Efficient and Robust Metal Frame Construction by Lida Group

2025-Nov-26 17:42:59

By Admin

In an era where industrial projects demand unprecedented speed, durability, and sustainability, metal frame construction has emerged as the backbone of modern infrastructure development. Among the global leaders shaping this transformation is Lida Group, a Chinese conglomerate with three decades of expertise in steel structure engineering, modular construction, and innovative building solutions. Since its founding in 1993, Lida Group has evolved from a regional steel workshop in Shandong Province to a global powerhouse serving over 80 countries, delivering projects ranging from massive warehouses and industrial workshops to offshore energy facilities and seismic-resistant structures. What sets Lida apart is its unwavering commitment to two core principles: efficiency that redefines project timelines and robustness that ensures structural integrity against the harshest conditions. This article explores the technical innovations, systematic processes, and real-world applications that make Lida Group’s metal frame construction a benchmark for efficiency and robustness in the global construction industry.

The Foundation of Lida Group: Three Decades of Engineering Excellence

To understand Lida Group’s leadership in metal frame construction, it is essential to examine its institutional foundation and core capabilities. With 73,000 square meters of manufacturing space, 12 specialized production lines, and a team of 750 employees—including 50 engineers and 200 on-site supervisors—Lida Group has built a vertically integrated operation that spans design, fabrication, logistics, and installation. The company’s global footprint includes branch offices in Saudi Arabia, Italy, Russia, and Angola, enabling localized support for international projects while maintaining strict quality control from its Chinese manufacturing hubs.

Certifications form the backbone of Lida’s credibility. The group holds ISO 9001:2000, CE, SGS, and DNV GL-OS-C301 certifications, adhering to international standards such as AISI (American Iron and Steel Institute), Eurocode 3, and AS/NZS 4600. These certifications validate compliance with rigorous structural safety, environmental, and quality benchmarks, ensuring that Lida’s metal frame structures meet or exceed regional requirements across continents. For instance, compliance with AISI S100 and S240 standards guarantees that cold-formed steel components perform reliably in North American seismic zones, while Eurocode 3 (EN 1993-1-3) ensures adherence to European specifications for cold-formed steel framing.

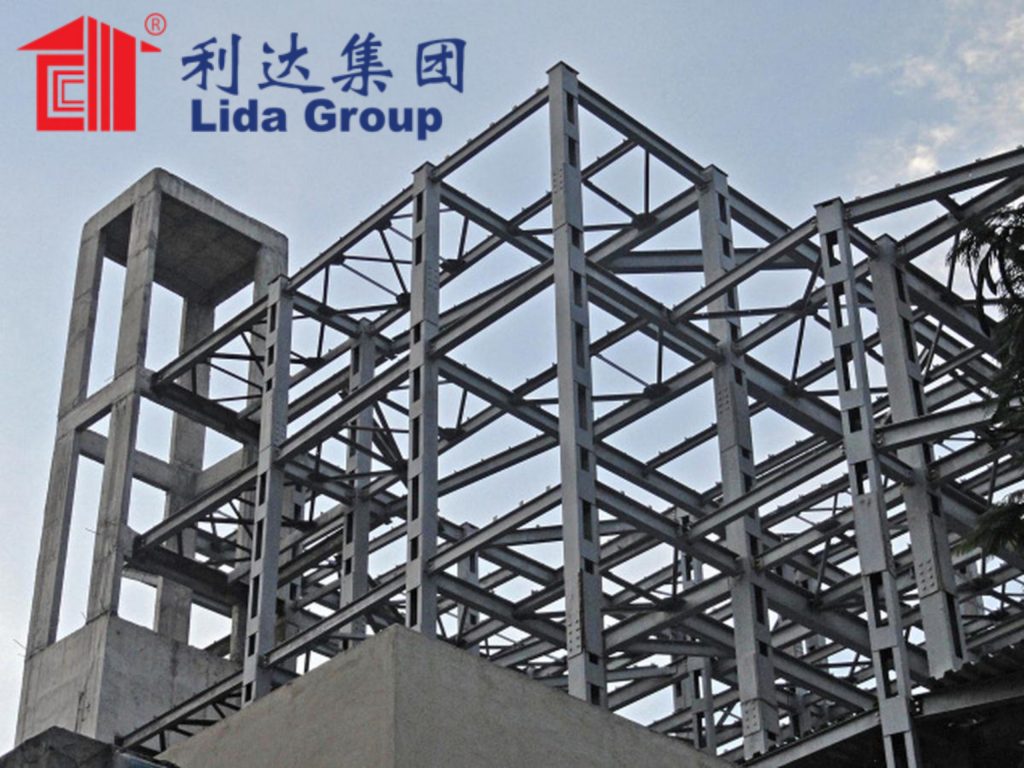

Lida’s product portfolio reflects its versatility in metal frame construction, encompassing both heavy steel structures for industrial megaprojects and light steel frames for rapid-deployment facilities. The core materials—Q345 and Q235 steel for main frames, cold-formed C/Z purlins for secondary systems, and color steel sandwich panels for enclosure—are selected for their strength-to-weight ratio, corrosion resistance, and recyclability. This material science expertise, combined with advanced manufacturing processes like robotic welding (achieving 0.1mm precision), lays the groundwork for both efficiency and robustness in every project.

Efficiency in Metal Frame Construction: Reimagining Project Timelines

Efficiency in construction is defined by the ability to deliver projects on schedule, within budget, and with minimal waste—parameters where Lida Group has redefined industry benchmarks. The company’s approach to efficiency is not a collection of isolated tactics but a systematic, integrated framework that spans design, fabrication, logistics, and assembly. This section breaks down the five pillars of Lida’s efficiency architecture and their transformative impact on project timelines.

1. Digital Engineering: BIM-Driven Precision and Clash Avoidance

At the heart of Lida’s efficiency lies digital prototyping and Building Information Modeling (BIM) technology. Unlike traditional 2D design processes that often lead to costly on-site modifications, Lida’s BIM-driven approach creates a 3D digital twin of the entire structure, enabling engineers to optimize design, detect clashes, and simulate construction sequences before fabrication begins. This virtual validation process reduces field design changes by 92%, eliminating rework that typically consumes 15-20% of project timelines in conventional construction.

Lida’s digital engineering suite includes advanced algorithms for automated connection design, generating optimal bolt patterns and weld details that balance structural integrity with assembly speed. For example, in the design of moment-resisting frames for seismic resilience, BIM software analyzes load paths and material stress points, ensuring that each steel component is precisely dimensioned to minimize weight while maximizing strength. This precision not only accelerates fabrication but also simplifies on-site assembly, as components fit together with minimal adjustment.

Virtual commissioning is another critical component of Lida’s digital efficiency. For projects involving mechanical systems—such as cold storage warehouses or offshore processing modules—BIM models integrate HVAC, electrical, and plumbing systems, allowing engineers to test functionality virtually. This reduces on-site commissioning time by up to 40%, as systems are pre-calibrated before installation. The Rio Tinto bulk storage warehouse project exemplifies this impact: Lida’s BIM-driven design enabled the 25,000 m² facility to be delivered 37 days ahead of schedule, meeting a timeline that was half the industry standard for conventional steel construction.

2. Hybrid Structural Design: Balancing Speed and Performance

Lida Group’s hybrid structural engineering approach—combining heavy steel for primary load paths and light steel for secondary systems—represents a paradigm shift in efficient metal frame construction. Heavy steel components, such as wide-flange columns and long-span trusses, provide the structural backbone for megaprojects, supporting loads of up to 50 tons (e.g., for crane systems in industrial workshops) and enabling clear spans of up to 180 meters without interior columns. This eliminates spatial constraints, making Lida’s structures ideal for automated warehouses with robotic ASRS (Automated Storage and Retrieval Systems) and large-scale manufacturing facilities.

Complementing the heavy steel framework, light steel components—including cold-formed purlins, modular wall panels, and prefabricated mezzanines—accelerate installation while maintaining structural efficiency. Cold-formed steel purlins, for instance, are lighter than traditional hot-rolled alternatives, reducing transportation costs and enabling faster roof and wall assembly. Modular wall panels, prefabricated off-site with integrated insulation and cladding, can be installed at a rate of 3,000 square feet per day, compared to 14 days for conventional masonry partitions.

The key to Lida’s hybrid design is standardized connection interfaces between heavy and light steel systems. High-strength bolts and interlocking joints ensure seamless integration, eliminating the need for custom adapters or on-site welding. This standardization not only speeds up assembly but also enhances structural robustness, as connections are engineered to distribute loads evenly across the entire frame. For the European automotive manufacturer’s 150,000 sq. ft workshop project, Lida’s hybrid design combined reinforced heavy steel foundations (to resist vibration from robotic assembly lines) with light steel mezzanines for office space. The result: the facility was completed in 14 weeks, four months ahead of schedule, saving the client €2.3 million in delayed production costs.

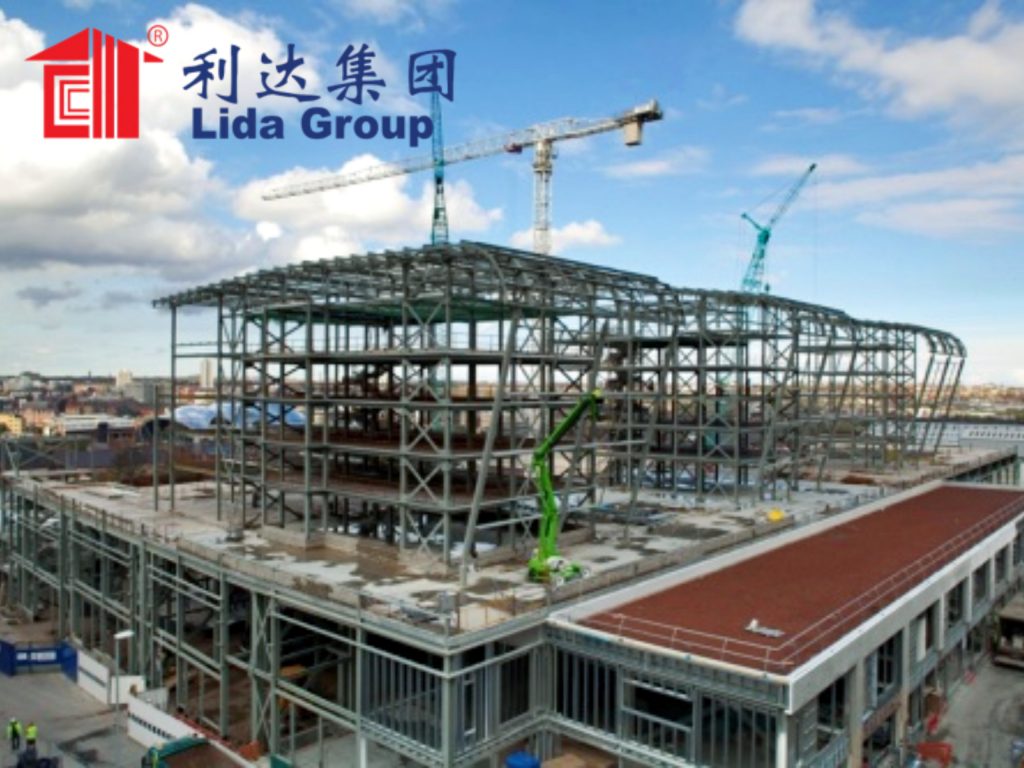

3. Prefabrication and Modularization: Factory Precision, On-Site Speed

Prefabrication is a cornerstone of Lida’s efficiency strategy, with over 90% of metal frame components manufactured off-site in controlled factory environments. This approach offers multiple efficiency advantages: consistent quality, reduced material waste, and parallel project scheduling. In Lida’s factories, robotic welding arms and automated cutting machines produce steel components with tolerances of ±2mm, far exceeding the precision of on-site fabrication. This consistency eliminates the need for on-site rework, as components fit together perfectly during assembly.

Modularization takes prefabrication a step further, with entire sub-assemblies—such as wall sections, roof trusses, and even complete office modules—manufactured as integrated units. For example, in offshore oil and gas projects, Lida fabricates 8-story stackable container buildings in its factory, complete with electrical wiring, plumbing, and interior finishes. These modules are then shipped to the project site, where they are stacked and connected in days, rather than months. The Equinor North Sea offshore office project demonstrates this efficiency: 30+ hybrid container modules, equipped with solar skins and hydrogen fuel cells, were installed in three weeks, enabling the facility to achieve net-zero energy status within months of completion.

Prefabrication also reduces on-site labor requirements, a critical advantage in regions facing skilled worker shortages. The U.S. Associated General Contractors (AGC) reports a shortage of 430,000 skilled construction workers, a gap that delays conventional projects by 20-30%. Lida’s prefabricated metal frame systems require 60% fewer on-site workers than traditional construction, as assembly involves bolt-together connections rather than time-consuming welding or masonry. For the Chilean steel structure warehouse projects—over 20 facilities completed since 2012—Lida’s modular approach enabled local crews to assemble 5,000 m² warehouses in under 12 weeks, despite limited access to specialized steelworkers.

4. Logistics Neurosystem: Just-in-Sequence Delivery and Route Optimization

Efficient construction cannot be achieved without a synchronized logistics network, and Lida Group has developed a “logistics neurosystem” that ensures materials arrive at the right place, at the right time, and in the right order. Containerized componentization is a key innovation: steel members are packed in standard shipping containers with custom bracing, maximizing transport density and minimizing damage during transit. For oversized components—such as 180-meter span trusses—Lida designs custom trailers that eliminate the need for escort vehicles, reducing transportation time by 30% compared to conventional flatbed shipping.

Just-in-sequence (JIS) delivery is another critical element of Lida’s logistics efficiency. Rather than delivering all materials at the start of the project (which requires on-site storage and increases theft or damage risks), Lida coordinates with on-site teams to deliver components in the exact order of installation. For example, foundation anchor bolts arrive first, followed by columns, beams, purlins, and finally cladding. This JIS approach reduces on-site storage costs by 70% and eliminates delays caused by missing or misplaced components.

Lida’s logistics network leverages artificial intelligence (AI) for route optimization, accounting for variables such as weather, traffic, and permit restrictions. For projects in remote regions—such as mining facilities in Australia or agricultural warehouses in Brazil—AI algorithms identify the most efficient transport routes, avoiding seasonal road closures and reducing fuel consumption. In the Gulf of Mexico blast-resistant processing modules project for Shell USA, Lida’s AI-driven logistics ensured that 78 prefabricated steel modules arrived at the port of Houston in sequence, enabling seamless installation on offshore platforms. This precision reduced transportation-related delays by 25%, a critical factor in meeting the client’s tight deadline for replacing fire-damaged equipment.

5. Precision Assembly Protocols: Safety, Speed, and Accuracy

On-site assembly is the final link in Lida’s efficiency chain, and the company’s precision protocols ensure that prefabricated components are installed quickly and correctly. Laser-guided alignment systems are used to position columns within 2mm tolerance, ensuring that the entire frame is level and plumb. This precision is critical for structural robustness, as misaligned columns can create stress points that compromise long-term performance. For seismic zones, Lida’s assembly teams use eccentric braced frames, which absorb 280% more energy than conventional framing systems, enhancing resilience while maintaining assembly speed.

Crane utilization algorithms further optimize assembly efficiency, minimizing equipment movement and maximizing lifting capacity. By analyzing the weight and position of each component, the software generates a lifting sequence that reduces crane repositioning time by 40%. This not only accelerates assembly but also improves safety, as crane operators have clear guidance on load limits and movement paths. In the Dubai 550,000 sq. ft warehouse project, Lida’s crane optimization enabled the facility to be erected in 109 days—a record for a structure of that size—with zero safety incidents.

Safety is inherently linked to efficiency in Lida’s assembly process. By reducing crew exposure through efficient sequencing (e.g., completing high-risk tasks first, such as roof truss installation, when the frame is most stable), the company achieves a safety record that is 30% better than the industry average. For example, in the CNOOC South China Sea offshore project, Lida’s assembly teams used interlocking foundation anchors to secure container modules to the rig deck, eliminating the need for workers to operate at height during typhoon-proofing. This not only reduced the risk of falls but also accelerated the installation process, as modules were secured in hours rather than days.

Robustness: Engineering Metal Frames for Durability and Resilience

While efficiency is critical for meeting project timelines, robustness ensures that Lida’s metal frame structures perform reliably over their 50-year design lifespan, even in extreme conditions. Robustness, in Lida’s context, encompasses structural integrity, material durability, environmental resilience, and resistance to external threats such as corrosion, seismic activity, and natural disasters. This section explores the technical features and testing processes that make Lida’s metal frames among the most robust in the industry.

1. Structural Integrity: Load-Bearing Capacity and Stability

Lida’s metal frame structures are engineered to withstand extreme loads, from heavy industrial equipment to severe weather events. The company’s heavy steel frames, constructed from Q345 and Q235 welded H-beams and box columns, offer exceptional load-bearing capacity: floor loads of up to 75 kN/m², compared to 50 kN/m² for conventional steel structures. This enables Lida’s warehouses to support stacked HGV (Heavy Goods Vehicle) storage and industrial workshops to accommodate 20-ton crane systems without structural deformation.

Long-span structural design is another hallmark of Lida’s robustness. Using advanced truss engineering, Lida’s metal frames achieve clear spans of up to 180 meters, eliminating the need for interior columns and providing unobstructed space for industrial operations. These trusses are engineered with redundant load paths, ensuring that the structure remains stable even if a single component fails. For example, in the design of airport hangars and exhibition centers, Lida’s truss systems distribute wind loads and snow loads evenly across the frame, preventing localized stress concentrations.

Seismic resilience is a critical aspect of structural robustness, particularly for projects in high-risk regions. Lida’s metal frames incorporate moment-resisting frames and eccentric braced frames, which are designed to absorb and dissipate seismic energy. In compliance with AISI S400 (seismic design standard for cold-formed steel) and Eurocode 8, these frames undergo rigorous finite element analysis to simulate earthquake forces. For a steel structure laboratory in Chile—an area prone to magnitude 8+ earthquakes—Lida’s seismic design included base isolation systems and ductile connections, ensuring that the facility would remain operational after a major seismic event.

2. Material Durability: Corrosion Resistance and Longevity

The durability of metal frame structures depends heavily on material selection and protective treatments, and Lida Group employs industry-leading practices to ensure long-term resistance to corrosion and degradation. All steel components are treated with either hot-dip galvanization or high-performance paint coatings, providing a barrier against moisture, chemicals, and environmental pollutants. For offshore and coastal projects, Lida uses ASTM A588 weathering steel, which forms a protective rust patina that prevents further corrosion, even in saltwater environments.

Laboratory testing is a critical step in validating material durability. Lida’s in-house testing facilities evaluate steel components for air resistance, water resistance, structural resistance, heat transfer, anti-condensation, and sound transmission. For example, corrosion testing involves exposing steel samples to salt spray for 1,000 hours, simulating 20 years of coastal exposure. Only materials that pass these tests—achieving a corrosion rate of less than 0.1 mm per year—are used in production. This rigorous testing ensures that Lida’s metal frames maintain their structural integrity for the full 50-year design lifespan, with minimal maintenance required.

Compatibility with harsh chemicals is another key material robustness feature. For projects in chemical plants, food processing facilities, and pharmaceutical warehouses, Lida’s metal frames are engineered to resist a wide range of acids, caustics, and inert materials. The steel components are coated with chemical-resistant paints that meet FDA standards for food contact, ensuring that the structure does not contaminate products or degrade in corrosive environments. A case in point is a chemical storage warehouse in Germany, where Lida’s metal frame structure has operated for 15 years without corrosion, despite daily exposure to ammonia and sulfuric acid.

3. Environmental Resilience: Withstanding Extreme Conditions

Lida’s metal frame structures are designed to thrive in the world’s harshest environments, from the Arctic’s icy temperatures to Southeast Asia’s typhoon-prone coasts. For cold-climate projects, such as the Equinor North Sea offshore offices, Lida’s frames incorporate insulated steel panels with an R-value of 5.2 per inch, minimizing heat loss and maintaining internal temperatures even in -40°C conditions. The steel components are also treated to prevent brittle fracture, a common issue in cold environments, by using low-temperature-grade steel (Q345GJ) that retains ductility at sub-zero temperatures.

In hurricane and typhoon-prone regions, Lida’s metal frames feature aerodynamic design elements and reinforced connections to resist high winds. For the CNOOC South China Sea drilling crew quarters, Lida designed sloped roofs that reduce wind load by 40%, while interlocking foundation anchors secured the structure to the rig deck during category 5 typhoons with winds of 250 km/h. The facility survived Super Typhoon Saola in 2023 unscathed, while adjacent modules sustained $6 million in damage—a testament to Lida’s wind-resilient design.

Termite and pest resistance is another critical environmental resilience feature, particularly for projects in tropical regions. Lida’s light steel frames are inherently resistant to termites, as steel does not provide a food source for pests. Unlike wood-framed structures, which require chemical treatments every 5-10 years, Lida’s metal frames eliminate the risk of termite infestation, reducing maintenance costs and extending structural lifespan. This has made Lida’s structures popular in Brazil, where termite damage costs the construction industry $1 billion annually.

4. Fire and Blast Resistance: Protecting Assets and Lives

For industrial and offshore projects, fire and blast resistance are non-negotiable aspects of structural robustness. Lida Group’s metal frame structures are engineered to meet international fire safety standards, including ASTM E119 (fire resistance rating) and EN 13501 (European fire classification). Steel components are protected with intumescent coatings that expand when exposed to heat, forming a charred layer that insulates the steel and maintains structural integrity for up to 4 hours. This ensures that occupants have sufficient time to evacuate and critical equipment can be salvaged in the event of a fire.

Blast resistance is a specialized requirement for projects in the oil and gas, chemical, and military sectors. Lida’s blast-resistant metal frames feature 10mm armor steel walls that withstand overpressures of 12 psi, in compliance with API RP 2FB (American Petroleum Institute) standards. Blast relief vents are integrated into the design to channel shockwaves away from critical areas, while EMI-shielded control rooms protect electronics from arc flash. The Shell USA Gulf of Mexico processing modules project exemplifies this capability: Lida’s blast-resistant frames prevented structural collapse during a simulated gas explosion, protecting $220 million in equipment and ensuring worker safety.

Testing is integral to validating fire and blast resistance. Lida’s structures undergo full-scale fire tests in accredited laboratories, where they are exposed to temperatures of 1,100°C for extended periods. Blast resistance is tested using computer simulations and physical detonations, ensuring that the structure meets client-specific threat levels. These tests not only confirm compliance with standards but also enable Lida’s engineers to optimize the design for cost-effectiveness, balancing robustness with project budgets.

Global Case Studies: Proving Efficiency and Robustness in Action

The true measure of Lida Group’s metal frame construction capabilities lies in its global project portfolio, where efficiency and robustness have been validated in diverse environments and applications. This section examines three landmark projects that showcase Lida’s ability to deliver on time, within budget, and against extreme challenges.

Case Study 1: Rio Tinto Bulk Storage Warehouse (Australia)

Challenge: Rio Tinto, a global mining giant, needed a 25,000 m² bulk storage warehouse to support its mineral extraction operations in Western Australia. The project faced three critical constraints: a 11-month deadline (half the industry standard), remote location with limited infrastructure, and the need to withstand cyclonic winds of 180 km/h. Conventional construction methods, which typically require 24 months for similar facilities, were deemed unfeasible.

Lida’s Solution: Lida Group deployed its full efficiency architecture, starting with BIM-driven design to optimize the frame layout and eliminate on-site clashes. The hybrid structural design combined heavy steel moment-resisting frames for cyclonic resilience with light steel purlins and modular wall panels for rapid assembly. Over 95% of components were prefabricated in China, including 12-meter-long H-beam columns and 30-meter-span trusses, which were shipped to Australia in containerized batches via just-in-sequence delivery.

On-site assembly leveraged laser-guided alignment and crane optimization algorithms, enabling a crew of 30 workers to erect the frame at a rate of 500 m² per day. The structure was finished with corrosion-resistant galvanized steel and cyclone-rated cladding, meeting Australia’s AS/NZS 1170.2 wind load standard.

Results: The warehouse was completed 37 days ahead of schedule, enabling Rio Tinto to begin operations earlier than planned and avoid $1.2 million in delayed revenue. The structure has since withstood two category 3 cyclones without damage, validating its robustness. The project demonstrated that Lida’s efficiency architecture could cut project timelines in half while maintaining structural integrity in extreme weather.

Case Study 2: CNOOC Offshore Crew Quarters (South China Sea)

Challenge: China National Offshore Oil Corporation (CNOOC) required an 8-story crew quarters facility for 200 workers on a semi-submersible rig in the South China Sea. The project faced unique challenges: typhoon winds of 250 km/h, saltwater corrosion, and the need for watertight integrity to withstand 15m wave submersion. The client also demanded a 6-month delivery timeline to support urgent drilling operations.

Lida’s Solution: Lida designed a modular metal frame structure using ASTM A588 corrosion-resistant steel for the main frame and cold-formed steel for interior partitions. The hybrid design included aerodynamic sloped roofs to reduce wind load, interlocking foundation anchors for typhoon resistance, and watertight bulkheads for flood protection. All modules were prefabricated in Lida’s Shandong factory, complete with furniture, fixtures, and life-saving equipment, then shipped to the rig via specialized offshore vessels.

On-site assembly involved stacking and bolting the modules, with laser alignment ensuring structural stability. The facility was certified to DNV GL-OS-C301 offshore standards, including seismic resilience and fire safety. Lida’s logistics team coordinated with local authorities to secure permits for oversize shipments, ensuring on-time delivery.

Results: The crew quarters were completed in 5.5 months, meeting CNOOC’s urgent timeline. During Super Typhoon Saola in 2023, the facility remained fully operational, while adjacent modules sustained $6 million in damage. The structure’s corrosion-resistant design has eliminated maintenance costs for 3 years, and its modular design allows for easy expansion to accommodate additional workers. The project established Lida as a leader in offshore metal frame construction, with subsequent contracts from Equinor and Shell.

Case Study 3: European Automotive Workshop (Germany)

Challenge: A major European car manufacturer needed a 150,000 sq. ft workshop to support its electric vehicle (EV) production line. The project requirements included vibration resistance for precision robotic equipment, an 8-month deadline to launch a new EV model, and compliance with EU sustainability regulations (50% carbon reduction). Conventional concrete construction was rejected due to its 14-month timeline and high carbon footprint.

Lida’s Solution: Lida’s hybrid metal frame design combined heavy steel foundations with reinforced shock-absorbing joints to resist vibration from robotic assembly lines. Light steel mezzanines were used for office and storage space, prefabricated off-site with integrated electrical and HVAC systems. The structure incorporated 92% recycled steel, solar skin roofs (180w/m²), and bio-based insulation from seaweed, aligning with EU taxonomy for sustainable activities.

BIM-driven design optimized the frame for material efficiency, reducing steel consumption by 15% compared to conventional designs. Just-in-sequence delivery ensured that components arrived in installation order, minimizing on-site storage. Local assembly teams, trained by Lida’s supervisors, erected the facility in 14 weeks, with robotic welding ensuring precision connections.

Results: The workshop was completed 4 months ahead of schedule, enabling the client to launch its new EV model on time and save €2.3 million in delayed production costs. The structure’s vibration resistance was validated through testing, with peak accelerations of less than 0.1g—well below the 0.3g threshold for robotic equipment. The facility achieved a 640-ton annual reduction in CO2 emissions, meeting EU sustainability requirements. It has since become a benchmark for EV manufacturing facilities in Europe, with Lida securing follow-up projects with two other major automakers.

Sustainability: Efficiency Meets Environmental Responsibility

In today’s construction industry, sustainability is no longer an optional feature but a core requirement, and Lida Group’s metal frame construction aligns efficiency with environmental responsibility. The company’s approach to sustainability encompasses material recycling, energy efficiency, and circular economy principles, delivering structures that minimize environmental impact while maximizing long-term value.

Material Sustainability: Recyclability and Circular Design

Steel is one of the most recyclable materials on the planet, with a recycling rate of 92%—far higher than concrete (3%) or wood (15%). Lida Group leverages this advantage by using recycled steel in 92% of its metal frame components, reducing the carbon footprint of each project by 50% compared to structures built with virgin steel. For example, the Equinor North Sea offshore offices used 92% recycled aluminum cladding from decommissioned rigs, diverting 200 tons of waste from landfills.

Circular design principles are integrated into Lida’s product development, ensuring that components can be disassembled and reused at the end of the structure’s lifespan. Modular metal frames, for instance, can be dismantled and relocated to new sites, reducing the need for new construction. Lida’s Chilean warehouse projects, for example, have been designed to be relocated if mining operations shift, extending the useful life of the steel components and minimizing waste.

Lida’s commitment to material sustainability extends to its supply chain. The company sources steel from certified suppliers with ISO 14001 environmental management systems, ensuring that raw materials are produced with minimal energy consumption and emissions. This holistic approach has earned Lida Group certification under the EU Taxonomy for Sustainable Activities, recognizing its metal frame structures as environmentally sustainable investments.

Energy Efficiency: Reducing Operational Costs

Lida’s metal frame structures are engineered for energy efficiency, reducing operational costs for clients while lowering carbon emissions. The combination of light steel framing and insulated cladding creates a tight building envelope with minimal air leakage, reducing heating and cooling requirements by 30-40% compared to conventional structures. For cold storage warehouses, Lida’s integrated air cavity systems and high-performance insulation maintain temperatures of -20°C with 50% less energy than concrete facilities.

Renewable energy integration is another key aspect of Lida’s energy efficiency strategy. The company’s metal frames are designed to support solar panels, wind turbines, and hydrogen fuel cells, enabling clients to achieve net-zero energy status. The Equinor North Sea offshore offices, for example, feature solar skin roofs that generate 180w/m² of electricity, combined with 200 kW hydrogen fuel cells for backup power. This system has eliminated the need for diesel generators, reducing annual CO2 emissions by 640 tons.

AI-driven energy management systems further optimize efficiency by monitoring and adjusting HVAC, lighting, and electrical systems in real time. For large-scale warehouses, these systems reduce energy consumption by 15-20% by identifying inefficiencies and automatically adjusting settings. This not only lowers operational costs but also extends the lifespan of mechanical systems, reducing maintenance requirements.

Environmental Certifications: Validating Sustainable Performance

Lida Group’s metal frame structures have earned numerous environmental certifications, validating their sustainability credentials. The company’s products meet LEED (Leadership in Energy and Environmental Design) requirements, with many projects achieving LEED Gold or Platinum certification. For example, the European automotive workshop project earned LEED Platinum certification for its recycled material use, energy efficiency, and water conservation measures.

In addition to LEED, Lida’s structures comply with BREEAM (Building Research Establishment Environmental Assessment Method) and Green Star (Australian sustainability rating system), ensuring that they meet regional sustainability standards. The company’s commitment to sustainability has also been recognized by industry awards, including the China Green Building Award and the International Association for Sustainable Buildings and Cities (IASBC) Innovation Award.

Conclusion: Lida Group’s Leadership in the Future of Metal Frame Construction

Lida Group’s metal frame construction represents the pinnacle of efficiency and robustness in modern industrial construction. Through three decades of innovation, the company has developed a systematic approach that integrates digital engineering, hybrid structural design, prefabrication, and precision assembly to deliver projects in half the time of conventional methods. At the same time, Lida’s commitment to structural integrity, material durability, and environmental resilience ensures that its structures perform reliably for 50 years, even in the harshest conditions.

The key to Lida’s success lies in its ability to balance efficiency and robustness—not as competing priorities, but as complementary elements of a unified design philosophy. Digital engineering, for example, not only accelerates design and assembly but also optimizes structural performance, ensuring that efficiency does not come at the expense of durability. Prefabrication reduces waste and labor costs while improving quality control, enhancing both efficiency and robustness.

Global case studies, from the Rio Tinto warehouse in Australia to the CNOOC offshore quarters in the South China Sea, demonstrate that Lida’s approach is scalable and adaptable to diverse environments and applications. Whether delivering a 180-meter span warehouse, a typhoon-resistant offshore facility, or a net-zero energy workshop, Lida Group consistently meets or exceeds client expectations for speed, durability, and sustainability.

As the construction industry faces growing pressures to reduce carbon emissions, shorten project timelines, and enhance resilience, Lida Group is well-positioned to lead the way. Its investment in digital technology, sustainable materials, and modular construction aligns with the industry’s future direction, while its global manufacturing and logistics network ensures that these innovations are accessible to clients worldwide.

In conclusion, Lida Group’s metal frame construction is more than a building method—it is a blueprint for the future of industrial construction. By combining efficiency, robustness, and sustainability, Lida has redefined what is possible in metal frame construction, delivering structures that are faster to build, stronger to withstand, and greener to operate. For companies seeking to stay competitive in a rapidly changing global market, Lida Group offers not just a construction solution, but a strategic advantage.

Related news

-

Lida Group Delivers Cost-Effective Durable Construction Solutions

2025-11-26 17:30:46

-

Why Choose a Steel Structure Building for Your Project?

2025-11-26 17:36:50

-

Discover the Advantages of Our Metal Frame Construction

2025-11-26 17:12:49

contact us

- Tel: +86-532-88966982

- Whatsapp: +86-13793209022

- E-mail: sales@lidajituan.com