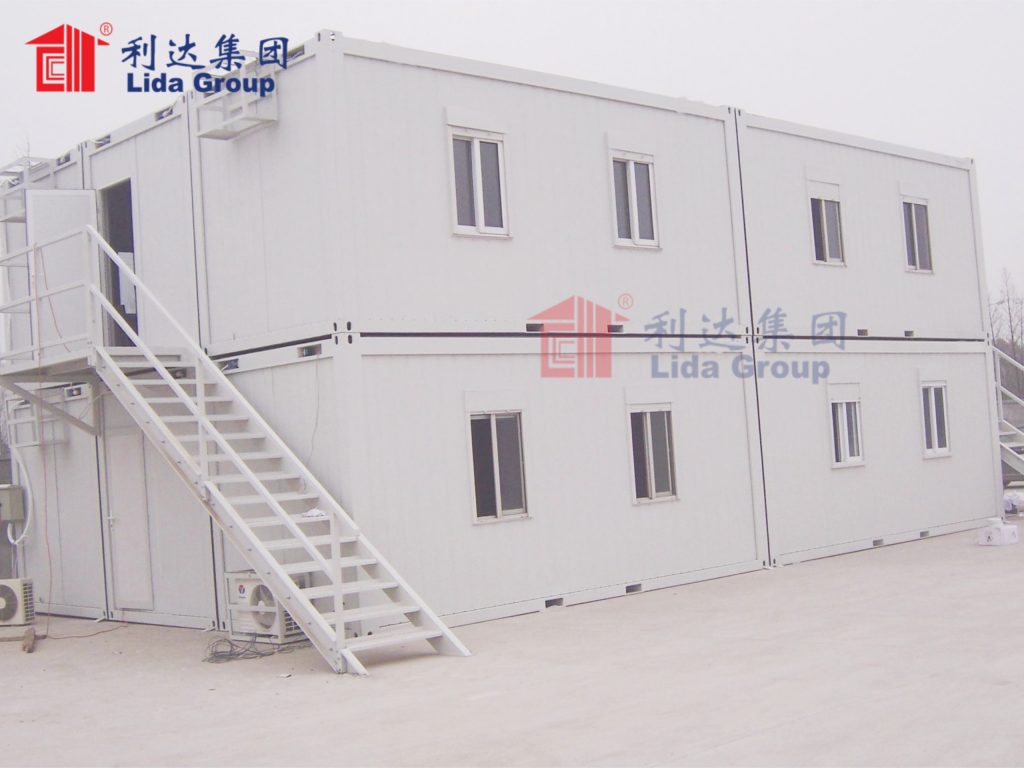

High-Strength Durable Modular Container Dormitory by Lida Group

2026-Feb-14 14:02:41

By Admin

In the global construction and industrial sectors, the demand for safe, durable, and efficient workforce accommodation has never been more critical. As industries such as mining, renewable energy, construction, and oil and gas expand into remote and harsh environments, traditional dormitory solutions often fail to meet the rigorous requirements of durability, portability, and long-term performance. Recognizing this gap, Lida Group—an industry leader in modular container construction with over 30 years of experience—has developed a high-strength durable modular container dormitory that redefines workforce housing standards. Combining advanced materials, innovative engineering, and rigorous quality control, Lida Group’s modular container dormitories deliver exceptional strength, longevity, and functionality, making them the preferred choice for organizations worldwide seeking reliable and cost-effective accommodation solutions.

Lida Group’s high-strength durable modular container dormitory is not just a temporary housing option; it is a purpose-built solution engineered to withstand the harshest environmental conditions while providing a comfortable, safe living environment for workers. Unlike conventional container dormitories that prioritize cost over durability, Lida’s product focuses on high-strength construction, corrosion resistance, impact resistance, and long service life—addressing the key pain points of traditional workforce accommodation. From extreme temperatures and high winds to seismic activity and coastal saltwater corrosion, these dormitories are designed to perform reliably for 15-20 years with minimal maintenance, delivering exceptional value across their entire lifecycle.

This article provides a comprehensive overview of Lida Group’s high-strength durable modular container dormitory, exploring its core design principles, technical features, high-strength and durability advantages, practical applications, real-world case studies, technical specifications, quality control processes, and market positioning. By delving into the engineering and innovation behind Lida’s product, we aim to demonstrate how it addresses the evolving needs of industries worldwide and why it stands out as a leader in the modular container dormitory market. From material selection to manufacturing processes, every aspect of Lida’s modular container dormitory is designed to prioritize strength, durability, and user comfort—making it a game-changer for workforce accommodation.

1. Overview of Lida Group and Its Modular Container Dormitory Vision

Founded in 1995, Lida Group has established itself as a global leader in modular container construction, specializing in the design, manufacturing, and installation of high-quality modular solutions for residential, commercial, industrial, and emergency applications. With headquarters in China and a global network of manufacturing facilities, logistics partners, and service centers, Lida Group serves clients in over 120 countries, delivering innovative and reliable modular solutions tailored to local needs and environmental conditions.

Lida Group’s core mission is to “build durable, efficient, and sustainable modular spaces that enhance quality of life and drive operational efficiency for our clients.” This mission is particularly evident in its high-strength durable modular container dormitory line, which was developed in response to the growing demand for workforce accommodation that can withstand harsh environments and provide long-term value. Unlike many competitors that focus on standardization alone, Lida Group combines standardization with customization, ensuring that each dormitory solution meets the specific requirements of the client’s industry, project location, and workforce size.

Lida Group’s high-strength durable modular container dormitory is a modular construction solution that uses high-strength steel frames, advanced sandwich panels, and innovative connection systems to create a robust, portable, and comfortable living space. Each dormitory module is prefabricated in a controlled factory environment, ensuring consistent quality, reduced waste, and minimal on-site installation time. The modular design allows for easy expansion, relocation, and customization, making it suitable for a wide range of applications—from remote mining camps and construction sites to temporary worker villages and military barracks.

What sets Lida Group’s modular container dormitory apart from competitors is its unwavering focus on high-strength and durability. Every component, from the steel frame to the insulation materials, is selected and engineered to withstand extreme conditions and heavy use. Lida Group’s commitment to quality is reflected in its ISO 9001 certification, CE certification, and compliance with global safety and environmental standards, ensuring that its dormitories meet the highest industry requirements for strength, safety, and sustainability.

2. Core Technical Features of Lida Group’s High-Strength Durable Modular Container Dormitory

Lida Group’s high-strength durable modular container dormitory owes its exceptional performance to a set of core technical features, each designed to enhance strength, durability, and functionality. These features work together to create a dormitory solution that is robust, reliable, and comfortable, even in the most challenging environments. Below is a detailed overview of the key technical features:

2.1 High-Strength Steel Frame Construction

The foundation of Lida Group’s modular container dormitory is its high-strength steel frame, which provides exceptional structural integrity and load-bearing capacity. Unlike conventional container dormitories that use thin-gauge steel (1.5mm-2.0mm), Lida’s dormitories feature a heavy-duty steel frame made from Q355B high-strength galvanized steel, with a frame thickness of 3.0mm-4.0mm. Q355B steel is known for its high tensile strength (355 MPa), excellent impact resistance, and superior corrosion resistance, making it ideal for harsh environments.

The steel frame is pre-welded in the factory using advanced robotic welding technology, ensuring consistent weld quality and structural stability. Each frame undergoes a rigorous inspection process to ensure that welds are strong, uniform, and free from defects. The frame is also treated with a dual-layer anti-corrosion coating: a hot-dip galvanized layer (100μm-120μm) to prevent rust and a fluorocarbon paint finish (30μm-40μm) to protect against moisture, UV radiation, and chemical exposure. This dual-layer treatment ensures that the steel frame can withstand coastal saltwater, industrial chemicals, and extreme humidity for 15-20 years with minimal maintenance.

The frame design is also optimized for strength and load distribution. Lida’s engineering team uses advanced finite element analysis (FEA) to design the frame, ensuring that it can withstand heavy loads (up to 2.5kN/㎡), high winds (up to 14 levels), seismic activity (up to 7.5 magnitudes), and heavy snow loads (up to 2.0kN/㎡). The frame is reinforced at key stress points, including corners, edges, and door/window openings, to prevent deformation and ensure long-term structural integrity.

2.2 Advanced High-Density Sandwich Panels

Lida Group’s modular container dormitories use advanced high-density sandwich panels for walls, roofs, and floors, combining strength, insulation, and durability in a single component. These panels consist of two high-strength steel sheets (1.0mm-1.2mm thick) bonded to a high-density insulation core, which is available in rock wool, polyurethane (PU), or extruded polystyrene (XPS) depending on the application requirements.

The high-density insulation core provides exceptional thermal insulation (thermal conductivity ≤0.038W/(㎡·K)), ensuring that the interior of the dormitory remains comfortable in extreme temperatures (from -40℃ to 50℃). This thermal efficiency reduces energy consumption for heating and cooling by 40%-50% compared to conventional container dormitories, lowering operational costs for clients. The insulation core also provides excellent sound insulation (≥50dB), creating a quiet living environment for workers even in noisy industrial settings.

The outer steel sheets of the sandwich panels are treated with the same dual-layer anti-corrosion coating as the steel frame, ensuring consistent corrosion resistance across the entire dormitory. The panels are also designed to be impact-resistant, with a compression strength of ≥1500kPa, making them resistant to dents, scratches, and damage from heavy equipment or severe weather. The sandwich panels are prefabricated in the factory and installed on the steel frame using high-strength bolts, ensuring a secure, airtight, and watertight connection.

2.3 Innovative High-Strength Connection Systems

To ensure the overall strength and stability of the modular container dormitory, Lida Group uses an innovative high-strength connection system that joins modules together securely and efficiently. Unlike conventional connection systems that use weak bolts or welding, Lida’s connection system features reinforced corner castings (made from Q355B steel) and high-strength galvanized bolts (M20-M24), creating a connection that is as strong as the steel frame itself.

The corner castings are integrated into the steel frame during manufacturing, with pre-drilled holes aligned to ensure precise connection between modules. The high-strength bolts are tightened to a torque of 500-600 N·m, creating a secure bond that can withstand heavy loads, high winds, and seismic activity. This connection system eliminates the need for on-site welding, reducing installation time and ensuring consistent quality across all modules.

In addition to module-to-module connections, Lida’s dormitories feature high-strength floor and roof connection systems that enhance overall structural integrity. The floor panels are connected to the steel frame using high-strength screws and adhesive, ensuring a flat, stable floor surface that can withstand heavy furniture and foot traffic. The roof panels are connected using a watertight seam system, with silicone sealant applied to all joints to prevent water leakage.

2.4 Reinforced Flooring and Roofing Systems

Lida Group’s modular container dormitories feature reinforced flooring and roofing systems designed to enhance strength and durability. The flooring system consists of a high-strength steel substrate, a layer of high-density insulation, and a wear-resistant surface (vinyl, linoleum, or concrete), providing a durable, slip-resistant floor that can withstand heavy use.

The steel substrate of the flooring system is made from Q355B steel, with a thickness of 2.5mm-3.0mm, ensuring exceptional load-bearing capacity (up to 3.0kN/㎡). The insulation layer provides thermal and sound insulation, while the wear-resistant surface is resistant to scratches, stains, and chemicals, making it easy to clean and maintain. The flooring system is also designed to be waterproof, with a water-resistant membrane applied between the steel substrate and insulation layer to prevent moisture penetration.

The roofing system is reinforced with additional steel beams and high-strength sandwich panels, ensuring that it can withstand heavy snow loads, high winds, and hail. The roof is also equipped with a drainage system, including gutters and downspouts, to channel rainwater away from the dormitory and prevent water accumulation. The roofing system is designed to be watertight, with all joints sealed with silicone sealant and reinforced with metal flashing to prevent leaks.

3. High-Strength and Durability Advantages of Lida Group’s Modular Container Dormitory

Lida Group’s high-strength durable modular container dormitory offers a range of advantages over conventional container dormitories and traditional construction, particularly in terms of strength and durability. These advantages are directly derived from the technical features outlined above and address the key challenges of workforce accommodation in harsh environments. Below are the core high-strength and durability advantages:

3.1 Exceptional Structural Strength and Load-Bearing Capacity

The high-strength steel frame, reinforced panels, and innovative connection system of Lida’s dormitory ensure exceptional structural strength and load-bearing capacity. Unlike conventional container dormitories that can only support light loads and are prone to deformation, Lida’s dormitories can withstand heavy loads (up to 3.0kN/㎡) and are designed to be stacked vertically up to 4 levels (with proper foundation support). This stacking capacity makes them ideal for projects with limited space, such as urban construction sites or remote mining camps.

The structural strength of Lida’s dormitories is also evident in their ability to withstand extreme weather conditions. The high-strength steel frame and reinforced panels can resist high winds up to 14 levels (wind speed 150-166 km/h), seismic activity up to 7.5 magnitudes, and heavy snow loads up to 2.0kN/㎡. This makes them suitable for use in regions prone to hurricanes, earthquakes, heavy snow, and other extreme weather events, ensuring that workers remain safe and comfortable even in the most challenging conditions.

3.2 Superior Corrosion Resistance for Long-Term Use

Corrosion is a major issue for container dormitories, particularly in coastal regions, industrial areas, and humid environments. Conventional container dormitories often use thin-gauge steel and minimal anti-corrosion treatment, leading to rust and degradation within 5-10 years. In contrast, Lida’s dormitories feature a dual-layer anti-corrosion coating (hot-dip galvanization + fluorocarbon paint) on all steel components, ensuring superior corrosion resistance.

The hot-dip galvanization layer (100μm-120μm) provides a protective barrier against rust, while the fluorocarbon paint finish (30μm-40μm) protects against moisture, UV radiation, and chemical exposure. This dual-layer treatment ensures that Lida’s dormitories can withstand coastal saltwater, industrial chemicals, and extreme humidity for 15-20 years with minimal maintenance. In tests conducted by independent laboratories, Lida’s dormitories showed no signs of rust or corrosion after 10 years of exposure to coastal salt spray, demonstrating their long-term durability.

3.3 Impact Resistance and Damage Tolerance

Workforce dormitories in industrial and remote settings are often exposed to heavy equipment, tools, and harsh handling, making impact resistance a critical requirement. Conventional container dormitories are prone to dents, scratches, and structural damage from impact, leading to reduced durability and increased maintenance costs. Lida’s dormitories address this issue with high-strength sandwich panels and reinforced steel components, ensuring exceptional impact resistance and damage tolerance.

The high-density sandwich panels have a compression strength of ≥1500kPa, making them resistant to dents and scratches from heavy equipment. The reinforced steel frame and corner castings are designed to absorb impact energy, preventing structural deformation and damage. In addition, the wear-resistant flooring and roofing surfaces are resistant to stains, chemicals, and heavy foot traffic, ensuring that the dormitory remains in good condition even after years of heavy use.

3.4 Long Service Life with Minimal Maintenance

One of the key advantages of Lida Group’s modular container dormitory is its long service life of 15-20 years with minimal maintenance. This is significantly longer than conventional container dormitories (5-10 years) and traditional temporary housing (3-5 years), making it a cost-effective solution for organizations seeking long-term workforce accommodation.

The long service life is made possible by the high-quality materials, rigorous engineering, and superior anti-corrosion treatment used in the dormitory’s construction. The dual-layer anti-corrosion coating reduces the need for repainting and rust removal, while the high-strength components are resistant to wear and tear. In addition, the modular design allows for easy replacement of individual components (such as panels or fixtures) if they become damaged, extending the overall service life of the dormitory.

Maintenance requirements for Lida’s dormitories are minimal: regular inspection of connections and seals, occasional cleaning of gutters and downspouts, and repainting every 8-10 years (if needed). This minimal maintenance reduces operational costs for clients, making Lida’s dormitories a cost-effective investment over their entire lifecycle.

3.5 Resistance to Extreme Temperatures and Environmental Conditions

Lida Group’s modular container dormitories are designed to withstand extreme temperatures and environmental conditions, making them suitable for use in virtually any region of the world. The high-density insulation core of the sandwich panels provides exceptional thermal insulation, ensuring that the interior remains comfortable in temperatures ranging from -40℃ (arctic regions) to 50℃ (desert regions).

In cold regions, the dormitories can be equipped with enhanced insulation (200mm thick sandwich panels) and floor heating systems to ensure worker comfort. In hot regions, reflective roof coatings and solar-powered ventilation systems can be added to reduce interior temperatures and improve air circulation. The dormitories are also designed to be waterproof (IP68 rating), with no water leakage even in heavy rain (300mm/24h), and dustproof, making them suitable for use in desert and mining regions.

4. Practical Application Scenarios and Real-World Case Studies

Lida Group’s high-strength durable modular container dormitories are suitable for a wide range of applications, particularly in industries that require workforce accommodation in remote, harsh, or temporary settings. Each application leverages the dormitory’s high-strength and durability advantages to address specific accommodation needs. Below are the key application scenarios, along with real-world case studies demonstrating the effectiveness of Lida’s product:

4.1 Remote Mining Camps

Mining operations often take place in remote, harsh environments with extreme temperatures, high winds, and corrosive conditions. Traditional dormitories in mining camps are often flimsy, prone to damage, and require frequent maintenance. Lida’s high-strength durable modular container dormitories are ideal for mining camps, as they can withstand the harsh conditions and provide a comfortable living environment for miners.

Case Study: A large mining company in Australia needed accommodation for 300 miners at a remote gold mine in the Western Australian outback. The site is characterized by extreme temperatures (ranging from -5℃ to 45℃), high winds, and dusty conditions. The company chose Lida Group’s 40-foot high-strength modular container dormitories to create a mining camp. Lida delivered 60 dormitory modules, each accommodating 5 miners, along with communal facilities (kitchens, bathrooms, recreation rooms).

The dormitories featured Q355B steel frames, rock wool insulation, and dual-layer anti-corrosion coating to withstand the harsh outback conditions. The modular design allowed the camp to be installed in 5 days by a small team of workers, and the high-strength construction ensured that the dormitories remained in excellent condition despite frequent dust storms and temperature fluctuations. After 5 years of use, the dormitories showed no signs of rust or structural damage, and maintenance costs were less than 10% of those for conventional mining camp dormitories. The mining company was so satisfied with the performance that it expanded the camp with an additional 40 modules from Lida Group.

4.2 Construction Site Worker Accommodation

Construction sites often require temporary accommodation for workers, particularly in urban areas or remote construction projects. Conventional temporary dormitories are often flimsy, unsafe, and difficult to relocate. Lida’s modular container dormitories are ideal for construction sites, as they are portable, durable, and can be quickly installed and relocated as the project progresses.

Case Study: A construction company in the Middle East was building a large highway in a remote region of Saudi Arabia, requiring accommodation for 250 construction workers for a 4-year project. The site is characterized by extreme heat (up to 50℃), high winds, and sandstorms. The company chose Lida Group’s 20-foot high-strength modular container dormitories, which were customized with enhanced insulation, reflective roof coatings, and solar-powered ventilation systems to cope with the extreme heat.

Lida delivered 50 dormitory modules, along with communal facilities, which were installed in 3 days. The high-strength steel frames and impact-resistant panels withstood frequent sandstorms and heavy equipment movement, while the thermal insulation kept the interior temperature comfortable (25-28℃) without excessive energy consumption. The modular design allowed the camp to be relocated twice as the construction project advanced, with minimal disruption to workers. After 4 years of use, the dormitories were disassembled and transported to another construction project in Oman, demonstrating their reusability and long-term durability.

4.3 Renewable Energy Project Camps

Renewable energy projects (wind, solar, hydro) often take place in remote regions with harsh environmental conditions, requiring accommodation for construction and maintenance workers. Lida’s high-strength durable modular container dormitories are suitable for these projects, as they can withstand extreme weather and provide a comfortable living environment for workers.

Case Study: A European renewable energy company was building a large wind farm in the remote mountains of Norway, requiring accommodation for 150 workers for a 3-year project. The site is characterized by extreme cold (down to -40℃), heavy snow, and high winds. The company chose Lida Group’s high-strength modular container dormitories, which were customized with enhanced insulation (200mm thick sandwich panels), floor heating systems, and snow guards on the roof.

Lida delivered 30 dormitory modules, which were installed in 4 days. The dual-layer anti-corrosion coating prevented rust in the humid, snowy environment, while the reinforced roof withstood heavy snow loads (up to 2.0kN/㎡). The floor heating systems kept the interior warm and comfortable, even in extreme cold, and the thermal insulation reduced energy consumption for heating by 45% compared to conventional dormitories. Over the 3-year project, the dormitories required minimal maintenance, and when the project was completed, they were relocated to another wind farm in Sweden—demonstrating their reusability and durability in cold climates.

4.4 Military Barracks and Field Operations

Military forces often require temporary barracks for field operations, training exercises, or peacekeeping missions in remote or hostile environments. Lida’s high-strength durable modular container dormitories are well-suited for military applications, as they are robust, portable, and can be quickly installed with minimal equipment.

Case Study: A NATO military force needed temporary barracks for 200 soldiers for a 6-month training exercise in a remote region of Eastern Europe. The site is characterized by harsh weather, including high winds and heavy rain, and required accommodation that was secure, durable, and comfortable. The military chose Lida Group’s 40-foot high-strength modular container dormitories, which were customized with reinforced security doors, camouflage paint, and communication systems.

Lida delivered 40 dormitory modules, which were installed in 2 days by a small team of soldiers using basic tools and a small crane. The high-strength connection system ensured that the modules were securely joined, even in high winds, and the impact-resistant panels withstood damage from military equipment. The dual-layer anti-corrosion coating prevented rust in the humid environment, and the dormitories provided a comfortable living space for the soldiers during the training exercise. When the exercise was completed, the dormitories were disassembled and transported to a nearby military base for future use—demonstrating their portability and durability.

5. Technical Specifications and Quality Control Processes

Lida Group’s high-strength durable modular container dormitories are built to strict technical standards and undergo rigorous quality control processes to ensure exceptional strength, durability, and safety. Below is a detailed overview of the key technical specifications and quality control processes:

5.1 Technical Specifications

-

Frame Material: Q355B high-strength galvanized steel, frame thickness 3.0mm-4.0mm

-

Anti-corrosion Treatment: Hot-dip galvanized layer (100μm-120μm) + fluorocarbon paint finish (30μm-40μm)

-

Module Dimensions: Standard 20-foot (6055mm × 2438mm × 2896mm); 40-foot (12192mm × 2438mm × 2896mm); custom sizes available

-

Weight: 20-foot module: 2.8-3.2 tons; 40-foot module: 4.8-5.2 tons

-

Stacking Capacity: Up to 4 levels (with concrete foundation support)

-

Connection System: Reinforced Q355B steel corner castings, M20-M24 high-strength galvanized bolts

-

Walls/Roof/Floor: 150mm-200mm thick high-density sandwich panels (steel sheets + insulation core); outer steel sheet thickness 1.0mm-1.2mm

-

Insulation Core: Rock wool (density ≥120kg/㎥), polyurethane (PU) (density ≥40kg/㎥), or XPS (density ≥32kg/㎥)

-

Windows: Aluminum alloy windows with double-layer tempered glass (6mm+12A+6mm); sound insulation ≥50dB; thermal insulation U-value ≤2.5W/(㎡·K)

-

Doors: Heavy-duty steel security doors (1.5mm thick) with anti-theft locks and weatherstripping

-

Structural Performance: Wind resistance up to 14 levels; seismic resistance up to 7.5 magnitudes; snow load resistance up to 2.0kN/㎡; load-bearing capacity up to 3.0kN/㎡

-

Service Life: 15-20 years (with proper maintenance); Reusable for ≥10 relocations

-

Safety Compliance: ISO 9001 certified, CE certified, compliant with GB50011-2010 (seismic standard) and ISO 14001 (environmental standard)

5.2 Quality Control Processes

Lida Group places a high priority on quality control, with a comprehensive quality management system that covers every stage of the manufacturing and installation process. The quality control processes are designed to ensure that each dormitory module meets the highest standards of strength, durability, and safety.

1. Raw Material Inspection: All raw materials (steel, sandwich panels, bolts, insulation) are inspected before entering the factory. The steel is tested for tensile strength, impact resistance, and corrosion resistance, while the sandwich panels are tested for compression strength, thermal insulation, and water resistance. Only materials that meet Lida’s strict standards are used in production.

2. In-Process Inspection: During the manufacturing process, each component undergoes regular inspections. The steel frame is inspected for weld quality, dimensions, and anti-corrosion coating thickness. The sandwich panels are inspected for bonding strength, insulation core density, and surface quality. The connection systems are inspected for precision and strength.

3. Pre-Assembly Inspection: Before shipping, each module is pre-assembled in the factory to test fit, functionality, and structural integrity. The pre-assembly inspection includes testing the connection systems, checking for water leakage, and verifying that all fixtures and utilities are working properly.

4. Final Inspection: After pre-assembly, each module undergoes a final inspection by a team of quality control experts. The inspection includes a visual inspection of all components, testing of structural strength and load-bearing capacity, and verification of compliance with technical specifications and safety standards. Only modules that pass the final inspection are shipped to clients.

5. On-Site Installation Inspection: Lida’s quality control team also provides on-site inspection during installation to ensure that modules are connected properly, the foundation is stable, and all utilities are installed correctly. This ensures that the final dormitory camp meets Lida’s strict standards of strength and durability.

6. Market Advantages of Lida Group’s High-Strength Durable Modular Container Dormitory

In addition to its high-strength and durability advantages, Lida Group’s modular container dormitory offers several market advantages that set it apart from competitors. These advantages make it the preferred choice for organizations worldwide seeking reliable, cost-effective workforce accommodation solutions:

6.1 Customization Capabilities

Lida Group offers extensive customization capabilities, allowing clients to tailor the dormitory modules to their specific needs. Clients can choose from a range of module sizes, insulation materials, interior layouts, and additional features (such as floor heating, solar power, and ventilation systems). Lida’s engineering team works closely with clients to design a dormitory solution that meets their industry requirements, project location, and workforce size.

6.2 Fast Deployment and Easy Installation

Lida’s modular container dormitories are prefabricated in the factory, with a prefabrication rate of 95% or higher. This means that nearly all components are manufactured and assembled in the factory, reducing on-site installation time to a minimum. A single 20-foot module can be installed in 4-6 hours by a team of 2-3 workers, and a large camp with 50 modules can be fully operational in 3-5 days. This fast deployment is critical for projects with tight timelines, such as emergency accommodation or remote industrial projects.

6.3 Cost-Effectiveness Across the Lifecycle

Lida’s modular container dormitories are cost-effective not just in terms of initial deployment, but across their entire lifecycle. The lower maintenance costs, long service life, and reusability of the modules reduce total lifecycle costs by 30%-50% compared to conventional container dormitories and traditional construction. Additionally, the high prefabrication rate reduces material waste by 70%-80%, further lowering costs.

6.4 Global Logistics and Service Network

Lida Group has a global network of manufacturing facilities, logistics partners, and service centers, allowing it to deliver dormitory solutions to clients in over 120 countries. The company’s logistics team specializes in transporting modular containers to remote and hard-to-reach locations, using standard shipping methods (trucks, ships, trains) and specialized transportation (helicopters, off-road trucks) when needed. Lida also provides on-site installation, maintenance, and after-sales support, ensuring that clients receive a seamless, hassle-free experience.

6.5 Environmental Sustainability

Lida Group’s modular container dormitories are environmentally sustainable, aligning with global efforts to reduce carbon emissions and promote green construction. The high prefabrication rate reduces construction waste, the steel frame is made from recycled steel (where possible), and the insulation materials are eco-friendly and recyclable. The energy-efficient design reduces energy consumption for heating and cooling, lowering carbon emissions. Additionally, the reusability of the modules reduces the need for new construction, minimizing the environmental impact.

7. Challenges and Solutions in High-Strength Modular Container Dormitory Deployment

While Lida Group’s high-strength durable modular container dormitories offer numerous advantages, they also face several challenges in deployment, particularly in remote and harsh environments. Below are the key challenges and Lida’s practical solutions to address them:

7.1 Challenge: High Transportation Costs for Remote Locations

Shipping modular container dormitories to remote locations can be expensive, particularly for regions with no access to major roads or ports. This can increase the overall cost of the project for clients.

Solution: Lida Group has partnered with local logistics providers in remote regions to reduce transportation costs. The company also offers foldable modular modules, which reduce shipping volume by 60%-70%, allowing more modules to be transported in a single shipment. For extremely remote locations, Lida provides kit-form modules, where components are shipped separately and assembled on-site—reducing the size and weight of each shipment.

7.2 Challenge: Adaptability to Extreme Environmental Conditions

While Lida’s dormitories are designed to withstand harsh environments, extreme conditions (such as arctic temperatures below -40℃ or desert heat above 50℃) can still pose challenges to comfort and functionality.

Solution: Lida offers specialized modules for extreme environments, including arctic modules with enhanced insulation and floor heating, desert modules with reflective roof coatings and solar-powered cooling, and coastal modules with enhanced corrosion resistance. The company also provides custom utility solutions (such as solar power, water purification, and ventilation systems) to ensure functionality in off-grid extreme environments.

7.3 Challenge: Regulatory Compliance in Different Countries

Building codes and regulations vary widely by country and region, making it difficult for clients to obtain permits for modular container dormitories, particularly for long-term use.

Solution: Lida Group works closely with local governments and building code organizations to ensure that its dormitories comply with local regulations. The company’s products are certified to international standards (ISO, CE), which demonstrate compliance with global safety and environmental requirements. Lida also partners with local architects and engineers to adapt its dormitory solutions to local building codes, ensuring that clients can obtain permits quickly and easily.

8. Conclusion

Lida Group’s high-strength durable modular container dormitory represents a significant advancement in workforce accommodation, combining exceptional strength, durability, and functionality to meet the rigorous requirements of modern industries. Designed to withstand the harshest environmental conditions, from extreme temperatures and high winds to corrosion and impact, these dormitories deliver a long service life of 15-20 years with minimal maintenance, providing exceptional value across their entire lifecycle. By leveraging advanced materials, innovative engineering, and rigorous quality control, Lida Group has created a dormitory solution that addresses the key pain points of traditional workforce accommodation—flimsiness, high maintenance costs, and short service life.

This article has explored the full scope of Lida Group’s high-strength durable modular container dormitory, from its core technical features and strength advantages to its practical applications, technical specifications, and market positioning. The real-world case studies demonstrate that Lida’s dormitories are not just a theoretical solution, but a proven, effective tool that is already making a difference in industries worldwide—from mining and construction to renewable energy and military operations. Whether deployed in remote mining camps, construction sites, or military barracks, Lida’s dormitories provide a safe, comfortable, and reliable living environment for workers, while delivering cost savings and operational efficiency for clients.

Lida Group’s commitment to innovation, quality, and customer-centricity sets it apart from competitors. The company’s extensive customization capabilities, fast deployment, global logistics network, and after-sales support ensure that clients receive a tailored solution that meets their specific needs. Additionally, Lida’s focus on environmental sustainability aligns with global efforts to promote green construction, making its dormitories a responsible choice for organizations seeking to reduce their environmental impact.

As industries continue to expand into remote and harsh environments, the demand for high-strength durable workforce accommodation will only grow. Lida Group’s high-strength durable modular container dormitory is well-positioned to meet this demand, offering a reliable, cost-effective, and sustainable solution that redefines workforce housing standards. With its unwavering focus on strength, durability, and user comfort, Lida Group remains a leader in the modular container construction industry, delivering innovative solutions that enhance quality of life and drive operational efficiency for clients worldwide.

In conclusion, Lida Group’s high-strength durable modular container dormitory is more than just a housing solution—it is a strategic investment that helps organizations streamline operations, reduce costs, and ensure the safety and comfort of their workforce. For organizations seeking a reliable, long-lasting, and cost-effective workforce accommodation solution, Lida Group stands as the trusted partner, delivering high-strength durable modular container dormitories that perform reliably in the most challenging environments, anywhere in the world.

Related news

-

Lida Group Delivers Turnkey Prefabricated Container Worker Camp

2026-02-14 13:48:00

-

Rapid Deployment with Easy Install Container House Technology

2026-02-14 13:55:22

-

Durable Modular Dormitories Ideal for Remote Workforce Housing

2026-02-14 13:38:16

contact us

- Tel: +86-532-88966982

- Whatsapp: +86-13793209022

- E-mail: sales@lidajituan.com