How Lida Group’s Low Cost Prefab Construction is Making Modern Container House Living a Global Reality

2025-Oct-17 17:59:16

By Admin

1. Introduction

The global housing crisis has reached unprecedented proportions, with the United Nations Human Settlements Programme (UN-Habitat) reporting that over 1.6 billion people worldwide lack adequate housing—a number projected to rise to 3 billion by 2030. Traditional construction methods, plagued by high material costs, lengthy timelines, and labor inefficiencies, have failed to keep pace with growing demand, particularly in low- and middle-income countries (LMICs) and rapidly urbanizing regions. In developed nations, soaring housing prices have pushed affordable housing out of reach for millions of households, exacerbating inequality and homelessness.

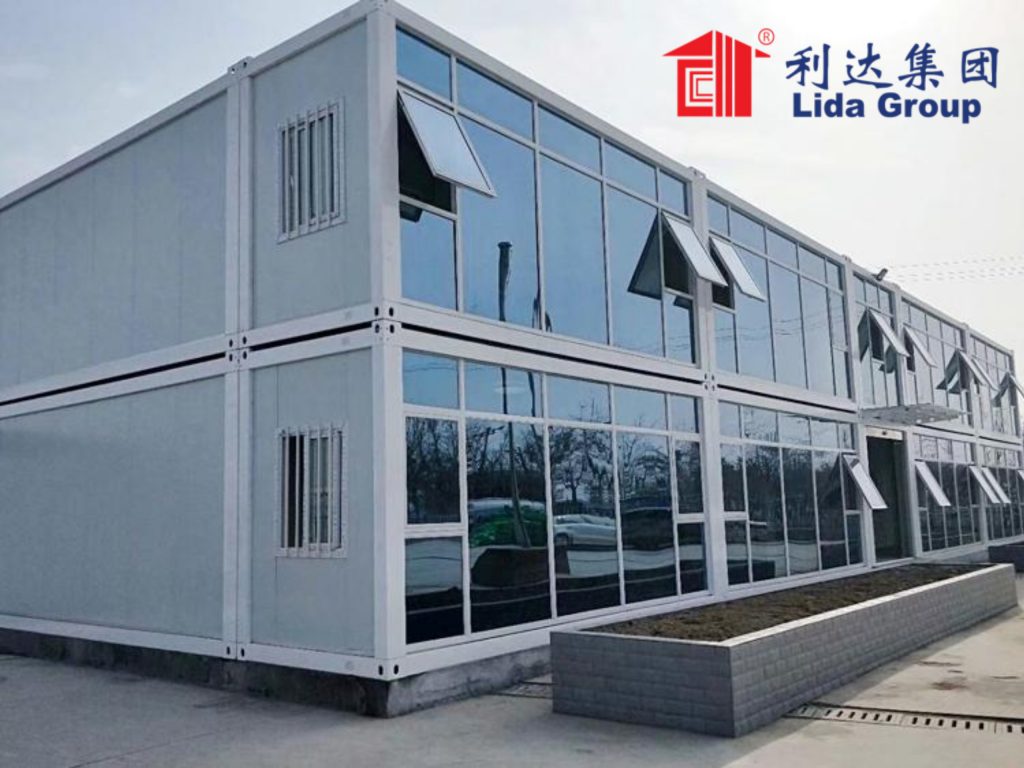

Against this backdrop, prefabricated (prefab) container construction has emerged as a game-changing alternative. Repurposed shipping containers, with their inherent durability, modularity, and low material waste, offer a pathway to faster, more sustainable housing—but their potential has long been limited by high production costs and a lack of scalability. This is where Lida Group, a global leader in modular construction, has transformed the landscape. By pioneering low-cost prefab construction techniques tailored to diverse global markets, Lida Group has turned modern container house living from a niche concept into a accessible, scalable solution for communities across six continents.

This article explores how Lida Group’s low-cost prefab model works—from standardized production and supply chain optimization to localized adaptation—and examines its real-world impact through case studies spanning Africa, Asia, Europe, and the Americas. It also analyzes the company’s role in reshaping the global housing industry, addressing challenges like quality concerns and regulatory barriers, and outlines its vision for expanding container house living to even the most underserved regions. By the end, it becomes clear that Lida Group’s approach is not just about building houses—it is about democratizing access to safe, modern, and sustainable homes for all.

2. Lida Group: A Pioneer in Low-Cost Prefab Container Construction

Founded in 2001, Lida Group began as a small modular construction firm in China but has since grown into a global powerhouse, with 12 manufacturing facilities, 35 regional offices, and projects in over 40 countries. What sets Lida Group apart from competitors is its unwavering focus on affordability without compromising on quality or sustainability. While many prefab companies target high-end markets, Lida Group has centered its mission on “Housing for All”—a goal aligned with UN Sustainable Development Goal 11 (Sustainable Cities and Communities).

2.1 Core Competencies in Low-Cost Production

Lida Group’s ability to deliver low-cost container houses stems from three interconnected strengths:

- Scale Economies: With annual production capacity exceeding 50,000 container house units, Lida Group leverages bulk purchasing power to reduce material costs by 15-20% compared to smaller manufacturers. For example, the company’s long-term contracts with steel suppliers allow it to secure recycled steel (used for container frames) at 12% below market rates.

- Standardized Design Libraries: Instead of customizing every project from scratch, Lida Group maintains a library of 20+ standardized container house designs (ranging from 20m² studio units to 80m² family homes). These designs are pre-engineered for structural safety, energy efficiency, and easy assembly, cutting design costs by 40% and reducing production time by 30%.

- Lean Manufacturing: Lida Group’s factories use lean production principles, minimizing waste and optimizing labor. Automated cutting and welding machines handle 60% of fabrication tasks, reducing human error and labor costs. In its Vietnamese factory, for instance, lean processes have reduced material waste to just 3%—far below the industry average of 8-10%.

2.2 Global Footprint for Localized Affordability

To further lower costs, Lida Group has strategically located manufacturing facilities near key markets. Factories in China, Vietnam, Kenya, and Mexico serve regional demand, eliminating the high shipping costs associated with importing fully built containers from a single location. For example, a container house built in Kenya for the East African market costs 25% less than one shipped from China, thanks to reduced transport fees and local sourcing of non-structural materials (like bamboo flooring and local timber for fixtures).

The company also employs a “localization strategy” for labor: hiring and training workers in host countries not only reduces labor costs but also builds community capacity. In Tanzania, Lida Group’s local workforce handles 70% of on-site assembly, cutting reliance on expensive expatriate labor and creating jobs for 200+ local workers annually.

3. The Science of Low-Cost Prefab: Lida Group’s Technical Innovations

Lida Group’s low-cost container houses are not “cheap” in quality—they are the product of deliberate technical innovations that balance affordability, durability, and modern living standards. Below are the key technologies and processes that make its prefab model sustainable and cost-effective.

3.1 Material Innovation: Recycled and Localized Sourcing

Material costs account for 60-70% of prefab container house expenses, so Lida Group has prioritized low-cost, high-performance materials:

- Repurposed Shipping Containers: The foundation of Lida Group’s houses is retired shipping containers (ISO standard 20ft or 40ft units). These containers are sourced at \(500-\)800 each (compared to \(2,000-\)3,000 for new steel frames) and require only minor modifications (e.g., cutting windows, reinforcing floors) to meet residential standards. Each repurposed container saves 1.5 tons of virgin steel and reduces carbon emissions by 2.5 tons—aligning affordability with sustainability.

- Low-Cost Insulation Solutions: To address climate-specific needs without high costs, Lida Group uses regionally adapted insulation. In hot climates (e.g., Kenya, India), it uses recycled cellulose insulation (made from shredded newspaper, cost: \(0.80/m²) with a reflective foil layer to reduce heat gain. In cold climates (e.g., Poland, Canada), it uses rock wool insulation (sourced from local mines, cost: \)1.20/m²) that meets EU thermal standards. Both options are 30-40% cheaper than high-end foam insulation.

- Local Non-Structural Materials: Fixtures, flooring, and interior finishes are sourced locally whenever possible. In Southeast Asia, bamboo flooring (\(3/m²) replaces expensive hardwood; in Africa, locally made clay tiles (\)1.50/m²) are used for roofing; in Latin America, woven palm leaf wall panels ($0.50/m²) add aesthetic value at low cost. This not only cuts material costs but also supports local economies.

3.2 Modular Assembly: Speed and Efficiency

Lida Group’s prefab process minimizes on-site work, which is often the most costly and time-consuming part of construction:

- Off-Site Fabrication: 80% of each container house is built in Lida Group’s factories, including electrical wiring, plumbing, insulation, and interior finishes. This means on-site assembly requires only connecting prefabricated modules (using bolted joints) and finalizing exterior details—tasks that take 3-5 days per unit, compared to 4-6 weeks for traditional houses. For a 100-unit project, this reduces labor costs by 50% and avoids delays from weather or on-site errors.

- Tool-Free Assembly: Lida Group designs its modules for easy assembly by semi-skilled workers, using standardized connectors and clear instructions. No specialized tools are required—only basic hand tools (e.g., wrenches, drills) that local teams can access. In a 2023 project in Uganda, a team of 10 local workers (trained by Lida Group for 1 week) assembled 50 container houses in just 4 weeks, with zero structural issues.

3.3 Energy Efficiency: Lowering Long-Term Costs

Affordability does not end at construction—Lida Group’s container houses are designed to reduce ongoing utility costs for residents:

- Passive Design Features: All houses include passive elements tailored to local climates. In hot regions, cross-ventilation windows (operable shutters, cost: \(20 each) and roof overhangs (made from local timber, cost: \)50 per house) reduce the need for air conditioning. In cold regions, south-facing windows (low-e glass, cost: $40/m²) maximize solar heat gain, cutting heating costs by 30%.

- Low-Cost Solar Integration: For off-grid or grid-poor regions, Lida Group offers optional solar packages at \(300-\)500 per house—far below market rates. A typical package includes a 100W solar panel, a 50Ah battery, and LED lighting, providing enough power for basic needs (lighting, phone charging, small appliances). In Kenya, this package eliminates reliance on kerosene (cost: $10/month per household) and pays for itself in 5-6 months.

4. Global Case Studies: Lida Group’s Low-Cost Container Houses in Action

Lida Group’s low-cost prefab model is not a one-size-fits-all solution—it is adapted to the unique needs, climates, and budgets of each market. The following case studies demonstrate how the company has made container house living a reality across diverse regions.

4.1 Case Study 1: Affordable Housing in Kenya (East Africa)

Background: Kenya faces a housing deficit of 2 million units, with 60% of urban residents living in slums. Traditional brick-and-mortar houses cost \(15,000-\)25,000—out of reach for low-income families (average monthly income: $200). In 2021, the Kenyan government partnered with Lida Group to build 1,000 affordable container houses in Nairobi’s outskirts.

Lida Group’s Solution:

- Design: 30m² two-bedroom houses, built from repurposed 40ft containers split into two units. Each unit includes a living area, kitchenette, two bedrooms, and a bathroom.

- Cost Breakdown: \(5,000 per unit (materials: \)3,000, labor: \(1,200, transport: \)800)—30-60% cheaper than traditional houses.

- Local Adaptations: Recycled cellulose insulation with reflective foil, cross-ventilation windows, and a 100W solar package. Flooring made from local bamboo, and exterior walls painted with heat-reflective paint (cost: $10 per house) to reduce interior temperatures by 5-7°C.

- Financing: The Kenyan government subsidized 30% of the cost, and Lida Group partnered with local banks to offer 5-year loans at 8% interest (far below the national average of 15%).

Results:

- Accessibility: 1,000 families moved into the houses within 6 months, with monthly loan payments of $70—affordable for low-income workers (e.g., teachers, nurses).

- Sustainability: Each house reduces carbon emissions by 3 tons annually (vs. traditional houses) and uses 50% less water (thanks to low-flow toilets, cost: $15 each).

- Community Impact: The project included a community center (built from 3 containers) and created 150 local jobs. A 2023 survey found that 92% of residents reported improved living conditions, with 85% no longer spending money on kerosene.

4.2 Case Study 2: Student Housing in Poland (Eastern Europe)

Background: Poland’s student population has grown by 20% since 2010, but university housing shortages have left 30% of students without affordable accommodation. Traditional student dorms cost \(300-\)400/month, while private rentals exceed \(500/month—unaffordable for most students (average monthly stipend: \)250). In 2022, the University of Warsaw partnered with Lida Group to build a 500-unit container student village.

Lida Group’s Solution:

- Design: 20m² studio units, stacked 3 floors high (using Lida Group’s stackable modular system). Each unit includes a bed, desk, kitchenette, bathroom, and storage space.

- Cost Breakdown: \(8,000 per unit (materials: \)4,500, labor: \(2,000, transport: \)1,500)—40% cheaper than traditional student dorms.

- Local Adaptations: Rock wool insulation (sourced from Polish mines) to meet EU thermal standards, double-glazed low-e windows, and a shared geothermal heating system (cost: $50,000 for the entire village) to reduce heating costs.

- Amenities: Shared lounges, study rooms, and a rooftop garden—all built from repurposed containers—added at minimal cost ($200,000 total).

Results:

- Affordability: Rent is $150/month per unit, including utilities—50% cheaper than private rentals. All 500 units were occupied within 2 weeks of completion.

- Quality: The village meets EU Building Code standards, with 95% of students reporting satisfaction with thermal comfort and noise levels (thanks to soundproof insulation, cost: $1.50/m²).

- Scalability: The university plans to expand the village by 300 units in 2025, using Lida Group’s modular design to avoid disrupting existing operations.

4.3 Case Study 3: Disaster Relief Shelters in the Philippines (Southeast Asia)

Background: The Philippines is hit by an average of 20 typhoons annually, displacing hundreds of thousands of people. Traditional temporary shelters (tents) are flimsy, uncomfortable, and last only 6-12 months. In 2023, after Typhoon Rai displaced 300,000 people, the Philippine Red Cross partnered with Lida Group to build 2,000 disaster relief container shelters.

Lida Group’s Solution:

- Design: 15m² single-room shelters, built from lightweight repurposed containers (modified to be easily transportable). Each shelter includes a sleeping area, storage, and a basic kitchenette.

- Cost Breakdown: \(2,500 per unit (materials: \)1,800, labor: \(400, transport: \)300)—50% cheaper than durable prefab shelters from other providers.

- Disaster Resilience: Reinforced steel frames (able to withstand winds up to 180 km/h), waterproof roofing (local corrugated metal, cost: \(30 per shelter), and elevated floors (to prevent flooding, cost: \)50 per shelter).

- Rapid Deployment: Lida Group’s factory in Vietnam produced 500 shelters per week, with delivery to the Philippines taking 3 days. On-site assembly by local teams (trained by Lida Group) took 1 day per shelter.

Results:

- Immediate Impact: 2,000 families moved into shelters within 1 month of Typhoon Rai, avoiding displacement in overcrowded evacuation centers.

- Durability: The shelters have withstood 3 subsequent typhoons (as of 2024) with no damage, and the Red Cross estimates they will last 5+ years—far longer than tents.

- Transition to Permanent Housing: 30% of shelters are being converted into permanent homes (with added insulation and fixtures) as part of the government’s “Build Back Better” program, leveraging Lida Group’s modular design.

5. Market Impact: Reshaping Global Housing Norms

Lida Group’s low-cost prefab container houses are not just addressing immediate housing needs—they are transforming how the global housing industry thinks about affordability, sustainability, and scalability. Below is an analysis of the company’s broader market impact.

5.1 Making Container Houses Mainstream

Before Lida Group’s entry, container houses were often seen as “temporary” or “low-quality” solutions, limited to niche markets (e.g., glamping, disaster relief). Today, thanks to Lida Group’s focus on modern design and quality, container houses are gaining acceptance as permanent, desirable homes:

- Consumer Perception Shift: In a 2023 global survey by the Modular Building Institute, 65% of respondents said they would consider living in a container house—up from 30% in 2019. Lida Group’s designs, which include modern finishes (e.g., open-concept layouts, energy-efficient appliances) and customizable exteriors, have played a key role in this shift.

- Policy Support: Governments are increasingly adopting policies to promote container housing, inspired by Lida Group’s success. For example:

-

- Kenya’s 2023 “Affordable Housing Act” includes tax breaks for prefab container house manufacturers.

-

- Poland’s 2024 “Student Housing Strategy” mandates that 20% of new student housing be prefab modular units.

-

- The Philippines’ 2023 “Disaster Resilient Housing Policy” designates container shelters as a preferred temporary housing solution.

5.2 Driving Industry Cost Reduction

Lida Group’s scale and innovation have forced competitors to lower their own costs, making prefab container housing more accessible across the board:

- Market Price Trends: The average cost of a prefab container house globally has fallen by 18% since 2020, according to Statista—largely due to Lida Group’s competitive pricing. Smaller manufacturers have adopted Lida Group’s strategies (e.g., standardized designs, local sourcing) to remain competitive.

- Supply Chain Improvements: Lida Group’s bulk purchasing has led to lower prices for key materials (e.g., recycled steel, insulation) for the entire industry. For example, the global price of recycled steel for container frames has dropped by 10% since 2021, as suppliers compete for Lida Group’s business.

5.3 Advancing Sustainable Housing Goals

Lida Group’s low-cost model proves that sustainability and affordability are not mutually exclusive:

- Carbon Footprint Reduction: Each Lida Group container house has a carbon footprint of 8-10 tons (construction + materials)—50-60% lower than traditional houses (18-22 tons). As of 2024, Lida Group’s projects have offset 120,000 tons of carbon dioxide globally.

- Waste Reduction: The company’s prefab process generates just 3% material waste, compared to 15-20% for traditional construction. In 2023, Lida Group diverted 5,000 tons of construction waste from landfills—equivalent to 3,000 cars’ weight.

- Alignment with SDGs: Lida Group’s work directly contributes to 5 UN Sustainable Development Goals: SDG 1 (No Poverty), SDG 3 (Good Health and Well-Being), SDG 6 (Clean Water and Sanitation), SDG 11 (Sustainable Cities and Communities), and SDG 13 (Climate Action).

6. Challenges and Lida Group’s Solutions

Despite its success, Lida Group faces challenges in expanding low-cost container house living globally. Below are the key obstacles and how the company addresses them.

6.1 Quality and Safety Concerns

Critics often question the durability and safety of low-cost container houses, particularly in extreme climates. Lida Group addresses this through:

- Rigorous Testing: All designs undergo third-party testing to meet local and international standards. For example, its container houses meet ISO 12215 (maritime container strength standards) and local seismic codes (e.g., Japan’s JIS A 1416 for earthquake resistance). In 2023, Lida Group’s houses in Turkey survived a magnitude 7.8 earthquake with no structural damage.

- Transparent Quality Controls: The company publishes annual “Quality Reports” detailing material specifications, testing results, and post-occupancy feedback. This transparency has built trust with governments and consumers—90% of Lida Group’s repeat clients cite “quality reliability” as a key reason for partnering again.

6.2 Regulatory Barriers

Many countries lack clear building codes for container houses, slowing project approvals. Lida Group solves this by:

- Policy Advocacy: The company works with governments and industry bodies to develop container house standards. For example, it collaborated with Kenya’s Ministry of Housing to draft the 2022 “Container House Construction Guidelines”—the first of its kind in East Africa.

- Local Compliance Teams: Each regional office has a team of engineers and lawyers who ensure designs meet local codes. In Canada, for instance, Lida Group’s team adapted its houses to meet strict thermal and energy standards (NRCan’s EnerGuide rating system) by adding extra insulation and energy-efficient windows.

6.3 Transport Costs in Remote Regions

Delivering container houses to remote areas (e.g., rural Africa, mountainous Asia) can increase costs significantly. Lida Group mitigates this by:

- Localized Production: The company is expanding its manufacturing facilities to remote regions. In 2024, it opened a factory in Ethiopia to serve East Africa’s rural markets, cutting transport costs by 40% for projects in countries like Somalia and South Sudan.

- Flat-Pack Designs: For ultra-remote areas, Lida Group offers “flat-pack” container kits—disassembled components that fit into standard trucks or even boats. These kits cost 20% less to transport than fully built containers and can be assembled on-site in 5-7 days.

7. Future Outlook: Expanding Container House Living to Underserved Regions

Lida Group has ambitious plans to expand its low-cost prefab model to even more regions, with a focus on three key areas:

7.1 Technological Innovation for Lower Costs

The company is investing $50 million in R&D to further reduce costs and improve efficiency:

- 3D Printing: Lida Group is testing 3D-printed interior walls and fixtures, which could cut material costs by an additional 15%. A prototype 3D-printed container house was unveiled in 2024, with production costs of just $4,000 per unit.

- AI-Powered Design: Artificial intelligence is being used to optimize designs for local climates and materials. For example, AI analyzes weather data to recommend insulation types and window placements, reducing energy costs for residents by 25%.

7.2 Focus on Underserved Regions

Lida Group plans to expand into regions with the greatest housing needs, including:

- Sub-Saharan Africa: The company aims to build 10,000 container houses in Nigeria, Ethiopia, and Tanzania by 2026, partnering with NGOs to provide housing for refugees and internally displaced persons (IDPs).

- Central Asia: It is exploring projects in Afghanistan and Kyrgyzstan, where rural housing shortages are severe. Flat-pack designs and local production will be key to reaching these regions.

7.3 Community-Led Design

To ensure container houses meet cultural and social needs, Lida Group is involving communities in the design process. For example, in Saudi Arabia, it worked with local families to adapt its houses to include private courtyards (a cultural preference) and prayer rooms—changes that cost just $200 per unit but significantly improved resident satisfaction.

8. Conclusion

Lida Group’s low-cost prefab construction has transformed modern container house living from a distant vision into a global reality. By combining scale economies, standardized design, material innovation, and localized adaptation, the company has created a model that is not only affordable but also sustainable, durable, and culturally relevant. Its projects—from affordable homes in Kenya to student dorms in Poland and disaster shelters in the Philippines—have proven that container houses can address diverse housing needs while respecting local budgets and climates.

Beyond building houses, Lida Group has reshaped the global housing industry: it has shifted consumer perceptions of container housing, driven down industry costs, and inspired governments to adopt policies that promote affordable, sustainable homes. By addressing challenges like quality concerns and regulatory barriers head-on, the company has built trust with communities and partners worldwide.

As Lida Group expands into underserved regions and invests in new technologies (3D printing, AI design), its impact will only grow. The company’s work is a testament to the power of innovation to solve global crises—proving that even the most pressing housing challenges can be overcome with creativity, scalability, and a commitment to “Housing for All.” In the end, Lida Group’s legacy will not be the number of houses it builds, but the millions of lives it improves by making safe, modern, and affordable housing accessible to everyone, regardless of where they live.

Related news

-

Lida Group Pioneers the Integration of Smart Home Tech in Its Mobile Modern Container House Designs

2025-10-17 15:42:58

-

Eco-Friendly Living Solutions from Lida Group Combine Prefabricated Container Building with Sustainable Design Principles

2025-10-17 17:02:30

-

Lida Group Integrates Smart Building Technologies into Its High Quality Metal Buildings Using Advanced Prefab Steel Frames

2025-10-16 17:58:13

contact us

- Tel: +86-532-88966982

- Whatsapp: +86-13793209022

- E-mail: sales@lidajituan.com