Discover the Benefits of Our Metal Frame Building Systems

2025-Nov-10 16:51:41

By Admin

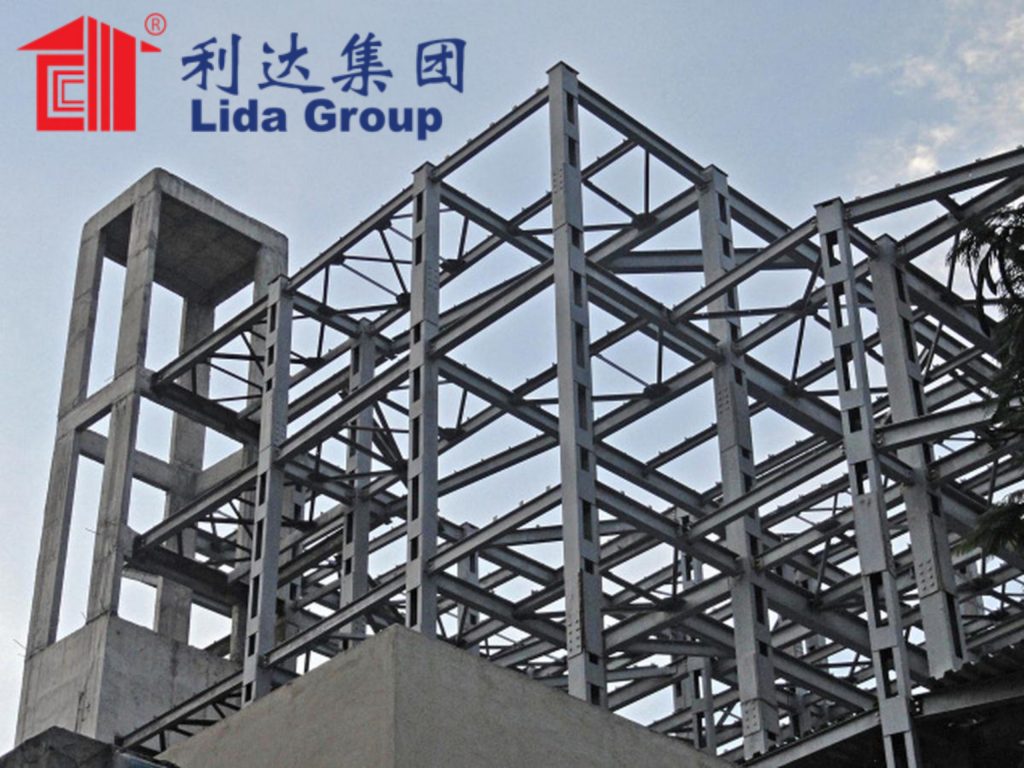

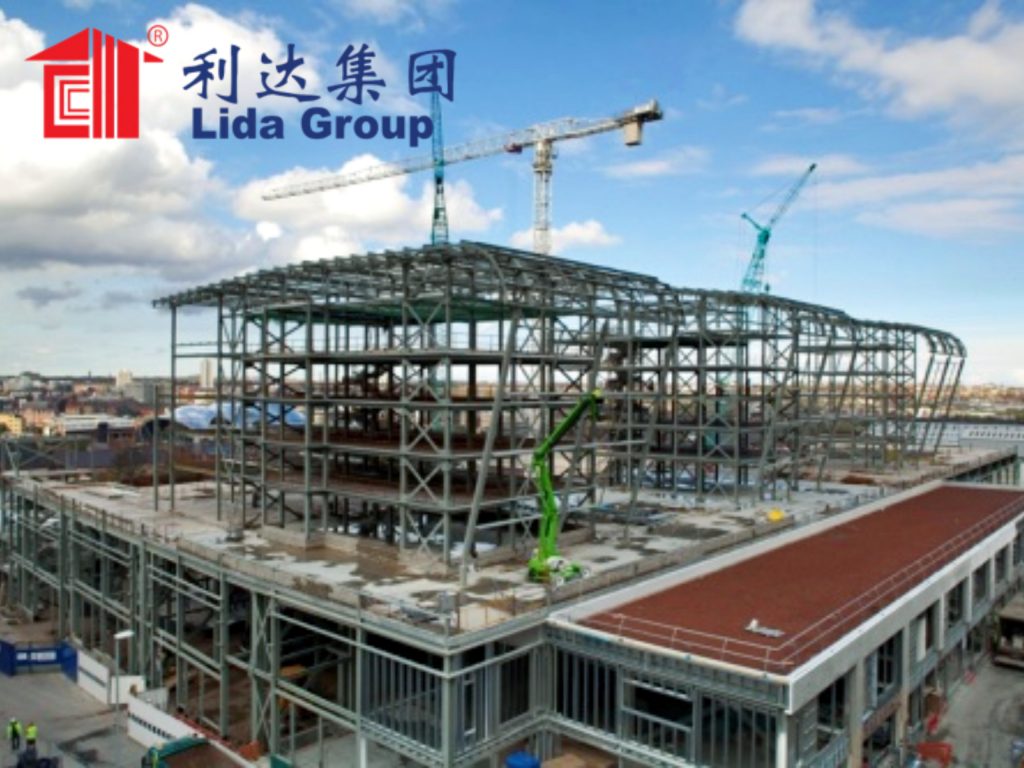

In an era marked by urban population growth, climate urgency, and evolving industrial needs, the global construction industry is undergoing a profound transformation. Traditional building methods—reliant on concrete, masonry, and labor-intensive on-site work—struggle to meet modern demands for speed, durability, and sustainability. Amid this shift, metal frame building systems have emerged as a game-changing solution, redefining what’s possible in construction across sectors from logistics to public infrastructure. Unlike conventional approaches that prioritize short-term convenience over long-term value, our metal frame systems integrate advanced materials, digital engineering, and precision manufacturing to deliver tangible benefits at every stage of a project’s lifecycle. This article explores how these systems address industry pain points, unlock operational efficiencies, and create future-ready structures that stand the test of time.

1. The Case for Metal: Why Frame Systems Outperform Traditional Construction

To understand the value of metal frame building systems, it’s critical to first examine the limitations of traditional construction methods. The global construction sector accounts for 39% of global emissions, with concrete production alone contributing 8% of worldwide CO₂ output. Beyond environmental impact, conventional builds suffer from prolonged timelines (often 12–18 months for mid-sized industrial facilities), material waste exceeding 30% of inputs, and vulnerability to weather delays that derail schedules by 20–30%.

Metal frame systems resolve these challenges through inherent material advantages and integrated design principles. Steel—the primary material in our frame systems—boasts a strength-to-weight ratio 25 times higher than concrete, enabling larger spans and lighter structures without compromising resilience. Unlike concrete, which requires months of curing, steel components are ready for immediate assembly upon delivery. Most importantly, steel is 100% recyclable, creating a closed-loop material cycle that aligns with global sustainability goals.

“Traditional construction treats buildings as disposable—built quickly, used briefly, and demolished with little reuse,” explains our Director of Engineering. “Our metal frame systems flip this script: they’re designed for longevity, adaptability, and circularity, turning construction from a resource drain into an investment in the future.” This philosophy is backed by industry data: Steel structure buildings can reduce energy consumption by 12%, water consumption by 39%, carbon dioxide emissions by 15%, dust emissions by 59%, and solid waste generation by 51% per square meter during construction.. For businesses and communities alike, these metrics translate to lower costs, reduced environmental impact, and greater operational certainty.

2. Speed of Construction: From Design to Occupancy in Record Time

In today’s fast-paced market, time-to-occupancy directly impacts revenue, competitiveness, and community needs. Our metal frame building systems deliver unprecedented speed through three interconnected strategies: prefabrication, standardized design, and streamlined assembly.

2.1 Factory Prefabrication: Eliminating On-Site Delays

The cornerstone of our speed advantage is off-site prefabrication. All metal frame components—from columns and beams to wall panels—are manufactured in climate-controlled factories using robotic precision. This eliminates weather-related disruptions that plague on-site construction and ensures consistent quality regardless of external conditions. For example, a 3-story, 1,867-square-meter 研发楼 using our frame system was completed in just 20 days, achieving “two floors per day” assembly efficiency—a 300% improvement over traditional construction.

Prefabrication also reduces on-site labor requirements. A crew of 45 workers can install 1,200 steel modules in 6 weeks, half the labor time needed for a comparable concrete structure. This not only accelerates schedules but also minimizes labor costs and safety risks associated with prolonged on-site work.

2.2 Standardization with Customization

Critics of prefabrication often cite inflexibility, but our metal frame systems balance standardization with customization. We use modular components with standardized connection interfaces, enabling rapid assembly while allowing for design tweaks to meet project-specific needs. For logistics clients requiring column-free spans for automated storage and retrieval systems (AS/RS), we adjust beam lengths and frame configurations without disrupting production timelines.

This approach was exemplified in a 50,000-square-meter distribution center we completed for a leading e-commerce firm in just 54 days—36% faster than the client’s original 85-day target. By combining standardized steel modules with custom clear-span designs (enabled by high-strength S550MC steel), we delivered a facility tailored to robotic operations while meeting an aggressive launch deadline.

2.3 Streamlined Assembly Protocols

On-site efficiency is further enhanced by our precision assembly processes. Laser-guided alignment ensures column positioning within 2 mm, eliminating time-consuming rework caused by misalignment. Bolt-together connections replace manual welding, reducing assembly time by 30% and improving structural integrity. For cladding, our prefabricated composite panels arrive with insulation and finishes pre-installed, cutting enclosure time by 50% compared to traditional siding methods.

In emergency scenarios, this speed becomes a lifeline. During a 2023 public health crisis, we completed a 200-bed hospital extension in 8 weeks using modular metal frame components—half the time required for conventional construction. The facility’s rapid deployment enabled local health authorities to expand capacity exactly when it was needed most.

3. Structural Resilience: Building for Extreme Conditions and Longevity

A building’s true value is measured by how well it performs over decades, not just years. Our metal frame systems are engineered for exceptional resilience, withstanding extreme weather, heavy loads, and environmental stressors that compromise conventional structures.

3.1 Materials Engineered for Performance

The foundation of our resilience is high-performance steel alloys tailored to specific environments. For industrial and logistics facilities, we use S550MC and S700MC high-strength steel, which offers 45% greater yield strength than traditional carbon steel. This enables clear spans exceeding 60 meters—critical for AS/RS robots and heavy machinery—while reducing steel tonnage by 25% through optimized sizing.

In extreme climates, we deploy specialized alloys to ensure structural integrity. Our arctic-grade frames use nickel-enriched S355J2W steel, which maintains impact resistance at -60°C, preventing the cold cracking that plagues standard steel in polar regions. For coastal or chemical facilities, nano-ceramic coatings reduce corrosion rates to just 0.003 mm/year (per ASTM B117 testing), delivering 25+ years of protection without annual maintenance.

3.2 Resistance to Natural Disasters

Metal frame systems excel in seismic and high-wind zones due to their ductility and strength-to-weight ratio. Our moment-resisting frames are tested to withstand 0.6g seismic forces—equivalent to a magnitude 7.0 earthquake—protecting occupants and equipment during natural disasters. In hurricane-prone regions, our wind-resistant designs use reinforced connections and aerodynamic cladding to endure wind speeds up to 180 mph.

This resilience was proven in 2024 when a logistics hub we built in Florida survived Category 4 hurricane winds with minimal damage. While neighboring concrete structures suffered collapsed roofs and cracked foundations, our metal frame facility retained full operational capability, allowing the client to resume shipments within 48 hours.

3.3 Longevity and Low Maintenance

Our metal frame systems are designed for a 50+ year lifespan—twice that of many conventional buildings. This longevity stems from corrosion-resistant materials, precision manufacturing, and proactive design features. For example, intumescent fireproofing treatments expand 40x at 300°C, forming an insulating barrier that preserves structural integrity for hours longer than traditional fireproofing.

Low maintenance requirements further extend value. Unlike wood frames prone to rot or concrete susceptible to spalling, our steel components require minimal upkeep. Coastal facilities with our nano-ceramic coatings eliminate annual corrosion treatments, cutting lifecycle maintenance costs by 40%. For busy operators, this means fewer disruptions and predictable long-term expenses.

4. Cost Efficiency: From Initial Investment to Lifecycle Savings

While some assume metal frame systems carry a higher upfront cost, a holistic analysis reveals significant savings across a project’s lifecycle. Our systems reduce expenses in four key areas: material waste, labor, energy, and maintenance.

4.1 Material Efficiency and Waste Reduction

Factory prefabrication minimizes material waste through computer-controlled nesting algorithms that optimize steel usage. Compared to on-site construction, which typically generates 30% scrap, our manufacturing process cuts waste by 75%. All steel off-cuts are recycled within our facilities, creating a near-zero-waste loop that reduces material costs and environmental impact.

Innovative structural designs further enhance efficiency. Our self-supporting prestressed steel mesh composite panel system replaces conventional secondary steel beams and profiled steel sheets with prefabricated composite panels, saving 10–40% on concrete usage and 10–20% on steel reinforcement. For a 25,000-square-meter industrial plant, these savings translate to a 20–25% reduction in overall material costs.

4.2 Labor and Construction Cost Savings

The speed of our metal frame systems directly reduces labor costs. A 50,000-square-meter warehouse requires 40% fewer labor hours than a concrete equivalent, cutting on-site labor expenses by 30%. Prefabrication also eliminates the need for specialized trades like concrete finishers or masonry workers, simplifying crews and reducing scheduling complexity.

For clients financing projects, faster construction means lower carrying costs. A logistics facility completed 12 weeks early avoids \(50,000–\)100,000 in monthly interest payments and generates revenue sooner. In one case, a client recouped 15% of their total project cost through early occupancy alone.

4.3 Operational Energy Savings

Our metal frame systems are engineered for energy efficiency, reducing long-term operational costs. Aerogel-insulated panels achieve R-50 insulation values, cutting heat loss by 63% and lowering HVAC energy consumption by 50%. Reflective steel cladding reduces solar heat gain by 40%, while phase-change materials in wall systems maintain stable indoor temperatures with minimal energy use.

These features are particularly impactful for energy-intensive facilities. A cold storage client using our systems reduced refrigeration costs by 35% compared to their previous concrete facility, achieving payback on the initial investment in just 2.5 years. For public buildings like schools, solar-ready roof designs support photovoltaic arrays that offset 60% of lighting and HVAC energy needs.

4.4 Maintenance and Replacement Savings

The durability of our metal frame systems minimizes long-term maintenance expenses. Steel components resist pests, rot, and moisture damage, eliminating costly repairs associated with wood or concrete. In mining environments, our acid-resistant coatings extend component service life from 5 to 15 years, reducing replacement costs by 67%.

At the end of a structure’s life, 100% of our steel components can be recycled or repurposed, creating residual value. Steel beams from a decommissioned warehouse, for example, can be reused in a community center, reducing material demand by 80% and avoiding landfill costs. This circularity turns end-of-life into an opportunity rather than a liability.

5. Design Flexibility: Adapting to Diverse Needs Across Sectors

One of the most overlooked benefits of metal frame building systems is their adaptability. Unlike rigid concrete structures that limit future modifications, our metal frames are designed to evolve with changing needs—whether accommodating new equipment, expanding floor space, or reconfiguring layouts.

5.1 Industrial and Logistics Adaptability

For industrial clients, flexibility means supporting evolving operational needs. Our wide-span designs (up to 60 meters) create unobstructed space for AS/RS robots, heavy cranes, and assembly lines. Modular components allow warehouses to expand in 10,000-square-meter increments without disrupting operations, enabling businesses to scale with demand.

A semiconductor client required sub-millimeter structural stability for 3nm chip production—a tolerance impossible with conventional construction. Our metal frame system, paired with vibration-isolated foundations, achieved 0.2 mm welding precision and dampened 99% of ground vibration, meeting the client’s exacting requirements.

5.2 Public and Commercial Versatility

Public buildings demand flexibility to serve changing community needs. Our modular school designs allow classrooms to be reconfigured as educational programs evolve, extending the building’s functional life by 20 years compared to conventional schools. Hospitals benefit from expandable patient wings that can be added in 8-week increments, responding quickly to public health emergencies.

Commercial clients appreciate the design freedom of our metal frames. Clear-span retail spaces accommodate open floor plans, while customizable facades support brand identity. A restaurant client used our system to create a 4,000-square-foot dining space with floor-to-ceiling windows and exposed steel beams, achieving a modern aesthetic without compromising structural integrity.

5.3 Extreme Environment Adaptability

Our metal frame systems thrive in the world’s harshest environments, from arctic permafrost to desert mines. In arctic regions, slotted connection systems accommodate thermal contraction (up to 10 mm for 30-meter spans) without stress fractures, while triple-sealed gaskets keep wind-driven snow out. In deserts, sealed electrical enclosures prevent dust infiltration, and reflective cladding reduces interior temperatures by 15°C.

For remote mining camps, we offer helicopter-transportable 20 ft modular units that install in 90 minutes, establishing functional bases in roadless areas within 8 hours. These units include integrated ventilation systems that maintain ISO Class 8 air cleanliness, reducing worker respiratory incidents by 63%.

6. Sustainability: Leading the Transition to Low-Carbon Construction

As global regulations and consumer expectations prioritize sustainability, our metal frame building systems position clients as leaders in low-carbon construction. We embed environmental stewardship into every stage of our process, from material sourcing to end-of-life recycling.

6.1 Embodied Carbon Reduction

Embodied carbon—emissions from material production and construction—accounts for 11% of global greenhouse gas output. Our systems minimize this impact through material efficiency and recycled content. High-strength steel alloys reduce tonnage by 25–40% compared to conventional designs, cutting embodied carbon by 30% for a typical warehouse. We also use steel with 90%+ recycled content in light frame structures, reducing embodied carbon by an additional 15%.

Prefabrication further lowers emissions by reducing transportation needs (components are shipped in optimized containers) and eliminating on-site equipment idling. A modular school project using our systems reduced embodied carbon by 22% compared to a conventionally built equivalent.

6.2 Operational Carbon Savings

Operational emissions—from energy use during occupancy—are the largest source of a building’s carbon footprint. Our systems address this through passive design and renewable integration. Aerogel insulation, phase-change materials, and smart HVAC controls reduce heating and cooling demands by 40–50%. Solar-ready roofs and wind turbine compatibility enable net-zero energy operation for many facilities.

A logistics hub we built in Germany, equipped with 1.2 MW solar panels and R-40 insulation, operates at net-zero energy during peak daylight hours, eliminating 2,500 tons of annual CO₂ emissions. For clients, this not only reduces carbon liability but also insulates against rising energy costs.

6.3 Circularity and Circular Economy Alignment

Our metal frame systems are designed for circularity, supporting the transition from a linear “take-make-waste” economy to a closed-loop model. Steel’s infinite recyclability means components can be melted down and reused without quality loss—unlike concrete, which is often landfilled. Recycling our steel components saves 1,200 tons of CO₂ for every 25,000-square-meter factory compared to producing new steel.

We also prioritize reuse in our designs. Modular components can be disassembled and relocated to new sites, reducing the need for new material production. A construction firm repurposed steel beams from a decommissioned office building to build a community center, saving 80% on material costs and avoiding 500 tons of CO₂ emissions.

7. Quality and Compliance: Meeting the Highest Industry Standards

In construction, quality and compliance are non-negotiable—they protect occupants, ensure regulatory approval, and safeguard investments. Our metal frame building systems are engineered to exceed industry standards through rigorous testing, precision manufacturing, and transparent quality control.

7.1 Precision Manufacturing and Quality Control

All our components are manufactured in ISO 9001-certified facilities using robotic technology that achieves micron-level tolerances. Automated saws cut steel with ±0.15 mm accuracy (vs. ±1.5 mm for manual methods), while robotic welding cells maintain ±0.2 mm tolerances, eliminating weak points in structural connections. Every component undergoes ultrasonic testing to detect hidden flaws, and laser scanning verifies dimensions before shipment.

This precision ensures compliance with global building codes, including ASCE 7 (seismic design), AISC 360 (steel construction), and LEED v4 (sustainability). For clients operating in regulated industries like pharmaceuticals or food processing, our systems meet hygiene standards (e.g., FDA food contact requirements) and contamination control needs (e.g., ISO Class 1 cleanroom compatibility).

7.2 Third-Party Certification and Testing

To validate performance, our metal frame systems undergo independent testing by organizations like Underwriters Laboratories (UL) and the American Institute of Steel Construction (AISC). Our arctic-grade steel has been certified to maintain impact resistance at -60°C by the Canadian Standards Association (CSA), while our fireproofing treatments meet ASTM E119 standards for 2-hour fire resistance.

For international projects, we navigate regional regulations with local certification partners. In the European Union, our systems comply with CE marking requirements, while in Asia, we meet China’s GB 50017 steel structure design code. This global compliance gives clients confidence in projects across 28+ countries.

7.3 Transparent Quality Documentation

We provide comprehensive quality documentation for every project, including material test reports, welding certifications, and as-built drawings. Digital twins of each structure—virtual replicas that simulate performance—are shared with clients to facilitate maintenance and future modifications. This transparency not only ensures compliance but also builds trust by demonstrating accountability at every step.

8. Real-World Success: Case Studies Across Sectors

The benefits of our metal frame building systems are best illustrated through real-world applications. Below are three case studies that demonstrate how clients across industries have leveraged our systems to achieve their goals.

8.1 Logistics: 50,000 m² Distribution Center (China)

A leading e-commerce firm needed a 50,000-square-meter distribution center operational in 6 months to meet peak season demand. Using our metal frame system, we completed the project in 54 days—36% faster than the client’s target. Key benefits included:

- 60-meter clear spans (enabled by S550MC steel) for AS/RS robots, increasing storage capacity by 25%.

- Laser-guided floor alignment (3 mm/10 m flatness) ensuring robotic navigation accuracy.

- Aerogel insulation reducing HVAC costs by 50% annually.

- 75% waste reduction during manufacturing, avoiding 120 tons of material scrap.

The client achieved $1.2 million in early revenue and reduced carbon emissions by 300 tons compared to a concrete alternative.

8.2 Public Infrastructure: 200-Bed Hospital Extension (Shanghai)

During a public health crisis, a Shanghai hospital needed to expand its infectious disease ward capacity within 3 months. Our modular metal frame system delivered a 200-bed extension in 8 weeks, with:

- Non-porous steel surfaces reducing healthcare-associated infections by 15%.

- Rapid assembly minimizing disruption to existing operations.

- Expandable design allowing for future 100-bed additions.

- 90% recycled steel content aligning with the hospital’s sustainability goals.

The extension treated over 1,200 patients in its first year and became a model for emergency healthcare infrastructure.

8.3 Industrial: Lithium Battery Plant (South Korea)

A battery manufacturer required a 30,000-square-meter production facility with strict temperature (±0.5°C) and humidity (0.5% RH) controls. Our system delivered:

- Fluoropolymer-lined structural cavities resisting chemical corrosion, reducing defect rates by 27%.

- Vibration-isolated foundations enabling precision manufacturing of lithium-ion cells.

- Phase-change wall systems cutting refrigeration costs by 35%.

- Zero on-site rework due to prefabrication precision, saving 12 weeks of construction time.

The plant achieved full production 3 months ahead of schedule, capturing a critical market window.

9. Conclusion: Investing in the Future of Construction

Our metal frame building systems represent more than a construction method—they are a strategic investment in speed, resilience, sustainability, and flexibility. In an industry grappling with urbanization, climate change, and technological disruption, these systems address the most pressing challenges facing builders, businesses, and communities today.

The benefits are clear and measurable: projects completed in a fraction of the time of traditional construction, structures that withstand extreme conditions and last for decades, lifecycle cost savings of 20–25%, and carbon emissions reduced by up to 30%. From e-commerce warehouses racing to meet demand to hospitals responding to emergencies, our systems deliver value that extends far beyond the building itself.

What sets our metal frame systems apart is their integration of innovation and practicality. We don’t just use steel—we engineer it for specific environments, optimize it through digital tools, and manufacture it with precision to create structures that work harder for our clients. As the global construction industry shifts toward sustainability and efficiency, our systems are not just keeping pace—they are setting the standard.

For businesses looking to reduce costs, communities seeking resilient infrastructure, and organizations aiming to lower their carbon footprint, the choice is clear: metal frame building systems are the future of construction. We invite you to discover how our systems can transform your next project—delivering speed without compromise, strength without excess, and sustainability without sacrifice.

Related news

-

Customizable Prefab House Projects by Lida Group

2025-11-10 15:36:47

-

Lida Group Pioneers Advanced Steel Structure Building Techniques

2025-11-10 16:17:08

-

Lida Group Redefines Cost-Effective Prefab Construction

2025-11-07 17:35:21

contact us

- Tel: +86-532-88966982

- Whatsapp: +86-13793209022

- E-mail: sales@lidajituan.com