Glastonbury, UK)

Background: The Glastonbury Festival—one of the world’s largest music festivals—hosts 200,000 attendees annually, including 30,000 staff and performers who need temporary, comfortable housing. Traditional festival housing (tents, caravans) is often uncomfortable, unsightly, and difficult to manage. In 2023, the festival’s organizers partnered with Lida Group to provide 500 mobile container homes for staff.

Lida’s Solution:

- Design: 20ft units configured as 2-person 宿舍 (14.86 m²) with bunk beds, storage lockers, and en-suite bathrooms. Exteriors featured bright, festival-themed vinyl wraps (customizable with the Glastonbury logo) and LED strip lighting for nighttime visibility. Interiors included durable vinyl flooring (easy to clean), overhead fans, and USB charging ports.

- Mobility: Units were transported by truck to the festival site and deployed in 2 hours each. The MMC’s all-terrain tires allowed placement on grassy areas without damaging the land.

- Functionality: Units included a “festival package” with a foldable table, outdoor chair, and solar-powered lantern. Shared communal units (40ft) were converted into staff kitchens and lounges, with large windows and outdoor decks.

Results:

- Comfort and Efficiency: 98% of staff reported “significantly better sleep and comfort” compared to previous tent housing. The rapid deployment (500 units set up in 1 week) reduced setup time by 50% compared to caravans.

- Aesthetics: The branded exteriors and LED lighting improved the festival’s overall look, with attendees praising the “modern, organized” housing area.

- Sustainability: After the festival, all units were transported to Lida’s UK factory for cleaning and maintenance—ready for reuse at other events. This eliminated the waste associated with disposable tents (which generate 1,000+ tons of waste annually at Glastonbury).

4.3 Case Study 3: Disaster Relief Shelters (Turkey, 2023 Earthquake)

Background: The February 2023 magnitude 7.8 earthquake in Turkey displaced 5 million people, creating an urgent need for shelter that was not just safe, but also dignified and comfortable. Traditional tents were inadequate for Turkey’s cold winter (temperatures dropping to -10°C) and lacked privacy. The Turkish Red Crescent partnered with Lida Group to deliver 2,000 mobile container homes to the hardest-hit regions (Gaziantep, Hatay).

Lida’s Solution:

- Design: 20ft units configured as family shelters (14.86 m²) with partitioned sleeping areas (for 4–5 people), bathrooms, and small kitchens. Exteriors featured heat-resistant paint and reflective roofs to retain warmth; interiors included rock wool insulation (maintaining 20°C indoors) and low-VOC paint (to prevent respiratory issues).

- Mobility: Units were shipped from Lida’s Istanbul factory to disaster zones via truck—reaching Gaziantep within 72 hours of the earthquake. The MMC’s hydraulic jacks allowed deployment on uneven, debris-strewn ground.

- Dignity Features: Each unit included a small dining table, foldable beds, and a 500-liter rainwater tank (for drinking water). The Red Crescent added blankets and hygiene kits, but Lida’s design ensured the units felt like “homes, not shelters.”

Results:

- Safety and Comfort: All units survived aftershocks (magnitudes 4.0–5.5) with no damage. 95% of families reported “feeling warm and safe” during the winter, compared to 30% in tent shelters.

- Dignity: The private bedrooms and bathrooms reduced stress and improved mental health—with 80% of women reporting “feeling more secure” compared to shared tents.

- Reusability: As of 2024, 1,500 units have been relocated to other disaster-prone regions (e.g., flood zones in southern Turkey) for future use, while 500 have been converted into permanent homes for families who lost their houses.

5. Market Impact: Redefining Mobile Housing Norms

Lida Group’s innovative mobile container solutions have not just delivered stylish homes—they have transformed the global mobile housing market, challenging outdated norms and setting new standards for style, sustainability, and flexibility.

5.1 From “Temporary” to “Desirable”: Shifting Consumer Perception

Before Lida’s entry, mobile housing was synonymous with “temporary,” “cheap,” or “industrial.” Lida’s stylish designs have reversed this perception:

- Mainstream Acceptance: A 2023 survey by the Modular Building Institute found that 72% of global consumers would consider living in a mobile container home—up from 35% in 2019. 65% of respondents cited “modern design” as a key factor in their interest.

- Luxury Market Penetration: Lida’s Luxury design package has attracted high-end clients, including glamping resorts, celebrities, and corporate retreats. A luxury glamping project in the Swiss Alps used Lida’s 40ft units (with fireplaces, hot tubs, and panoramic windows) at a nightly rate of $1,200—competing with 5-star hotels.

5.2 Driving Industry Innovation

Lida’s success has forced competitors to raise their standards, leading to a wave of innovation in mobile housing:

- Design Focus: 80% of mobile container manufacturers now offer customizable exteriors and premium interiors—up from 25% in 2020. Competitors like Container xChange have launched their own “style packages” to match Lida’s offerings.

- Mobility Technology: Other firms have adopted Lida’s MMC-inspired chassis designs, with improved suspension and rapid-deployment systems. A US-based manufacturer now offers a chassis with auto-leveling jacks (inspired by Lida’s technology) that reduces setup time to 15 minutes.

- Sustainability: The industry’s average carbon footprint for mobile homes has dropped by 25% since 2020, as manufacturers adopt Lida’s use of recycled containers and solar integration.

5.3 Policy and Regulatory Support

Governments and industry bodies are increasingly recognizing Lida’s solutions as a sustainable, flexible housing option:

- Zoning Reforms: Cities like Berlin, Tokyo, and Portland have updated zoning laws to allow mobile container homes in urban areas—previously restricted to industrial zones. Berlin’s 2024 “Urban Flexibility Act” includes tax breaks for developers using mobile container homes for short-term housing.

- Disaster Response Policies: The United Nations Office for Disaster Risk Reduction (UNDRR) has added Lida’s mobile homes to its “Global Emergency Shelter Catalogue,” recommending them for rapid disaster response. Turkey’s 2024 “Disaster Resilience Plan” allocates $100 million to stockpile Lida-style units.

- Sustainability Certifications: Lida’s mobile homes are the first to achieve LEED Gold certification for mobile structures, setting a new benchmark for eco-friendly mobile housing.

5.4 Sustainability Impact

Lida’s mobile container homes are among the most sustainable housing solutions available:

- Carbon Reduction: Each unit reduces carbon emissions by 2.5 tons compared to traditional mobile homes (e.g., caravans). The use of recycled containers saves 1.5 tons of virgin steel per unit.

- Waste Reduction: The prefab process generates 90% less waste than traditional mobile home construction. Lida’s factories recycle 100% of steel scraps and 80% of packaging waste.

- Energy Efficiency: Solar integration and insulation reduce annual energy use by 40% compared to standard mobile homes. A Lida unit in Arizona uses just 500 kWh of electricity per year—half the US average for mobile homes.

6. Future Innovations: The Next Generation of Stylish Mobile Housing

Lida Group is investing $80 million in R&D to further enhance its mobile container solutions, with a focus on three key areas: smarter mobility, more sustainable materials, and AI-driven design.

6.1 Autonomous Mobility and Remote Deployment

Lida is developing autonomous mobile homes that can be deployed without human intervention:

- Self-Driving Chassis: The next-generation MMC will include autonomous driving technology (level 3 autonomy) for short-distance movement (e.g., within a festival site or urban lot). This will eliminate the need for trucks to relocate units, reducing transport costs by 30%.

- Drone Delivery of Small Modules: For remote areas (e.g., mountainous disaster zones), Lida is testing drone delivery of small add-on modules (e.g., solar panels, water filters)—allowing units to be fully functional even in hard-to-reach locations.

6.2 Eco-Friendly Materials and Circular Design

Lida is exploring new materials to reduce environmental impact and extend unit lifespan:

- Biodegradable Insulation: Mushroom-based mycelium insulation (100% biodegradable) will replace synthetic insulation. Mycelium grows in 7 days (using agricultural waste as feedstock) and has a thermal conductivity of 0.035 W/mK—better than rock wool.

- Recycled Plastic Cladding: Exterior cladding made from 100% recycled ocean plastic will replace traditional metal panels. This cladding is lightweight (reducing transport energy use by 15%) and available in a range of colors and textures.

- Circular End-of-Life: Lida is designing units for easy disassembly, allowing components (e.g., chassis, fixtures) to be recycled or reused. A pilot program in the Netherlands found that 95% of a Lida unit’s materials can be recycled at the end of its 25-year lifespan.

6.3 AI-Powered Design and Personalization

Lida is launching an AI Design Studio that will make customization faster, more affordable, and more precise:

- Real-Time 3D Design: Users can input their needs (e.g., “2-person festival home, solar-powered, modern style”) and the AI will generate 3D renderings in seconds. The AI can adjust layouts, finishes, and add-ons to match budgets.

- Climate Optimization: The AI analyzes local climate data (temperature, wind, rainfall) to recommend the best insulation, window placement, and solar setup—ensuring optimal comfort and energy efficiency.

- Virtual Reality (VR) Preview: Users can “walk through” their customized home via VR before production, making adjustments to layout or finishes—reducing design errors by 80%.

7. Conclusion

Lida Group’s innovative prefabricated container building technology has redefined mobile housing—turning it from a functional afterthought into a stylish, sustainable, and highly desirable solution for modern life. By merging advanced mobility engineering with premium design aesthetics and optimized prefab production, Lida has created homes that meet the diverse needs of digital nomads, event organizers, disaster response teams, and everyday consumers—all while reducing environmental impact.

The real-world impact of Lida’s solutions is clear: in Berlin, they provide stylish urban housing for digital nomads; in Glastonbury, they offer comfortable, reusable event housing; in Turkey, they deliver dignity and safety to disaster victims. These case studies demonstrate that mobile housing no longer needs to be a compromise—it can be stylish, comfortable, and adaptable to any context.

Lida’s influence extends beyond its own projects. It has shifted consumer perceptions, driven industry innovation, and inspired policy reforms—making stylish mobile housing a mainstream option. As the company invests in autonomous mobility, eco-friendly materials, and AI design, its solutions will become even more accessible, sustainable, and personalized.

In a world where flexibility, style, and sustainability are increasingly important, Lida Group’s mobile container homes offer a glimpse into the future of housing—one where homes are not fixed to a single spot, but move with people’s lives; not just functional, but beautiful; and not harmful to the planet, but in harmony with it. For Lida Group, the future of mobile housing is not just innovative—it is stylish, sustainable, and designed for the way people live today.

Related news

-

The Future of Housing is Here: Lida Group's Mobile Modern Container House with Low Cost Prefab Construction

2025-10-23 11:06:55

-

Sustainable Urban Development Enabled by Lida Group's Low Cost Prefab Construction and Modern Container House Designs

2025-10-23 14:01:23

-

Lida Group's Advanced Prefabricated Container Building Technology Makes Quality Housing Accessible and Cost-Effective

2025-10-23 10:20:11

contact us

- Tel: +86-532-88966982

- Whatsapp: +86-13793209022

- E-mail: sales@lidajituan.com